A kind of flotation recovery method of high-calcium-magnesium-high-shale mixed lead-zinc ore

A recovery method, high calcium and magnesium technology, applied in flotation, recycling technology, mechanical material recovery, etc., can solve the problems of rich viscosity of flotation foam, high pH value of mineral processing backwater, low recovery rate of zinc oxide, etc., to achieve Save the cost of chemicals, improve the recovery rate and resource utilization rate, and avoid the effect of low recovery rate of zinc oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

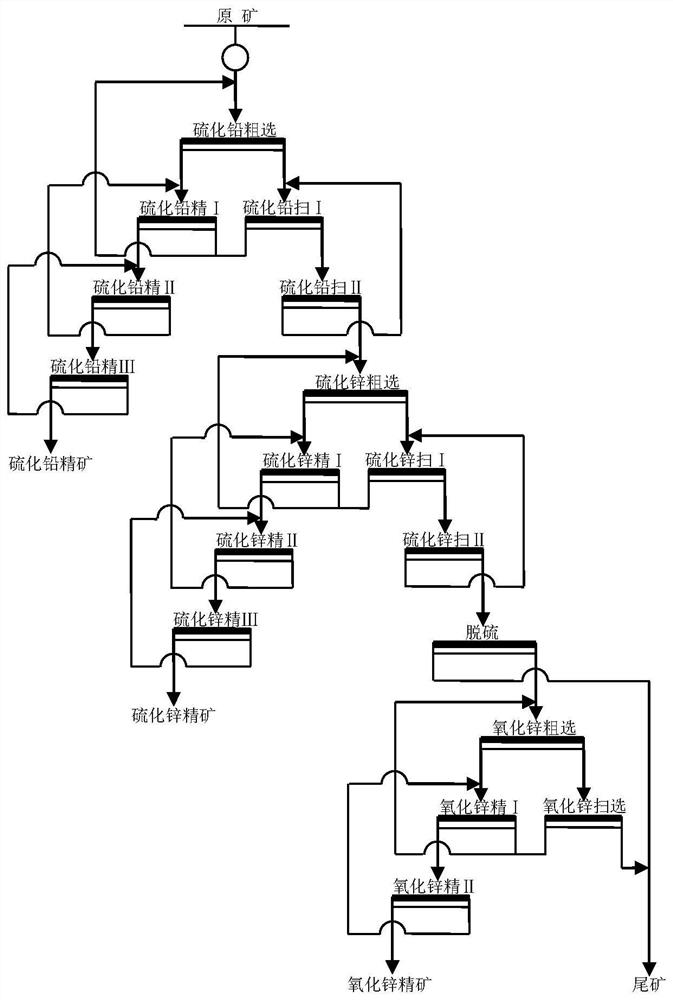

Image

Examples

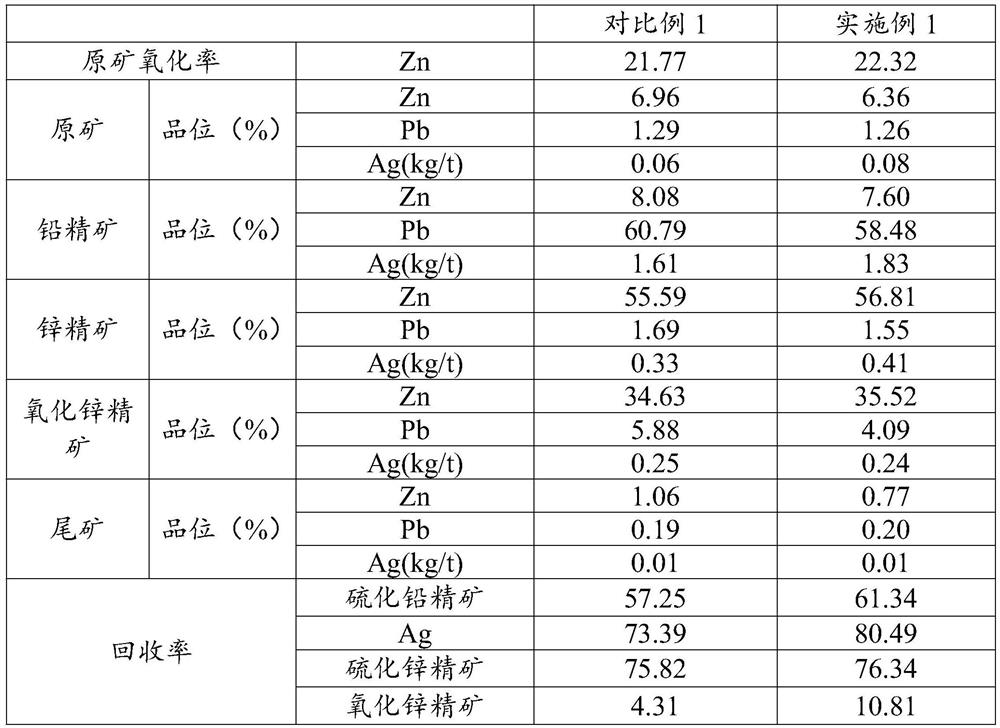

Embodiment 1

[0045] The present embodiment provides a flotation recovery method for a high-calcium-magnesium and high-shale mixed lead-zinc ore, comprising the following steps:

[0046] S1. After crushing the high-calcium-magnesium and high-shale mixed lead-zinc ore, add 750g / t of lime in the grinding process for wet grinding on a per ton of raw ore basis, so that the mass percentage of the ore with a particle size of less than 0.074mm is 80% ~85%, and add water to adjust the pulp concentration to 35%.

[0047] S2, adopt the process of one roughing, two sweeping and three selecting processes to carry out lead sulfide flotation on the pulp obtained in step S1, to obtain lead sulfide concentrate and roughing tailings for the first time; wherein, the roughing agent is 600g / t of sodium sulfide, 250g / t of zinc sulfate, 250g / t of sodium sulfite, 70g / t of ethion, 13g / t of black medicine and 15g / t of 2# oil; the agents selected for the first sweep are: 25g / t ethionine; 15g / t ethionine for the se...

Embodiment 2~3 and comparative example 2~3

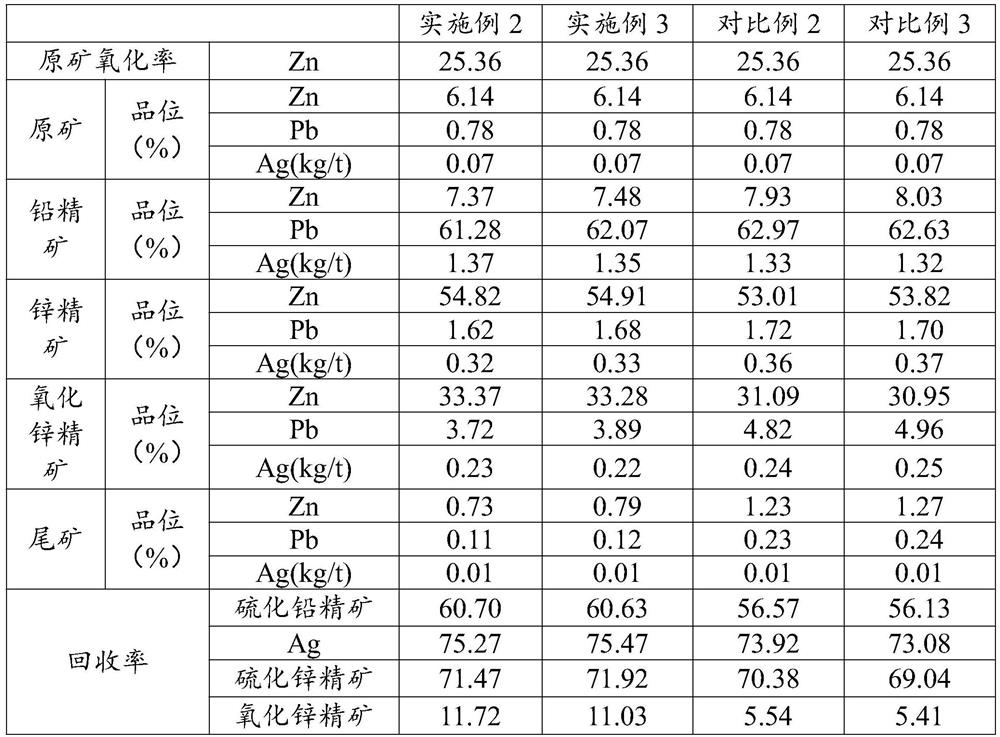

[0068] Embodiments 2-3 and Comparative Examples 2-3 respectively provide a flotation recovery method for mixed lead-zinc ore with high calcium and magnesium and high shale. Compared with embodiment 1, the difference is that the addition amount of lime is adjusted. Wherein, the addition amounts of lime in Examples 2-3 and Comparative Examples 1-2 were 500 g / t, 1000 g / t, 4000 g / t and 5000 g / t, respectively.

[0069] According to the methods provided in Examples 2 to 3 and Comparative Examples 2 to 3, flotation was performed on the mixed lead-zinc ore with high calcium and magnesium shale, and the results are shown in Table 3.

[0070] The beneficiation test results of Table 3 Examples 2-3 and Comparative Examples 2-3

[0071]

[0072] As can be seen from Table 3, under the same ore sample conditions, the lead-zinc sulfide low-alkali flotation process adopted in Examples 2-3 not only effectively reduces the lead-zinc sulfide high-alkali flotation process used in Comparative Ex...

Embodiment 4~5

[0074]Embodiments 4 to 5 respectively provide a flotation recovery method for a high-calcium-magnesium and high-shale mixed lead-zinc ore. Compared with Embodiment 1, the difference lies in that the chemical content in each step is adjusted, and the remaining steps are the same as those in the implementation. Example 1 is the same and will not be repeated here.

[0075] In embodiment 4, in step S2, the rough selection agent is sodium sulfide 500g / t, zinc sulfate 200g / t, sodium sulfite 200g / t, ethyl thiazide 60g / t, black medicine 10g / t, 2# oil 10g / t; The first cleaning agent is 20g / t ethion; the second cleaning agent is 10g / t ethion; the first cleaning agent is 100g / t zinc sulfate and 100g / t sodium sulfite; The selected agents are zinc sulfate 50g / t and sodium sulfite 50g / t. In step S3, the rough selection agents are sodium hexametaphosphate 200g / t, copper sulfate 450g / t, butyl xanthate 80g / t, 2# oil 10g / t; the first sweep selection agent is butyl xanthate 20g / t ; The second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com