Solvent-free highlight coating and preparation method thereof

A solvent-free and paint-free technology, applied in the direction of paper coating, coating, and pigment-free coating, etc., can solve the problems of complex production equipment, insufficient gloss, large paper deformation, etc., and achieve low cost, strong adhesion, and paper deformation. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

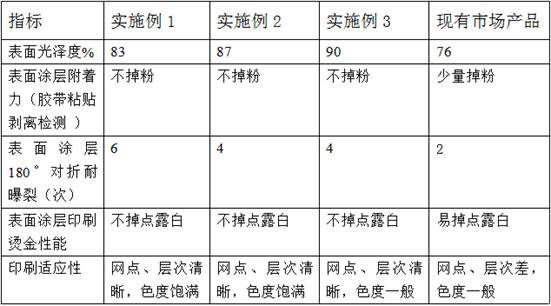

Examples

Embodiment 1

[0036] In the present embodiment, the preparation method of solvent-free high-gloss coating comprises the following steps:

[0037] (1) By weight, the following raw materials are equipped: 50% isocyanate (both diphenylmethane diisocyanate), 20% chain extension resin (both polycaprolactone diol with a molecular weight of 1000 (trade name: PCL -1000)), cross-linked resin 10% (both polyether polyols with a molecular weight of 595 sucrose as the initiator (trade name: Yinuowei YNW-8343)), active polysiloxane 10% (both α, ω-dihydroxyalkyl polysiloxane with a molecular weight of 1000), 2% hydroxyacrylate (both are hydroxyethyl acrylate), 2% chain extenders (both are hydroquinone dihydroxyethyl ether), Cross-linking agent 0.3% (both trimethylolpropane), pre-catalyst 0.1% (both stannous octoate), post-catalyst 0.1% (both bismorpholino diethyl ether), molecular sieve activation powder 2.5% ( Both are molecular sieve activation powder JLH-PU of Luoyang Jianlong Micro-nano New Material ...

Embodiment 2

[0046] In the present embodiment, the preparation method of solvent-free high-gloss coating comprises the following steps:

[0047] (1) By weight, the following raw materials are equipped: 36% isocyanate (both are isophorone diisocyanate), 30% chain extension resin (both are polyoxypropylene ether diamines with a molecular weight of 2000 (trade name: ZD- 1400)), cross-linked resin 20% (both polyether polyols with a molecular weight of 650 sorbitol as the initiator (trade name: Lianchuang LC-260S)), active polysiloxane 6% (both molecular weight 1000 aminopropyl-terminated polydimethylsiloxane), hydroxyacrylate 1.5% (both hydroxyethyl acrylate), chain extender 1.5% (both 1,4-butanediol), cross-linked Agent 0.1% (both trimethylolpropane), pre-catalyst 0.05% (both stannous octoate), post-catalyst 0.05% (both triethanolamine), molecular sieve activation powder 1% (both Luoyang Jianlong micro nano new Materials Co., Ltd.’s molecular sieve activation powder JLH-PU), leveling agent 0...

Embodiment 3

[0056] In the present embodiment, the preparation method of solvent-free high-gloss coating comprises the following steps:

[0057] (1) By weight, the following raw materials are equipped: 63.5% isocyanate (both hexamethylene diisocyanate trimer), 11% chain extension resin (both are polyoxypropylene glycol with a molecular weight of 2000 (trade name: YNW-220)), 5% cross-linked resin (both polyether polyols (trade name: NJ-303) with a molecular weight of 350 glycerol as the initiator), 8% reactive polysiloxane (both Aminopropyl-terminated polydimethylsiloxane with a molecular weight of 1000), 1.5% hydroxyacrylate (both hydroxyethyl methacrylate), 3% chain extender (both diethylene glycol), Cross-linking agent 0.2% (both glycerol), pre-catalyst 0.1% (both dibutyltin dilaurate), post-catalyst 0.2% (both dimethylethanolamine), molecular sieve activation powder 5% (both Luoyang Jian Molecular sieve activation powder JLH-PU of Longwei Nano New Material Co., Ltd.), 0.8% leveling age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com