Preparation method and application of carbon dot modified silicon dioxide nanoparticle-based hydrogel composite material

A technology of silica and nanoparticles, applied in the direction of gel preparation, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of urgent development and other applications, and achieve rapid adsorption and detection, good fluorescence performance, and good fluorescence stability and environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of cross-linkable carbon dot modified silica nanoparticles comprises the following steps:

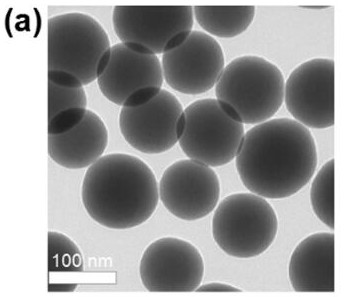

[0030] (1) Preparation of monodisperse silica nanoparticles: first mix 1-5mL tetraethyl orthosilicate and 50mL absolute ethanol evenly, then mix 1-5mL deionized water, 1-5mL ammonia water, 40mL absolute ethanol After mixing evenly, the above two solutions were mixed under room temperature and magnetic stirring, and the reaction was continuously stirred for 20 hours. After the reaction, it was washed three times by ethanol centrifugation. figure 1 shown.

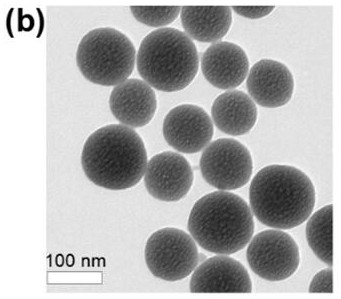

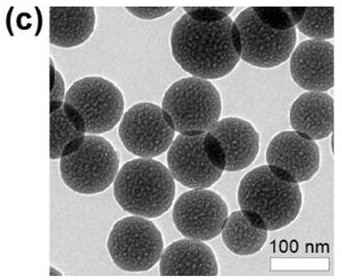

[0031] (2) Preparation of carbon dot-modified silica nanoparticles: mix the silica nanoparticles obtained in (1) with 1 wt% sodium alginate and 1 wt% ethylenediamine, and place them in a high-pressure hydrothermal reactor ( The pressure is 1-5MPa) and reacted in an oven at 180° C. for 5 hours, and the solvent is deionized water. After the reaction was completed, it was cooled to room temperature, washed with e...

Embodiment 2

[0034] The preparation method of the carbon dot modified silicon dioxide nanoparticle-based hydrogel composite film comprises the following steps:

[0035] (1) Blend 1wt% cross-linkable carbon dot modified silica nanoparticles with 0.3mL acrylic acid and 4mL hydroxyethyl methacrylate monomer, after mixing evenly, add 1wt% 1173 initiator, A homogeneous suspension was obtained.

[0036] (2) The suspension prepared above is poured into a mold, and then placed under 365nm UV light irradiation for 5-15 minutes to polymerize. After complete polymerization, the obtained carbon dot modified silica nanoparticle-based hydrogel The composite film and the mold are put into water together. After the swelling balance is reached, the hydrogel composite film is automatically peeled off from the mold, so that a carbon dot modified silica nanoparticle-based hydrogel composite film consistent with the shape of the mold is obtained, as shown in Figure 5 , 6 shown. The obtained hydrogel compos...

Embodiment 3

[0039] Adsorption and Detection of Copper Ions in Silica Nanoparticle-Based Hydrogel Composite Films Modified by Carbon Dots

[0040] (1) Prepare 10mM aqueous solutions of different metal ions, including Na + , K + , Zn 2+ , Cu 2+ ,Pb 2+ , Hg 2+ , Ni 2+ , Ca 2+ , Mg 2+ , Cr 3+ , Fe 3+ and other eleven metal ion aqueous solutions.

[0041] (2) Soak the prepared hydrogel composite film into the above-mentioned eleven kinds of metal ion aqueous solution, take it out after soaking for 1 hour, dry the water on the surface of the hydrogel film with filter paper, and then use the fluorescence spectrometer Measure the fluorescence intensity of the hydrogel composite film.

[0042] (3) Through comparative analysis, among the above ten metal ions, the hydrogel composite film only has a strong extinction phenomenon for copper ions, such as Figure 8 It is shown that the hydrogel composite film has a good ability to detect copper ions. In addition, before and after the adsorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com