Lithium vanadate with indium and cerium or indium-doped nanofiber structure as well as preparation method and application of lithium vanadate

A nanofiber and indium doping technology, which is applied in structural parts, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of time-consuming, complicated preparation process, and high energy consumption, and achieve simple process, uniform particle size distribution, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

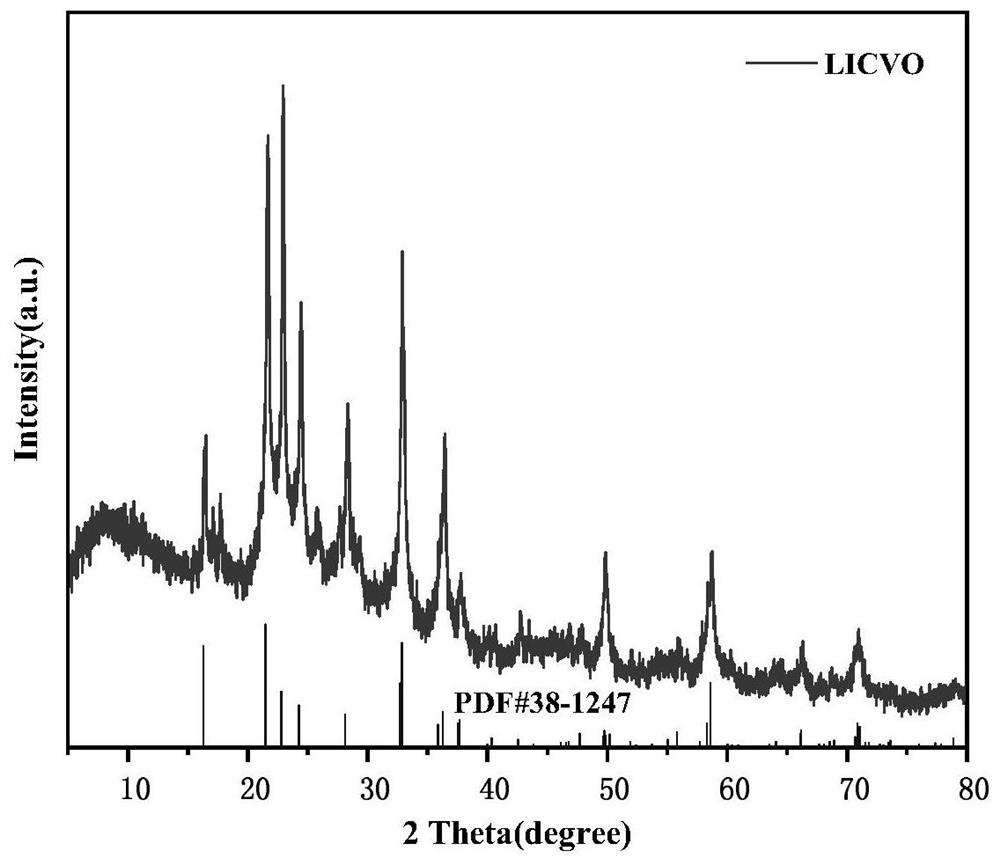

[0066] First, dissolve 0.5733g of lithium acetate in a solution consisting of 8.875mL of ethanol, 0.955mL of glacial acetic acid, and 4mL of deionized water, and stir at 50°C and 600r / min for 10min to form a transparent solution. Then add 0.3278g of citric acid monohydrate, 0.5g of ascorbic acid, and 0.2925g of ammonium metavanadate into the transparent solution, and continue to stir for 6 hours (exploring and finding that for the reaction system of this example, the stirring time needs to be at least 6 hours, otherwise the expected Morphology, the comparative example with insufficient stirring time is given later), and a dark brown solution is formed. Finally, 0.02273g ceric sulfate tetrahydrate (Ce(SO 4 ) 2 4H 2 O), 0.07767g indium sulfate and 0.8g polyvinylpyrrolidone (PVP) were added to the dark brown solution, and stirred for 3h to obtain the electrospinning precursor solution.

[0067] The positive pressure of electrospinning is 15kV, the negative pressure is -1kV, th...

Embodiment 2

[0070] The steps of this example are exactly the same as Example 1, only the choice of doping salt is different. The doping salt only selects the indium sulfate doping of the same dosage as that of Example 1, and obtains the required doping Li after calcination. 3 VO 4 Material (LIVO).

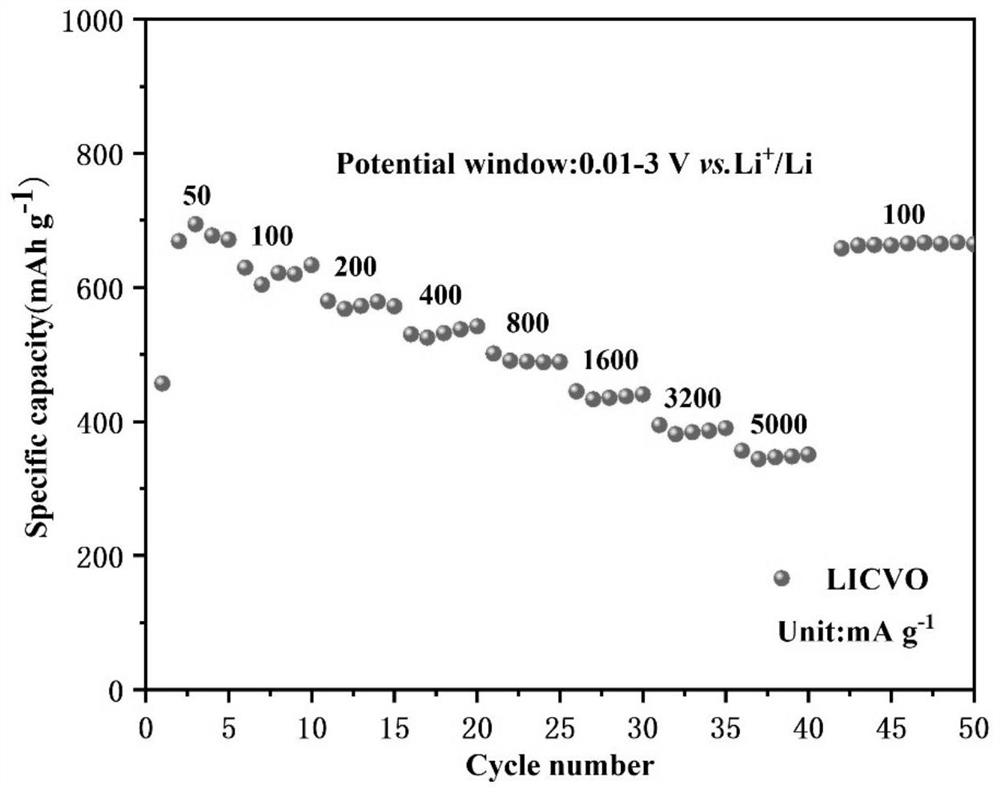

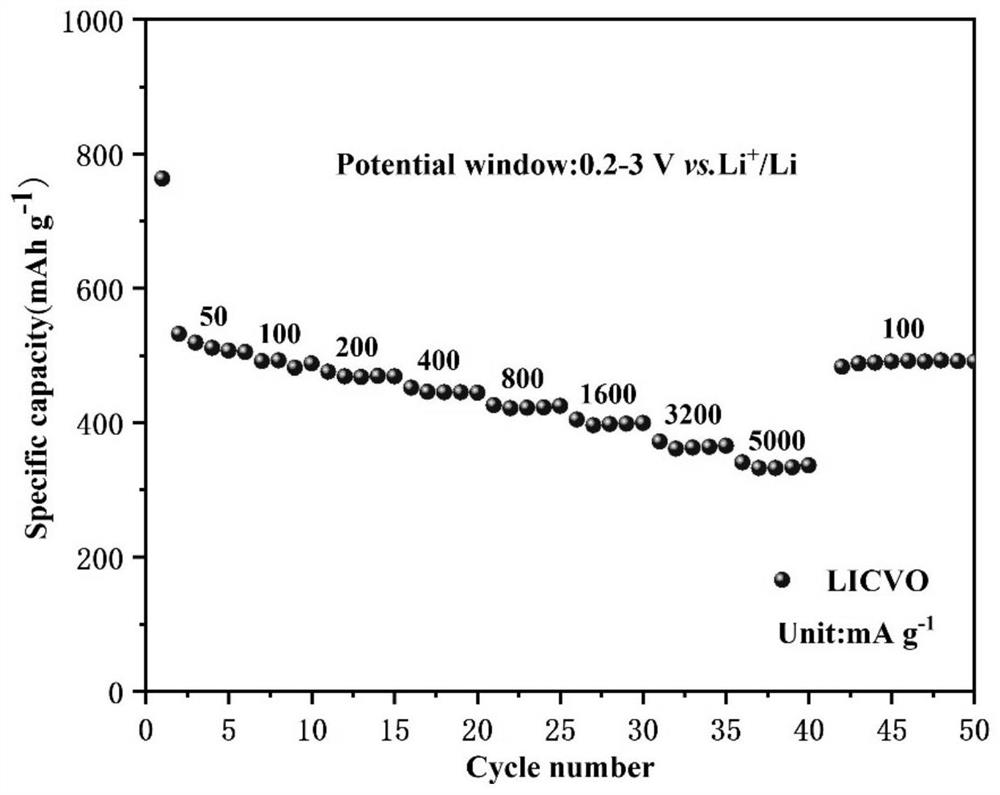

[0071] The obtained materials were assembled into a coin cell according to the method of Example 1 for rate performance test. Rate performance test voltage range is 0.01~3V, current density is 50~5000mA g -1 . The rate performance test results are as follows: Figure 4 As shown, it can be seen that only indium-doped Li 3 VO 4 , through electrospinning and subsequent calcination steps, doped Li with excellent rate performance can still be obtained 3 VO 4 Material.

Embodiment 3

[0073] With 0.3672g lithium hydroxide, 0.6629g vanadyl acetylacetonate, 0.02273g ceric sulfate tetrahydrate (Ce(SO 4 ) 2 4H 2 O), 0.07767g of indium sulfate was added to 12mL of N,N-dimethylformamide (DMF). Stir at 50°C and 600r / min for 3h to form a dark brown solution. Finally, 0.5 g of polyvinylpyrrolidone (PVP) and 0.5 g of polyacrylonitrile (PAN) were added, and stirring was continued for 3 h to obtain an electrospinning precursor solution.

[0074] The positive pressure of electrospinning is about 13kV, the negative pressure is -1kV, the distance between the syringe needle and the aluminum foil is 15cm, and the advancing speed of the needle tube is 0.060mm / min. The resulting spun product was kept in an Ar atmosphere at 700°C for 3 hours in a tube furnace to obtain the required doped Li 3 VO 4 Material (LICVO-1), heating rate 3°C / min.

[0075] The morphology and particle size of the sample were observed with a Nova NanoSEM 230 scanning electron microscope from FEI Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com