Modified epoxy resin composition, high-Tg low-loss laminated copper-clad plate and preparation method of high-Tg low-loss laminated copper-clad plate

A technology of epoxy resin and high-bromine epoxy resin, applied in chemical instruments and methods, other household appliances, electronic equipment, etc., can solve the problems of low product reliability, uneven performance, poor stability, etc., and achieve practicality Strong, excellent performance, good creative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

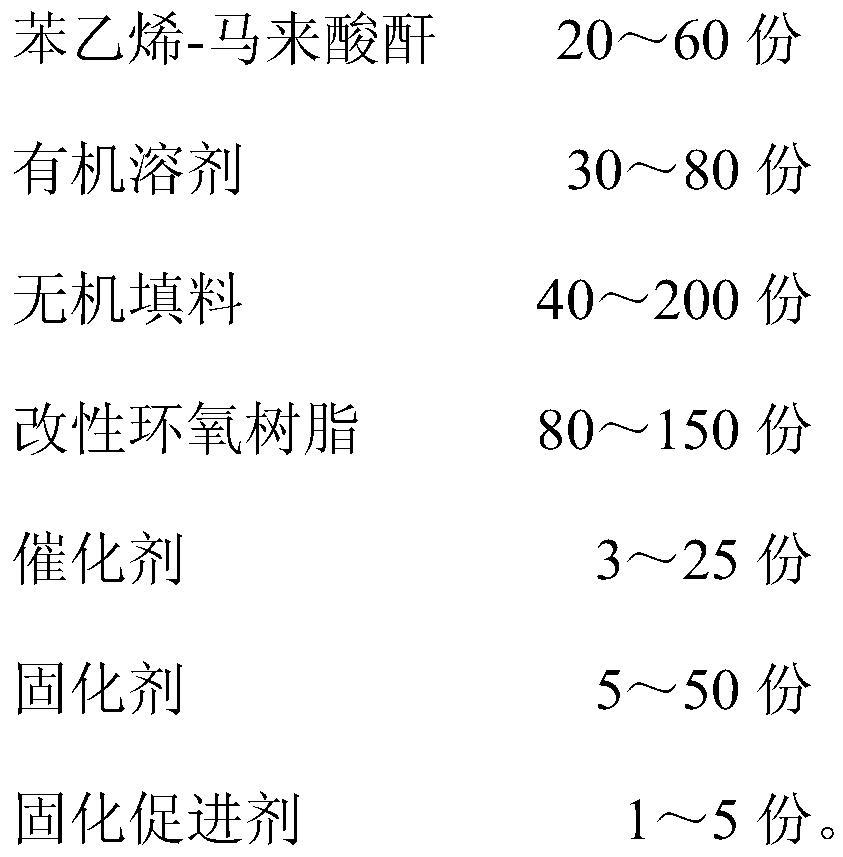

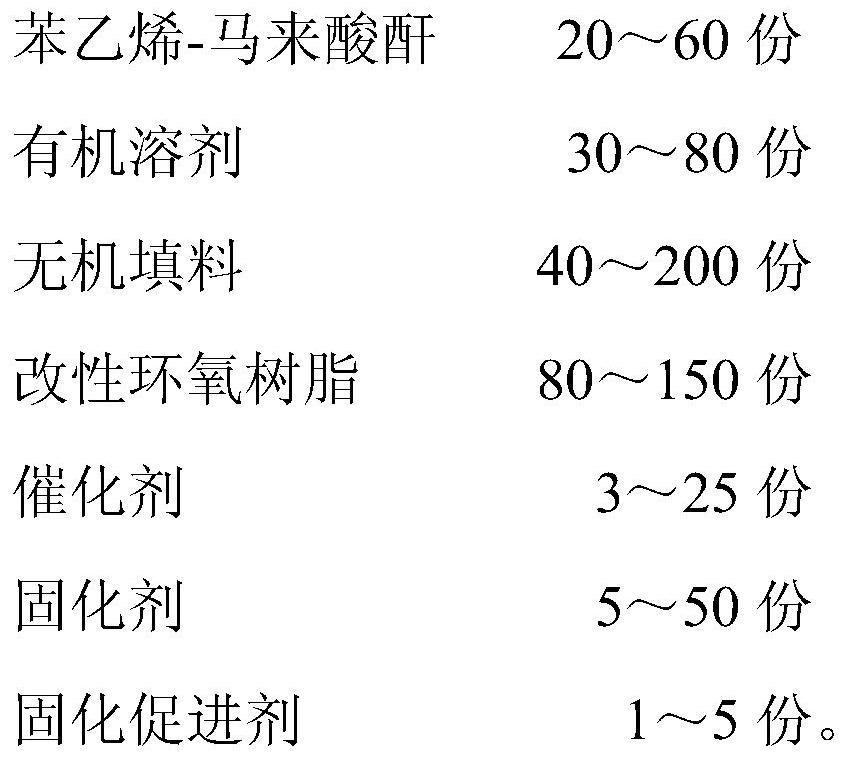

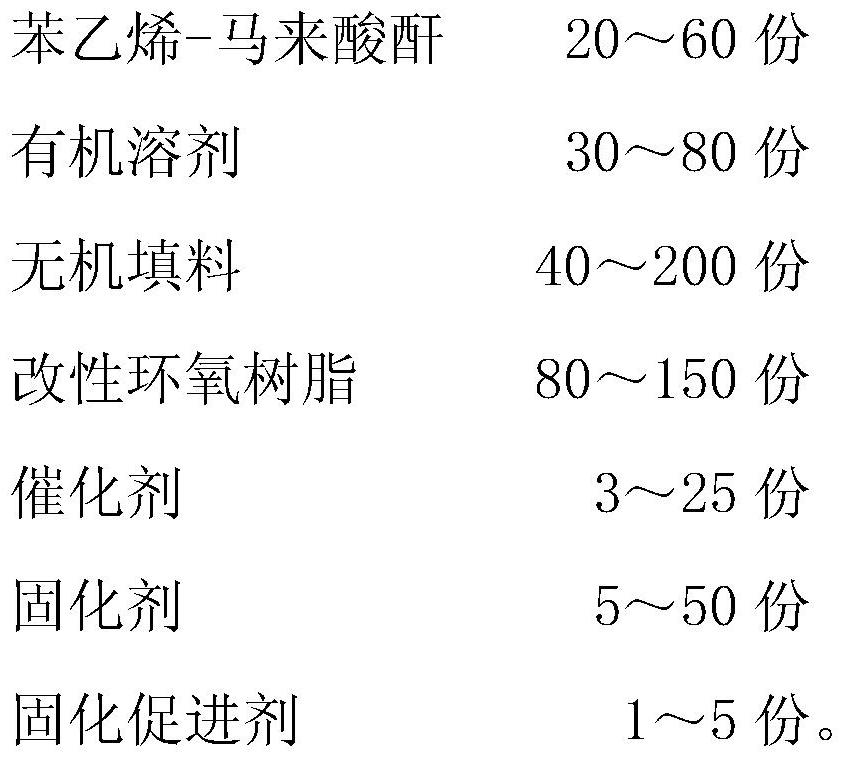

[0042] Turn on the ice water circulation system of the glue mixing tank, and set the ice water temperature to 10°C. Add 60 parts (parts by weight, the same below) of a mixture of styrene-maleic anhydride and 80 parts of DMF, butanone, and propylene glycol methyl ether, and stir for 180 minutes until styrene-maleic anhydride is completely dissolved; then add 100 parts of styrene-maleic anhydride to the mixture A mixture of boron nitride, silicon nitride, silicon carbide, diamond or silicon nitride, turn on the homogenizer and the shearing machine to stir for 100 minutes, and pass through the magnetic filter barrel to absorb the impurities in the filler; Add 150 parts of graphene modified high brominated epoxy resin, cyanate modified epoxy resin, graphene modified bisphenol S type epoxy resin mixture, 25 parts of cobalt acetylacetonate, butyl triphenyl A mixture of phosphorus bromide, 50 parts of aliphatic polyamines, diacetone acrylamide, a mixture of alicyclic polyamines, 5 pa...

Embodiment 2

[0045] Turn on the ice water circulation system of the glue mixing tank, and set the ice water temperature to 5°C. Add 40 parts (parts by weight, the same below) styrene-maleic anhydride and 60 parts of acetone, methyl butanone, methyl isobutyl ketone, ethylene glycol monomethyl ether, ethylene glycol monoethyl ether, ethylene glycol mono The mixture of butyl ether was stirred for 240min until the styrene-maleic anhydride was completely dissolved; The mixture of chemical kaolin, turn on the homogenizer and the shearing machine to circulate and stir for 120min, and pass through the magnetic filter barrel to absorb the impurities in the filler; add 150 parts of dimer acid modified epoxy resin, carboxyl-terminated epoxy resin to the obtained mixture Nitrile rubber modified epoxy resin, carboxyl-terminated nitrile rubber modified novolac epoxy resin, polyurethane modified bisphenol A epoxy resin, thermoplastic polyurethane modified epoxy resin or terpene modified epoxy resin Mixt...

Embodiment 3

[0047] Turn on the ice water circulation system of the glue mixing tank, and set the temperature of the ice water to 3°C. Add 30 parts (parts by weight, the same below) of styrene-maleic anhydride and 50 parts of ethanol, isopropanol, ether, propylene oxide, cyclohexane, cyclohexanone or tolyl cyclohexanone, and stir for 150min to Styrene-maleic anhydride is completely dissolved; then add 200 parts of a mixture of spherical silica (particle size 2 microns), fused silica (1.6 microns), and German BASF highly micronized kaolin to the mixture to start homogenization Machine and shear force machine circulated and stirred for 100min, and passed the high magnetic filter barrel to absorb impurities in the filler; in the mixture obtained, add 150 parts of glue-modified novolac epoxy resin, polyurethane modified bisphenol A epoxy resin, Thermoplastic polyurethane modified epoxy resin or mixture of terpene modified epoxy resin, 25 parts of cobalt acetylacetonate, mixture of butyl triphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com