Biodegradable magnetic nanoparticle, preparation method and application thereof

A technology of magnetic nanoparticles and biodegradation, which is applied in the field of nanomaterials of biotechnology, can solve the problems that magnetic nanoparticles cannot be biodegraded, and the adverse effects of cells, etc. It is easy to achieve trace detection and trace reaction, and the process is simple and speeds up. The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

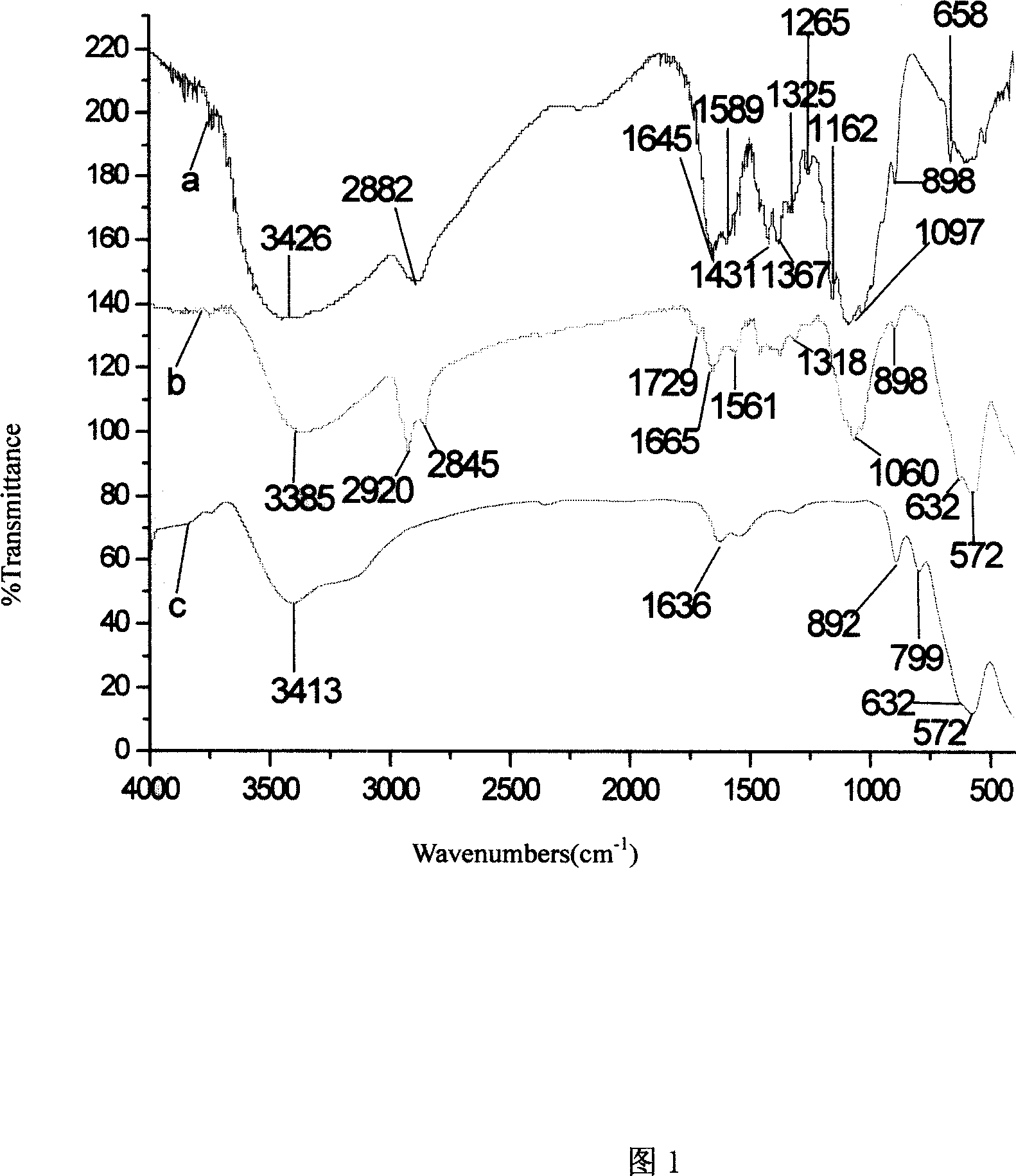

[0052] The present invention adopts the method for inverse microemulsion, prepares magnetic chitosan nano-composite material, obtains the spherical nano-particle that particle size is about 40nm, concrete implementation method is as follows:

[0053] 1. Weigh 1-100mg of chitosan powder with a deacetylation degree of 80-95% and add it to 1-10mL 1% acetic acid solution, ultrasonically dissolve, add 5-25mg γ-Fe 2 o 3 Particles, uniformly dispersed, as the water phase;

[0054] 2. Take 5-50g of paraffin, add 5-10g of Span, 5-10g of Tween, and stir to obtain a uniform system as the oil phase;

[0055] 3. Add the water phase to the oil phase and stir evenly to obtain a transparent brown water-in-oil type (W / O type) inverse microemulsion;

[0056] 4. Add 1-3mL glutaraldehyde to the system as a cross-linking agent, keep the constant temperature water bath at 25-40°C, and mechanically stir. After the reaction, wash the particles with isopropanol to remove the particle surfactant and ...

Embodiment 2

[0060] Magnetic liposomes were prepared by the classic reverse-phase evaporation method. Dissolve an appropriate amount of soybean lecithin and cholesterol (molar ratio 2:1) in a mixed solvent of methanol-chloroform (1:1), and rotate to evaporate to form a uniform transparent lipid film. After dissolving the lipid film with an appropriate amount of ether, add an appropriate amount of γ-Fe 2 o 3 Particle suspension, after ultrasonic emulsification, carry out the second rotary evaporation, and then carry out ultrasonic homogenization, and finally squeeze the liposome suspension through a 450nm microporous filter membrane to obtain magnetic liposomes, and pass nitrogen protection during the operation .

[0061] Liposomes have a cell-like structure, and when they enter the body, they are mainly swallowed by the reticuloendothelial system to activate the body's autoimmune function and change the distribution of the encapsulated drug in the body. Liposomes are stable in lymph, ent...

Embodiment 3

[0063] Using the same inverse microemulsion method as in Example 1, a magnetic blood albumin nanocomposite material was prepared, and spherical nanoparticles with a particle size of about 50 nm were obtained. When albumin is negatively charged, it can be absorbed by lymph under the mediation of receptors, and the absorption rate is related to the negative charge. Negatively charged albumin can reach the embryonic center of the lymph node and around the follicle, not only has the inhibitory effect on HIV replication itself, but also can be used as a carrier of anti-AIDS drugs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com