Molecular glass photoresist of metallocene compound and preparation method thereof

A metallocene compound and molecular glass technology, applied in the field of photoresist, can solve the problems of easy collapse of high-precision lines, increase of line edge roughness, residual exposure area, etc., achieve good dissolution inhibition effect, improve solubility contrast, structure regular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

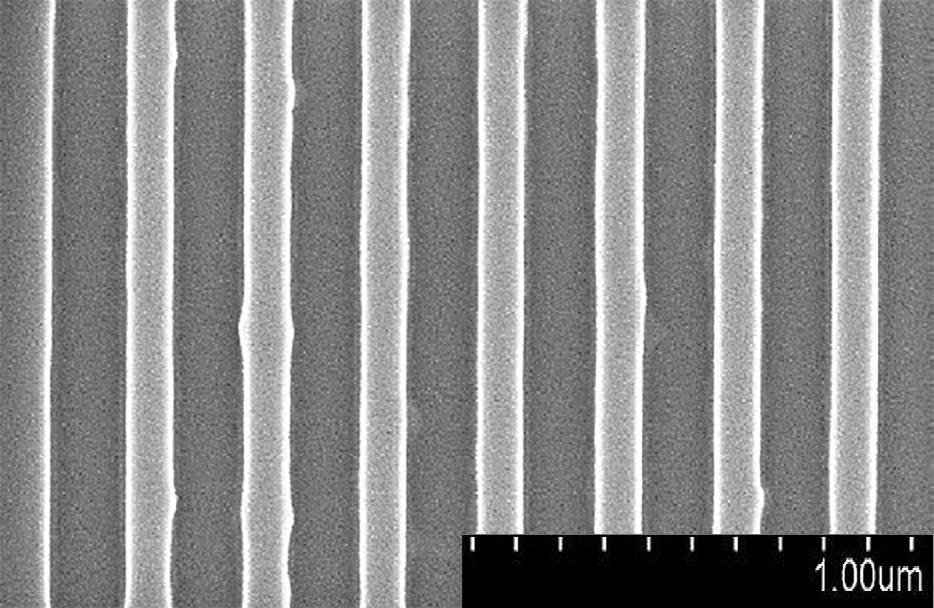

Image

Examples

Embodiment 1

[0025] Example 1 95.2g (about 0.22 mol) of tert-butyl lithocholic acid represented by formula (IV) and 31g (about 0.1 mol) of 1, 1 Ferrocenedicarboxylic acid chloride was dissolved in 2000 ml of anhydrous tetrahydrofuran; 62 ml of triethylamine was slowly added dropwise while stirring to produce precipitation; after 20 hours of reaction, it was quenched with deionized water; extracted 3 times with ethyl acetate; Washing with brine; drying over anhydrous magnesium sulfate, the solution was filtered and concentrated, and vacuum-dried to obtain molecular glass film-forming resin 1# represented by formula (VI).

[0026] Formula (IV)

[0027] Formula (V)

[0028] Formula (VI)

Embodiment 2

[0029] Example 2 In a state filled with nitrogen, 97.6g (about 0.21 mol) of tert-butyl cholic acid represented by formula (VII), and 31g (about 0.1 mol) of 1,1 Dissolve ferrocenedicarboxylic acid chloride in 2000 ml of anhydrous tetrahydrofuran; slowly add 62 ml of triethylamine dropwise to produce precipitation while stirring; quench with deionized water after 20 hours of reaction; extract with ethyl acetate three times; Washing; then drying over anhydrous magnesium sulfate, the solution was filtered and concentrated, and vacuum-dried to obtain molecular glass film-forming resin 2# represented by formula (VIII).

[0030] Formula (VII)

[0031] Formula (V)

[0032] Formula (VIII)

Embodiment 3

[0034]Dissolve 58.4 g (about 50 mmol) of 2# film-forming resin obtained in Example 2 and 12.2 g (about 100 mmol) of 4-dimethylaminopyridine in 400 ml of anhydrous tetrahydrofuran, and then add di-tert-butyl carbonic anhydride 32 g (about 147 mmol) was stirred at room temperature for 20 hours, then injected into 4000 ml of deionized water, collected the sediment, washed with sufficient deionized water, dissolved in 400 ml of ethyl acetate, washed with saturated brine; then washed with anhydrous magnesium sulfate After drying, the solution was filtered and concentrated, and vacuum-dried to obtain molecular glass film-forming resin 3# represented by formula (IX), the theoretical replacement rate of t-boc for hydroxyl was 75%. When the molar equivalent ratio of di-tert-butyl dicarbonic anhydride and film-forming resin 2# (metallocene compound-tert-butyl cholate molecular glass) is adjusted to 2~4, the replacement rate of t-boc for hydroxyl groups can be 50 %~100% metallocene compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com