Anaerobic ammonia oxidation strengthening process based on hydrophobic biomass charcoal

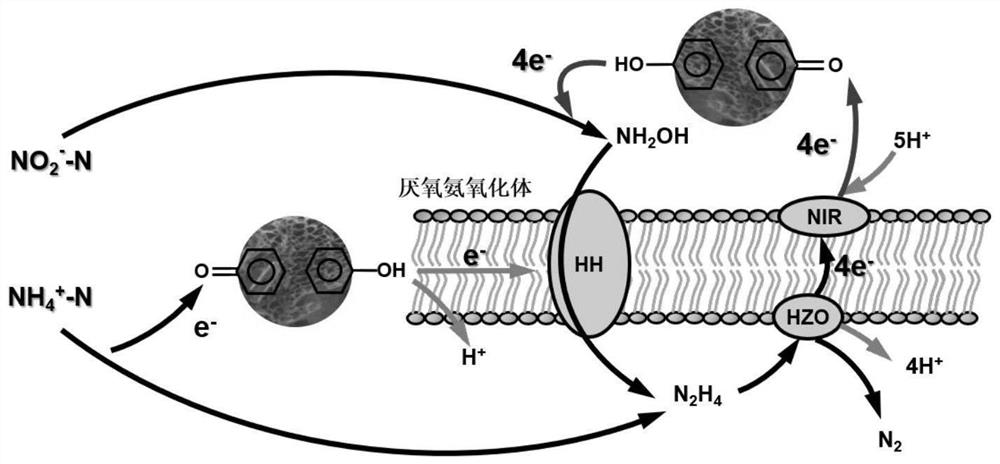

An anaerobic ammonia oxidation and biomass carbon technology, which is applied in anaerobic digestion treatment, water pollutants, biofuels, etc., can solve the problem of slow reactor start-up process, unstable denitrification rate and efficiency, and good water dispersibility, etc. problems, to achieve the effect of improving electron transfer rate and denitrification efficiency, fast start-up and stable operation, and rich surface functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Waste bamboo was used as raw material to prepare biochar, which was broken into small pieces of 0.5-2 cm and then dried at 60°C for 48 hours. A tube furnace was used to prepare biochar in one step. The pyrolysis temperature was 400 °C, the heating rate was 5 °C / min, and the holding time was 10 h. Nitrogen was used for anoxic protection during the pyrolysis process.

[0038] The water contact angle (θ) of the biochar prepared by the above-mentioned one-step method is 62°, and the electron transfer / exchange capacity (EEC) per unit mass of biochar (1g) is 2.46mM e - . After sieving the biochar, biochar particles with a particle size of about 3 mm were obtained, soaked in water for 24 hours, loaded into an upflow anaerobic biofilter, and inoculated with a certain A 2 / O The secondary sedimentation tank of the sewage plant concentrates the sludge, and supplements the anaerobic ammonium oxidation flocculent sludge according to 20% (mass ratio) of the inoculated sludge amoun...

Embodiment 2

[0040] Waste corn stalks are used as raw materials, broken into small pieces of 3 to 5 cm, and then dried at 45 ° C. Biochar is prepared by a two-step method. (1): High-temperature pyrolysis was carried out in a tube furnace, the pyrolysis temperature was 700°C, the heating rate was 10°C / min, and the holding time was 1h. During the pyrolysis process, argon gas was used for anoxic protection. (2): The biochar obtained in step (1) is crushed and sieved to obtain biochar particles with a particle diameter of about 5mm, and the biochar is obtained by H 2 SO 4 +HNO 3 modified, H 2 SO 4 with HNO 3 The mass ratio is 0.5:1, the modification time is 3h, and then put back into the tube furnace, in H 2 / N 2 under protection (H 2 The volume content is 5%) for partial reduction reaction. The reaction conditions are: heating rate 20°C / min, reduction temperature 400°C, holding time 1.0h, so that the surface has proper hydrophobicity and high electron transfer ability.

[0041] The wa...

Embodiment 3

[0043] Waste pine wood was used as raw material to prepare biochar, which was broken into small pieces of 2-4 cm and then dried at 100°C until constant weight. Using a tube furnace, a one-step method was used to prepare woody biomass charcoal. The pyrolysis temperature was 500 °C, the heating rate was 15 °C / min, and the holding time was 8 h. During the pyrolysis process, argon gas was used for anoxic protection.

[0044] The water contact angle (θ) of the biochar prepared by the above one-step method is 87°, and the electron transfer / exchange capacity (EEC) per unit mass of biochar (1g) is 1.52mM e - . The prepared biochar was sieved to obtain granular biochar with a particle size of 4-5 mm. After soaking in clean water for 48 hours, it was loaded into an upflow anaerobic biofilter, and inoculated with concentrated sludge from a secondary sedimentation tank of an oxidation ditch sewage plant. According to 10% (mass ratio) of the amount of inoculated sludge, anaerobic ammonium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com