Upper stratum anti-collapse drilling fluid and preparation method thereof

A drilling fluid and anti-slump technology, applied in chemical instruments and methods, drilling compositions, reagents, etc., can solve the problems of poor plugging inhibition ability and poor effect of low free water drilling fluid, and achieve convenient preparation and maintenance. , Low filtration loss, strong inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing the above-mentioned plugging and anti-slump inhibitor, comprising: mixing dimethyl dienyl ammonium chloride, polymer alcohol, granular plugging material, fibrous plugging material and initiator in water Heating and reacting to obtain the plugging and anti-slump inhibitor; the granular leakage plugging material includes fruit shells.

[0047] The present invention has no special restrictions on the sources of all raw materials, which can be commercially available; the dimethyl dienyl ammonium chloride, polymer alcohol, granular plugging materials and fibrous plugging materials are all the same as above, in This will not be repeated here.

[0048] In the present invention, it is preferred to first mix dimethyl dienyl ammonium chloride with water; the volume ratio of said dimethyl dienyl ammonium chloride to water is preferably (1-3): 100, more preferably (1~2.5):100, more preferably (1~2):100, most preferably 1.5...

Embodiment 1

[0067] (1) Experimental materials and reagents

[0068] Polyethylene glycol, AR; dimethyl diallyl ammonium chloride, technical grade; calcium carbonate, technical grade; husk fiber, technical grade; ammonium persulfate ((NH 4 ) 2 S 2 o 8 ), AR; sodium bisulfite (NaHSO 3 ), AR; deionized water.

[0069] During the experiment, the polyethylene glycol used was PEG-4000, AR grade; dimethylethylene ammonium chloride was selected as an industrial grade solution with a purity of 60%; the fruit shell fiber was selected as an industrial grade, and hickory shell and cotton fiber were selected As the main material, it is mixed at a ratio of 1:1. Hickory nut shells are ground and passed through a 10-mesh sieve. The cotton fibers can be short cotton fibers with an average length of 4mm and an average diameter of 20μm.

[0070] (2) Main experimental instruments

[0071] Digital constant temperature water bath box; three-neck round bottom flask (500mL); analytical balance; thermometer;...

Embodiment 2

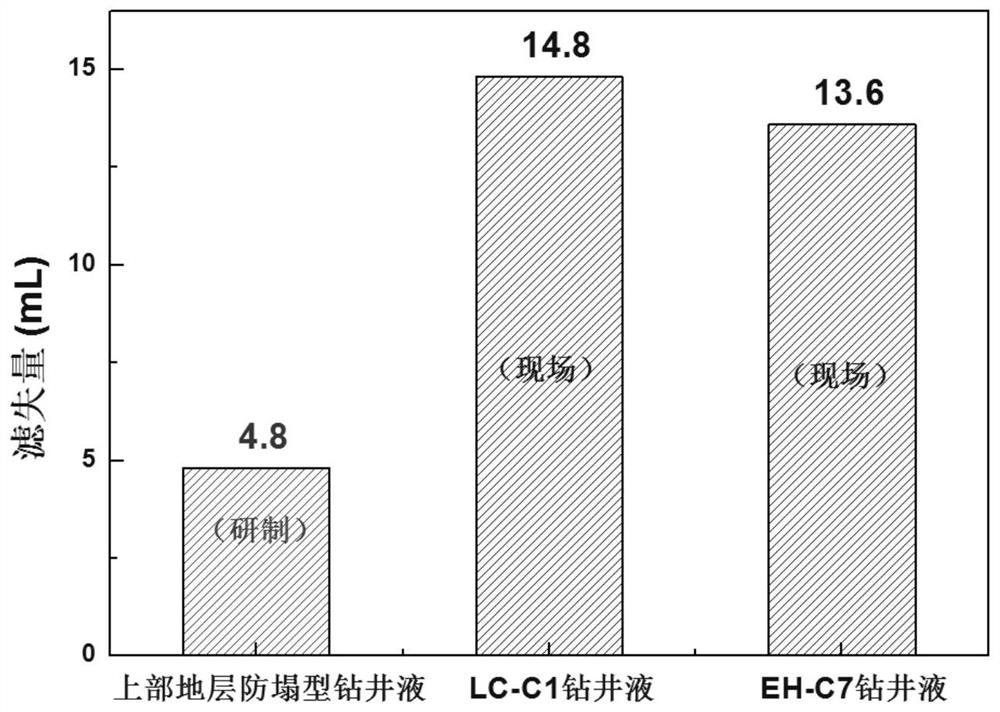

[0099] The upper formation anti-collapse drilling fluid system is constructed as follows:

[0100] 4% sodium soil + 1% plugging and anti-slump inhibitor GFJ (prepared in Example 1) + 1% ammonium salt + 2% carboxymethyl starch CMS + 0.4% potassium polyacrylate KPAM.

[0101] Plugging and anti-slump inhibitor GFJ performance indicators: API fluid loss: 12.4ml; penetration: 0.23mm; particle size after hot rolling: 0.38μm; (API fluid loss is added to 4% bentonite slurry with 1% GFJ, Follow the laboratory standard GB / T29170-2012. The needle penetration is measured by the SZR-3 needle penetration tester, and the particle size after hot rolling is the D50 data of the laser particle size distribution tester)

[0102] Potassium polyacrylate KPAM performance indicators: appearance, white or light yellow free-flowing powder; moisture, ≤10.0%; purity, ≥75%; sieve residue, ≤10%; degree of hydrolysis, 27% to 35%; potassium content, 11 %~16%; pH value, 8.0~10.0; intrinsic viscosity, 100ml / g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com