Preparation method of high-thermal-conductivity diamond reinforced silicon carbide substrate

A diamond-enhanced, silicon carbide substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the interface strength between SiC and diamond, thermal conductivity of nucleation defects, etching interface strength, interface thermal stress, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

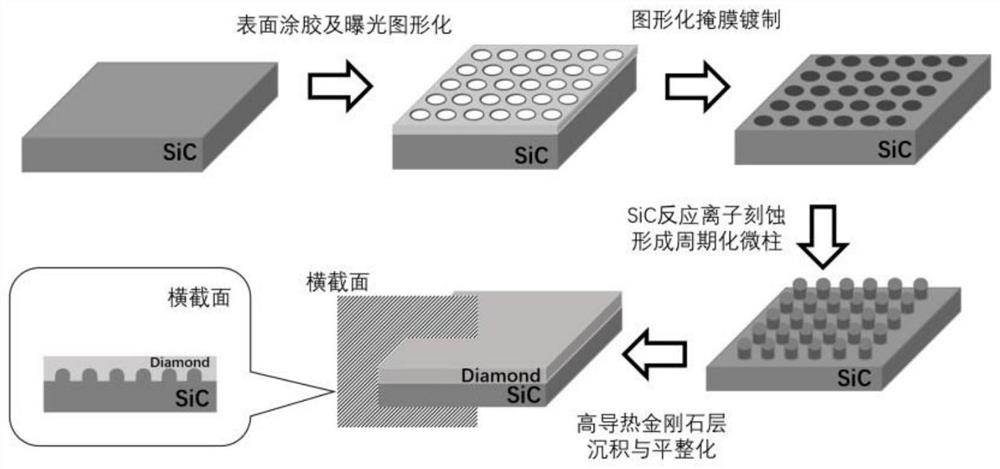

specific Embodiment approach 1

[0030] UV lithography is achieved by spin-coating photoresist on the carbon polar face of SiC and by mask-based. Then, periodic micropores with a diameter of 2 μm and an interval of 4 μm are realized by developing and degumming, revealing the periodically arranged diamond patterned surface. The SiC with the patterned photoresist is first deposited by electron beam evaporation with a Ti metal mask of 50nm and then an Al metal of 150nm. Then the remaining photoresist is removed to obtain the SiC with the metal pattern mask deposited on the surface. For SiC via gas source CF 4 :O 2 SiC was etched to an etching depth of 2 μm at a ratio of 5:1 and a bias power of 300 W. The metal mask is then removed by chemical dissolution. Subsequent passing SiC again through pure CF 4 The SiC was etched under the bias power of 20W to realize the rounded etching of the edge of the microcolumn. Then the patterned SiC sheet was placed in the microwave plasma chamber, the microwave power was c...

specific Embodiment approach 2

[0031] UV lithography is achieved by spin-coating photoresist on the carbon polar face of SiC and by mask-based. Then, periodic micropores with a diameter of 2 μm and an interval of 2 μm are realized by developing and degumming, revealing a periodically arranged diamond patterned surface. The SiC with patterned photoresist was first deposited with 30nm of Ti metal mask and then 120nm of Al metal by electron beam evaporation. Then the remaining photoresist is removed to obtain the SiC with the metal pattern mask deposited on the surface. For SiC via gas source CF 4 :O 2 SiC was etched to an etching depth of 1 μm at a ratio of 4:1 and a bias power of 200 W. The metal mask is then removed by chemical dissolution. Subsequent passing SiC again through pure CF 4 The SiC was etched under the bias power of 10W to realize the rounded etching of the edge of the microcolumn. Then the patterned SiC sheet was placed in the microwave plasma chamber, the microwave power was controlled ...

specific Embodiment approach 3

[0032] UV lithography is achieved by spin-coating photoresist on the carbon polar face of SiC and by mask-based. Then, periodic micropores with a diameter of 5 μm and an interval of 8 μm are realized by developing and degumming, and the periodically arranged diamond patterned surface is exposed. The SiC with patterned photoresist is first deposited with a Ti metal mask of 40 nm and then deposited with an Al metal of 150 nm by electron beam evaporation. Then the remaining photoresist is removed to obtain the SiC with the metal pattern mask deposited on the surface. For SiC via gas source CF 4 :O 2 SiC was etched to an etching depth of 3 μm at a ratio of 2:1 and a bias power of 100 W. The metal mask is then removed by chemical dissolution. Subsequent passing SiC again through pure CF 4 The SiC was etched under the bias power of 10W to realize the rounded etching of the edge of the microcolumn. Then the patterned SiC sheet was placed in the microwave plasma cavity, the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com