Methods of pulp fiber treatment

a technology of pulp fiber and pulp fiber, applied in the field of pulp fiber treatment, can solve the problems of reducing fiber yield and fiber strength, damage to cellulose fiber, and damage to cellulose fiber, and achieve the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

[0093]In some embodiments, the ROS-generating peracetate formulation of the present invention may be used for delignification and extraction of materials from pulp fibers for brightening and bleaching purposes. It may also be used for extracting lignin from cellulosic fibers for the recovery of lignin from the black liquor or spent oxidant liquor.

[0094]In some embodiments, the ROS generated by the parent peracetate formulation, particularly singlet oxygen, are the primary chemical species doing the delignification, brightening and bleaching of fibers. The direct reaction of peracetate with pulp is minimal, which contrasts with the use of peracetic acid in combination with hydrogen peroxide as the primary oxidants, which have much lower performance efficiency (and therefore, higher cost) for delignification, brightening and bleaching.

[0095]In some embodiments, the peracetate oxidant formulation of this invention produces singlet oxygen as the primary reactive oxidant species and ther...

example 1

Paper Mill Treatment

[0204]Sodium peracetate oxidant solution is used to control microbial growth in a printing paper mill in stock preparation and white water recovery. White water entrains fiber, chemicals and microbes from the paper web. Microbes have an opportunity to propagate during extended residence time in the white water chest. Pulp sources entering the machine chest, such as boke and recovered fiber, will carry elevated microbial loads after their recovery form the paper machine process. Microbial concentrations can exceed 106 to 107 cells / mL, a level that reduces paper quality, accelerates biofilm growth and microbially influenced corrosion, increases paper defects and odor problems. These problems increase the frequency of down time for maintenance and increase paper reject.

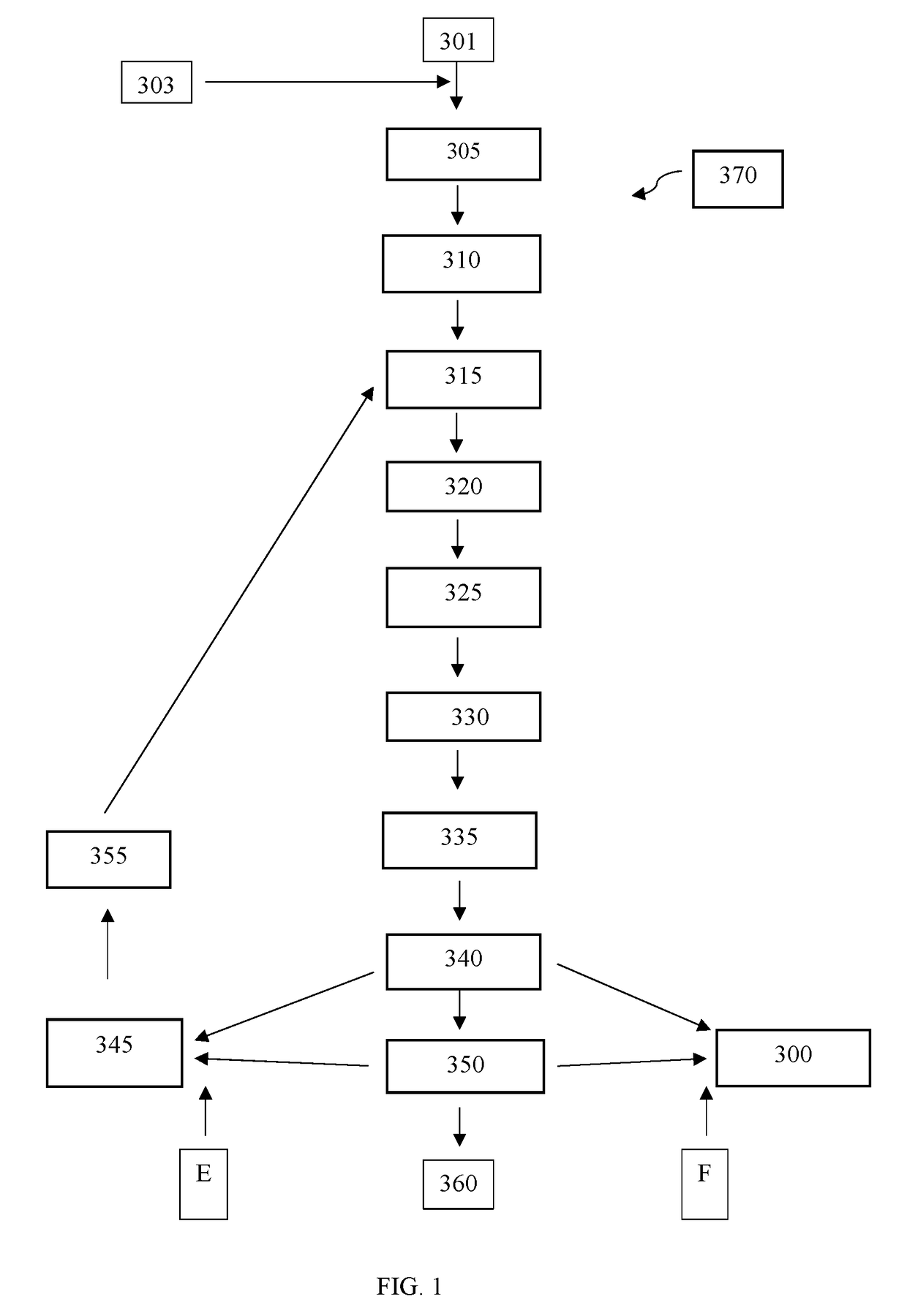

[0205]Several points exist where the peracetate oxidant solution can be added to the paper mill process. Ideally the peracetate solution is added to a fluid (water and pulp) where there is a contact t...

example 2

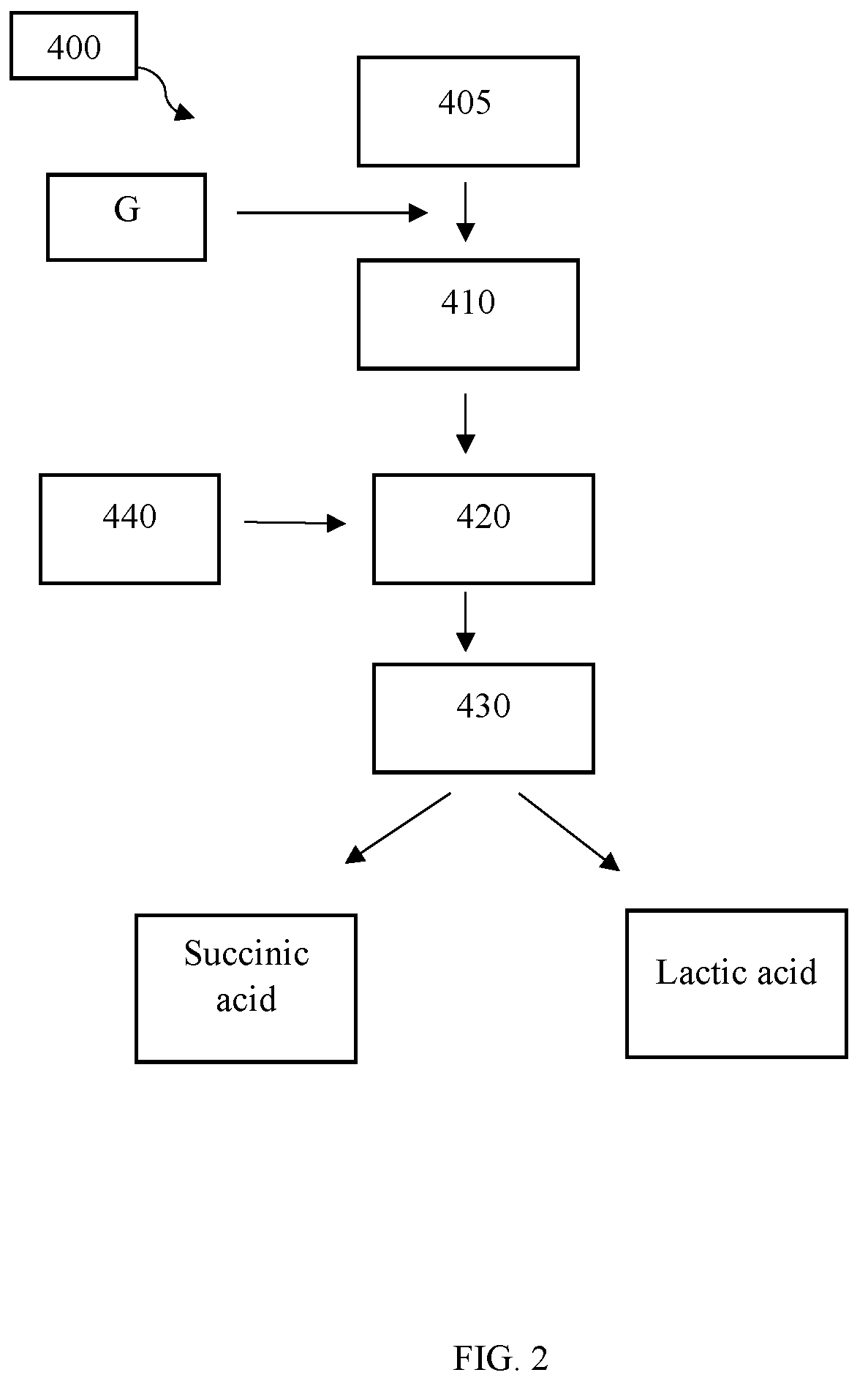

Disinfection of Feedstocks for Bio-Based Chemical Production

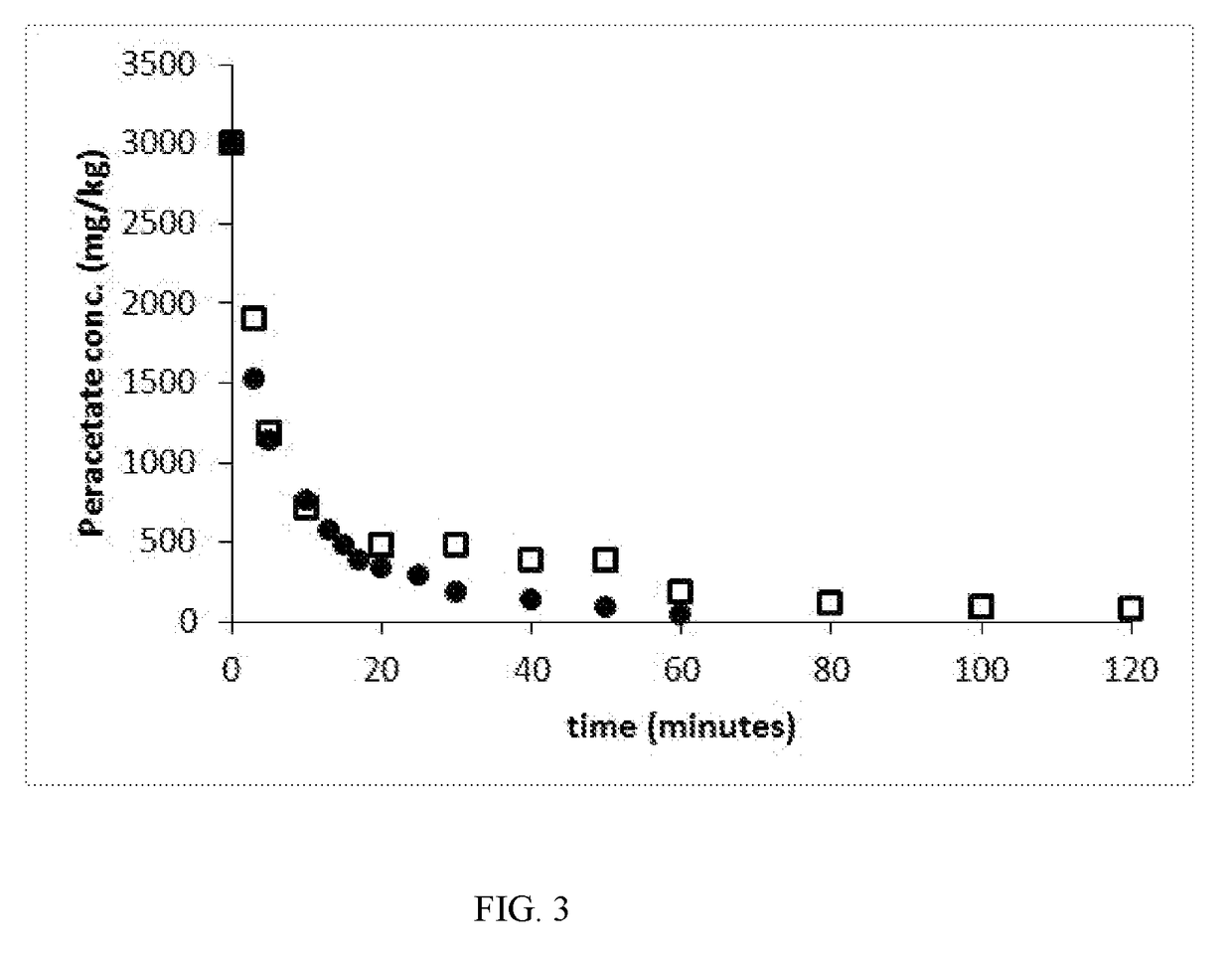

[0210]Sodium peracetate oxidant was used for microbial disinfection of polysaccharide feedstock materials used for producing succinic acid and lactic acid in a fermentation process. The peracetate is blended with the feedstock mixture in a blending tank to make an initial sodium peracetate concentration of up to about 130 ppm (by weight) and this mixture is heated to around its fermentation temperature of about 50-60° C. In this temperature range thermal activation of the peracetate oxidant occurs which increases antimicrobial activity and the rate of oxidant consumption such that the treatment is more rapidly finished and oxidant residual is eliminated before entering the fermentation stage containing the engineered microbes.

[0211]The thermally activated peracetate disinfection treatment is conducted for 30 to 90 minutes depending on the oxidant consumption rate, solids loading and particle size of the feedstock materials....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com