Spandex fiber with reversible shape memory effect, and preparation method and application thereof

A technology of spandex fiber and memory effect, applied in fiber processing, fiber chemical characteristics, melt spinning, etc., can solve the problems of non-reversibility, limiting the development and application of shape memory polymer fibers, non-reversibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

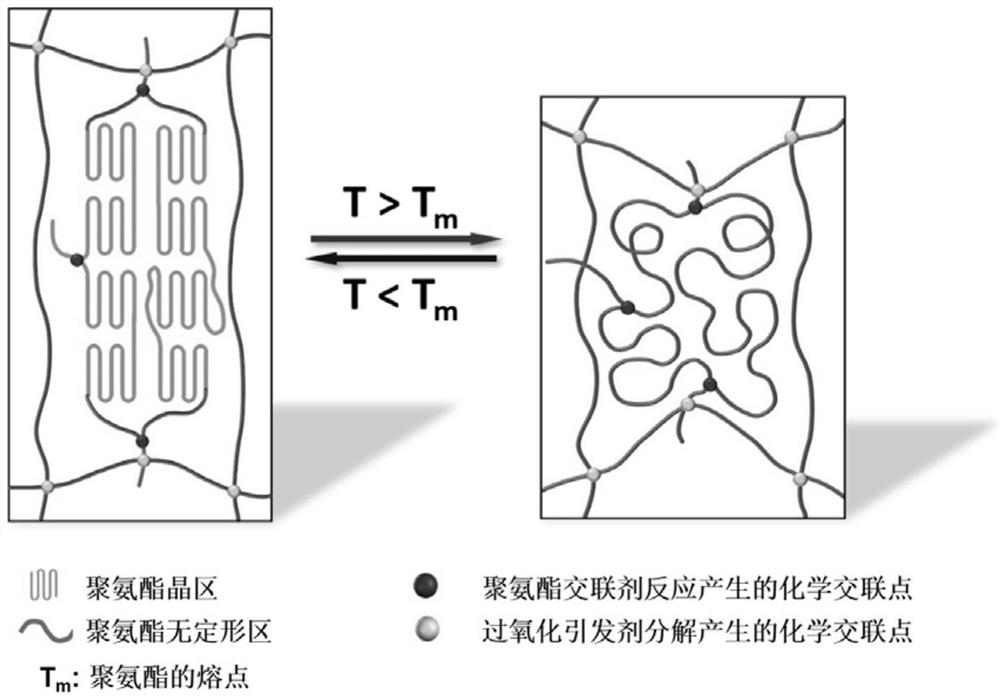

Method used

Image

Examples

preparation example Construction

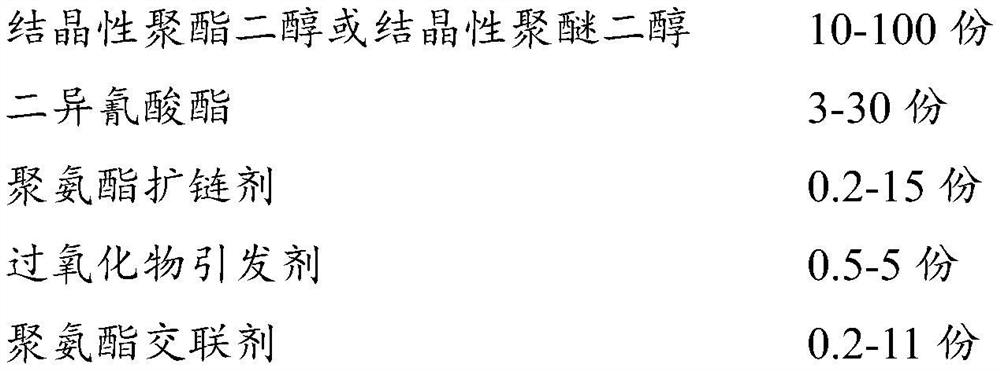

[0036] The preparation method of the spandex fiber with reversible shape memory effect comprises the following steps:

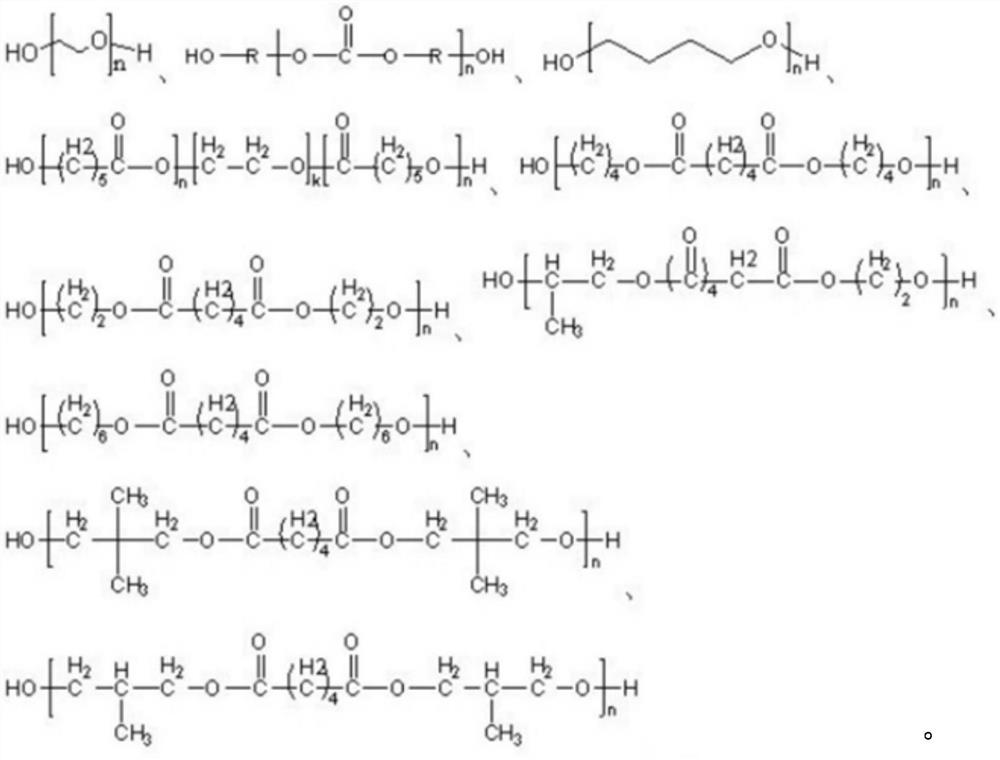

[0037] (1) Dissolve crystalline polyester diol or crystalline polyether diol and diisocyanate in an appropriate amount of solvent, react at 25-100°C for 1-3 hours, and react to produce polyester with isocyanate groups at both ends or polyether, then add polyurethane chain extender, react at 25-100°C for 2-24h, synthesize polyurethane prepolymer, then cool down to room temperature and add polyurethane cross-linking agent and peroxide initiator under stirring condition, by adjusting the The consumption of solvent, be mixed with the spinning stock solution that mass fraction is 35%;

[0038] (2) Degas the spinning stock solution obtained in step (1) for 30 minutes under vacuum conditions and room temperature to ensure that no air bubbles exist in the spinning stock solution, then press the spinning stock solution into the pipeline through a metering pump, and T...

Embodiment 1

[0043] Get 30 parts of molecular weight and be 3000 polycaprolactone glycols, 3.7 parts of hexamethylene diisocyanate and a small amount of dibutyltin dilaurate (catalyst) join in the three-necked flask with mechanical stirring, use tetrahydrofuran as solvent in React at 60°C for 1 hour; add 0.2 parts of 1,4-butanediol to the above system, and react at 60°C for 0.5 hours; then cool the polyurethane prepolymer solution obtained from the reaction to room temperature, and add 2.6 parts of trihydroxy Methylpropane tris(3-mercaptopropionate) and 0.9 parts of dicumyl peroxide were prepared into a spinning dope with a mass fraction of 35% by regulating the amount of tetrahydrofuran. The spinning stock solution was degassed for 30 minutes under vacuum conditions and room temperature to ensure that no air bubbles existed in the spinning stock solution. The spinning stock solution is pressed into the pipeline through the metering pump, and a thin stream of spinning stock solution is ext...

Embodiment 2

[0045] Get 20 parts of polycaprolactone diols with a molecular weight of 2000, 3.7 parts of hexamethylene diisocyanate and a small amount of catalyst dibutyltin dilaurate (catalyst) and join in a three-necked flask with mechanical stirring, using tetrahydrofuran as a solvent React at 60°C for 1h; add 0.2 parts of 1,4-butanediol to the above system, and react at 60°C for 0.5h; then cool down the polyurethane prepolymer solution obtained from the reaction to room temperature, and add 2.6 parts of three Methylolpropane tris(3-mercaptopropionate) and 0.9 part of dicumyl peroxide are prepared into a spinning dope with a mass fraction of 35% by regulating the amount of tetrahydrofuran. The spinning stock solution was degassed for 30 minutes under vacuum conditions and room temperature to ensure that no air bubbles existed in the spinning stock solution. The spinning stock solution is pressed into the pipeline through the metering pump, and a thin stream of spinning stock solution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com