Preparation method of transparent hydrophobic spherical silica aerogel adsorbent

A spherical silica, silica sol technology, applied in chemical instruments and methods, separation methods, alkali metal oxides/hydroxides, etc., can solve the problems of poor recycling ability, weak adsorption selectivity, poor mechanical properties, etc. , to achieve the effect of high safety, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

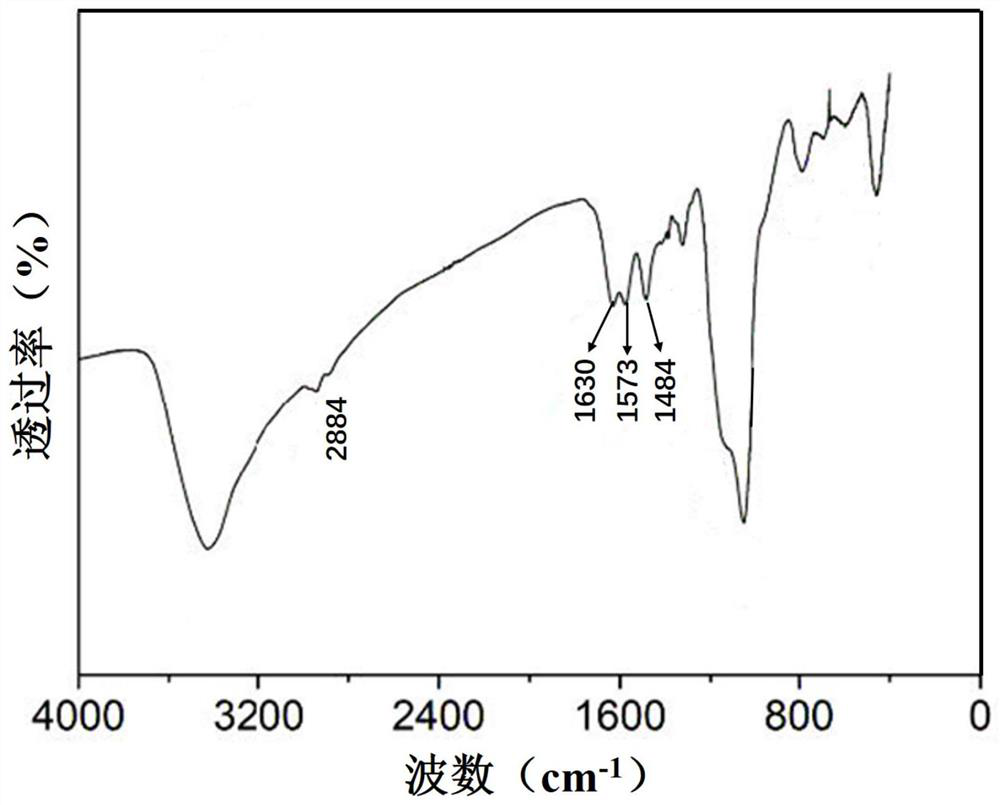

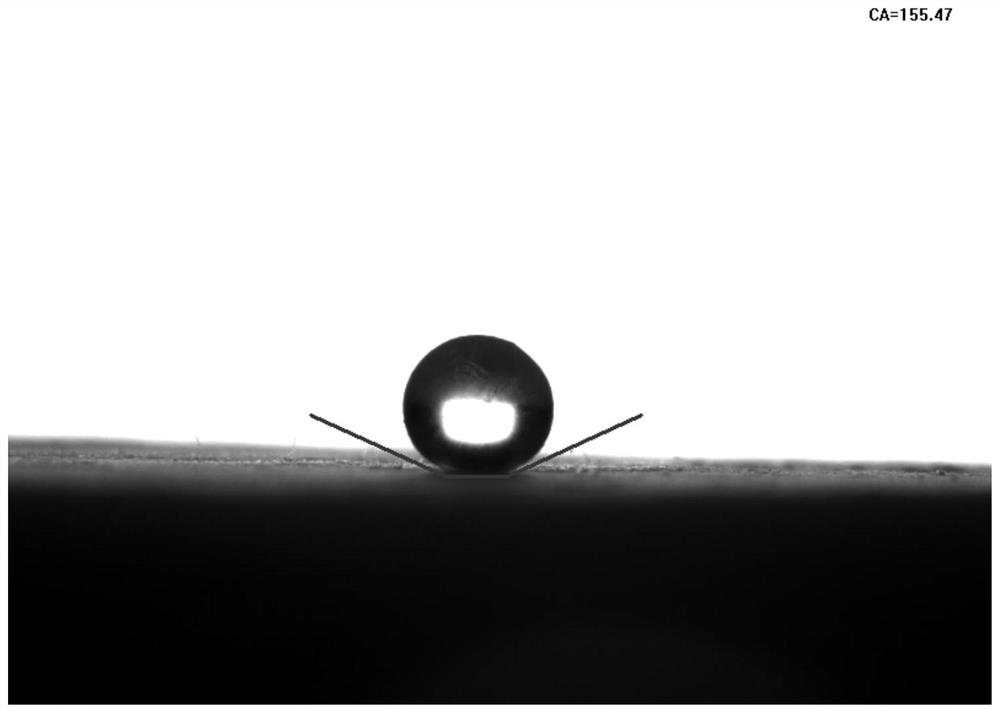

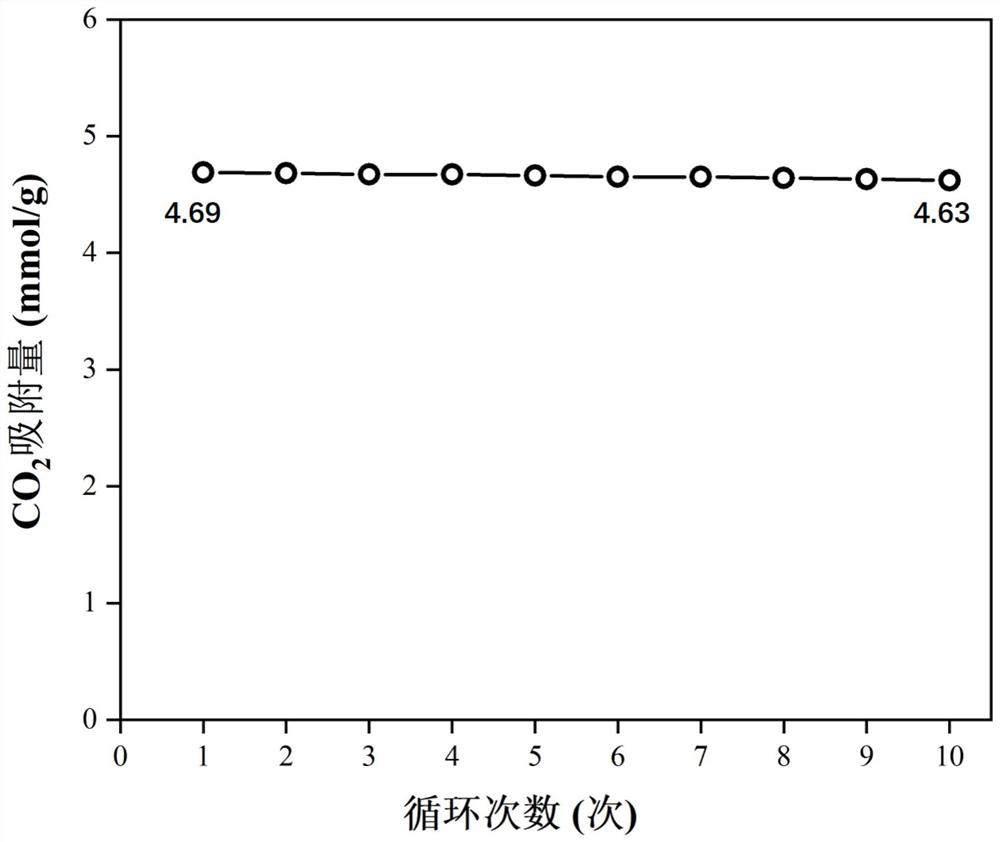

[0028] Under the condition of high shear stirring at a speed of 20000rpm, 20mol of acetic acid aqueous solution with a concentration of 1mM, 0.016mol of sodium dodecylbenzenesulfonate and 0.2mol of pyridine were mixed uniformly, and 1mol of methyltrimethoxysilane was mixed with The above mixed solution was dropped at a rate of 10 mL / min, continued stirring to obtain a homogeneous emulsion, and was allowed to stand for defoaming to obtain a clear and transparent silica sol. The sol was preheated at 90 °C for 5 min, and dropped into paraffin at 65 °C using an automatic ball dropper with an inner diameter of 3 mm, and allowed to stand for 5 min for gelation reaction to obtain spherical silica wet gel. The wet gel was washed three times with deionized water at 70 °C for 6 h each time, and then replaced with methanol at 50 °C for three times for 10 h each time to obtain spherical siloxane gel. Mix 100 ml of ethylenediamine and 100 ml of ethanol to obtain a modified liquid. At 60 °...

example 2

[0033] Under the condition of high-speed shear stirring at a speed of 18000rpm, 10mol of oxalic acid aqueous solution with a concentration of 5mM, 0.016mol of cetyltrimethylammonium bromide and 0.1mol of urea were mixed uniformly, and 1mol of methyltriethoxy Silane was added dropwise to the above mixed solution at a rate of 6 mL / min, continued stirring to obtain a homogeneous emulsion, which was allowed to stand for defoaming to obtain a clear and transparent silica sol. The sol was preheated at 80 °C for 10 min, and dropped into n-hexane at 20 °C using an automatic ball dropper with an inner diameter of 1 mm, and allowed to stand for 10 min for gelation reaction to obtain spherical silica wet gel. The wet gel was washed 5 times with deionized water at 20 °C for 12 h each time, and then replaced with ethanol at 20 °C for 5 times for 12 h each time to obtain spherical siloxane gel. 100 ml of hexamethylenediamine and 200 ml of acetonitrile were mixed to obtain a modified liquid....

example 3

[0035] Under the condition of high-speed shear stirring at a speed of 15000rpm, 30mol of 0.1mM aqueous carbonate solution, 0.032mol of cetyltrimethylammonium chloride and 0.8mol of ammonium bicarbonate were mixed uniformly, and 1mol of dimethyl ammonium chloride was mixed. Dimethoxysilane was dropped into the above mixed solution at a rate of 4.5 mL / min, continued stirring to obtain a homogeneous emulsion, which was allowed to stand for defoaming to obtain a clear and transparent silica sol. The sol was pre-heated at 70 °C for 15 min, and dropped into corn oil at 80 °C using an automatic ball dropper with an inner diameter of 5 mm, and allowed to stand for 3 min for gelation reaction to obtain spherical silica wet gel. The wet gel was washed three times with deionized water at 80 °C for 4 h each time, and then replaced with acetonitrile at 60 °C for four times for 9 h each time to obtain spherical siloxane gel. 100 ml of 3-aminopropyltriethoxysilane and 500 ml of isopropanol w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com