Membrane functional material for improving performance of lithium metal battery as well as preparation and application of membrane functional material

A technology for lithium metal batteries and functional materials, applied in nanotechnology for materials and surface science, battery pack components, circuits, etc., can solve problems such as difficult synthesis, affect nanoscale performance, etc. Cyclic stability and improved safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

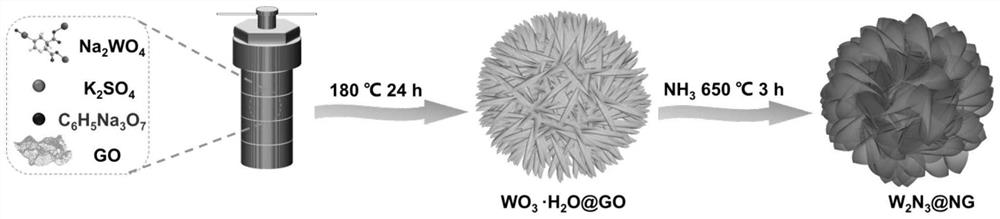

[0039]A method for preparing a separator functional material for improving the performance of lithium metal batteries, comprising the following steps:

[0040] Step 1: 3mmol sodium tungstate, 6mmol potassium sulfate, and 1mmol sodium citrate are used as raw materials, hydrochloric acid is used as a pH regulator, and distilled water is used as a solvent;

[0041] Step 2: Dissolve the above-mentioned potassium sulfate, sodium tungstate, and sodium citrate in 70 mL of distilled water containing 60 mg of graphene oxide, stir until the solid raw materials are completely dissolved, and then adjust the pH to 1-2 with hydrochloric acid to obtain a mixed solution and adjust the acidity The concentration of hydrochloric acid is 3mol / L;

[0042] Step 3: Pour the mixed solution obtained in Step 2 into a 100mL reaction kettle, and conduct a hydrothermal reaction at 160°C for 18 hours; after the hydrothermal reaction is completed, naturally cool to room temperature, filter, wash, and freeze...

Embodiment 2

[0047] A method for preparing a separator functional material for improving the performance of lithium metal batteries, comprising the following steps:

[0048] Step 1: Use 6mmol sodium tungstate, 14mmol potassium sulfate, and 4mmol sodium citrate as raw materials, hydrochloric acid as a pH regulator, and distilled water as a solvent;

[0049] Step 2: Dissolve the above-mentioned potassium sulfate, sodium tungstate, and sodium citrate in 70 mL of distilled water containing 100 mg of graphene oxide, stir until the solid raw materials are completely dissolved, and then adjust the pH to 1-2 with hydrochloric acid to obtain a mixed solution and adjust the acidity The concentration of hydrochloric acid is 6mol / L;

[0050] Step 3: Pour the mixed solution obtained in step 2 into a 100mL reaction kettle, and conduct a hydrothermal reaction at 200°C for 36 hours; after the hydrothermal reaction is completed, naturally cool to room temperature, filter, wash, and freeze-dry to obtain tun...

Embodiment 3

[0055] A method for preparing a separator functional material for improving the performance of lithium metal batteries, comprising the following steps:

[0056] Step 1: Use 5mmol sodium tungstate, 10mmol potassium sulfate, and 2.5mmol sodium citrate as raw materials, hydrochloric acid as a pH regulator, and distilled water as a solvent;

[0057] Step 2: Dissolve the above-mentioned potassium sulfate, sodium tungstate, and sodium citrate in 70mL of distilled water containing 80mg of graphene oxide, stir until the solid raw material is completely dissolved, then adjust the pH to 1.5 with hydrochloric acid to obtain a mixed solution, and adjust the acidity with hydrochloric acid The concentration is 3~6mol / L;

[0058] Step 3: Pour the mixed solution obtained in step 2 into a 100mL reaction kettle, and conduct a hydrothermal reaction at 180°C for 24 hours; after the hydrothermal reaction, naturally cool to room temperature, filter, wash, and freeze-dry to obtain tungsten oxide and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com