Modified bacterial cellulose lithium-sulfur battery diaphragm

A technology of bacterial cellulose membrane and bacterial cellulose, which is applied in the field of modified bacterial cellulose lithium-sulfur battery diaphragm, can solve the problems of affecting battery cycle stability, poor electrolyte absorption rate, unfavorable high current charging and discharging, etc. It achieves the effect of enhancing the rate cycle performance, reducing the risk of combustion and explosion, and avoiding coating peeling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of bacterial cellulose membrane

[0024] Take the activated strain of Gluconacetobacter xylinum and inoculate it in the fermentation medium for dynamic culture. After culturing for 60 hours at 30°C, add silicon dioxide to the fermentation medium, and then ferment for 11 days at 30°C. , to obtain the fermentation broth, take out the bacterial cellulose film on the upper layer of the fermentation broth, wash the cellulose film with alkaline solution, then wash it to neutrality, place it in a freeze-drying box and dry it to obtain a spongy bacterial cellulose film; bacterial cellulose The thickness of the membrane is 30-40μm; the diameter of the bacterial fiber is 200-500nm;

[0025] The composition of the fermentation medium is that 1L medium contains 45g of sucrose, 15g of beef extract, 4.5g of disodium hydrogen phosphate, 0.8g of citric acid, and 8g of ethanol; 10%-12% of mass;

[0026] Preparation of Boric Acid Modified Silica

[0027] Disperse 100g of s...

Embodiment 2

[0032] A modified bacterial cellulose lithium-sulfur battery diaphragm, which is prepared by culturing sulfate-reducing bacteria with bacterial cellulose membrane as a carrier, and then coating the surface with boric acid-modified silicon dioxide; the preparation method is specific Include the following steps: ;

[0033] (1) Immerse the spongy bacterial cellulose membrane (prepared in Example 1) in the nutrient solution of sulfate-reducing bacteria, ferment and cultivate it at 30°C for 6 days in a closed environment, and take out the bacterial fibers loaded with sulfate-reducing bacteria after cultivation Plain film; Wherein, the composition of described sulfate-reducing bacteria culture solution is to contain 11g ferrous ammonium sulfate, 7g ferric citrate, 25g guar gum, 18g polyethylene glycol, 10g cysteine in 1L deionized water; Sulfuric acid The quality of salt-reducing bacteria accounts for 13% of the culture solution;

[0034] (2) 100g boric acid modified silica No. 2...

Embodiment 3

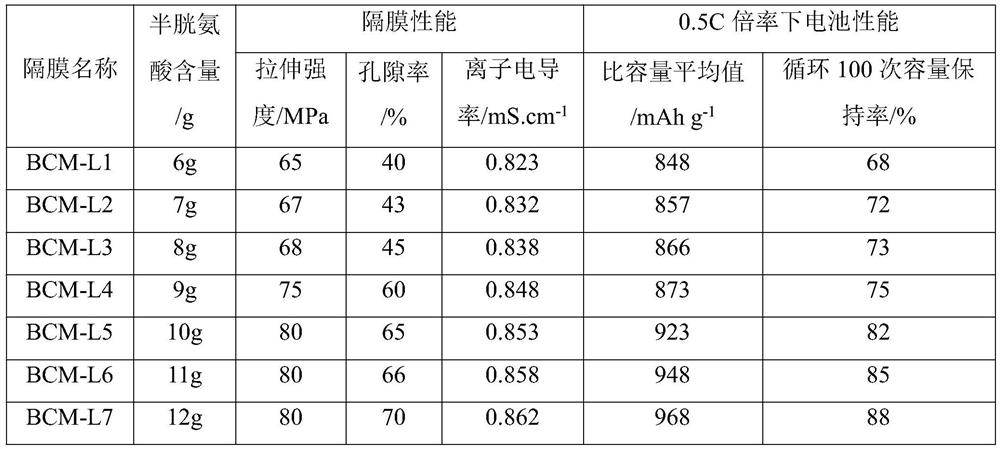

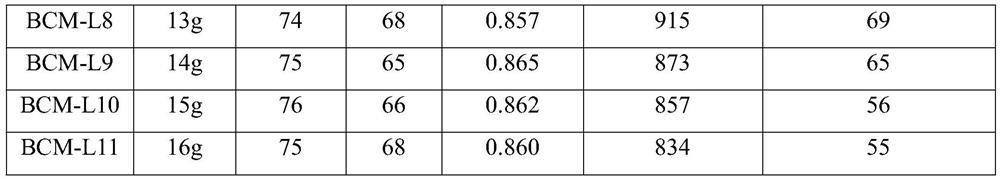

[0036]The preparation method of the diaphragm of embodiment 3 is basically the same as that of embodiment 2, the difference is that: the content of other components in the fermentation broth of sulfate-reducing bacteria is controlled to be constant, the content of cysteine is adjusted, and the obtained diaphragm is successively recorded as BCM-L1, BCM-L2, BCM-L3, BCM-L3, BCM-L4, BCM-L5, BCM-L6, BCM-L7, BCM-L8, BCM-L9, BCM-L10, BCM-L11, and the performance of the diaphragm At the same time, the diaphragm was assembled into a lithium-sulfur battery, and the rate performance and cycle performance of the battery were tested respectively. The test method used the method described in the specification below, and the test results are recorded in Table 1.

[0037] Table 1

[0038]

[0039]

[0040] From the data in Table 1, it can be seen that with the increase of cysteine content in the fermentation broth, the tensile strength, porosity, ion conductivity, average value of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com