Monocrystalline silicon texturing additive for weak rough polishing process and use method thereof

A technology of crystalline silicon texturing and additives, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as difficult removal of diamond wire marks and limited photoelectric conversion efficiency of solar cells, and achieve The effect of improving photoelectric conversion efficiency, promoting the development of large-size thin slices, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

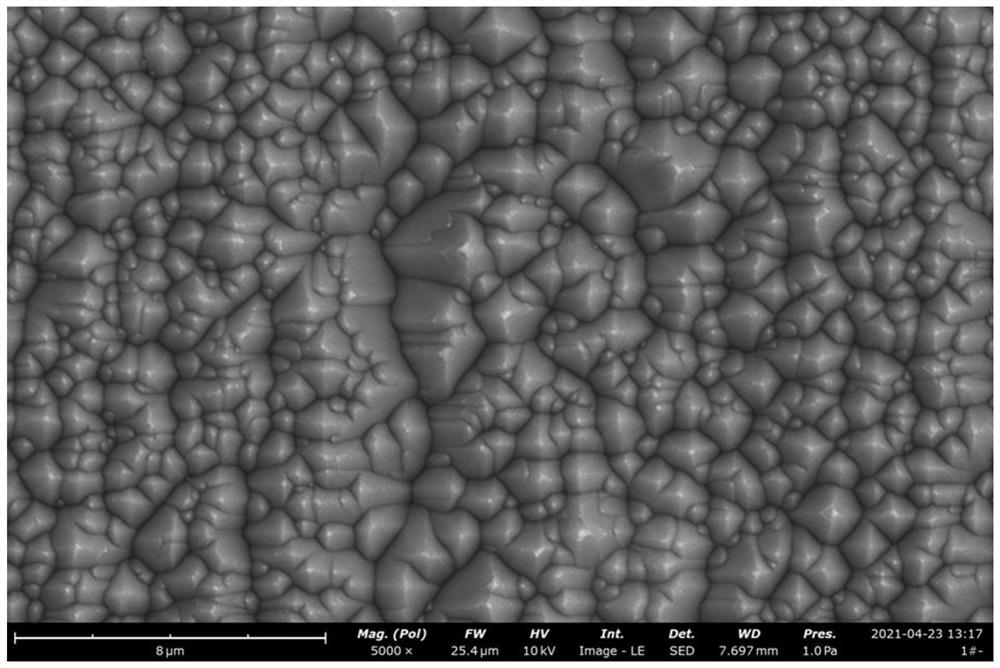

Embodiment 1

[0031] 1) Additive preparation: With 1L deionized water as solvent, add 10g dehydrobispressoyl glucoside, 4g protocatechuic acid, 0.02g fatty alcohol phosphate potassium salt, 0.6g sodium carbonate, 0.2g sodium thiosulfate , 0.6g oxalic acid, the above substances are fully stirred and mixed; 2) Texturing liquid preparation: add 500g sodium hydroxide in 50L deionized water, add 250ml additives and stir well, and make alkaline texturing liquid; 3) Silicon chip cleaning liquid Preparation: Add 100g of sodium hydroxide to 50L of deionized water, fully dissolve and stir evenly to prepare a silicon wafer cleaning solution; 4) Preparation of hydrogen peroxide pre-cleaning solution: Add 500ml of 30% hydrogen peroxide into 50L of deionized water, add 100g of alkali, and stir to mix Uniformly prepare hydrogen peroxide pre-cleaning solution; 5) Preparation of mixed acid solution: HF and HCl are prepared with a molar ratio of 1:2 to prepare a mixed acid concentration of 1.5moL / L; 6) Put th...

Embodiment 2

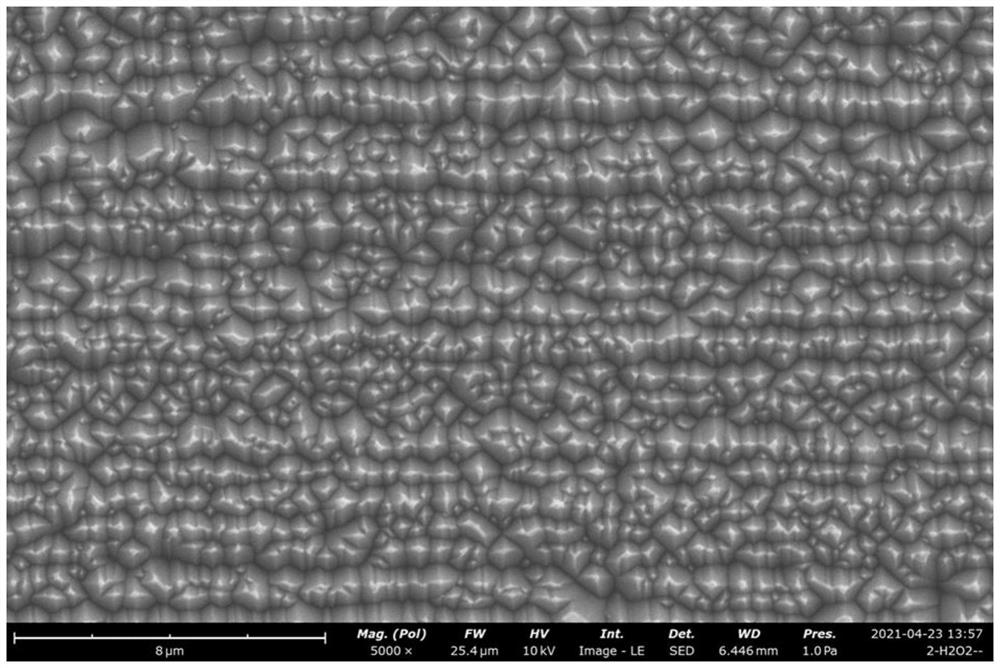

[0033]1) Additive preparation: With 1L deionized water as solvent, add 15g of quercetin rhamnosyl, 2g of gallic acid, 0.04g of potassium lauryl phosphate, 0.3g of sodium carbonate, 0.1g of sodium thiosulfate, 0.4g malic acid, the above substances are fully stirred and mixed; 2) Preparation of texturing solution: add 750g sodium hydroxide to 50L deionized water, add 250ml of additives and stir well to obtain an alkaline texturing solution; 3) Silicon chip cleaning solution Preparation: Add 125g of sodium hydroxide to 50L of deionized water, fully dissolve and stir evenly to prepare a cleaning solution for silicon wafers; 4) Preparation of hydrogen peroxide pre-cleaning solution: add 500ml of 30% hydrogen peroxide to 50L of deionized water, add 100g of alkali, stir and mix Uniformly prepare hydrogen peroxide pre-cleaning solution; 5) Preparation of mixed acid solution: HF and HCl are prepared with a molar ratio of 1:2 to prepare a mixed acid concentration of 1.5moL / L; 6) Put the ...

Embodiment 3

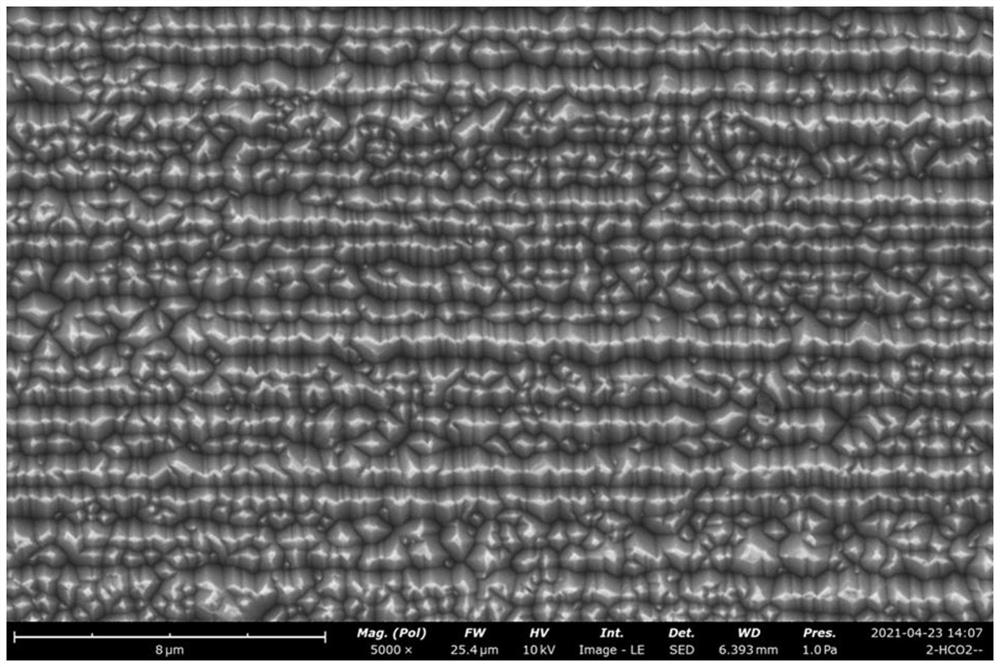

[0035] 1) Additive preparation: With 1L deionized water as solvent, add 15g dehydrobispressoyl glucoside, 4g syringic acid, 0.04g polyoxyethylene ether phosphate potassium salt, 0.5g sodium citrate, 0.2g sodium sulfite, 0.8 g oxalic acid, the above substances are fully stirred and mixed; 2) preparation of texturing solution: add 500g of sodium hydroxide in 50L of deionized water, add 250ml of additives and fully stir to obtain an alkaline texturing solution; 3) preparation of silicon chip cleaning solution: Add 150g of sodium hydroxide to 50L of deionized water, fully dissolve and stir evenly to prepare a cleaning solution for silicon wafers; 4) Preparation of hydrogen peroxide pre-cleaning solution: add 500ml of 30% hydrogen peroxide to 50L of deionized water, add 100g of alkali, stir and mix to prepare Obtain hydrogen peroxide pre-cleaning solution; 5) Preparation of mixed acid solution: HF and HCl are prepared with a molar ratio of 1:2 to prepare a mixed acid concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com