Preparation method of fuel cell metal pole plate ceramic phase low-temperature nucleation nano coating

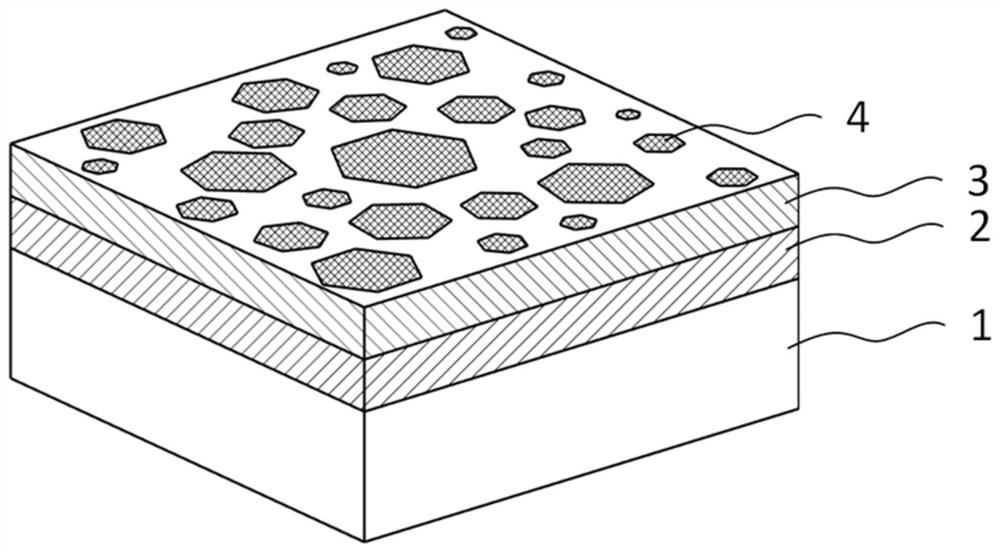

A metal plate, fuel cell technology, applied in the direction of fuel cells, fuel cell parts, circuits, etc., can solve the problem that the degree of crystallization of metal carbide coatings, the stability of service performance has a significant impact, and the reduction of coating internalization. Stress and other problems, to achieve the effect of improving corrosion resistance, electrical conductivity and stability, enhancing the nucleation and crystallization of ceramic nanocrystals, and promoting the nucleation and crystallization of ceramic phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Taking the stainless steel bipolar plate as the substrate, the titanium carbide nanocrystalline coating is prepared on its surface. The process is as follows:

[0028] 1) Plate pretreatment: use deionized water, acetone, and anhydrous ethanol successively to ultrasonically clean the surface of the stainless steel bipolar plate and dry it;

[0029] 2) Suspend the pretreated stainless steel bipolar plate on the planetary turret in the unbalanced magnetron sputtering ion plating furnace cavity, keep the rotating speed of the turret at 4r / min, and evacuate to the background vacuum of 3×10 -5 After Torr, fill with argon and keep working pressure at 4×10 -4 Torr, a bias voltage of -700V is applied to the stainless steel substrate, so that ions continue to bombard the surface of the substrate and remove the passivation film on the surface, and the cleaning time is 30min;

[0030] 3) Pour 20sccm argon gas as sputtering gas, keep the substrate bias at -100V, turn on the titaniu...

Embodiment 2

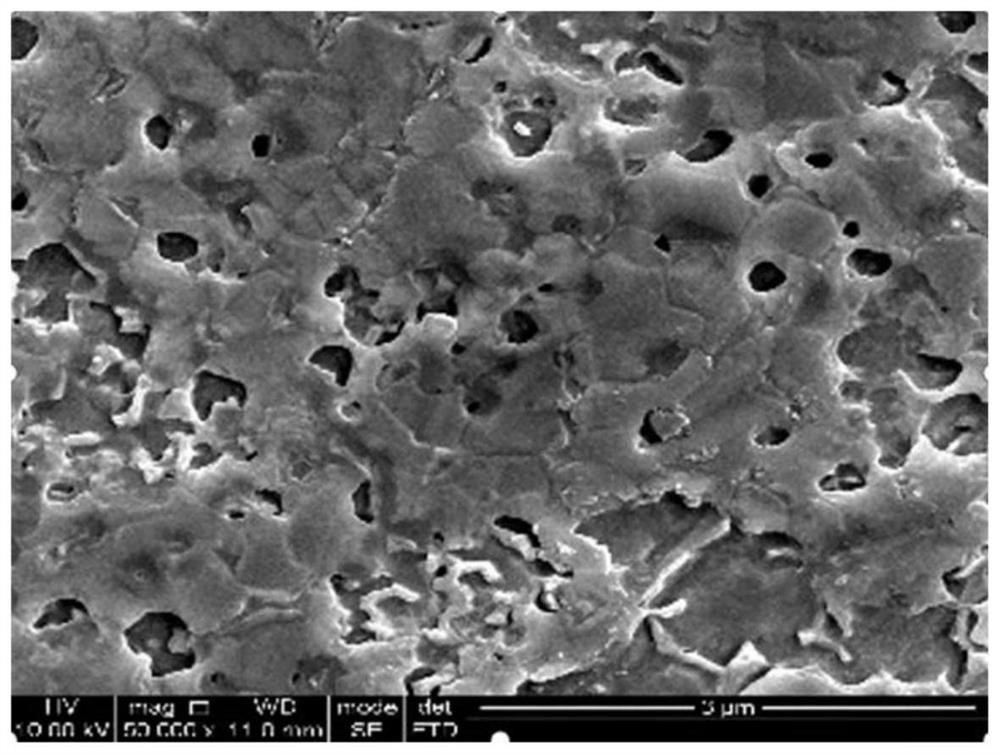

[0037] The stainless steel bipolar plate is used as the substrate, and the niobium carbide coating is prepared on its surface, and the corrosion resistance and conductivity of the niobium carbide nanocrystalline coating are improved by wet etching. The process is as follows:

[0038] 1) Plate pretreatment: use deionized water, acetone, and anhydrous ethanol successively to ultrasonically clean the surface of the stainless steel bipolar plate and dry it;

[0039] 2) Suspend the pretreated stainless steel bipolar plate on the planetary turret in the unbalanced magnetron sputtering ion plating furnace cavity, keep the rotating speed of the turret at 4r / min, and evacuate to the background vacuum of 3×10 -5 After Torr, fill with argon and keep working pressure at 4×10 -4 Torr, the stainless steel substrate applies a bias voltage of -700V, so that the ions continue to bombard the surface of the substrate and remove the passivation film on the surface, and the cleaning time is 30min;...

Embodiment 3

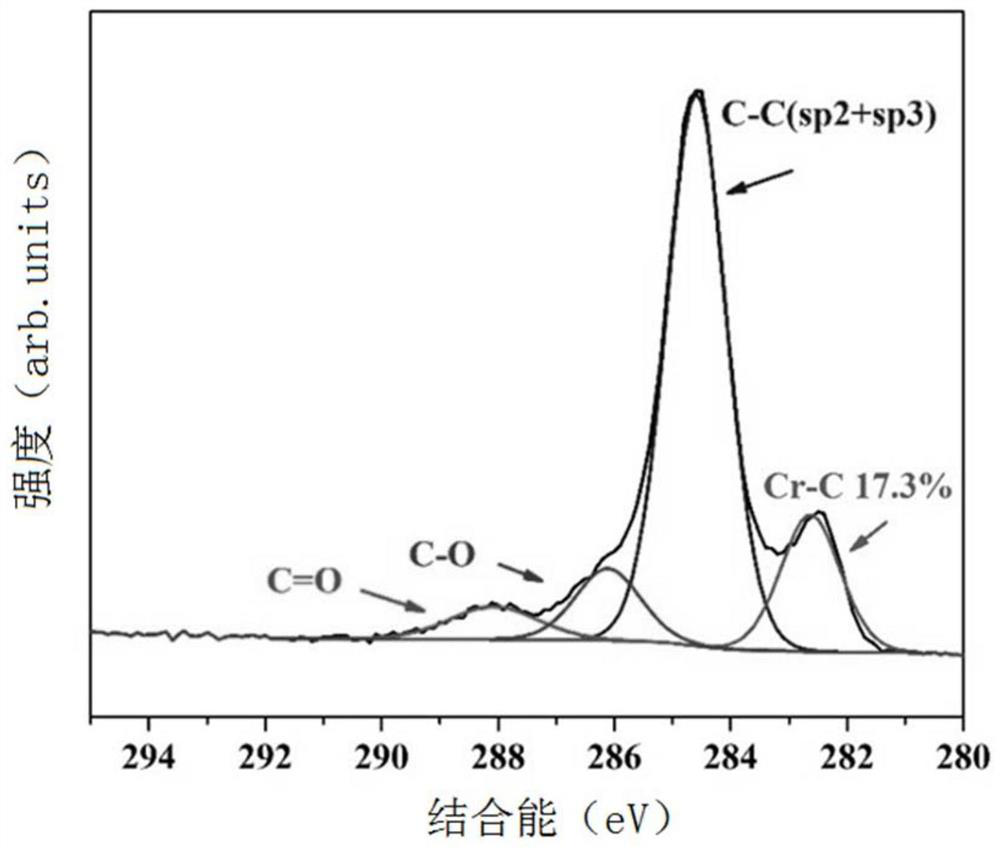

[0045] The stainless steel bipolar plate is used as the substrate, and the chromium carbide coating is prepared on its surface, and the corrosion resistance and conductivity of the chromium carbide nanocrystalline coating are improved by wet etching. The process is as follows:

[0046] 1) Plate pretreatment: use deionized water, acetone, and anhydrous ethanol successively to ultrasonically clean the surface of the stainless steel bipolar plate and dry it;

[0047] 2) Suspend the pretreated stainless steel bipolar plate on the planetary turret in the unbalanced magnetron sputtering ion plating furnace cavity, keep the rotating speed of the turret at 4r / min, and evacuate to the background vacuum of 3×10 -5 After Torr, fill with argon and keep working pressure at 4×10 -4 Torr, the stainless steel substrate applies a bias voltage of -700V, so that the ions continue to bombard the surface of the substrate and remove the passivation film on the surface, and the cleaning time is 30mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com