Single-component UV delayed-curing adhesive composition as well as preparation method and application method thereof

A technology of adhesives and compositions, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of small molecular weight, low assembly efficiency, penetration migration, etc., achieve high bonding strength, improve assembly Efficiency, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Photobase Generator DBU·HBPh 4 The preparation method is: weigh 0.55g of 1,8-diazabicycloundec-7-ene (DBU) and dissolve it in 1.4mL of 10% hydrochloric acid aqueous solution, then weigh 1.37g of sodium tetraphenylborate (Na ·BPh 4 ) was dissolved in 60mL of deionized water; then, under magnetic stirring, the hydrochloric acid aqueous solution of the above-mentioned DBU was slowly added dropwise to the aqueous solution of sodium tetraphenylborate to produce a white precipitate. Carry out suction filtration at last, respectively use deionized water and methanol to wash three times respectively, then place in 40 ℃ oven and dry 24h to obtain photobase generator (DBU·HBPh 4 ).

[0040] Photobase Generator TEA·HBPh 4 The preparation method is: weigh 0.36g of triethylamine (TEA) and dissolve it in 1.4mL of 10% hydrochloric acid aqueous solution, then weigh 1.37g of sodium tetraphenylborate (Na BPh 4 ) was dissolved in 60mL deionized water; then, under magnetic stirring, th...

Embodiment 1~8

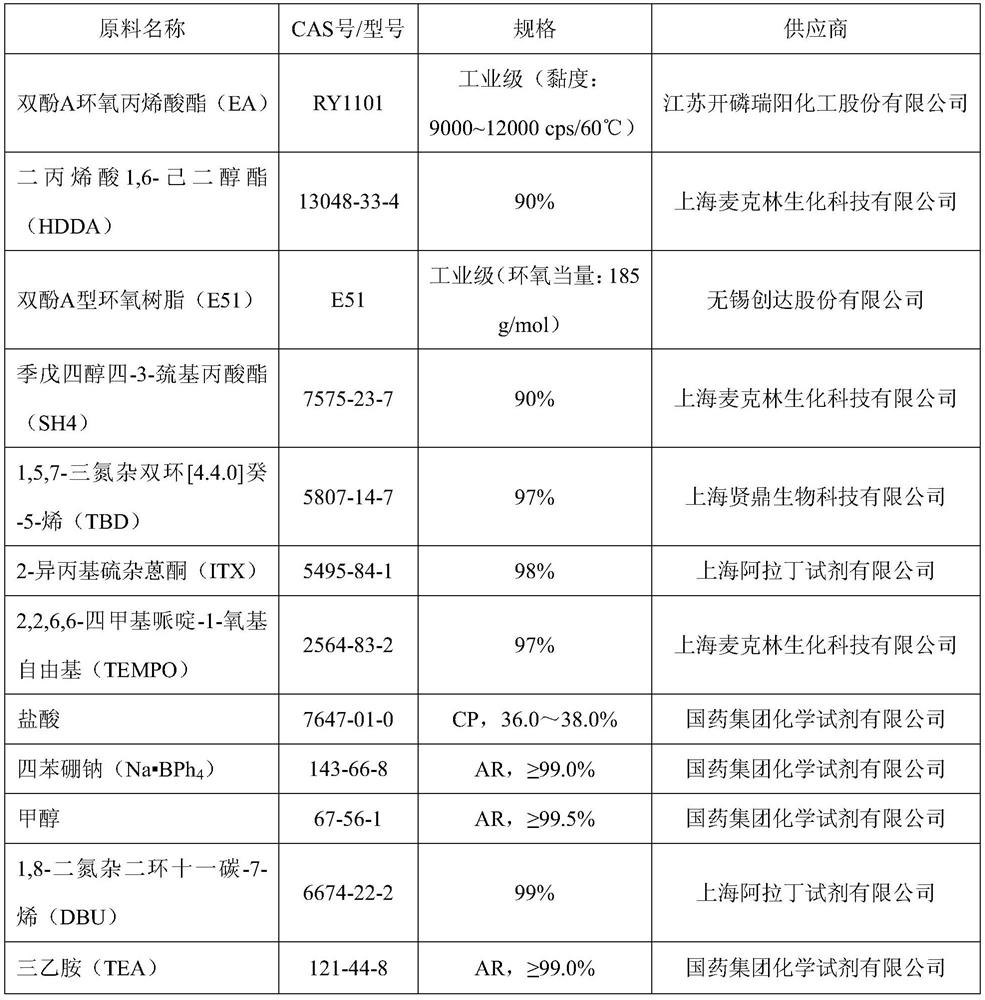

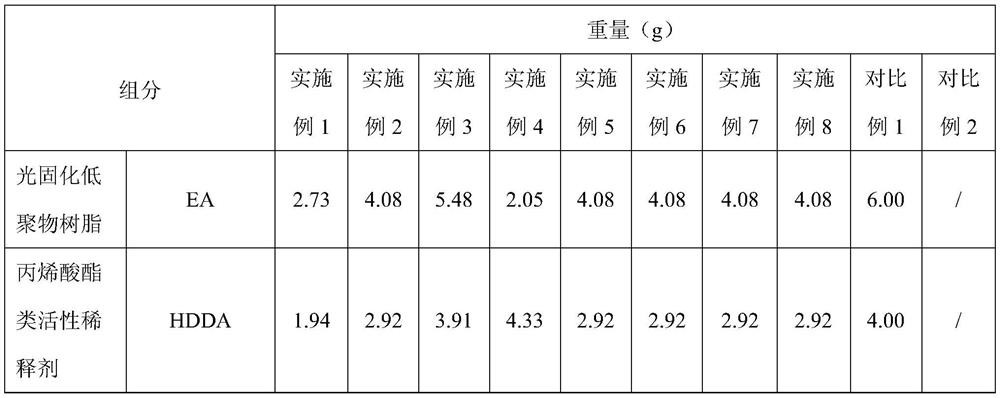

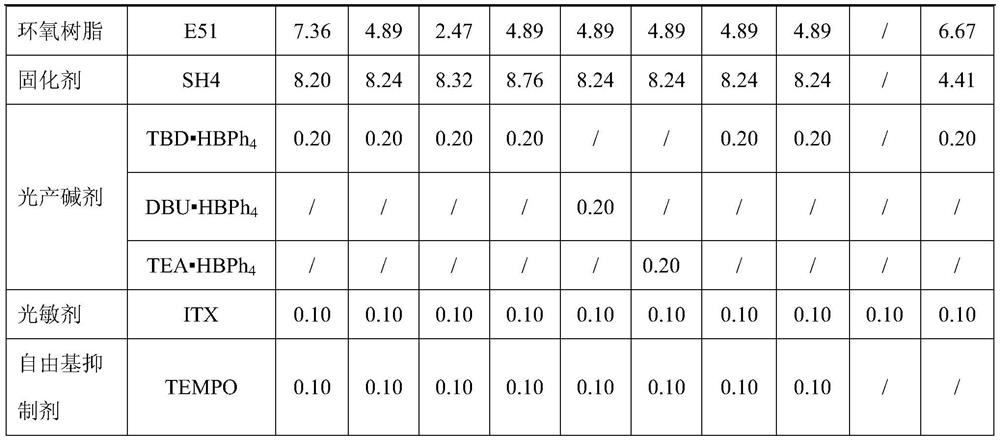

[0042] The preparation method of a kind of one-component UV delayed curing adhesive composition of embodiment 1~8, concrete steps are: according to the proportion shown in table 2, photobase generator and bisphenol A type epoxy resin (E51) Mix and stir at 110°C until clear and transparent, then cool to room temperature; then add bisphenol A epoxy acrylate (EA), 1,6-hexanediol diacrylate (HDDA), pentaerythritol tetra- 3-mercaptopropionate (SH4), photosensitizer 2-isopropylthioxanthone (ITX), free radical inhibitor 2,2,6,6-tetramethylpiperidin-1-oxyl radical ( TEMPO), use a double-center mixing and dispersing machine to mix and disperse for 10 minutes at a speed of 1600 rpm / min, to obtain a one-component UV delayed curing adhesive composition. The whole experiment process must be strictly protected from light.

[0043] The application method of a one-component UV delayed-curing adhesive composition of Examples 1-6, the specific steps are: apply the one-component UV delayed-cure...

Embodiment 7

[0044] The application method of a one-component UV delayed curing adhesive composition in Example 7, the specific steps are: apply the one-component UV delayed curing adhesive composition on the surface of the stainless steel substrate to be bonded by scraping, and apply The coating thickness is 60μm; use a UV high-pressure mercury lamp (350-450nm, the main wavelength is 365nm) at 30mW / cm 2 The intensity of irradiation for 10s is used to activate the adhesive composition; within 90-120s after the adhesive composition is activated, the lap joint between the substrates to be bonded is completed, and the initial bonding strength is achieved after being placed at room temperature for a certain period of time. The bonding between the base materials is finalized; finally, post-curing is performed at 80° C. for 2 hours, so that the adhesive composition is fully cured into an adhesive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com