Patents

Literature

184 results about "Mandible maxilla" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

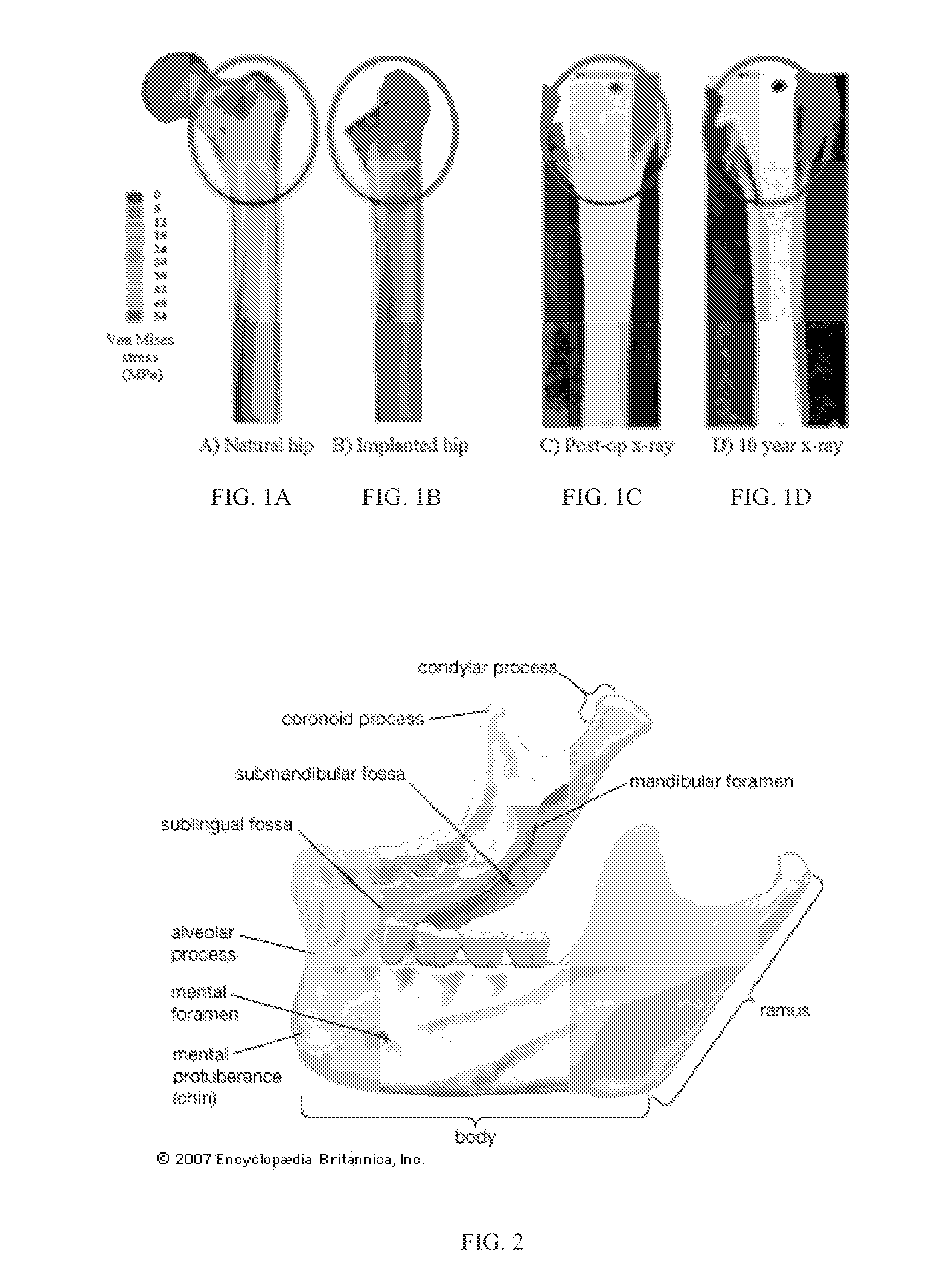

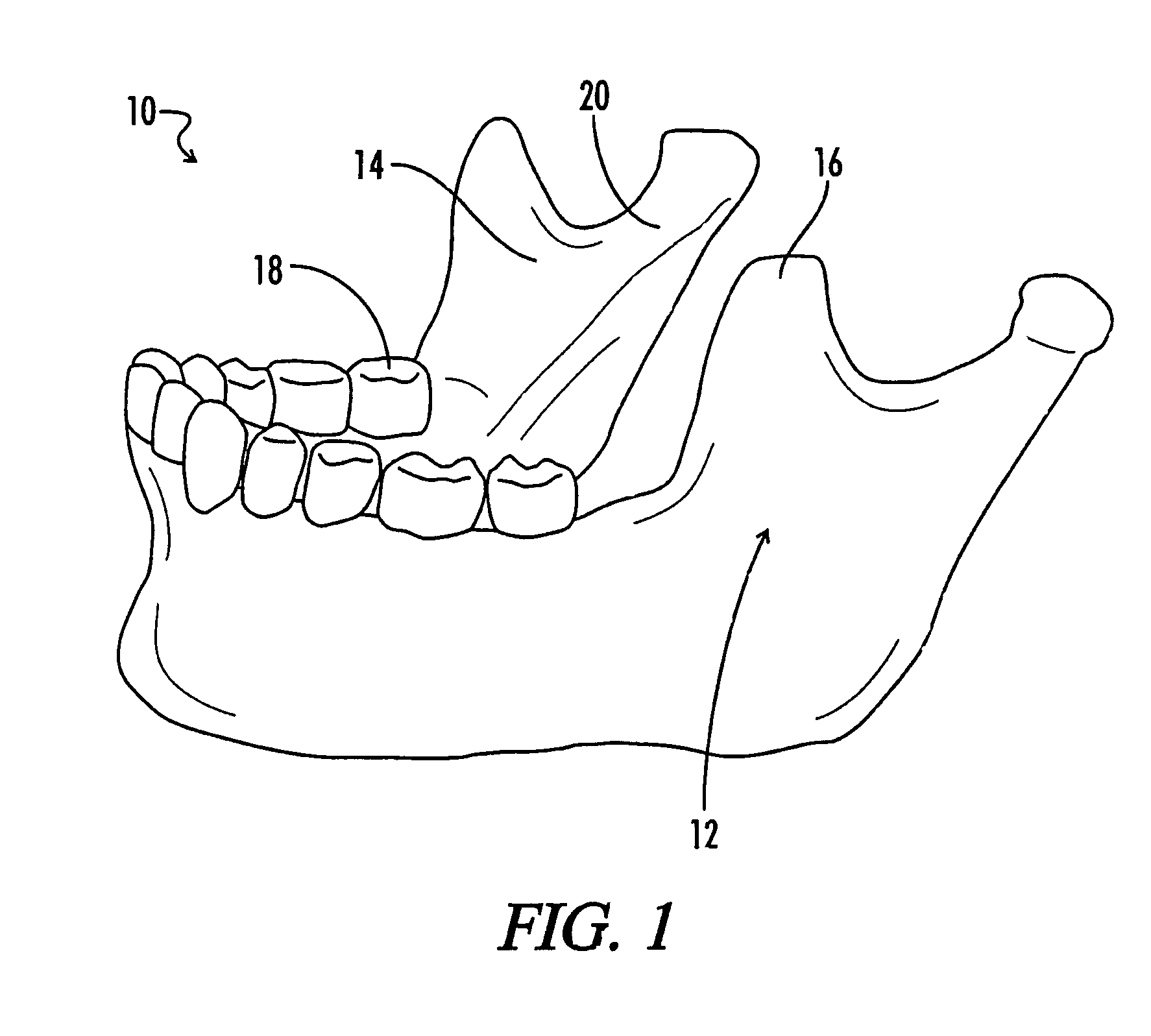

The mandible, lower jaw or jawbone is the largest, strongest and lowest bone in the human face. It forms the lower jaw and holds the lower teeth in place. The mandible sits beneath the maxilla. The mandible is the only movable bone of the skull not counting the ossicles of the middle ear.

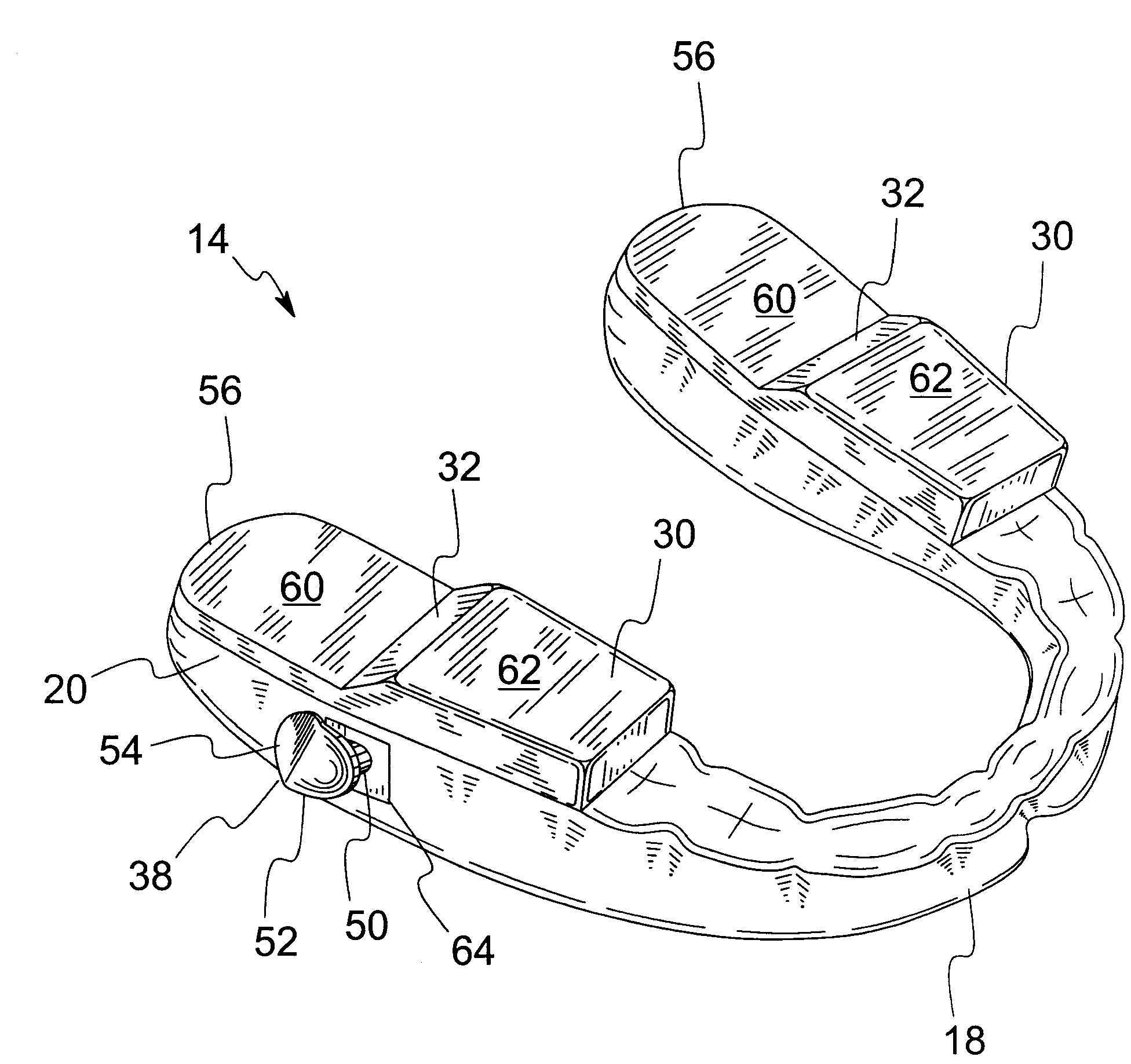

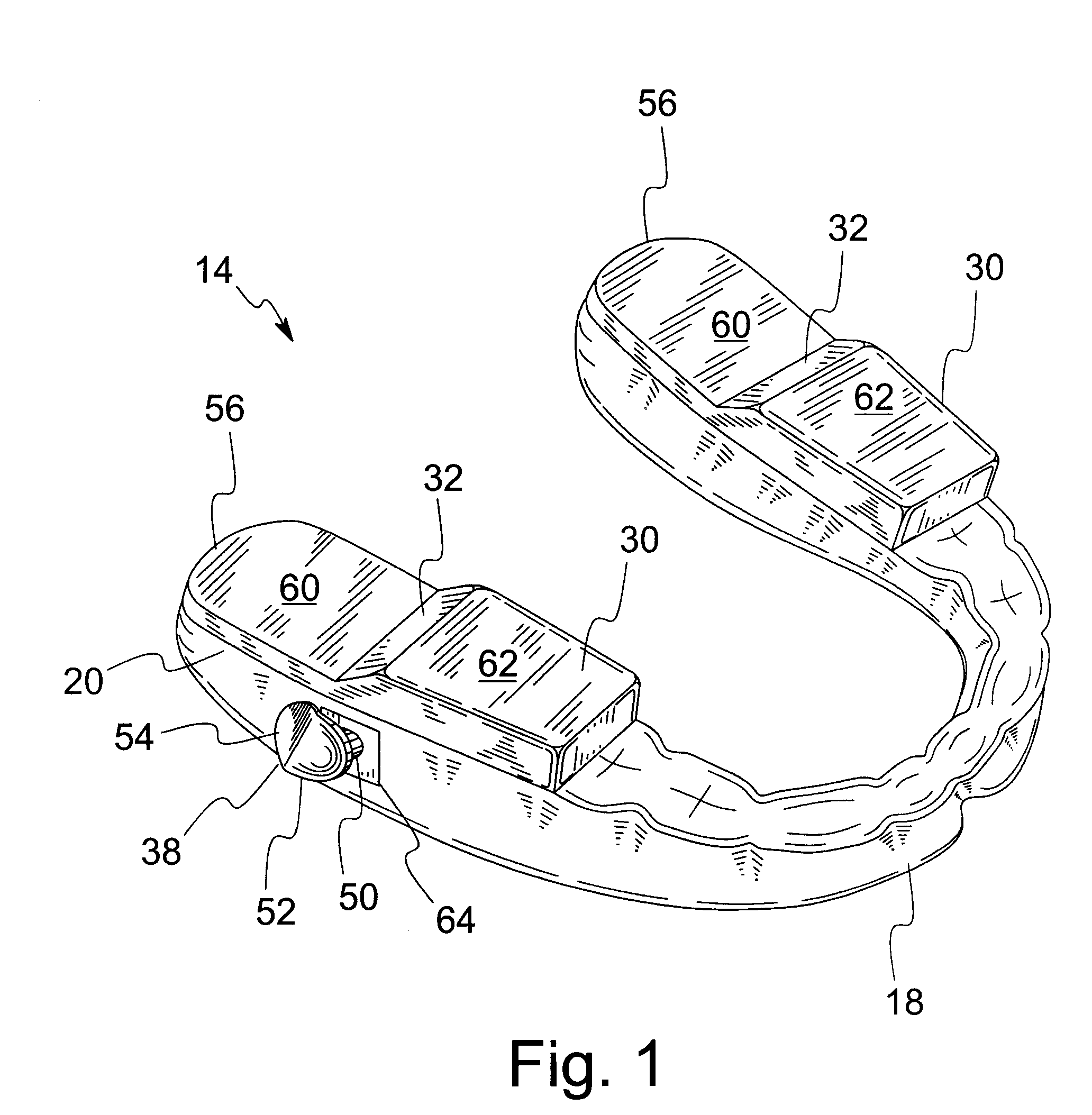

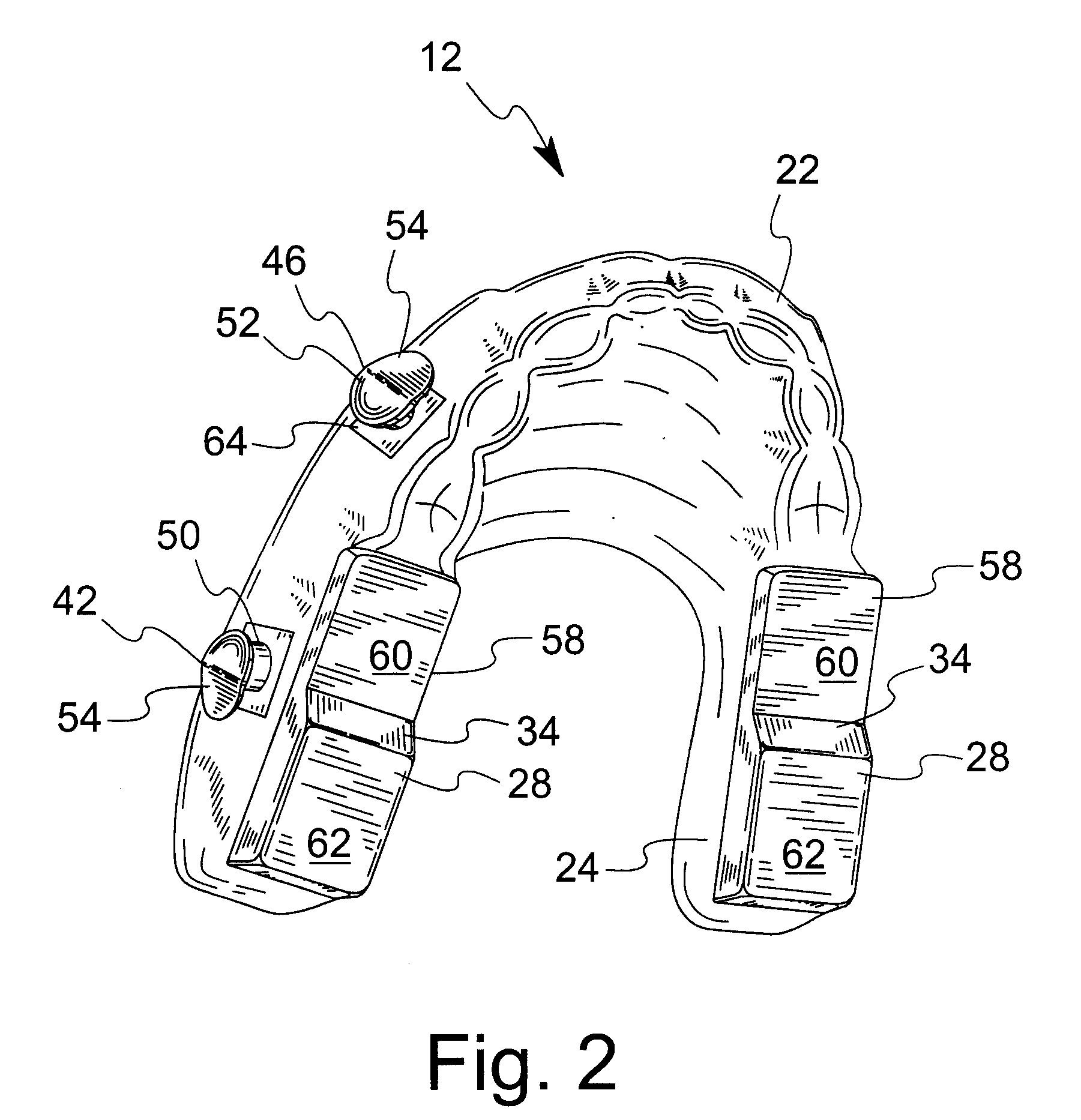

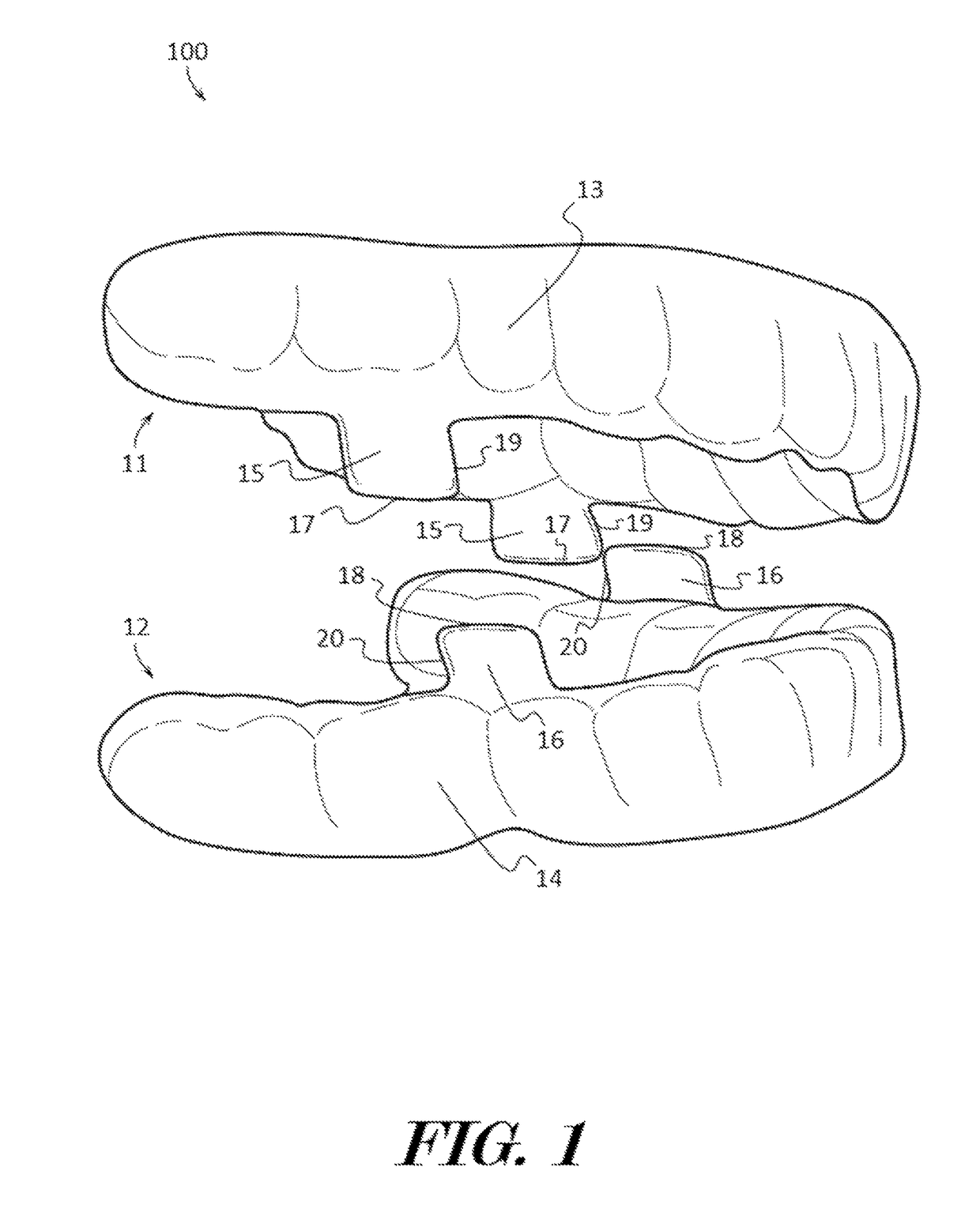

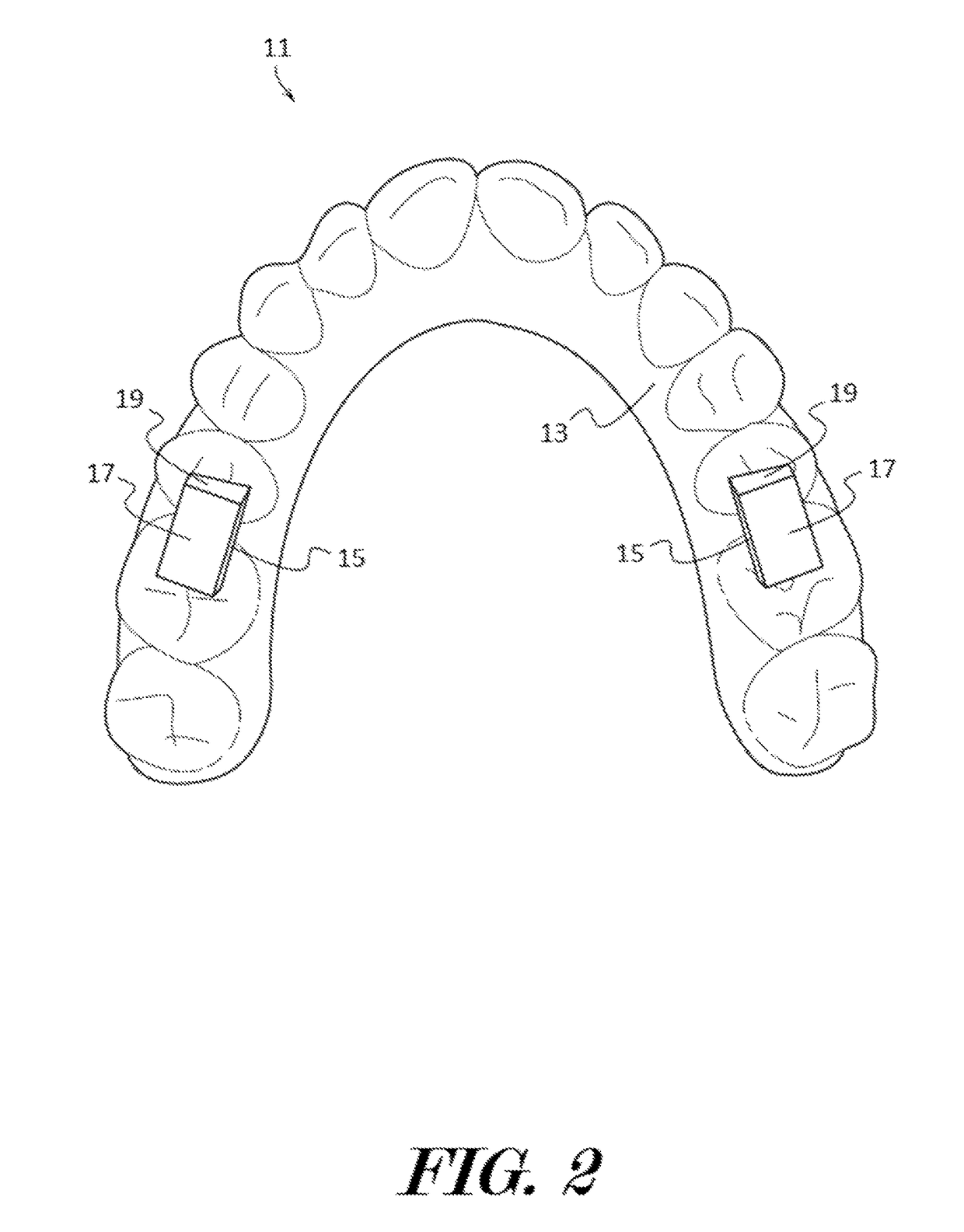

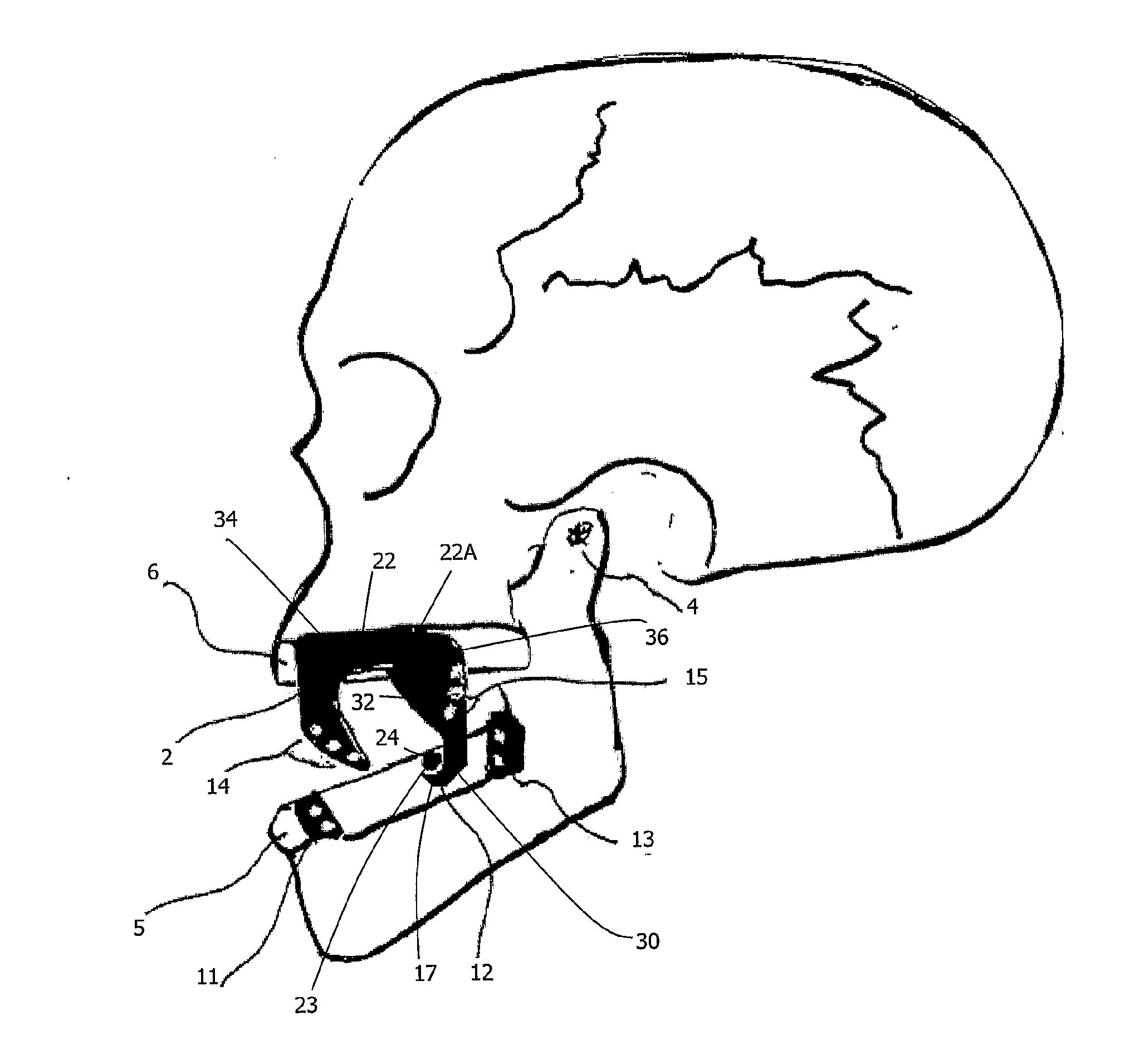

Anti-retrusion oral appliance

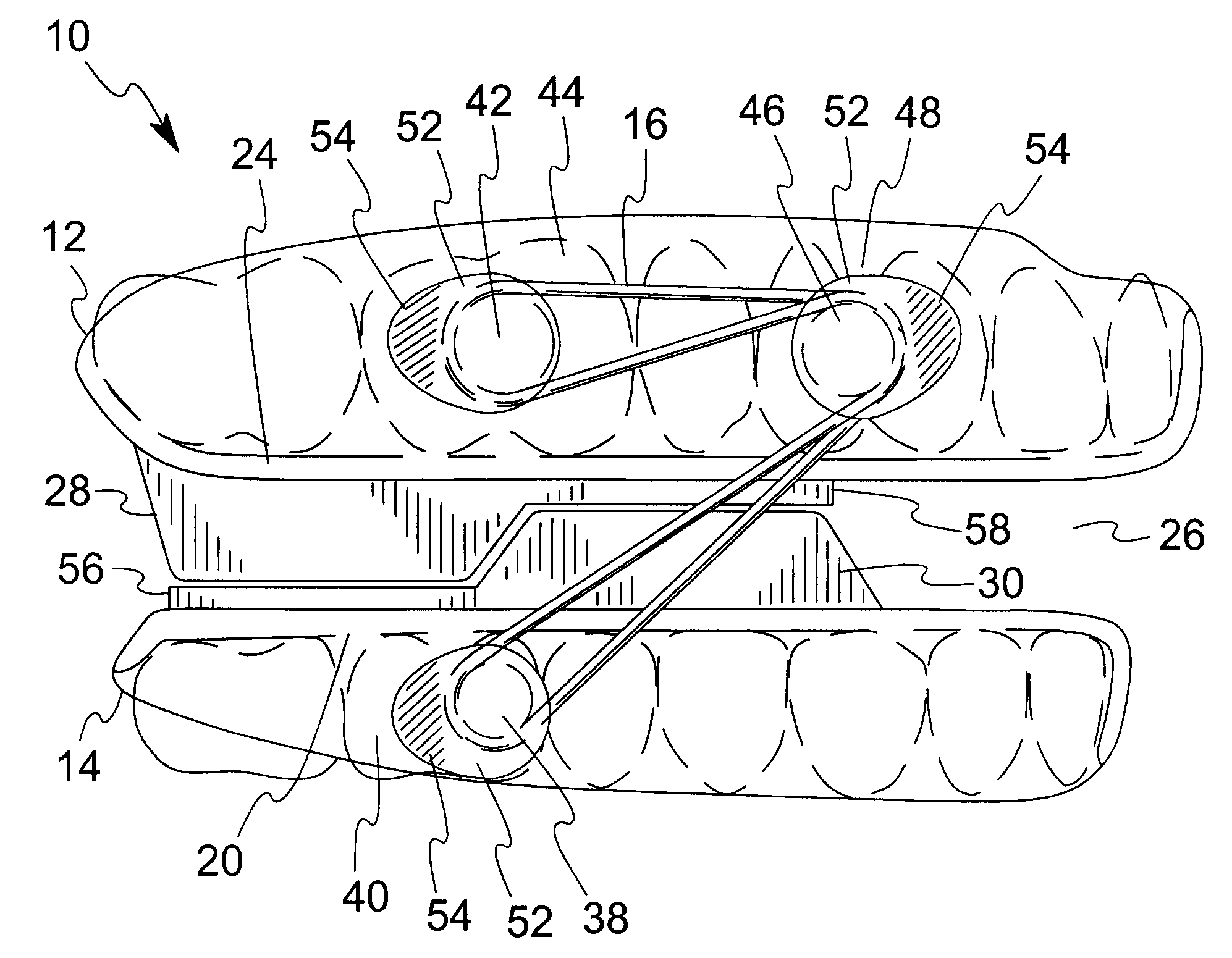

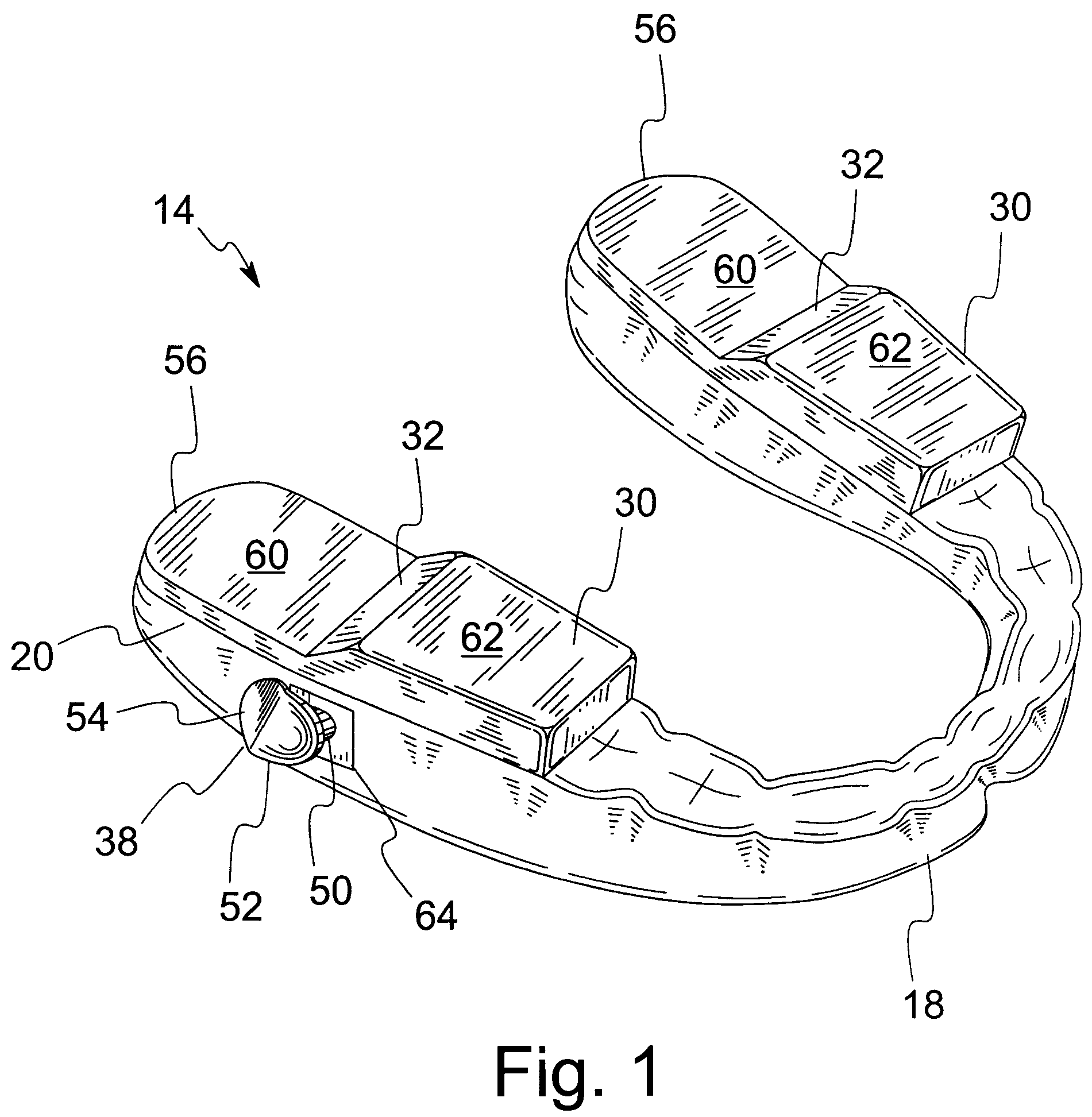

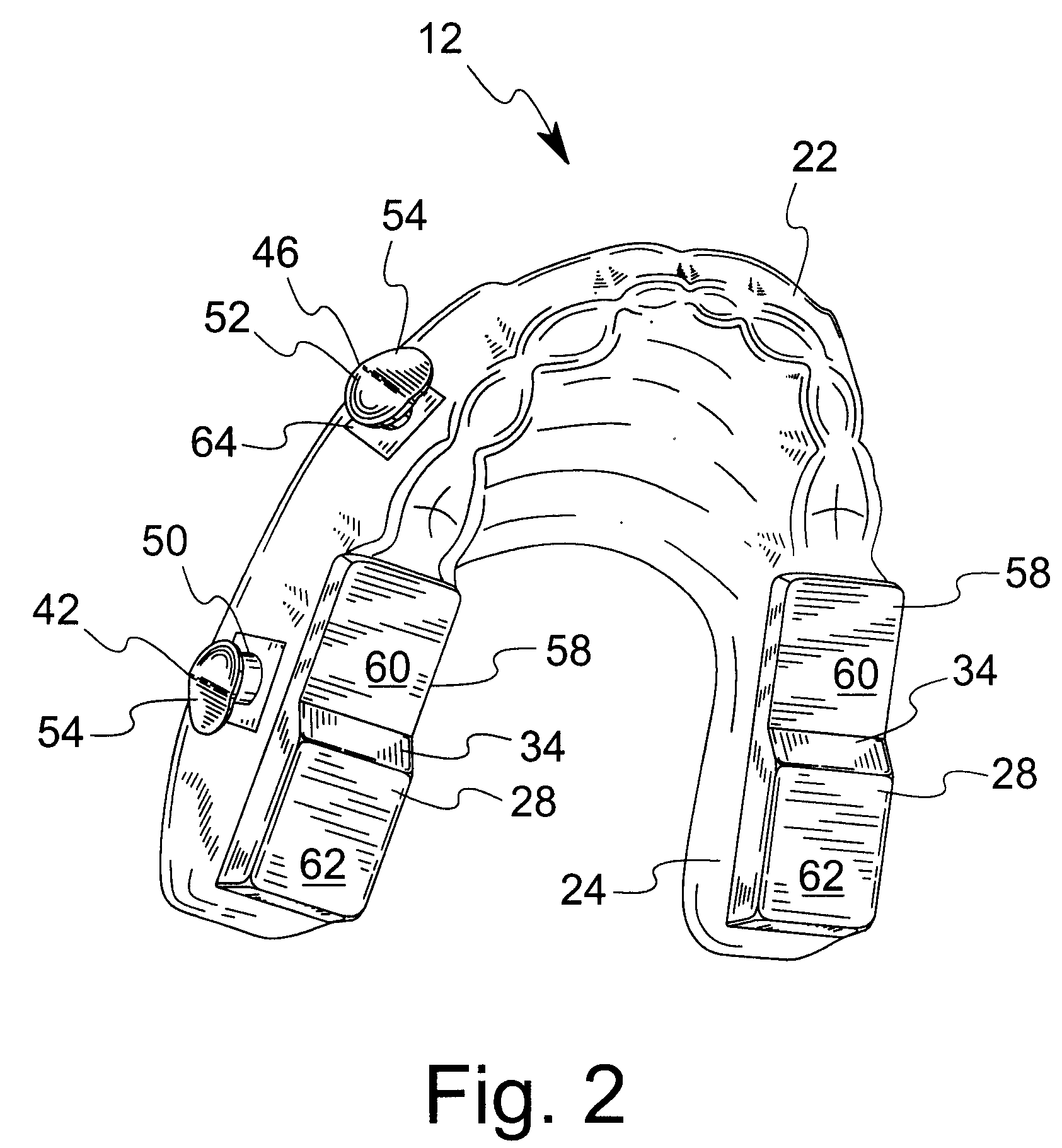

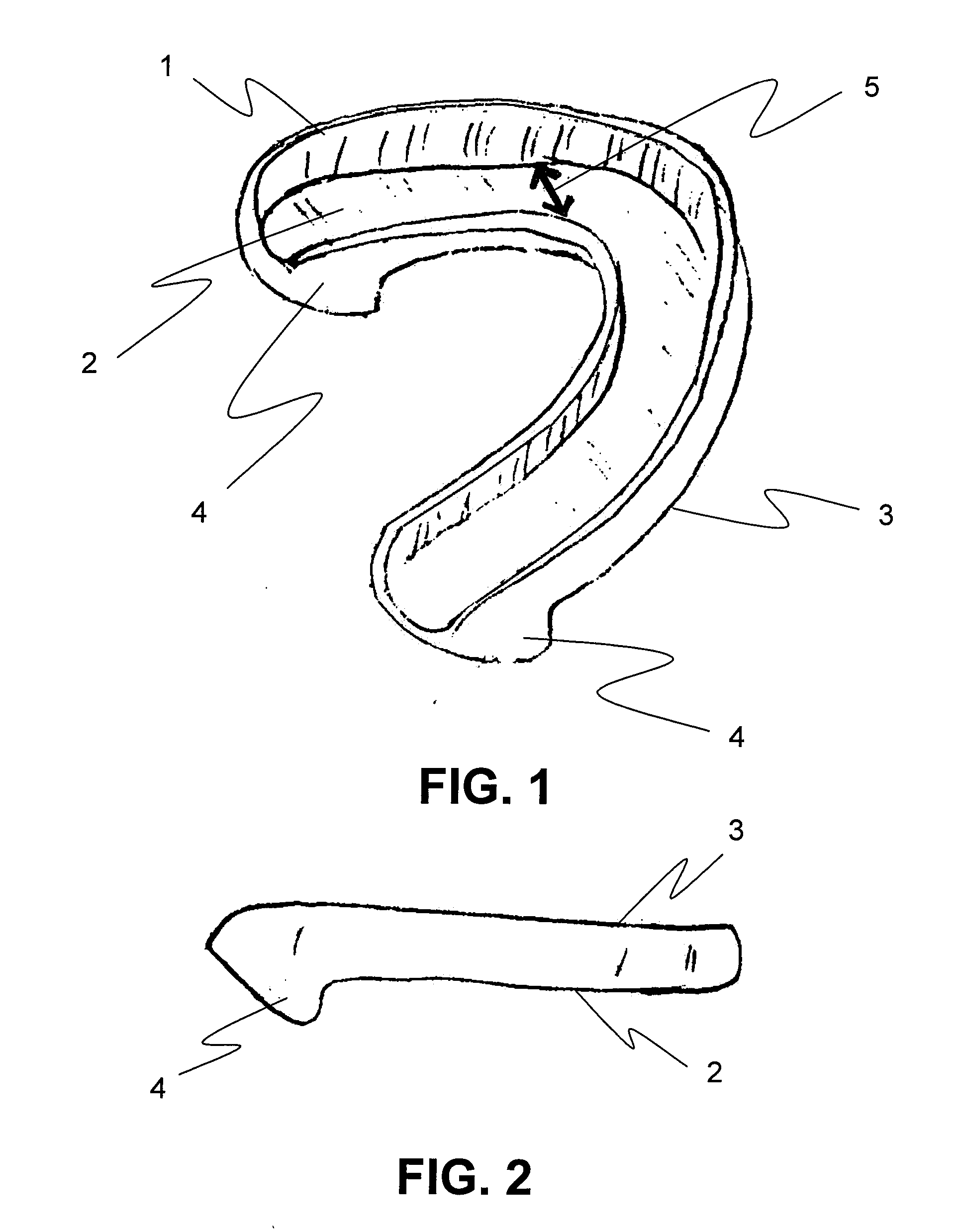

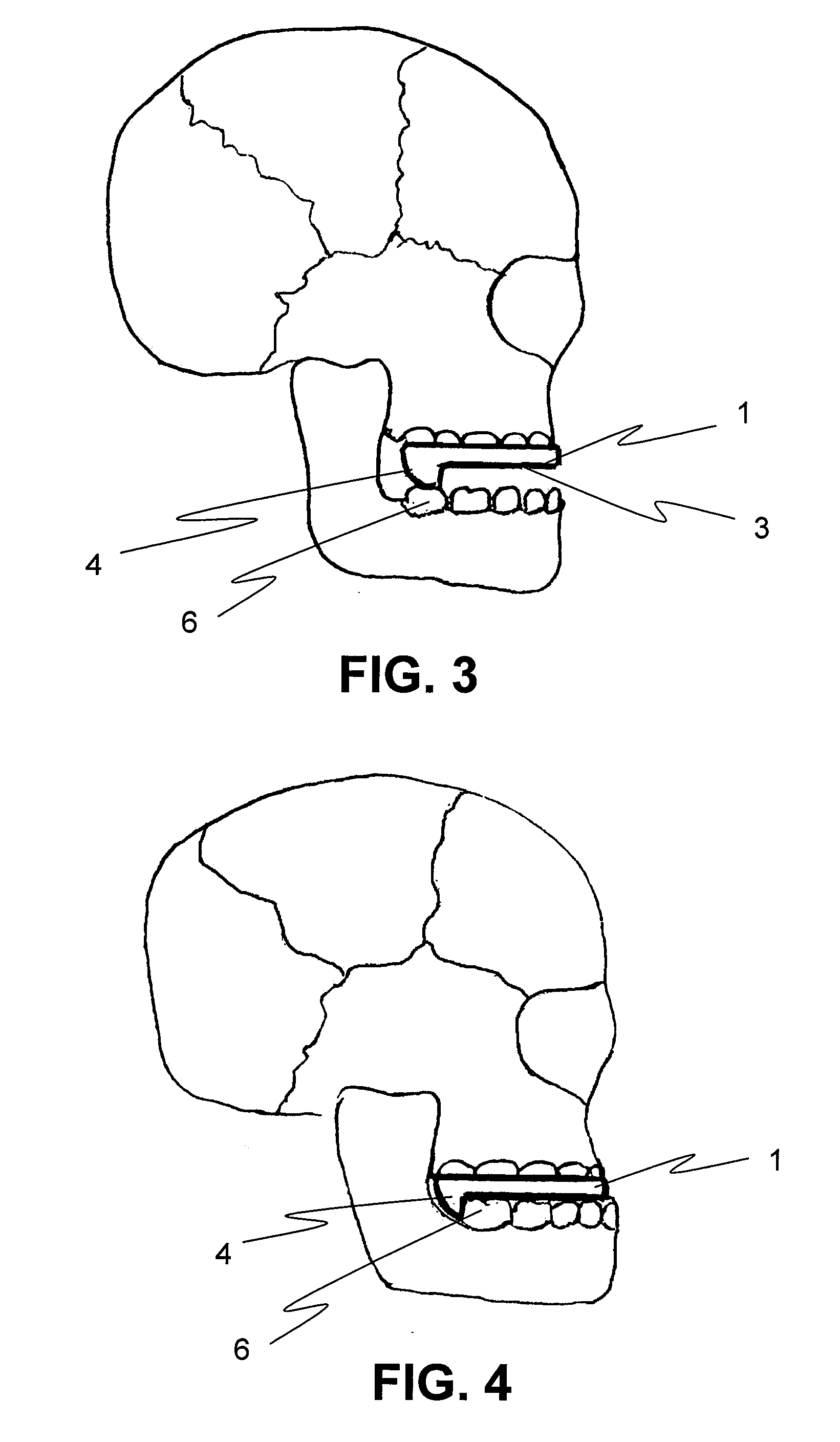

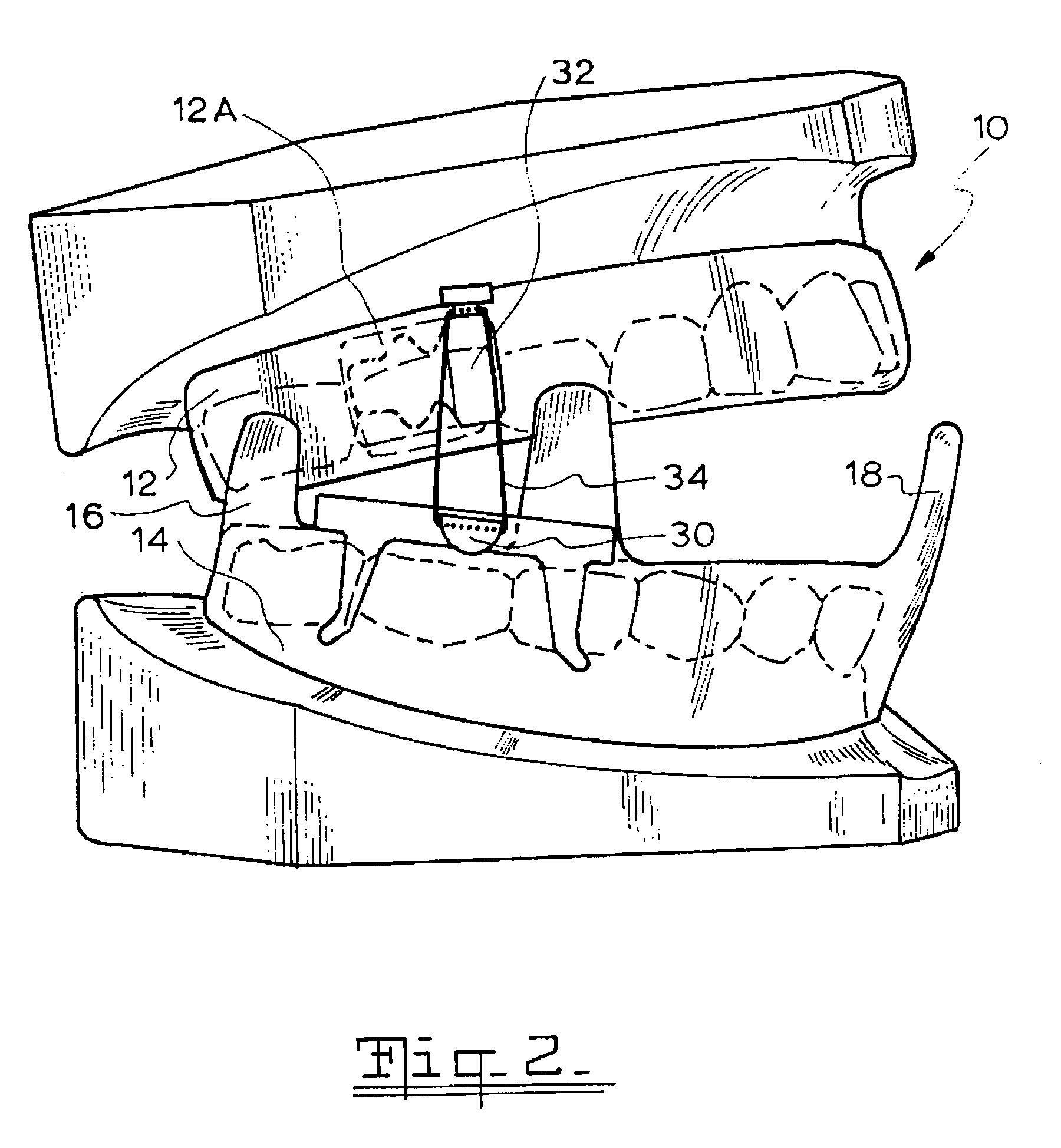

An oral appliance for treating sleep apnea and bruxism is formed of a maxillary tray and a mandibular tray. The maxillary tray carries a maxillary bite pad projecting downwardly toward an opposed mandibular occlusal surface. The mandibular tray carries a mandibular bite pad projecting upwardly toward an opposed maxillary occlusal surface. The maxillary bite pad is posterior to the mandibular bite pad such that upon sufficient relative posterior movement of the mandibular tray, the maxillary bite pad engages the mandibular bite pad and limits posterior movement of the mandibular tray. At least one surface, chosen from the anterior face of the maxillary bite pad and the posterior face of the mandibular bite pad, defines a guide plane disposed at an upward and forward slant. The maxillary bite pad and the mandibular bite pad are engageable at the guide plane for advancing the mandibular tray along the guide plane upon vertical closure between the trays. A smooth pad is disposed over the occlusal surface of at least one of the trays, guarding the occlusal surface from engagement with the opposed bite pad.

Owner:BAILEY DENNIS R

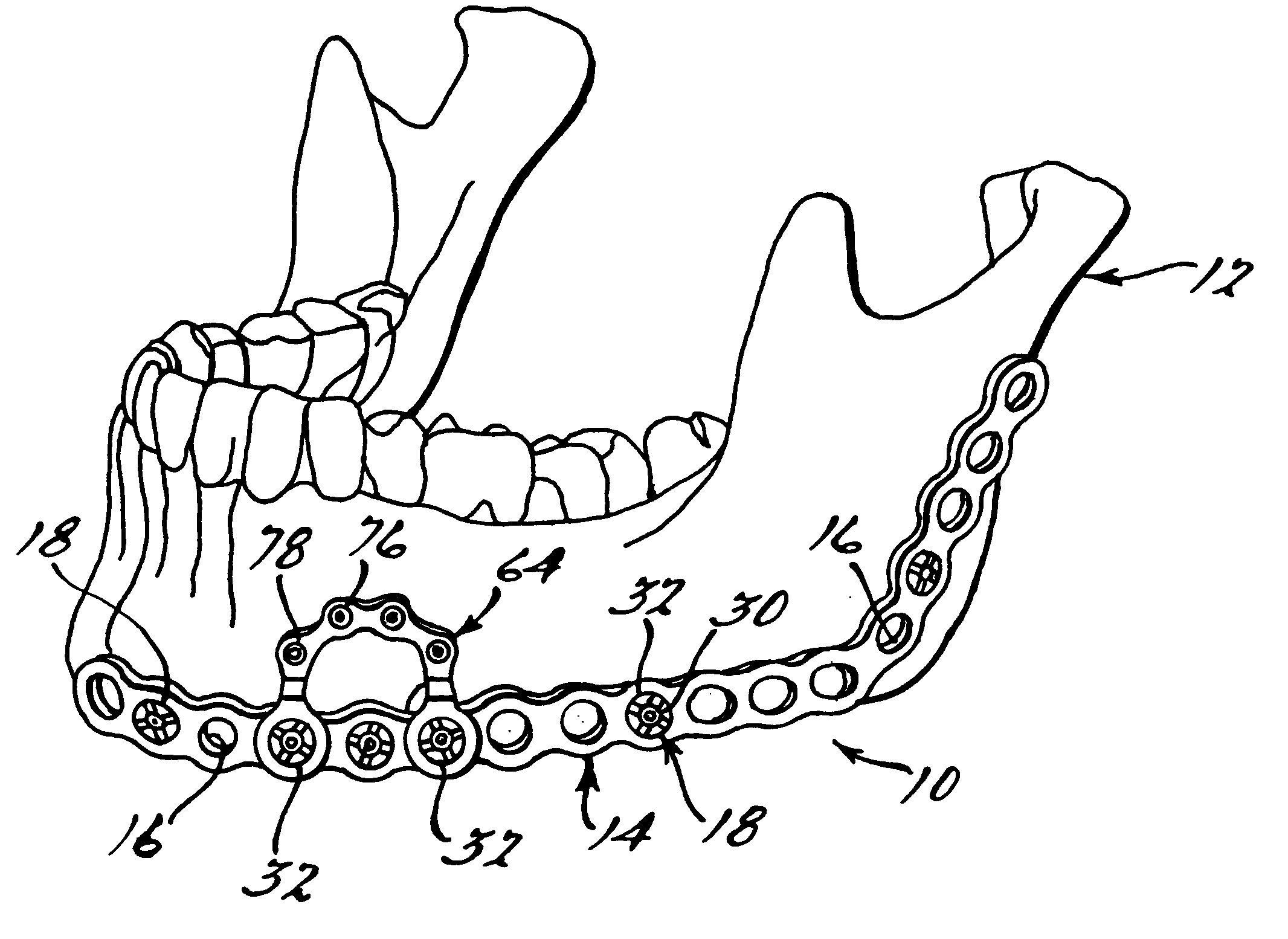

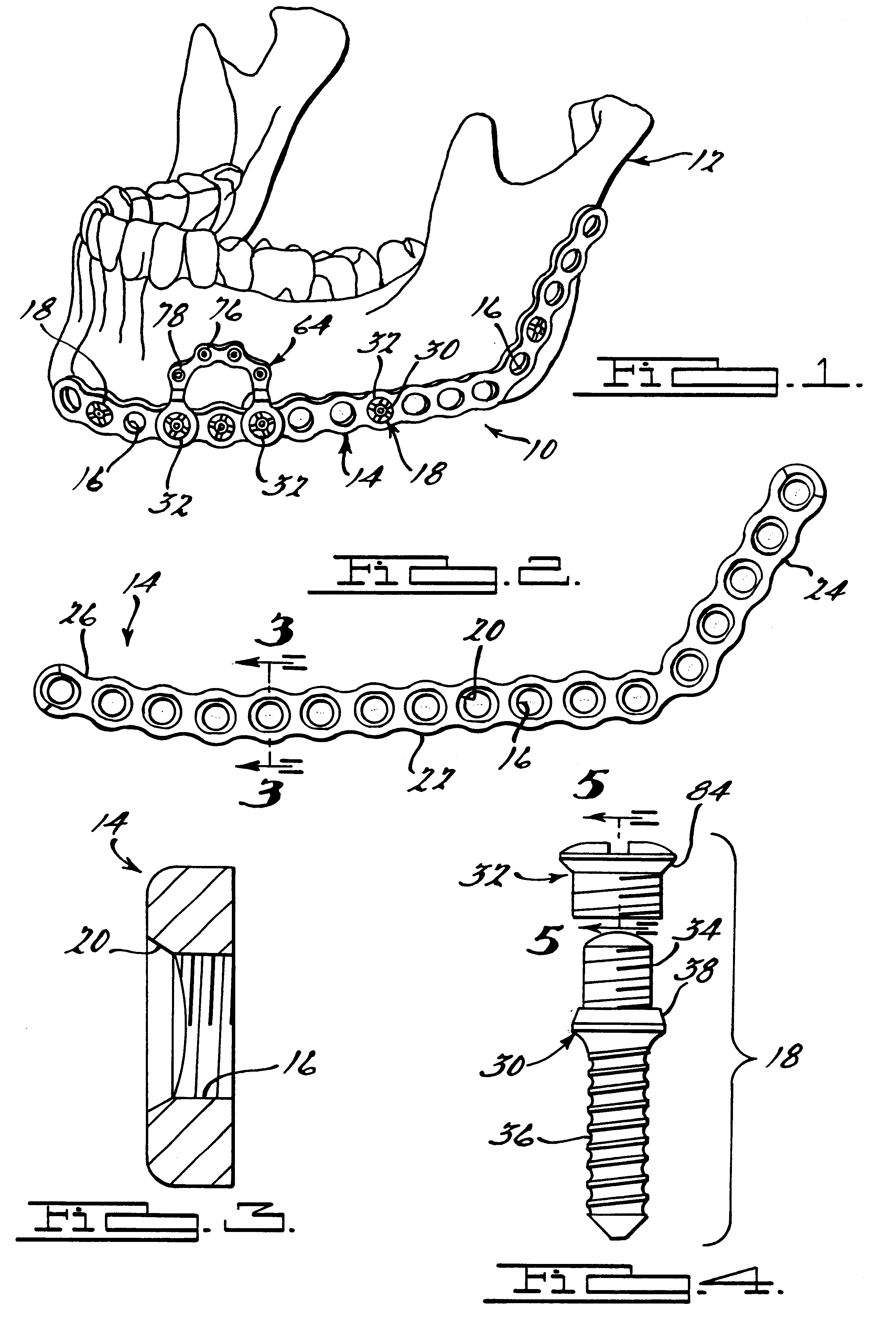

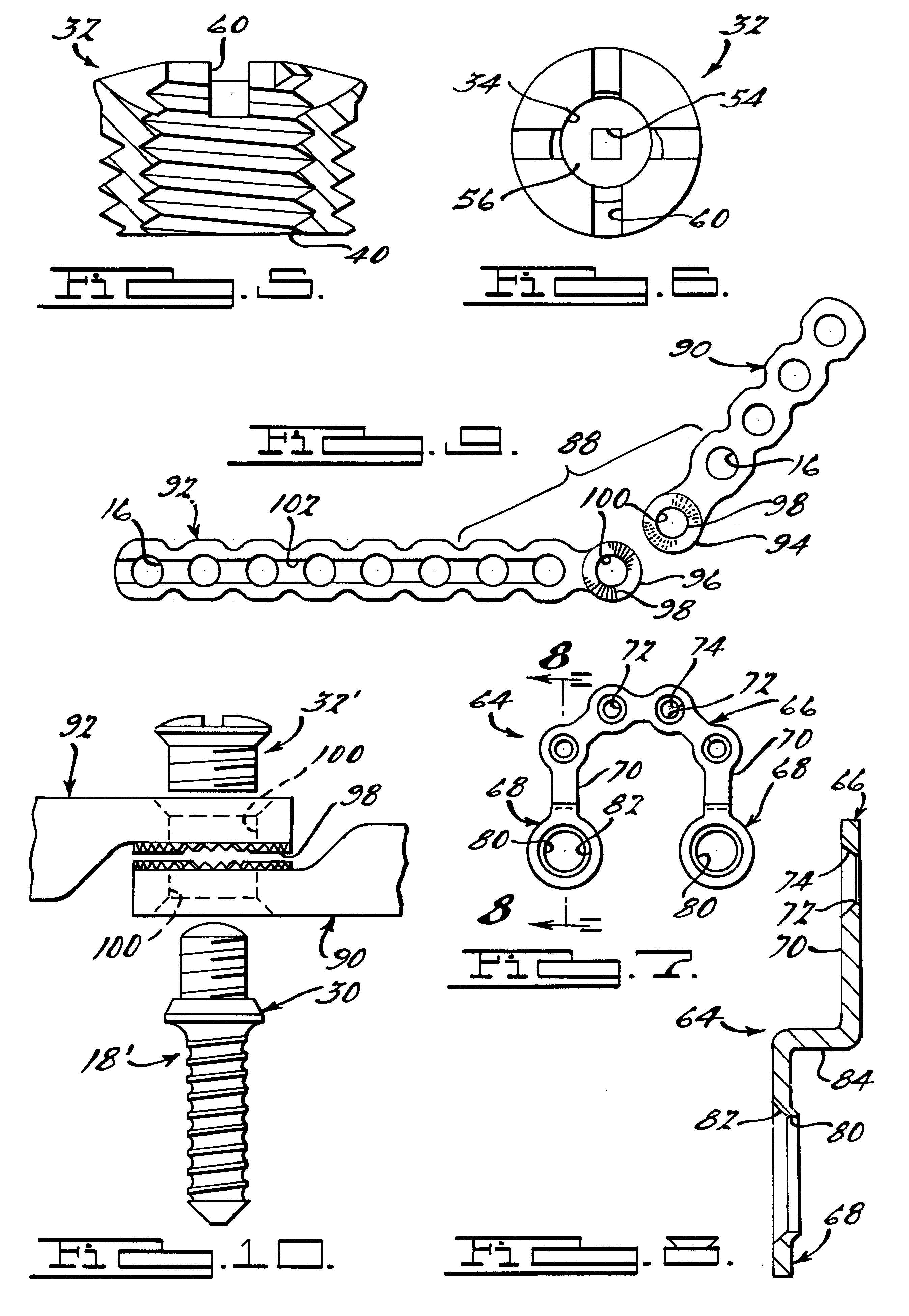

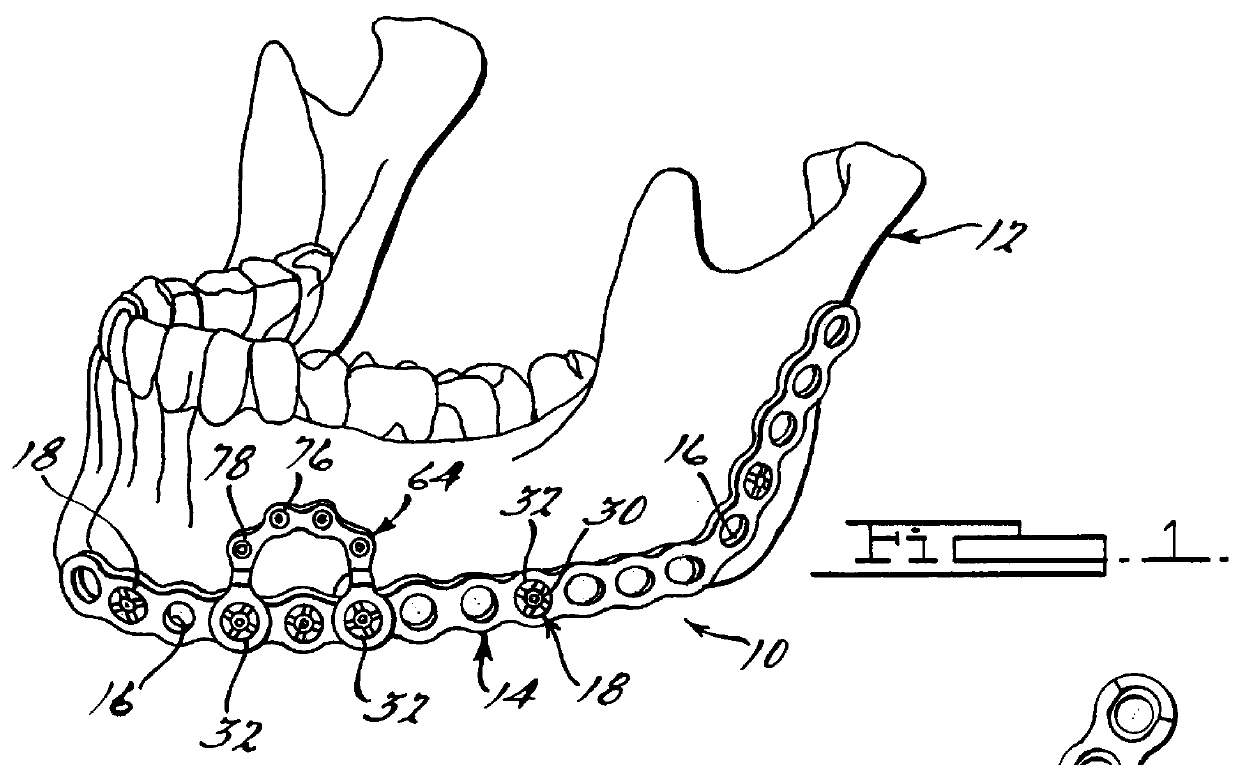

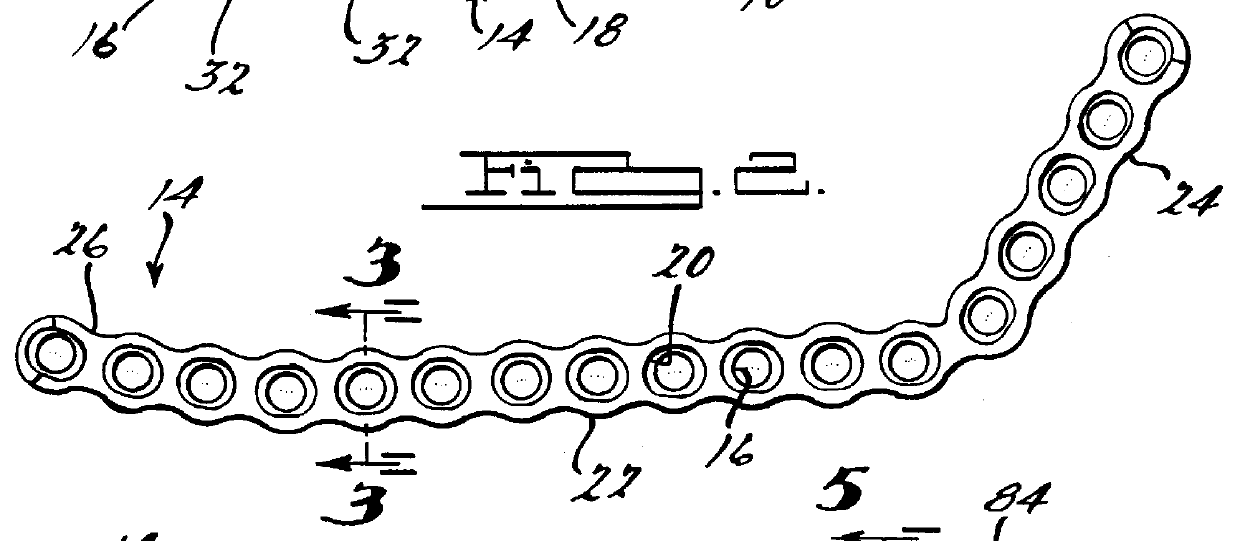

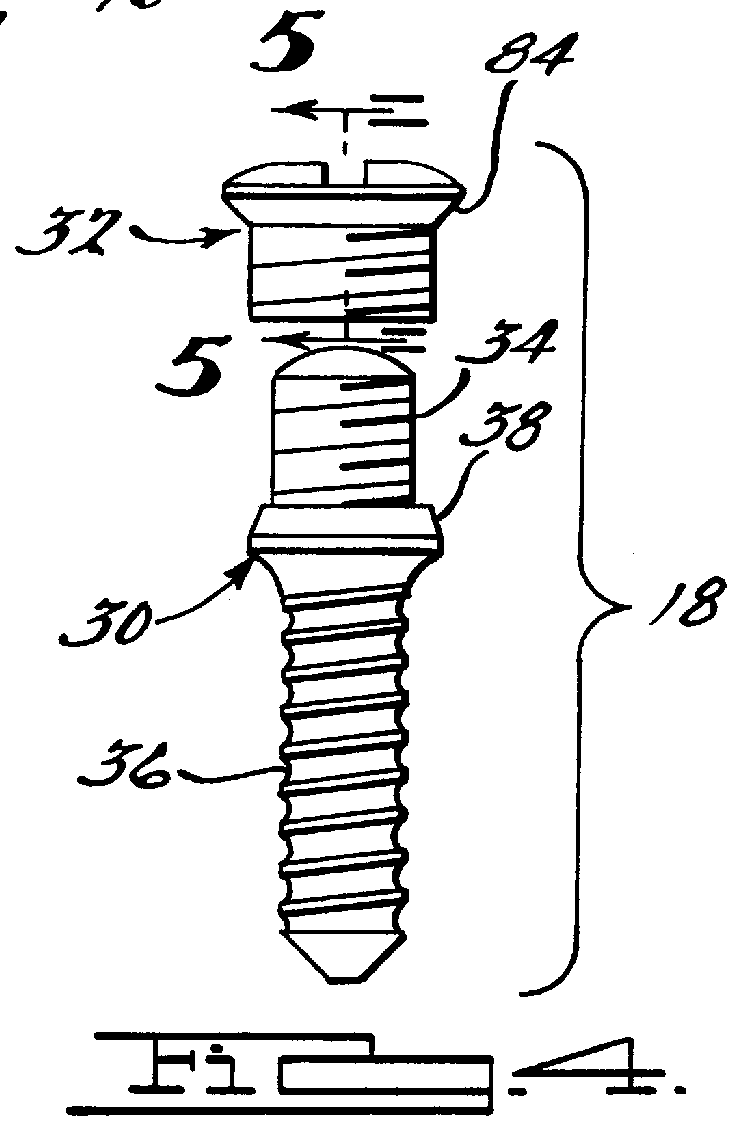

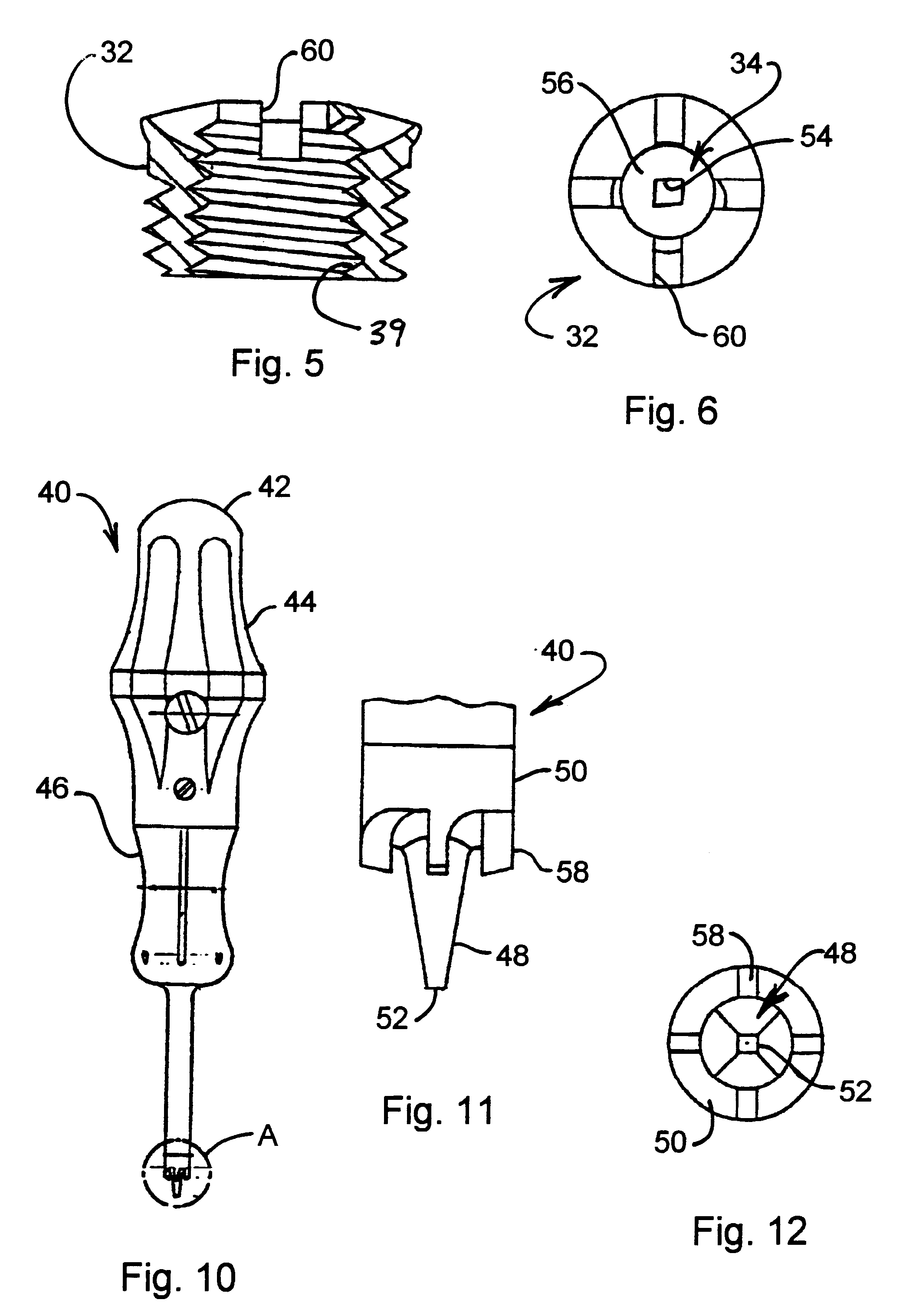

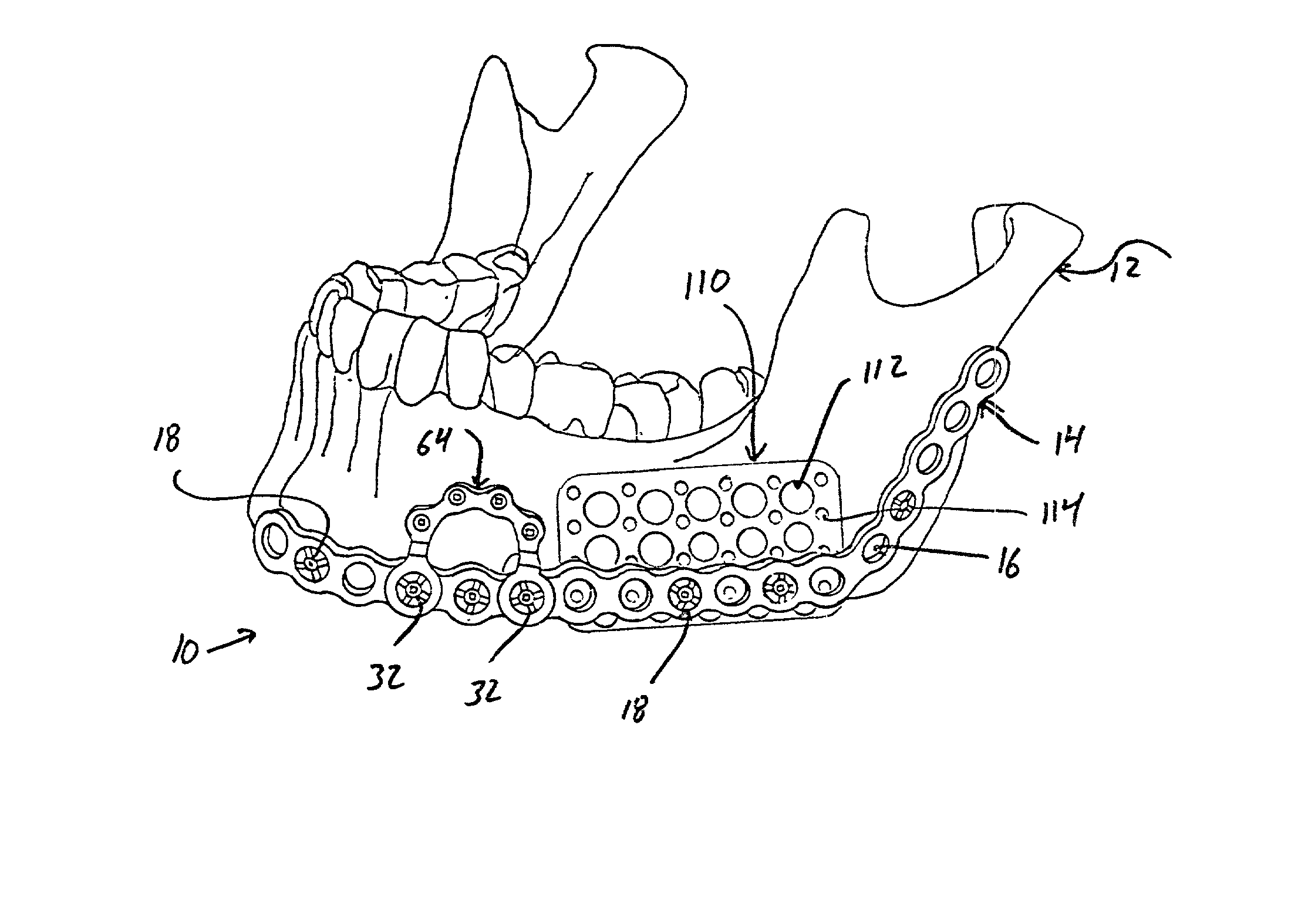

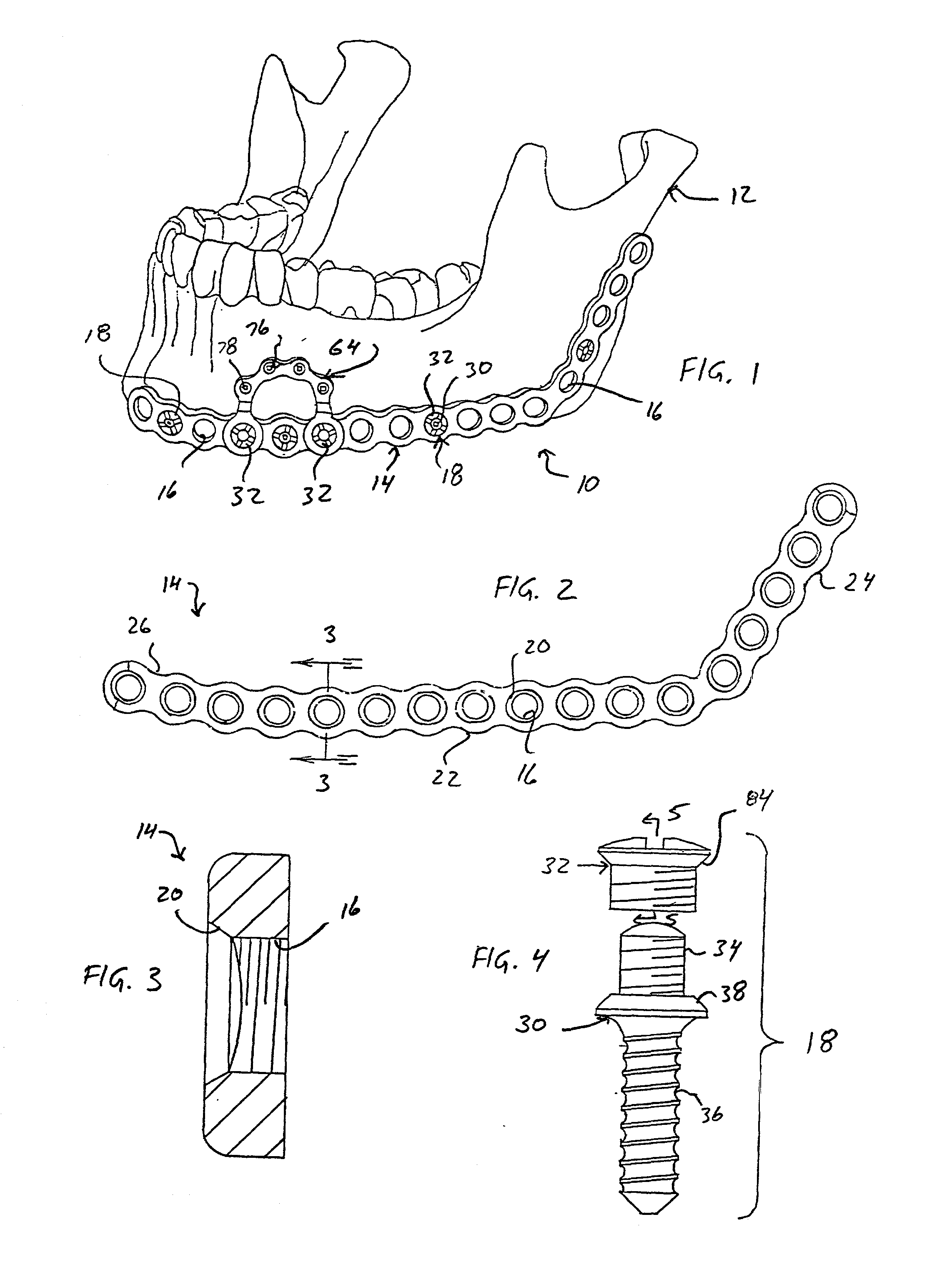

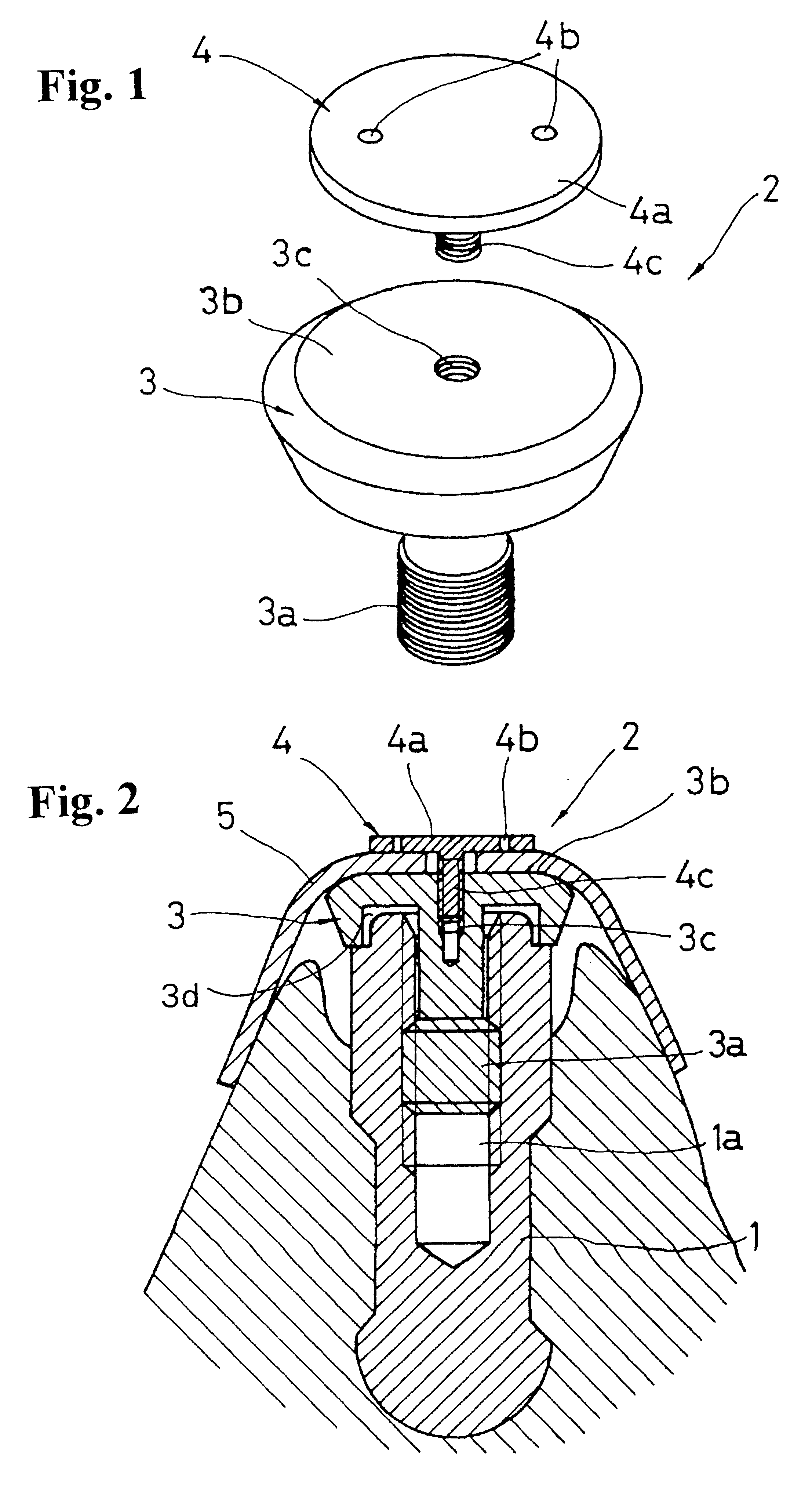

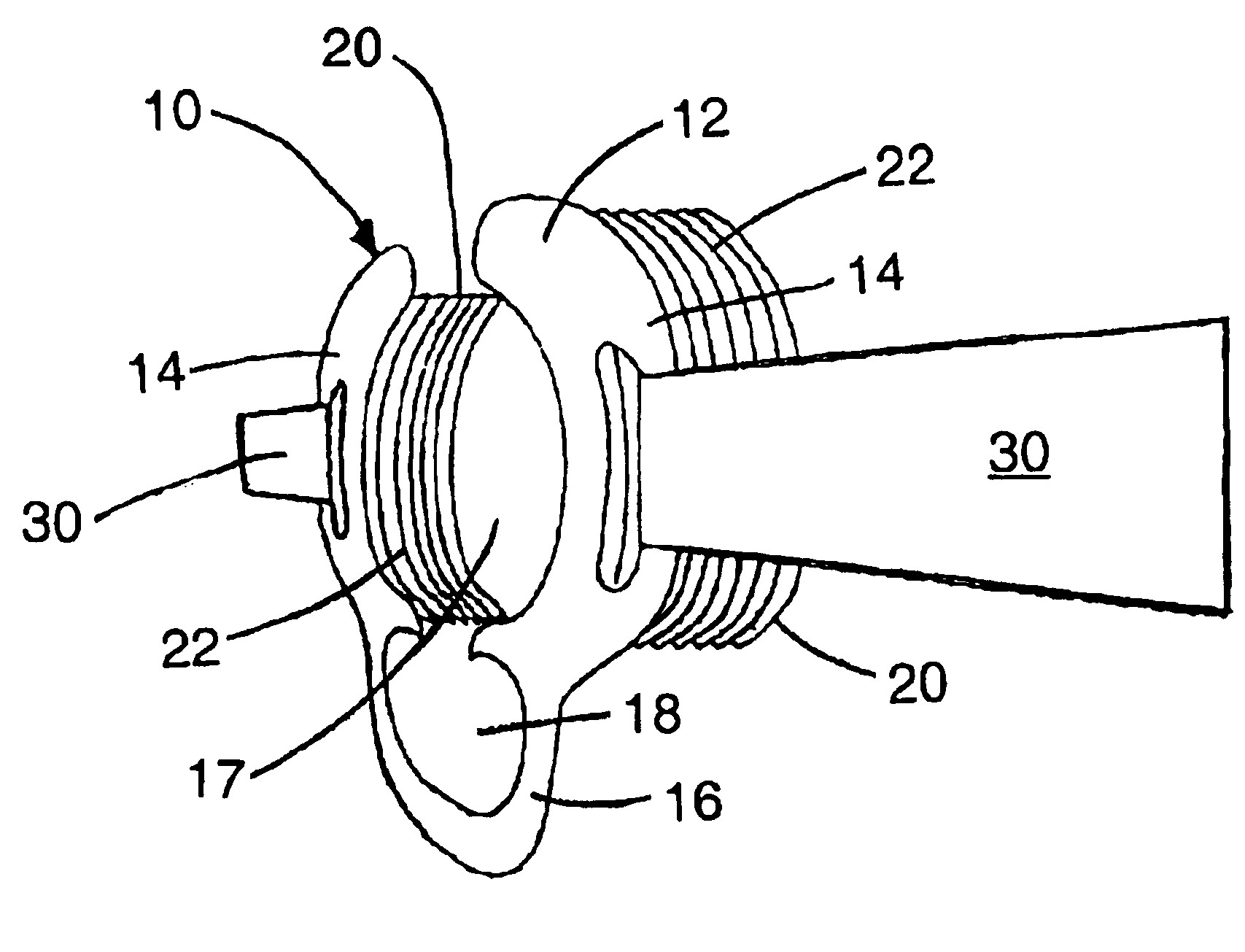

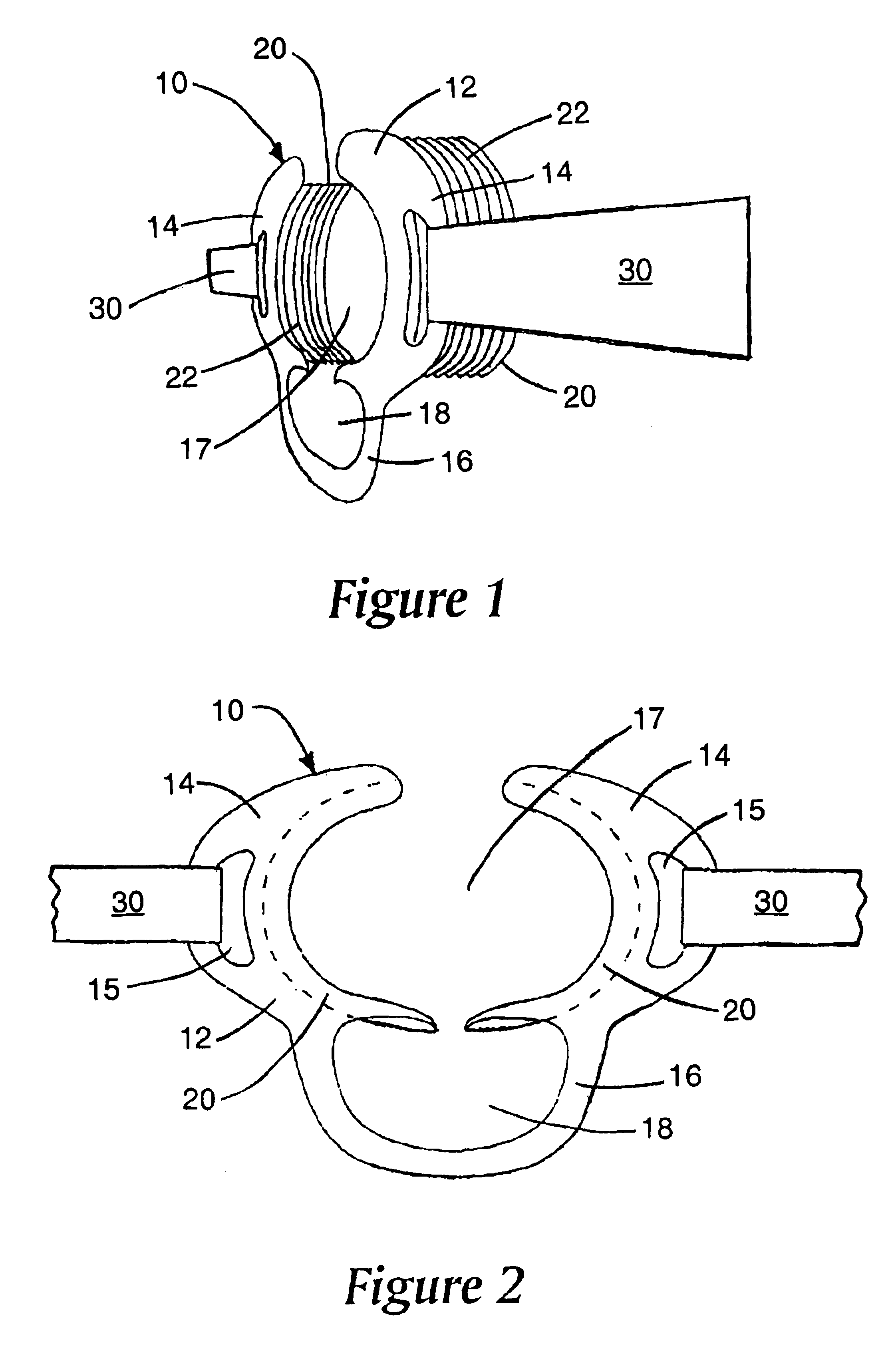

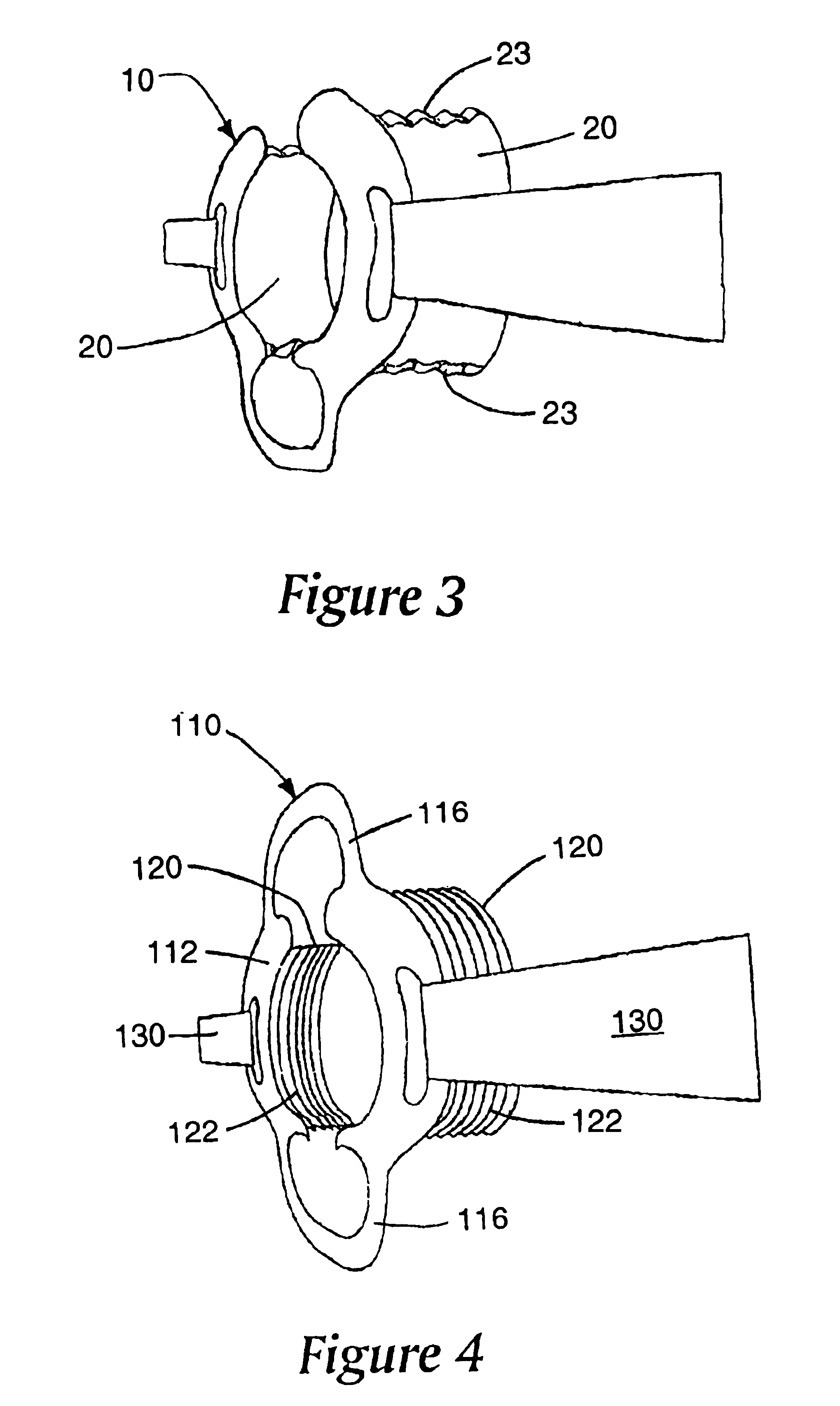

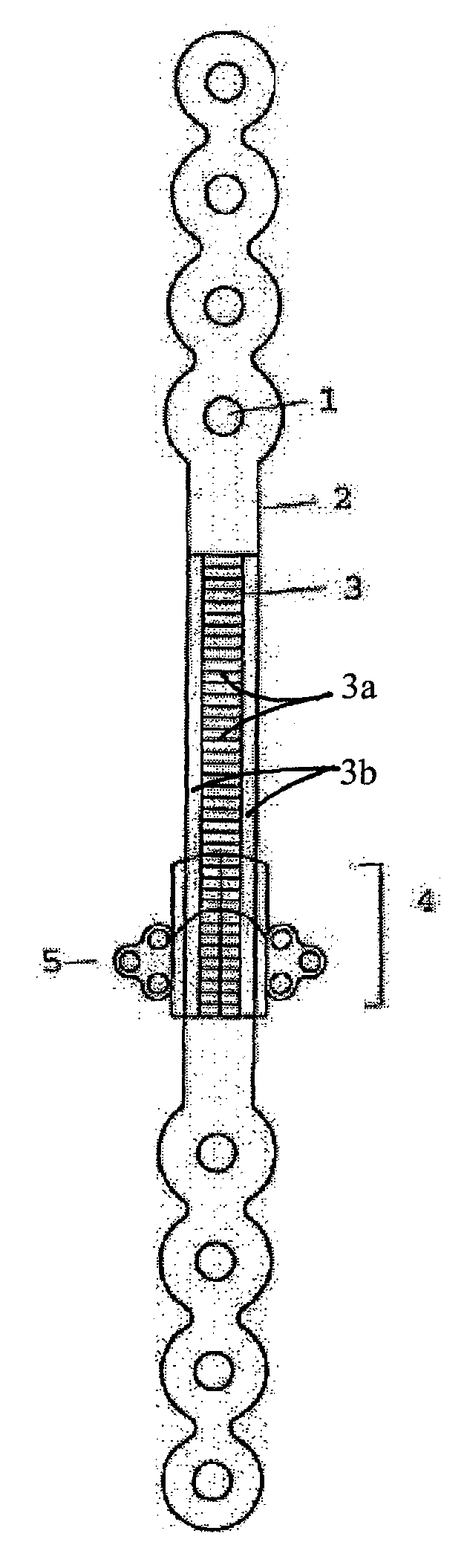

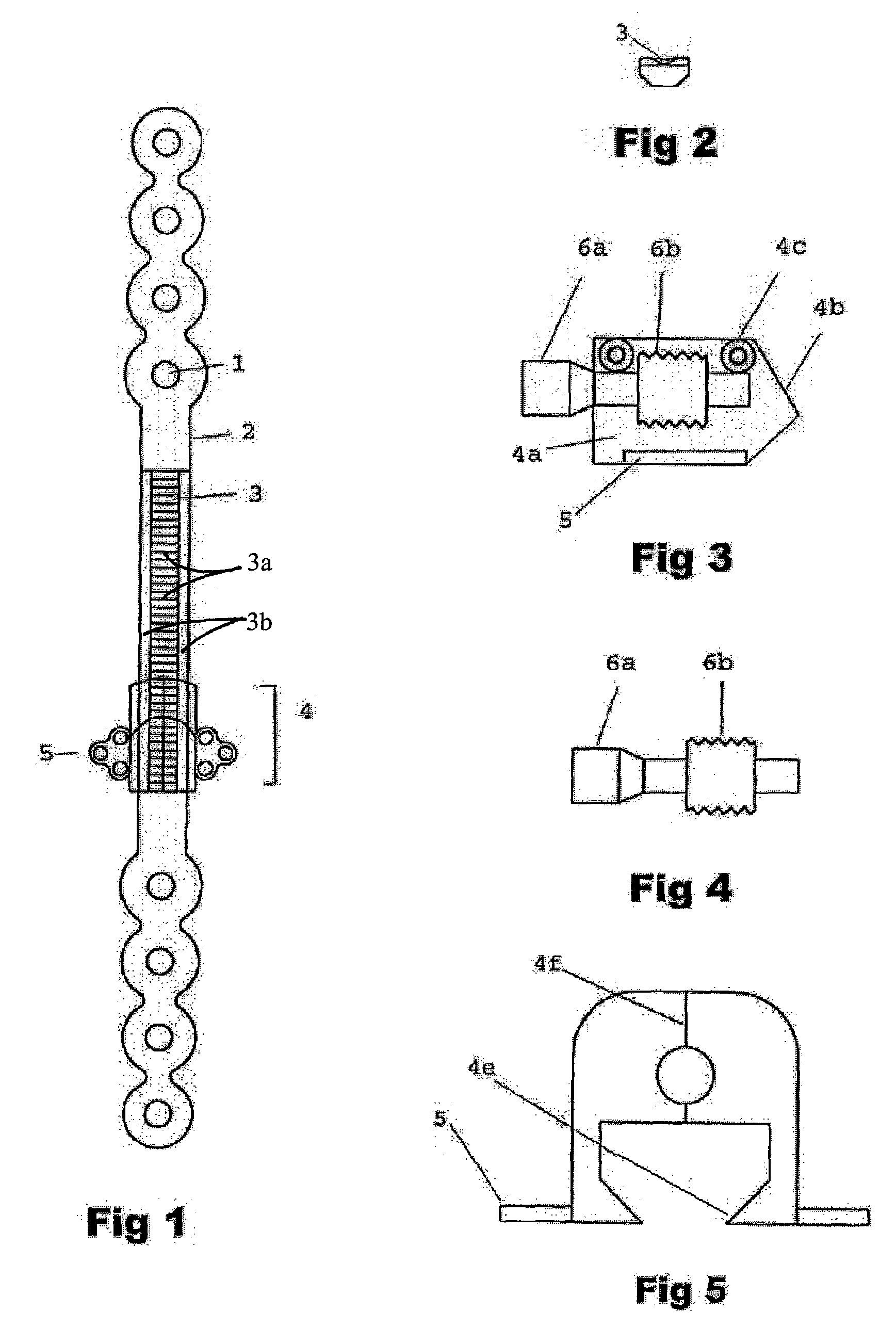

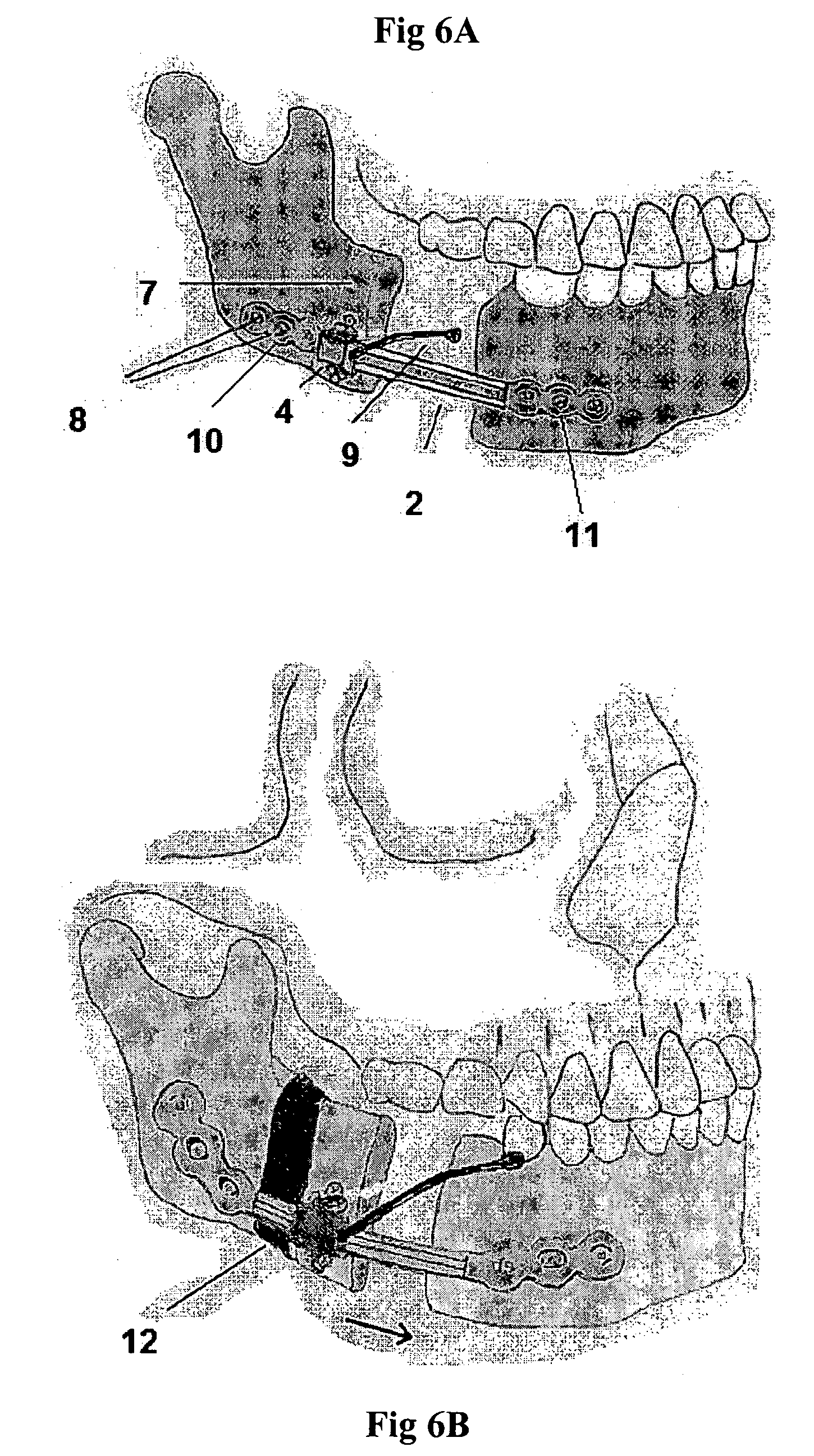

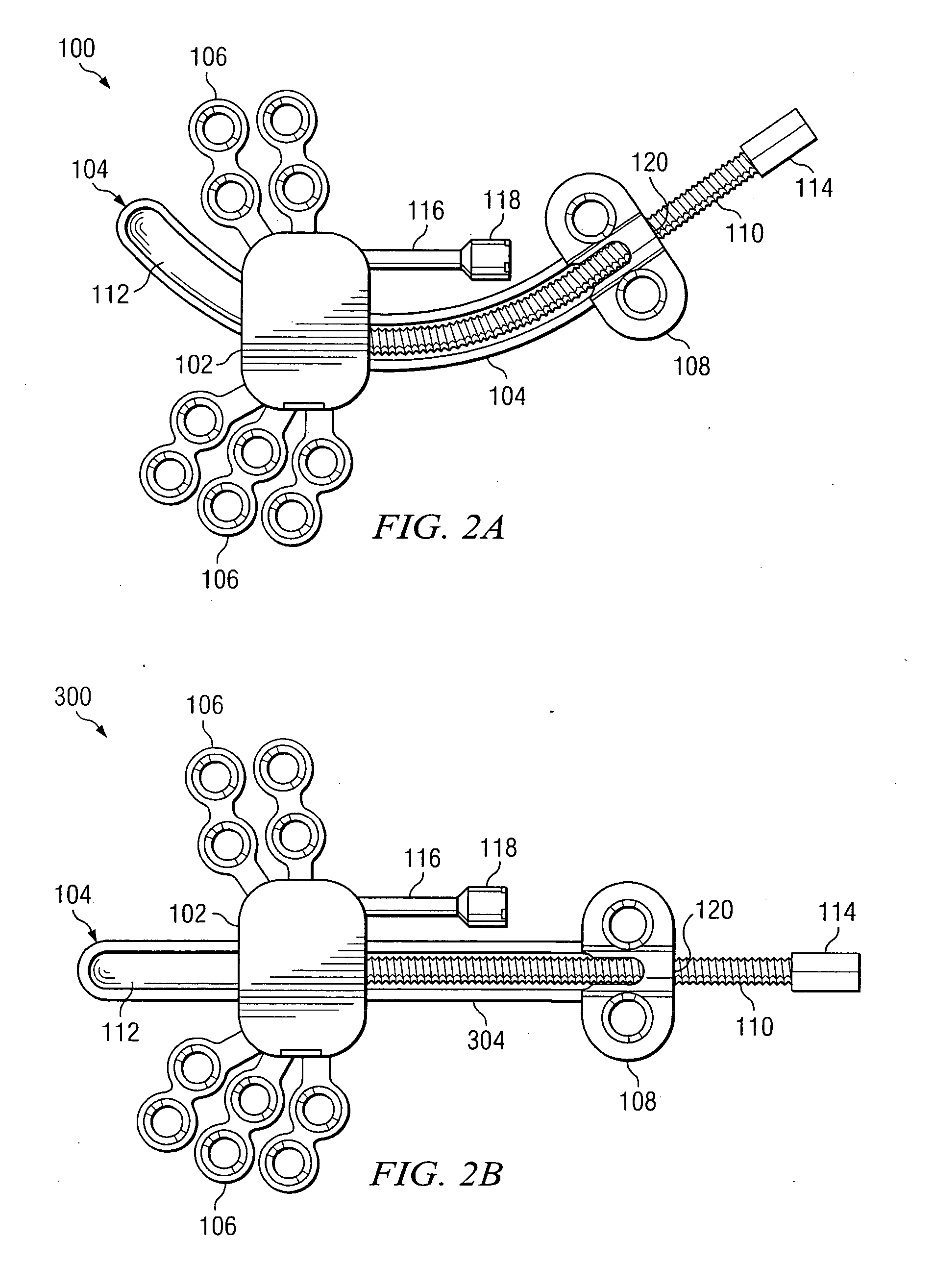

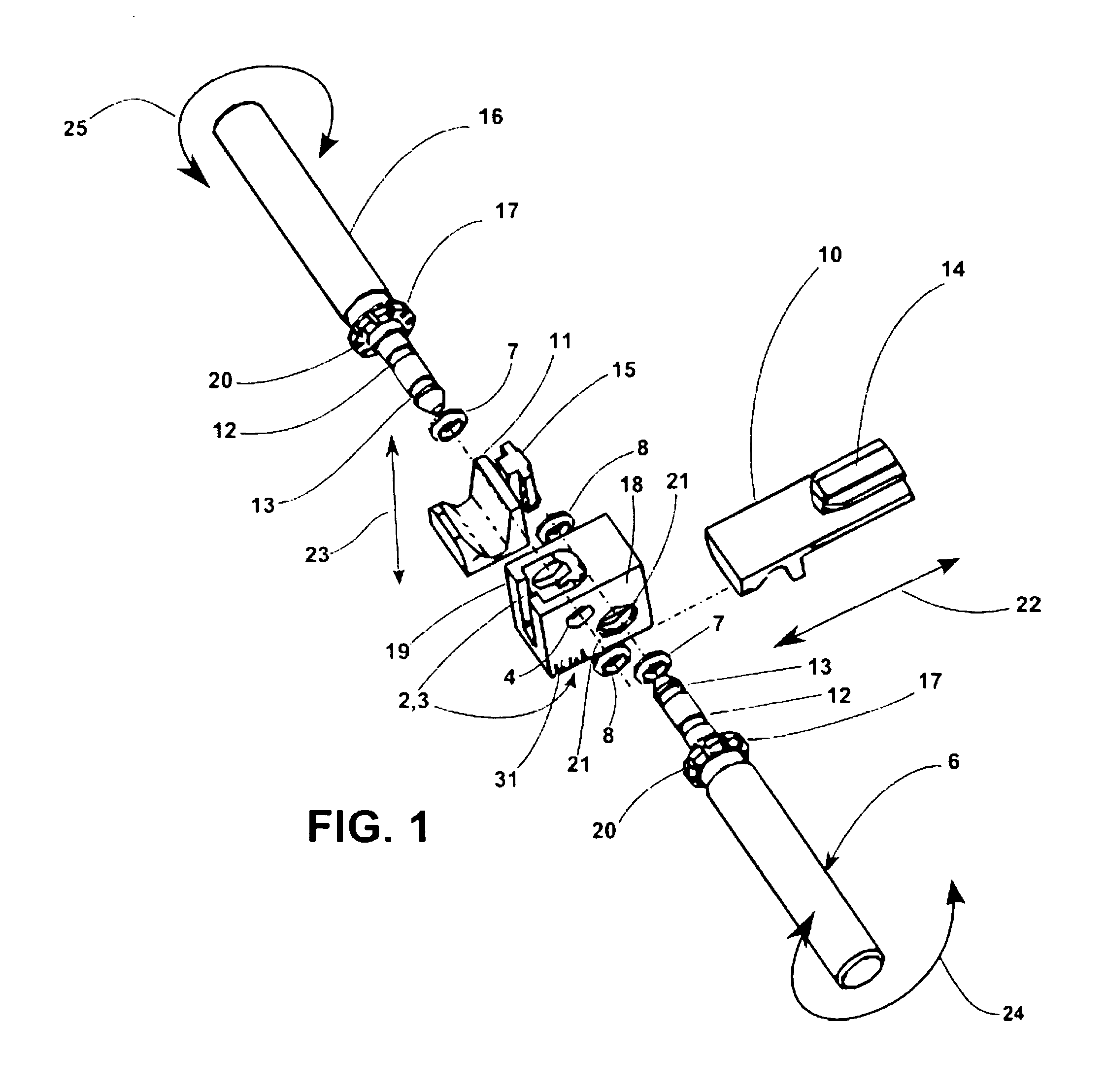

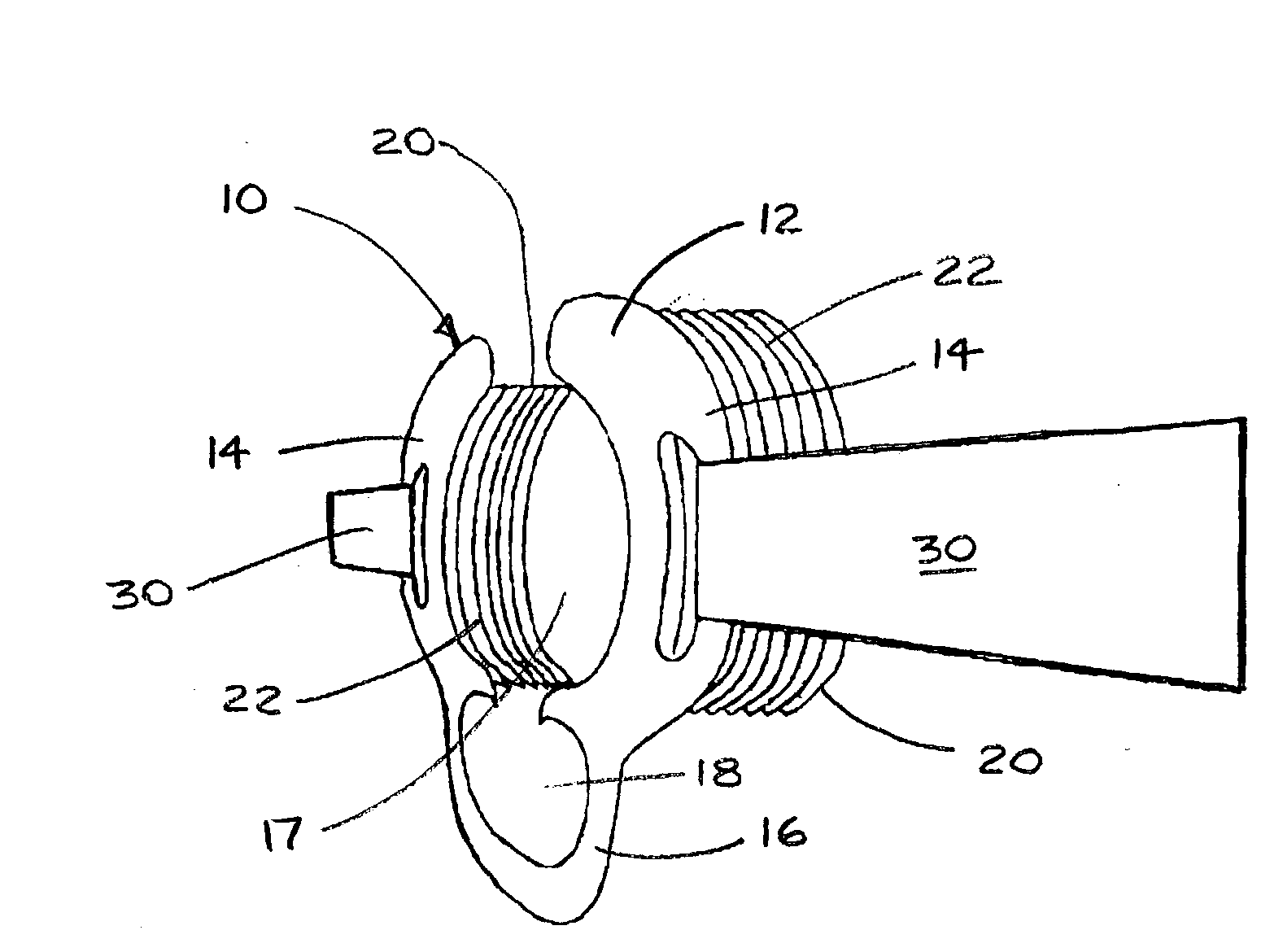

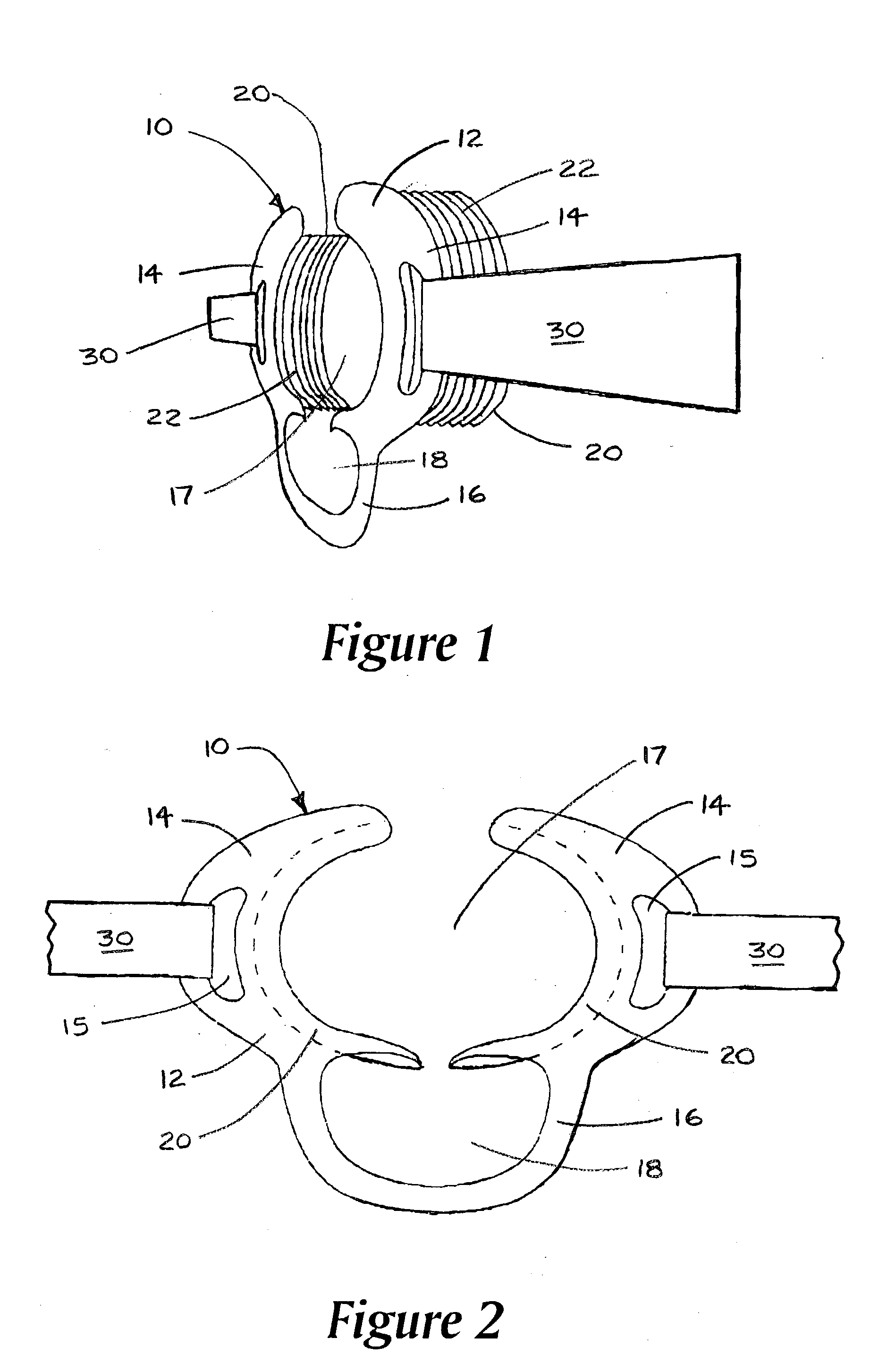

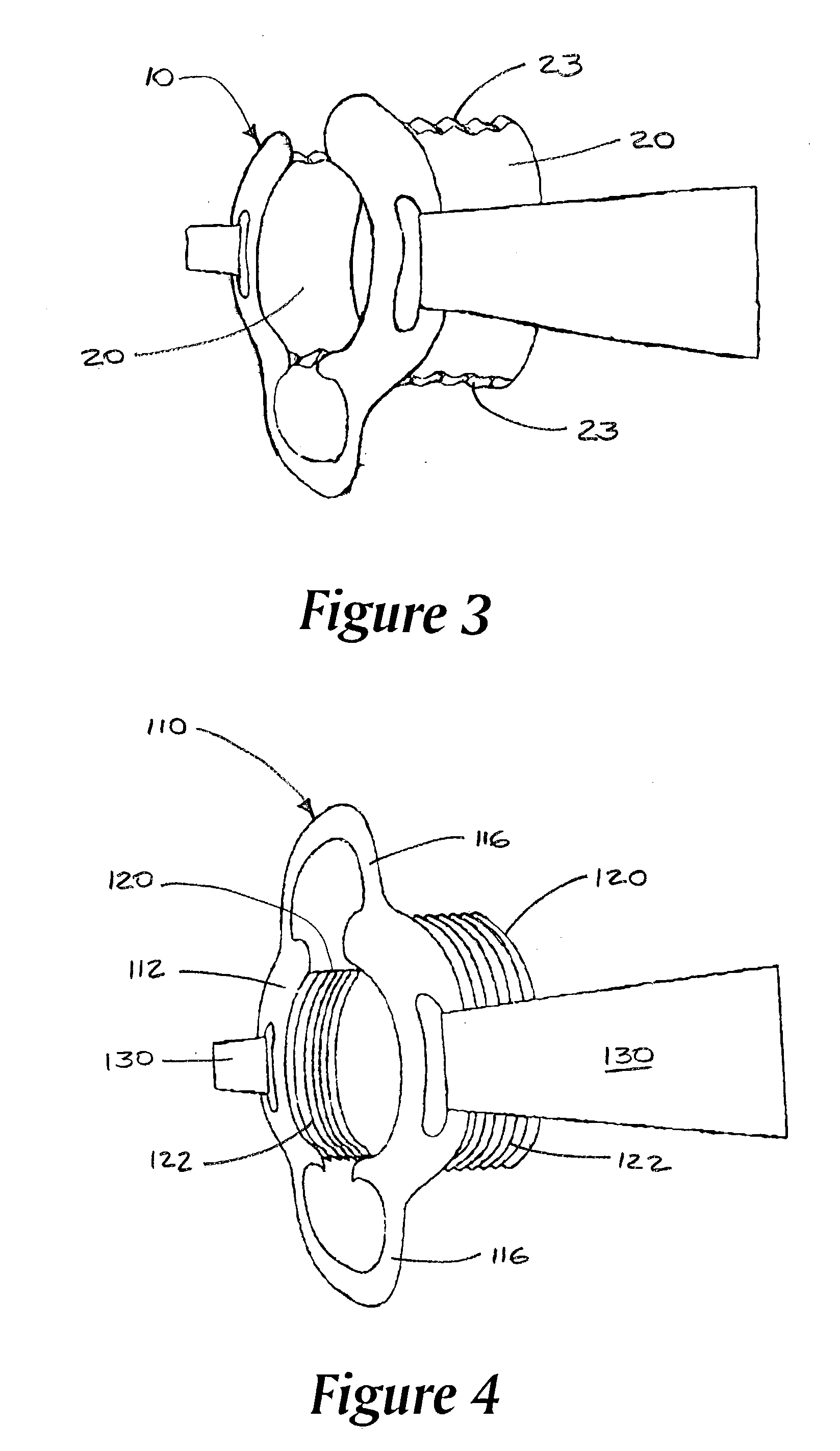

Method and apparatus for mandibular osteosynthesis

InactiveUS6325803B1Quickly and easily contoursCooperate accuratelySuture equipmentsInternal osteosythesisBody of mandibleScrew thread

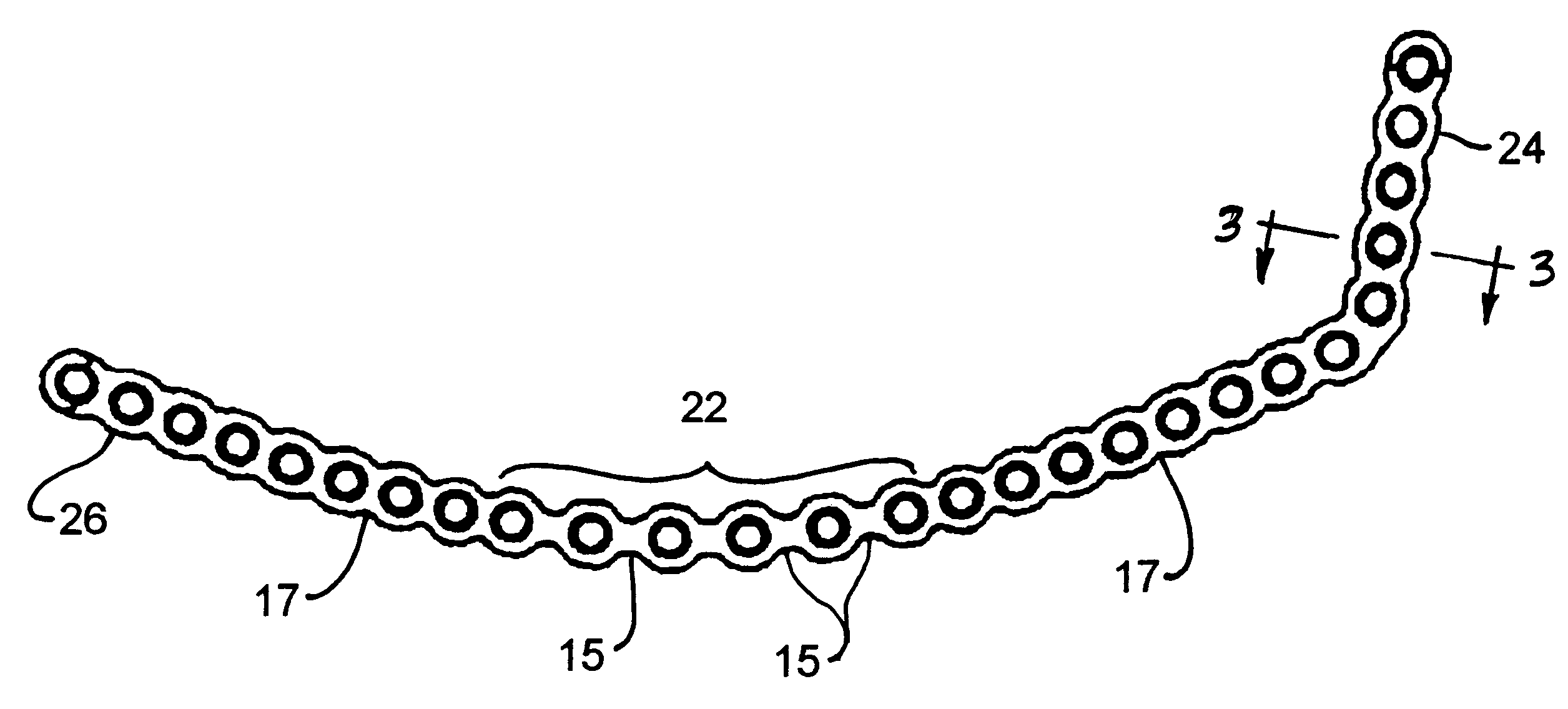

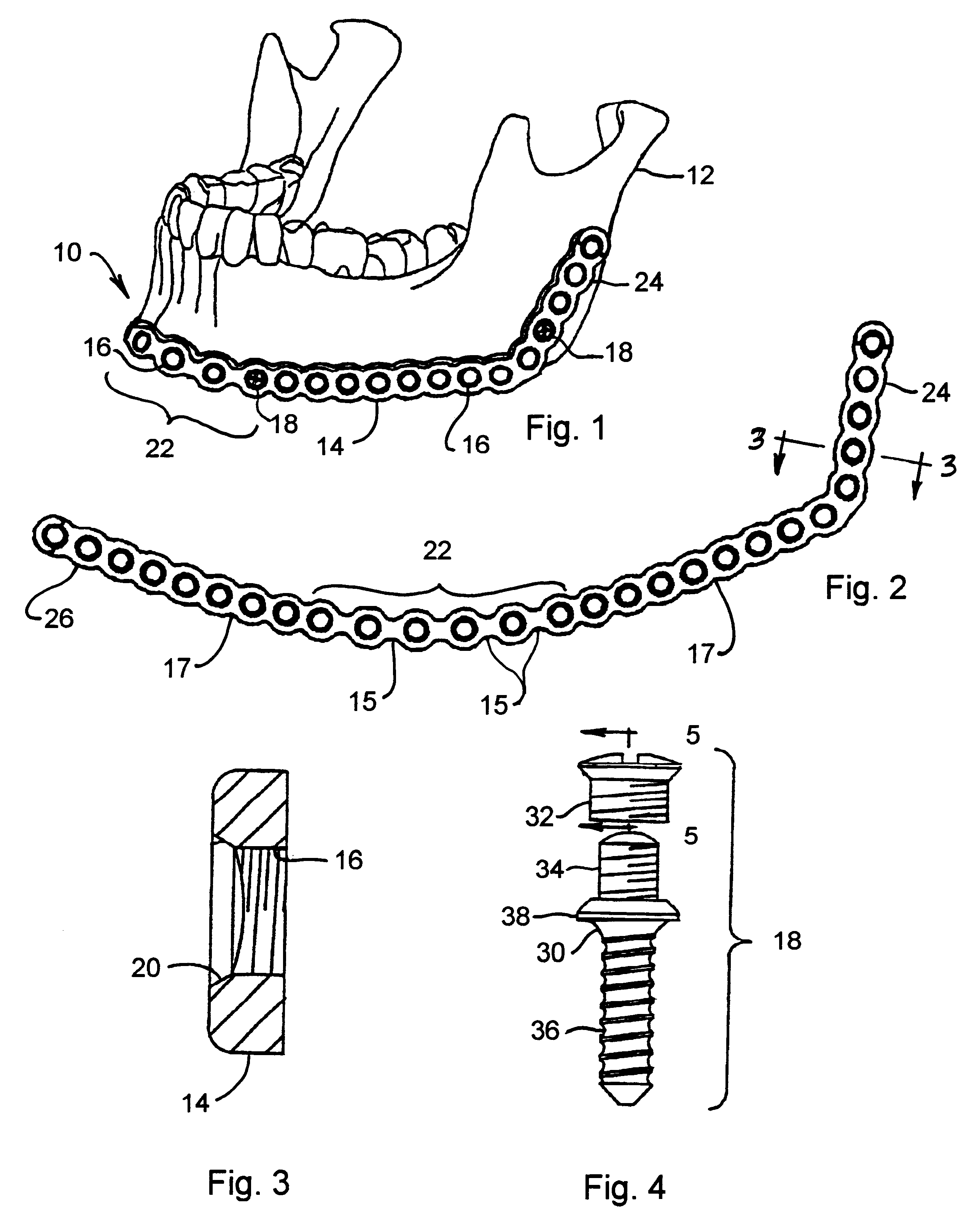

A system for mandibular reconstruction generally includes an elongated locking plate having a plurality of internally threaded apertures and a plurality of fasteners. Each fastener includes a main body portion having an upper threaded shaft and a lower threaded shaft. The lower threaded shaft is adapted to engage the mandible. Each fastener further includes a removable head portion internally threaded for engaging the upper shaft portion and externally threaded for engaging a selected one of the internally threaded apertures of the locking plate. In the preferred embodiment, the thread leads of the head portion and lower shaft of the main body portion are identical. A method of mandibular osteosynthesis utilizes the system of osteosynthesis and generally comprises the steps of temporarily securing the elongated locking plate to the mandible with at least one fastener by engaging the threads of the lower portion with the mandible and threadably engaging the head with the locking plate, unthreading the head portion from the main body of the fastener to thereby allow displacement of the locking plate from the mandible without removing the fasteners from the mandible, performing a surgical procedure (e.g., removal of a cancerous growth), and re-securing the elongated plate to the fastener with the removable head portion.

Owner:ELECTRO BIOLOGY INC +1

Method and apparatus for mandibular osteosynthesis

InactiveUS6129728AQuickly and easily contoursCooperate accuratelySuture equipmentsInternal osteosythesisBody of mandibleEngineering

A system for mandibular reconstruction generally includes an elongated locking plate having a plurality of internally threaded apertures and a plurality of fasteners. Each fastener includes a main body portion having an upper threaded shaft and a lower threaded shaft. The lower threaded shaft is adapted to engage the mandible. Each fastener further includes a removable head portion internally threaded for engaging the upper shaft portion and externally threaded for engaging a selected one of the internally threaded apertures of the locking plate. In the preferred embodiment, the thread leads of the head portion and lower shaft of the main body portion are identical. A method of mandibular osteosynthesis utilizes the system of osteosynthesis and generally comprises the steps of temporarily securing the elongated locking plate to the mandible with at least one fastener by engaging the threads of the lower portion with the mandible and threadably engaging the head with the locking plate, unthreading the head portion from the main body of the fastener to thereby allow displacement of the locking plate from the mandible without removing the fasteners from the mandible, performing a surgical procedure (e.g., removal of a cancerous growth), and re-securing the elongated plate to the fastener with the removable head portion.

Owner:ZIMMER BIOMET CMF & THORACIC

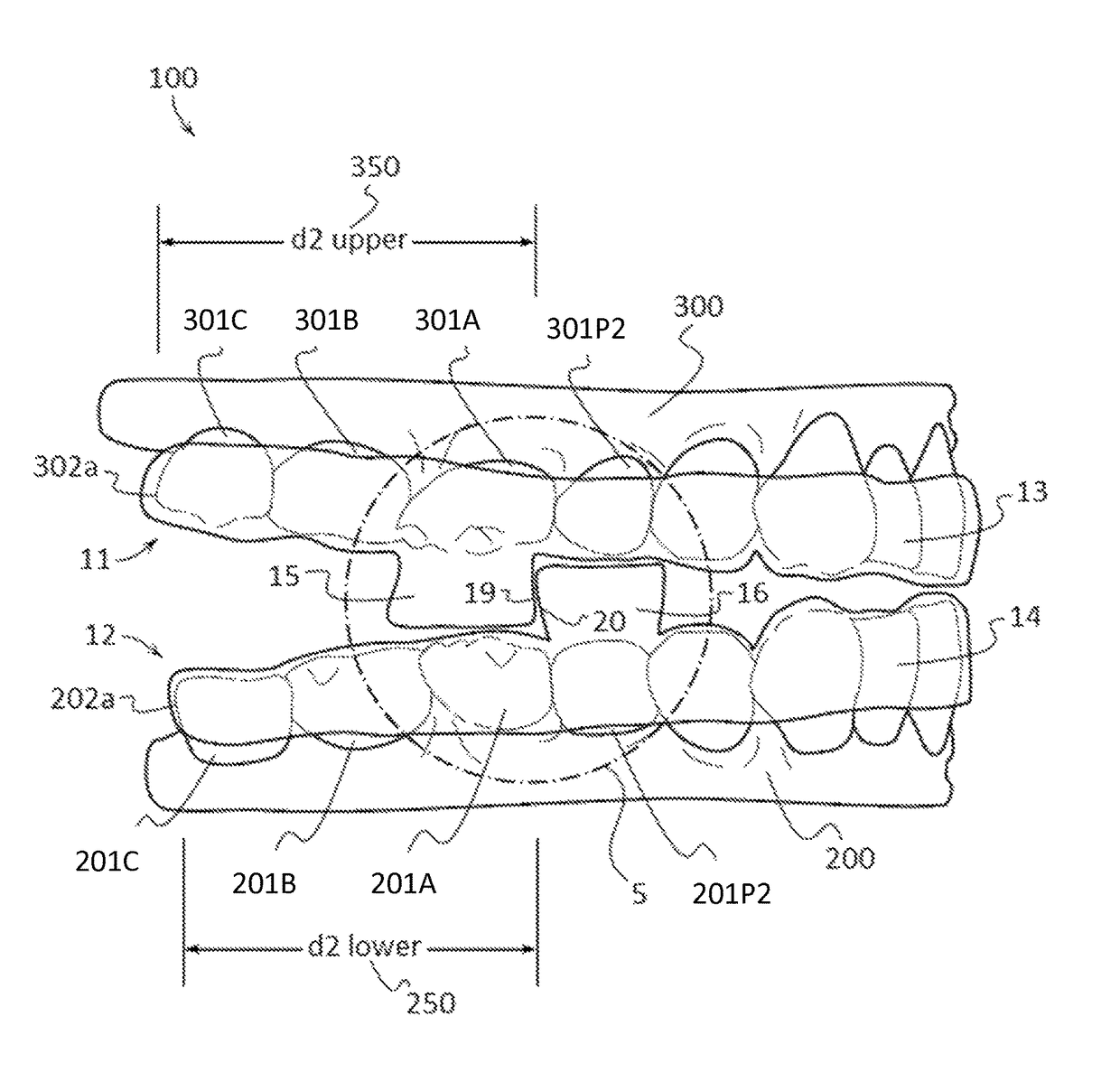

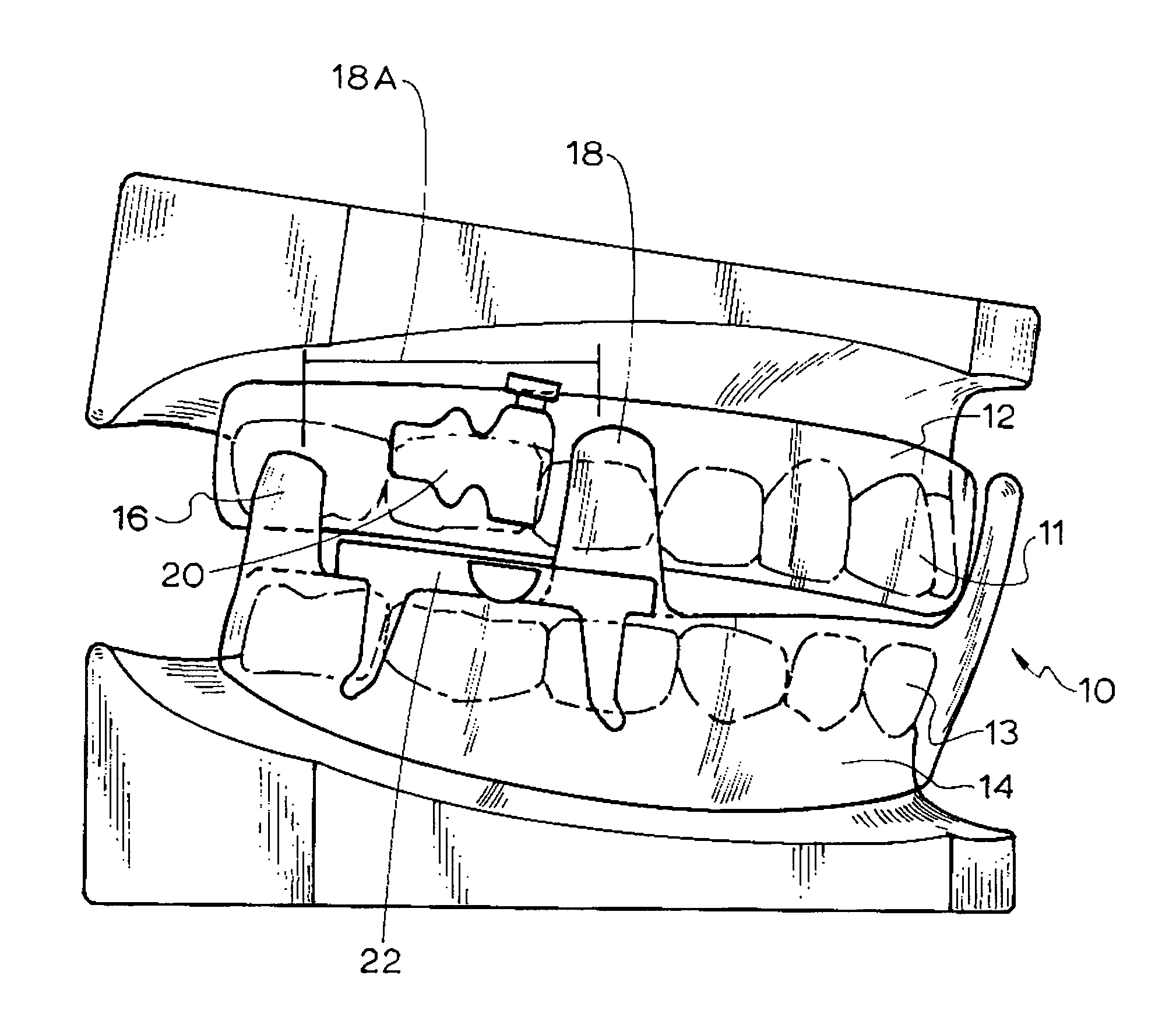

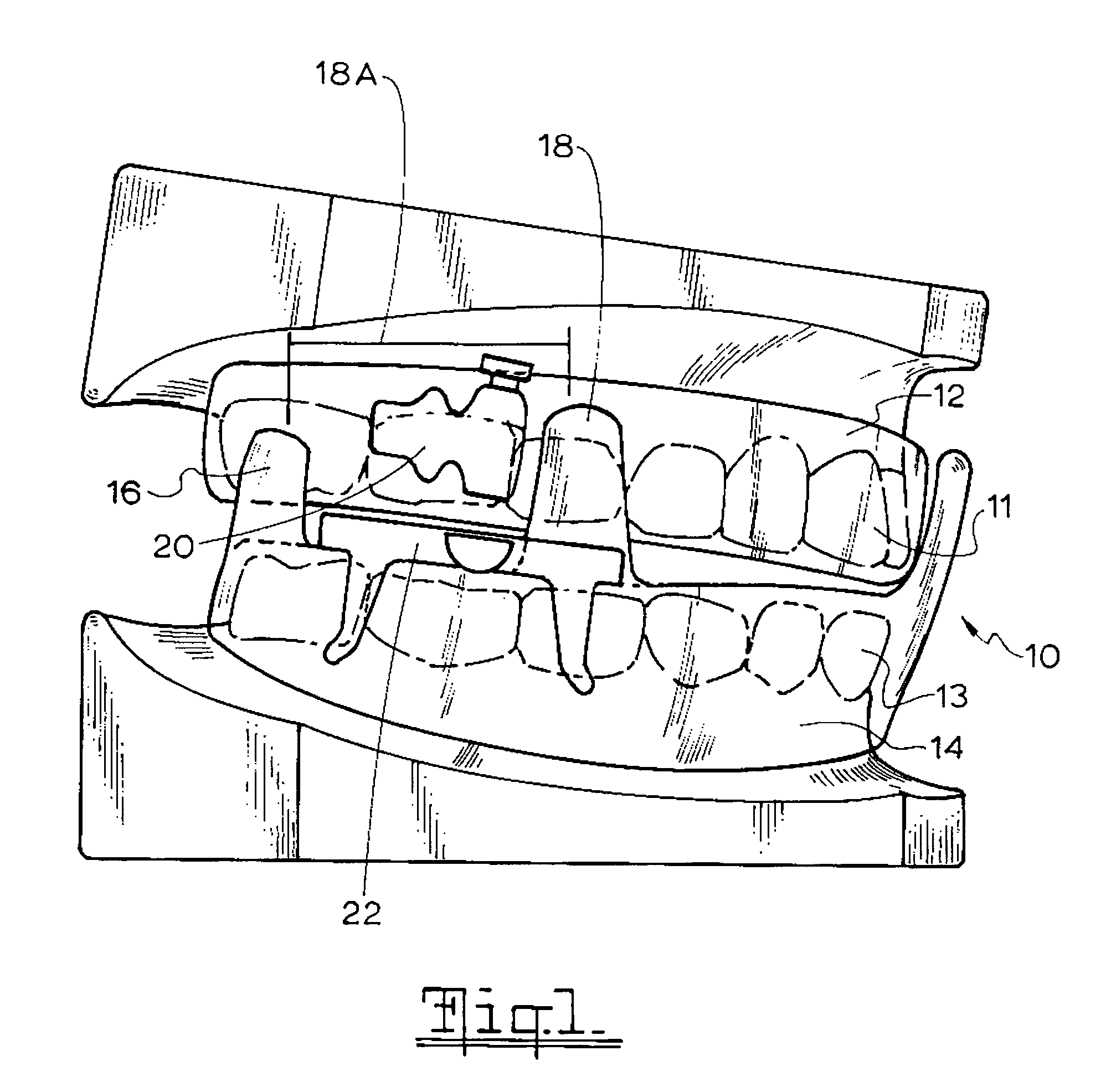

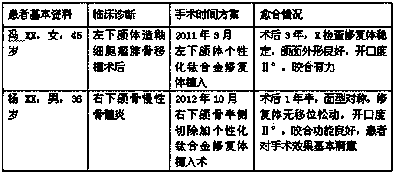

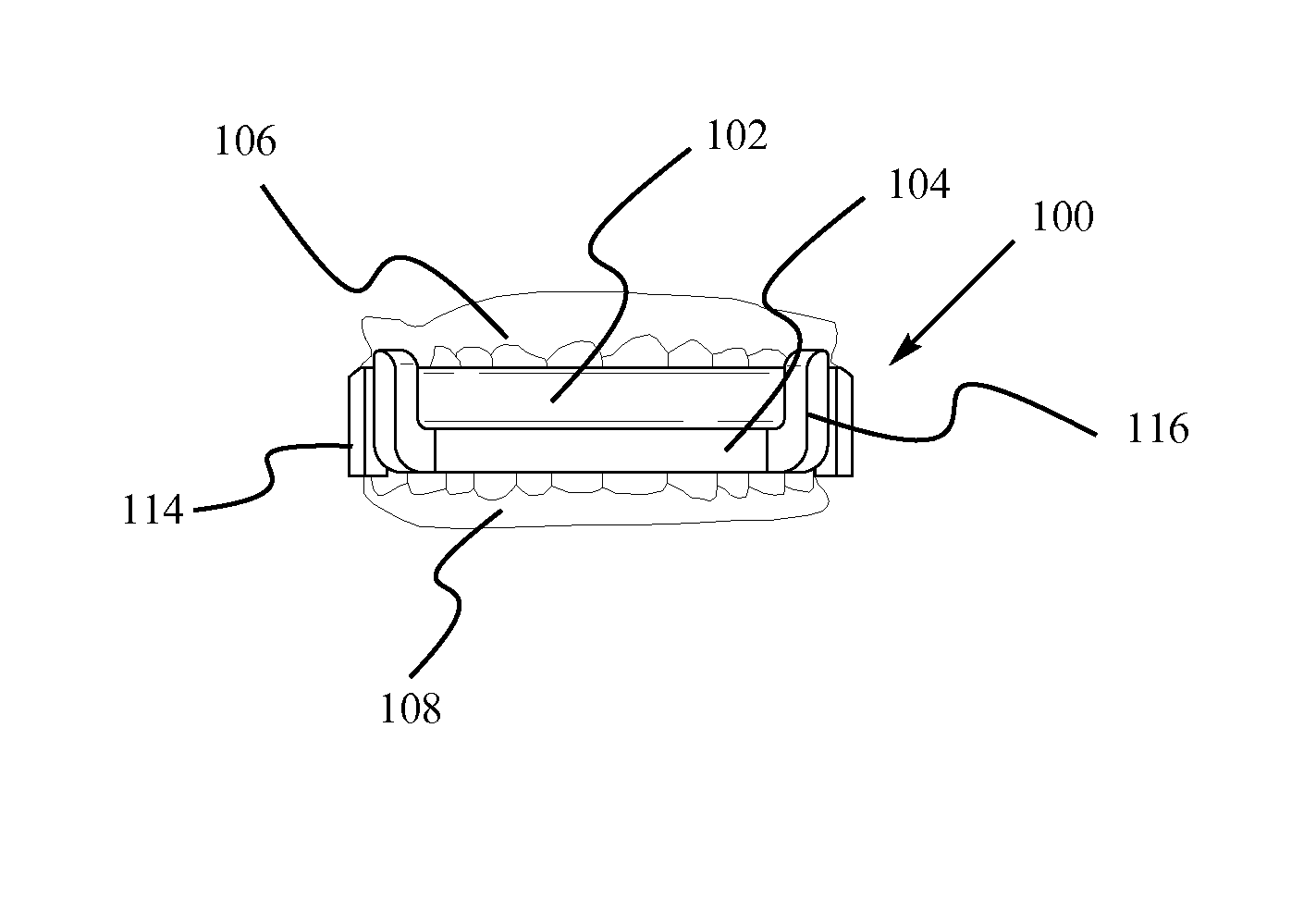

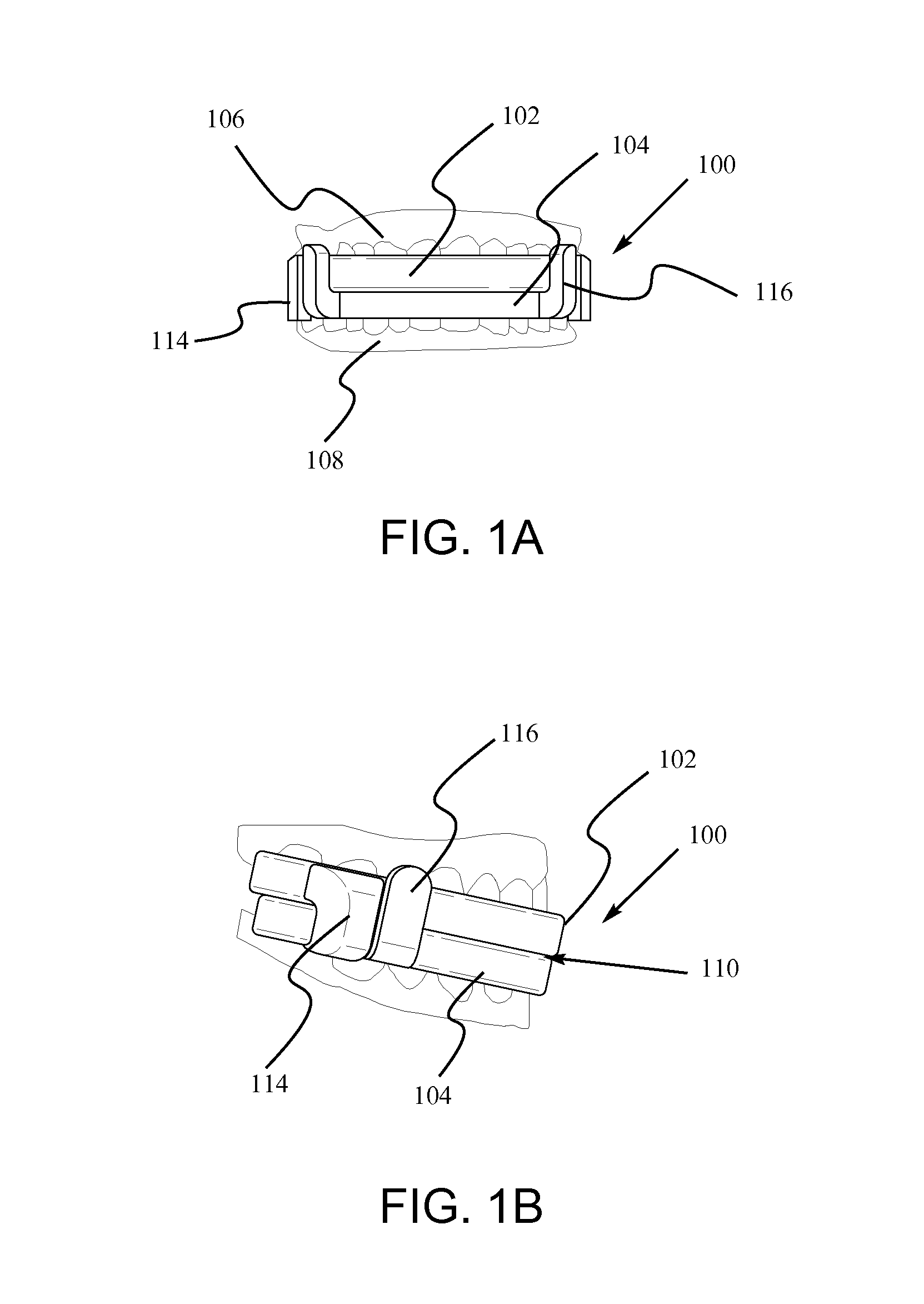

Anti-Retrusion Oral Appliance

An oral appliance for treating sleep apnea and bruxism is formed of a maxillary tray and a mandibular tray. The maxillary tray carries a maxillary bite pad projecting downwardly toward an opposed mandibular occlusal surface. The mandibular tray carries a mandibular bite pad projecting upwardly toward an opposed maxillary occlusal surface. The maxillary bite pad is posterior to the mandibular bite pad such that upon sufficient relative posterior movement of the mandibular tray, the maxillary bite pad engages the mandibular bite pad and limits posterior movement of the mandibular tray. At least one surface, chosen from the anterior face of the maxillary bite pad and the posterior face of the mandibular bite pad, defines a guide plane disposed at an upward and forward slant. The maxillary bite pad and the mandibular bite pad are engageable at the guide plane for advancing the mandibular tray along the guide plane upon vertical closure between the trays. A smooth pad is disposed over the occlusal surface of at least one of the trays, guarding the occlusal surface from engagement with the opposed bite pad.

Owner:BAILEY DENNIS R

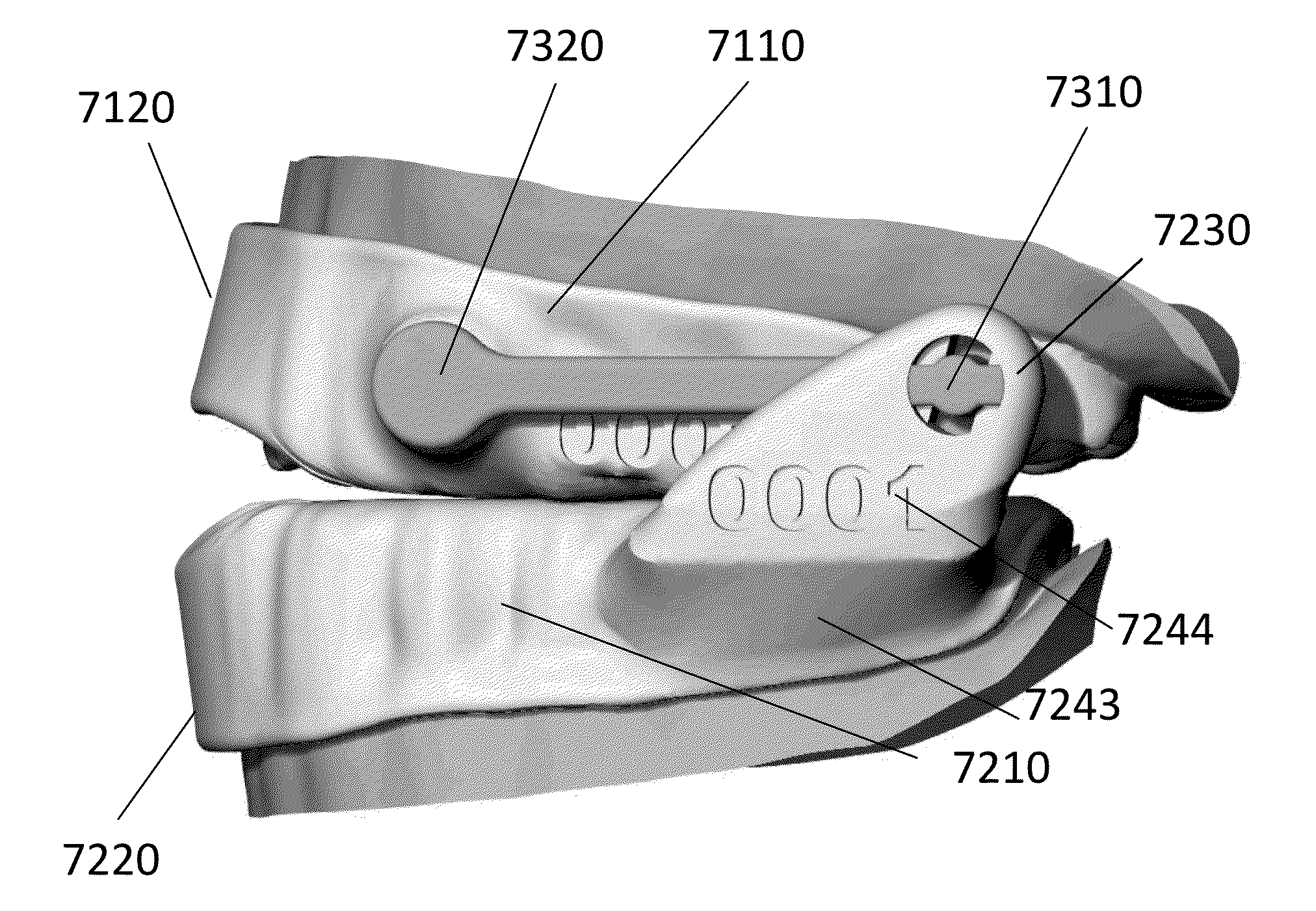

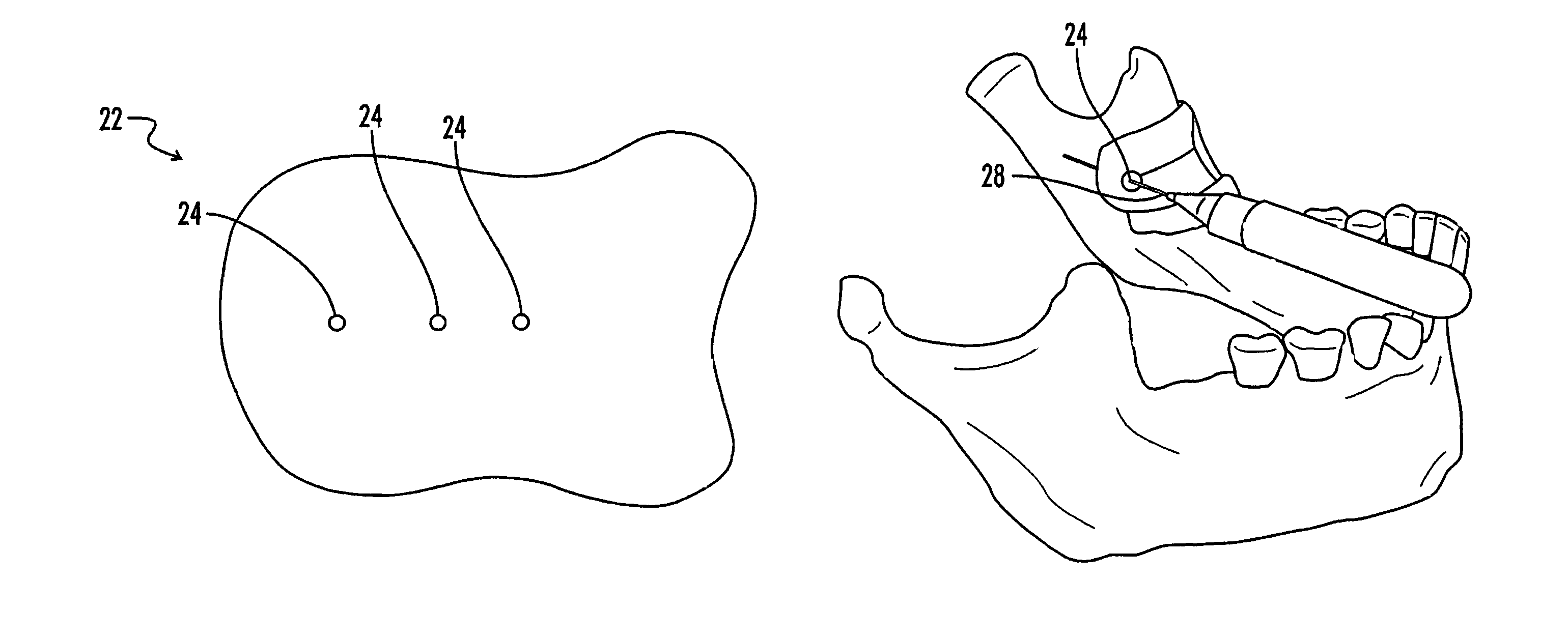

Methods, devices, and manufacture of the devices for musculoskeletal reconstructive surgery

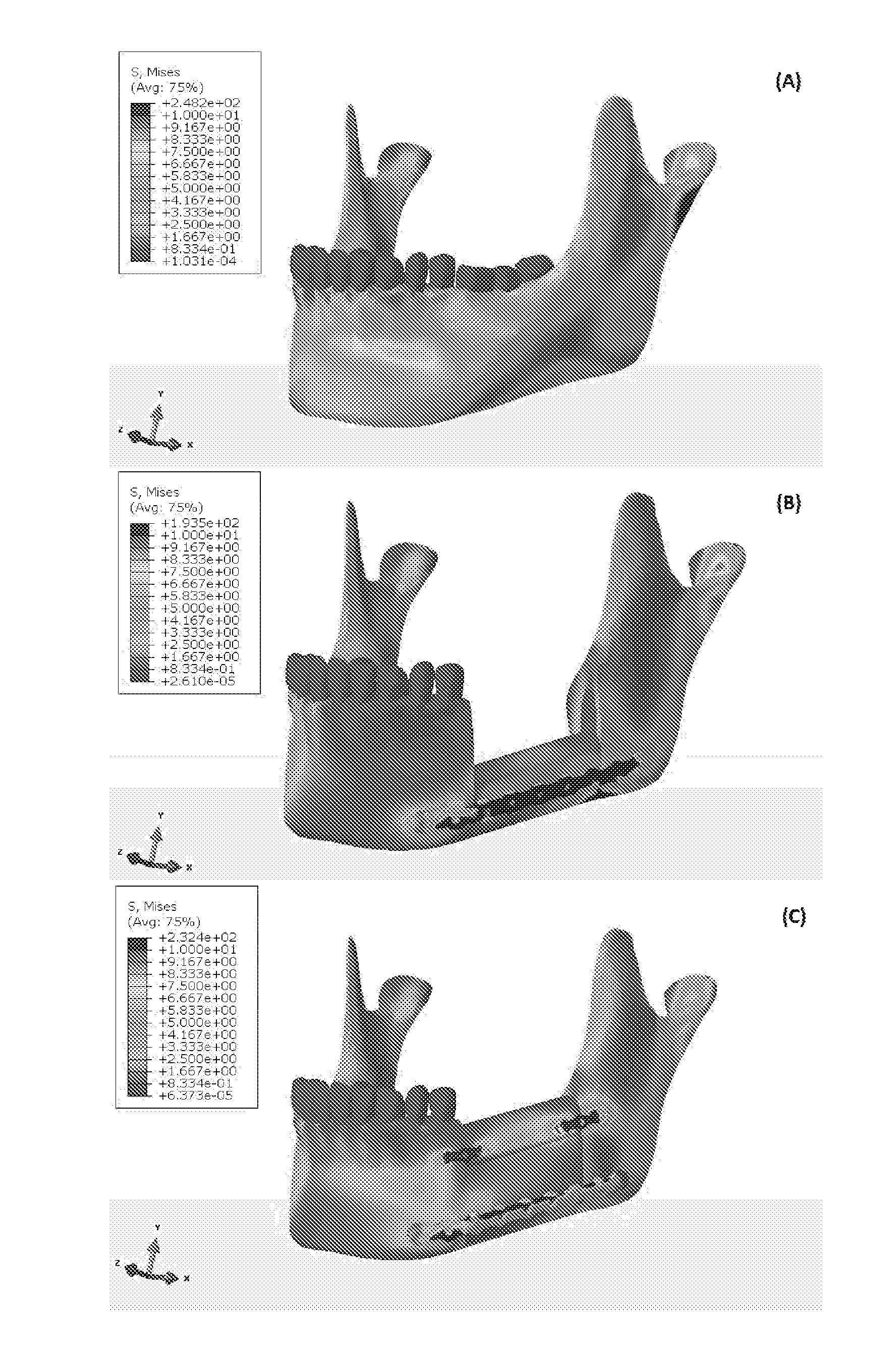

ActiveUS20170014169A1Guaranteed functionAccurate analysisBone implantJoint implantsBite force quotientCombined use

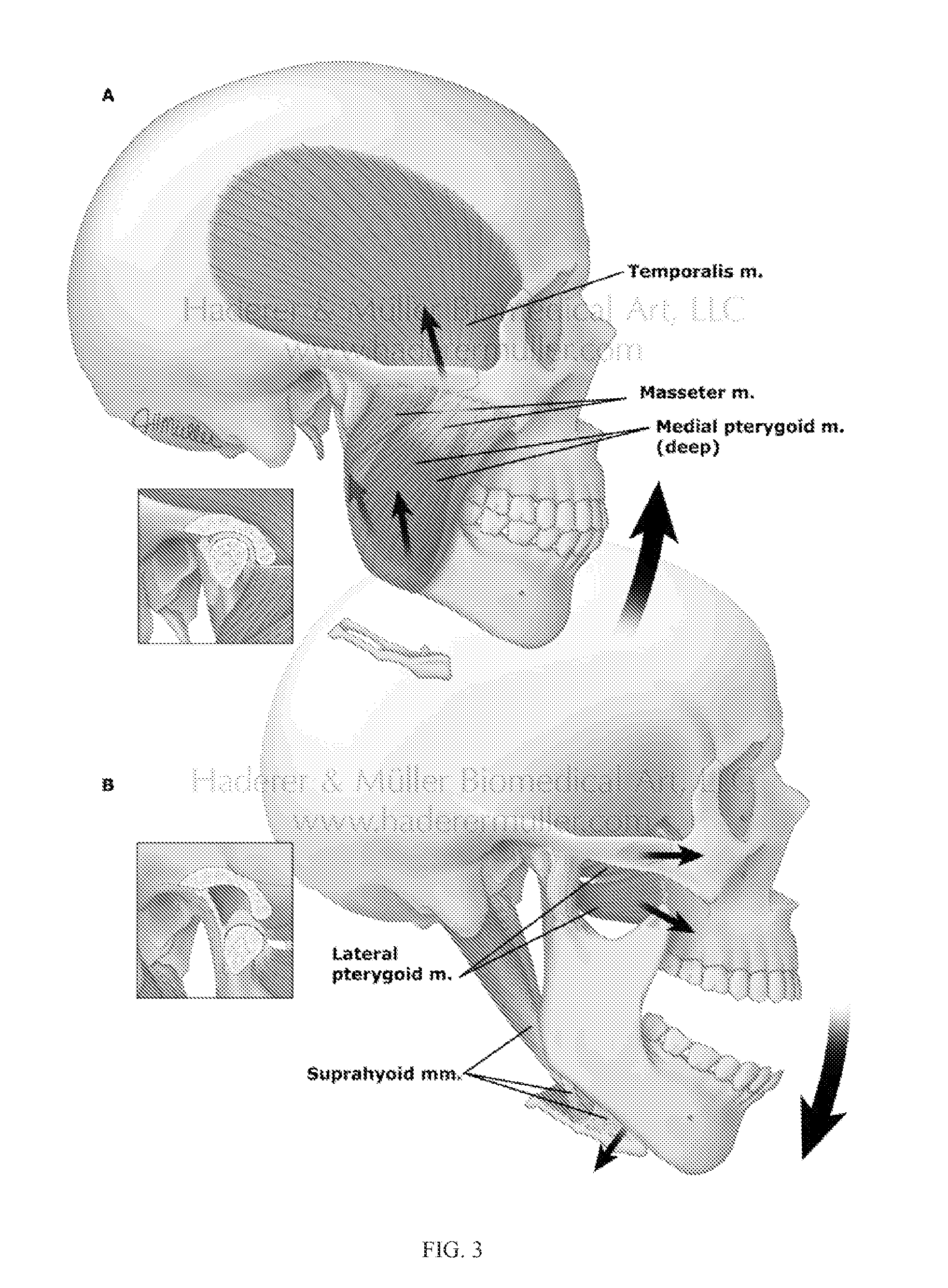

A device used in conjunction with fixation hardware to provide a two-stage process to address the competing needs of immobilization and re-establishment of normal stress-strain trajectories in grafted bone. A method of determining a patient-specific stress / strain pattern that utilizes a model based on 3D CT data of the relevant structures and cross-sectional data of the three major chewing muscles. The forces on each of the chewing muscles are determined based on the model using predetermined bite forces such that a stiffness of cortical bone in the patient's mandible is determined. Based on the stiffness data, suitable implantation hardware can be designed for the patient by adjusting external topological and internal porous geometries that reduce the stiffness of biocompatible metals to thereby restore normal bite forces of the patient.

Owner:OHIO STATE INNOVATION FOUND +1

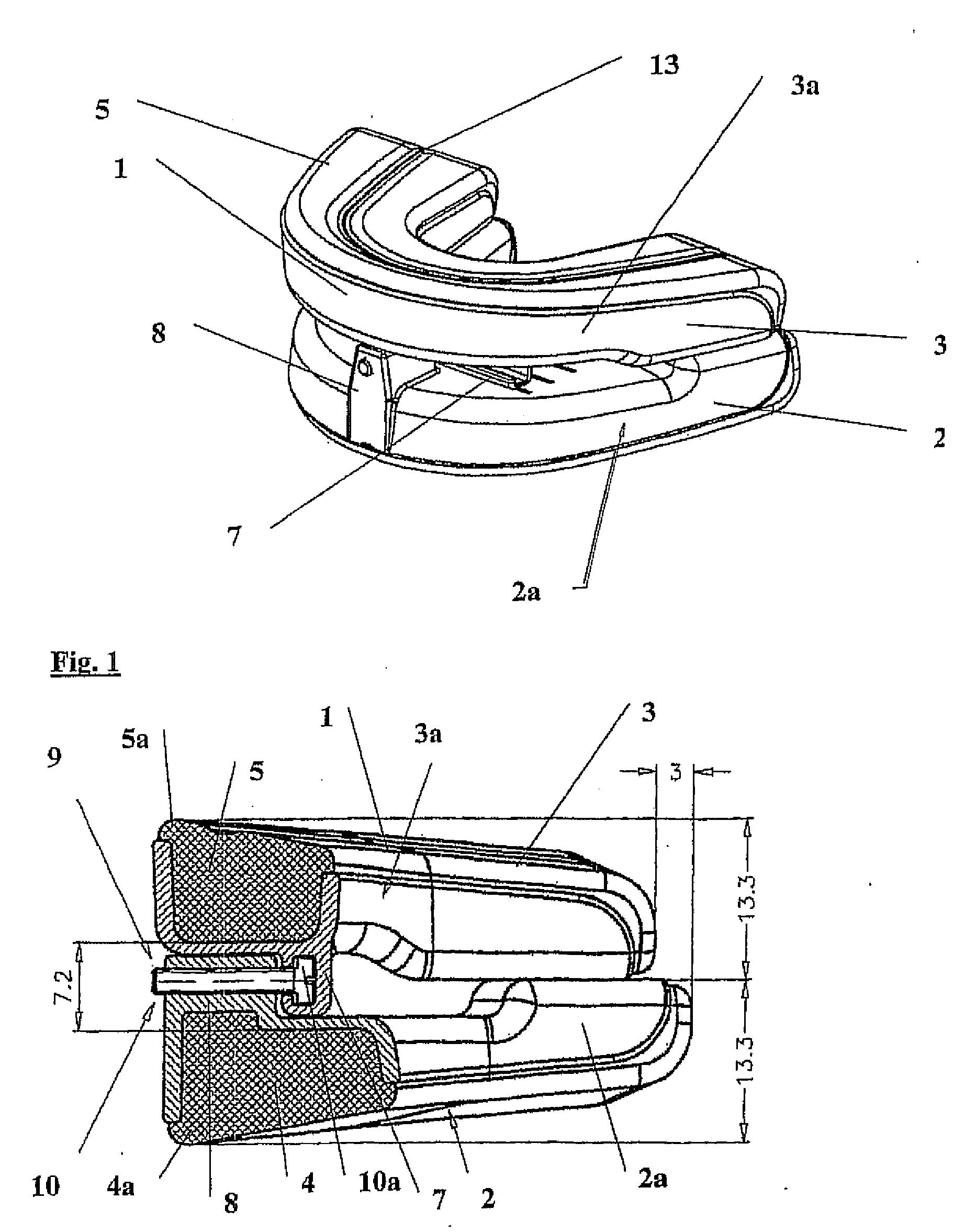

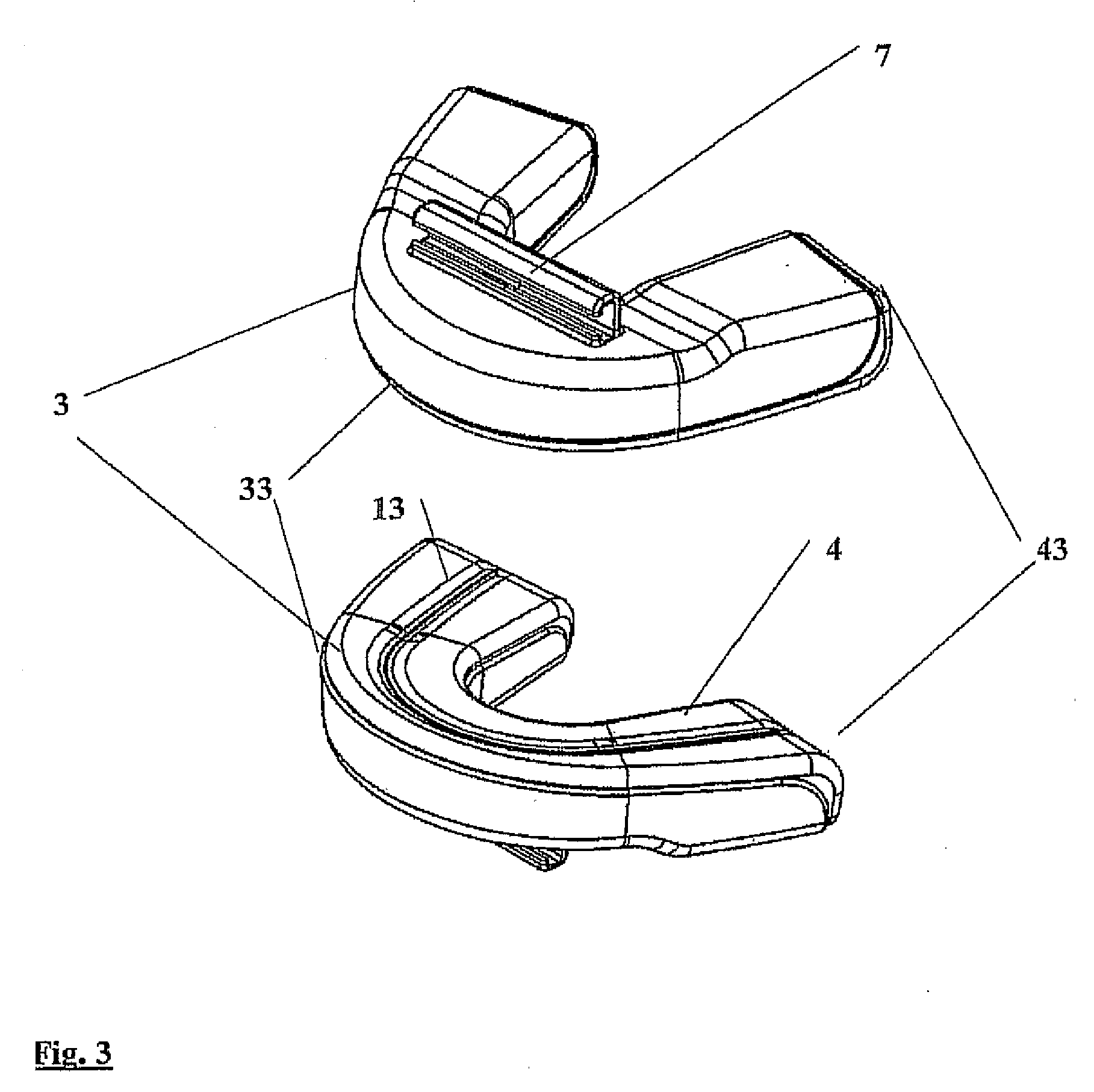

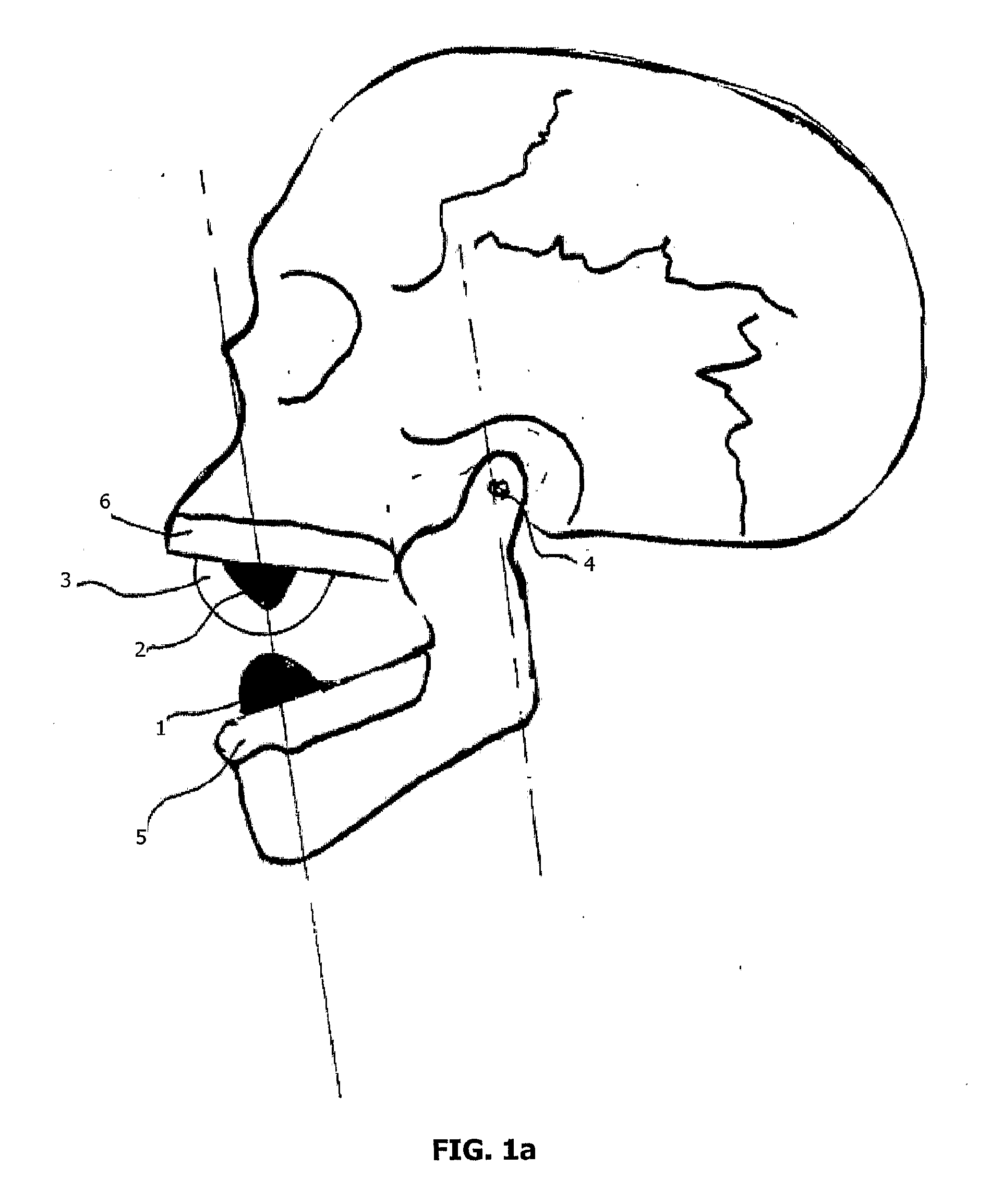

Mandibular Advancement Mouthpiece, An Intraoccusal Removable Improved Device For Eliminating Or Reducing Snoring

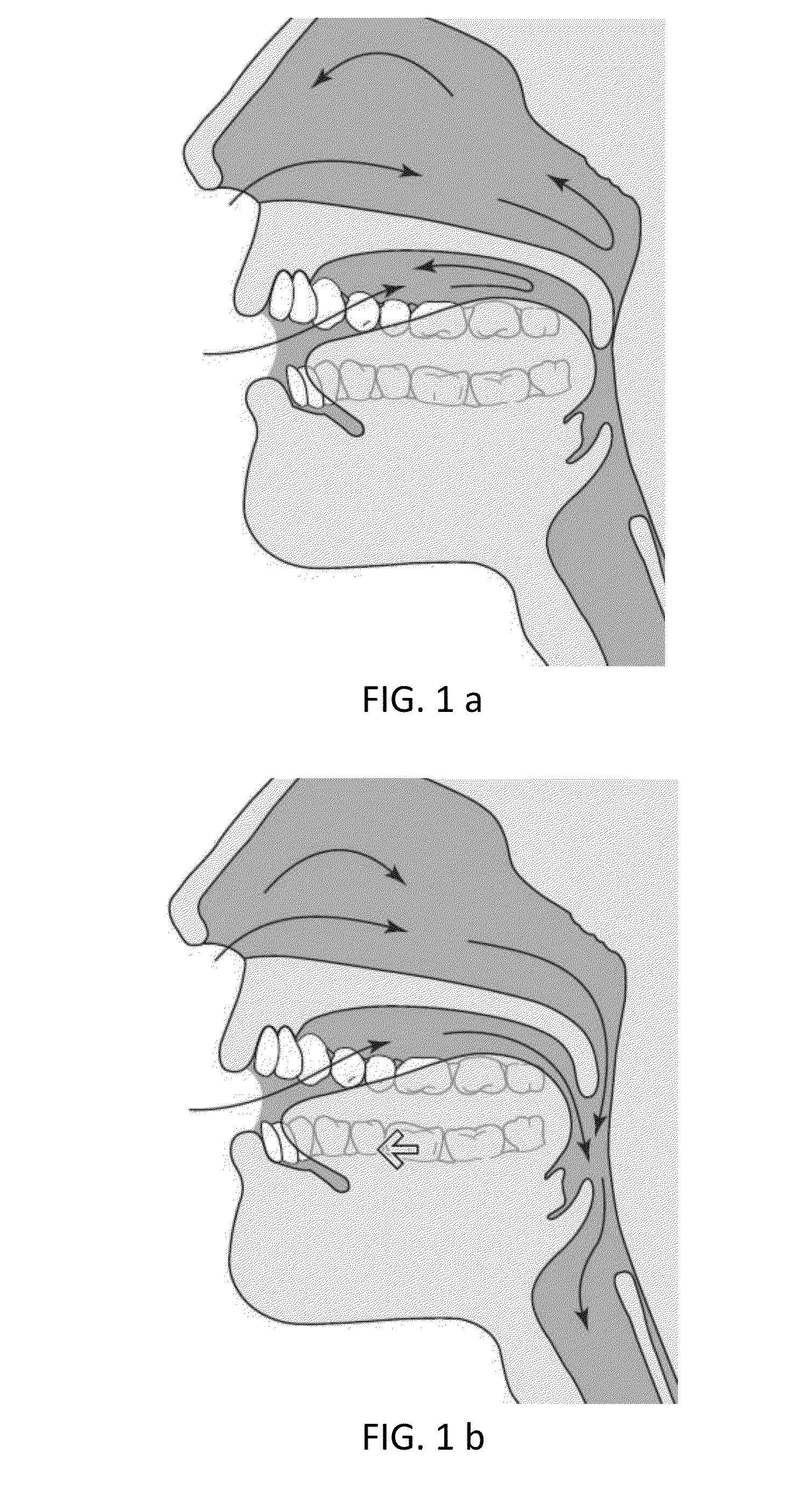

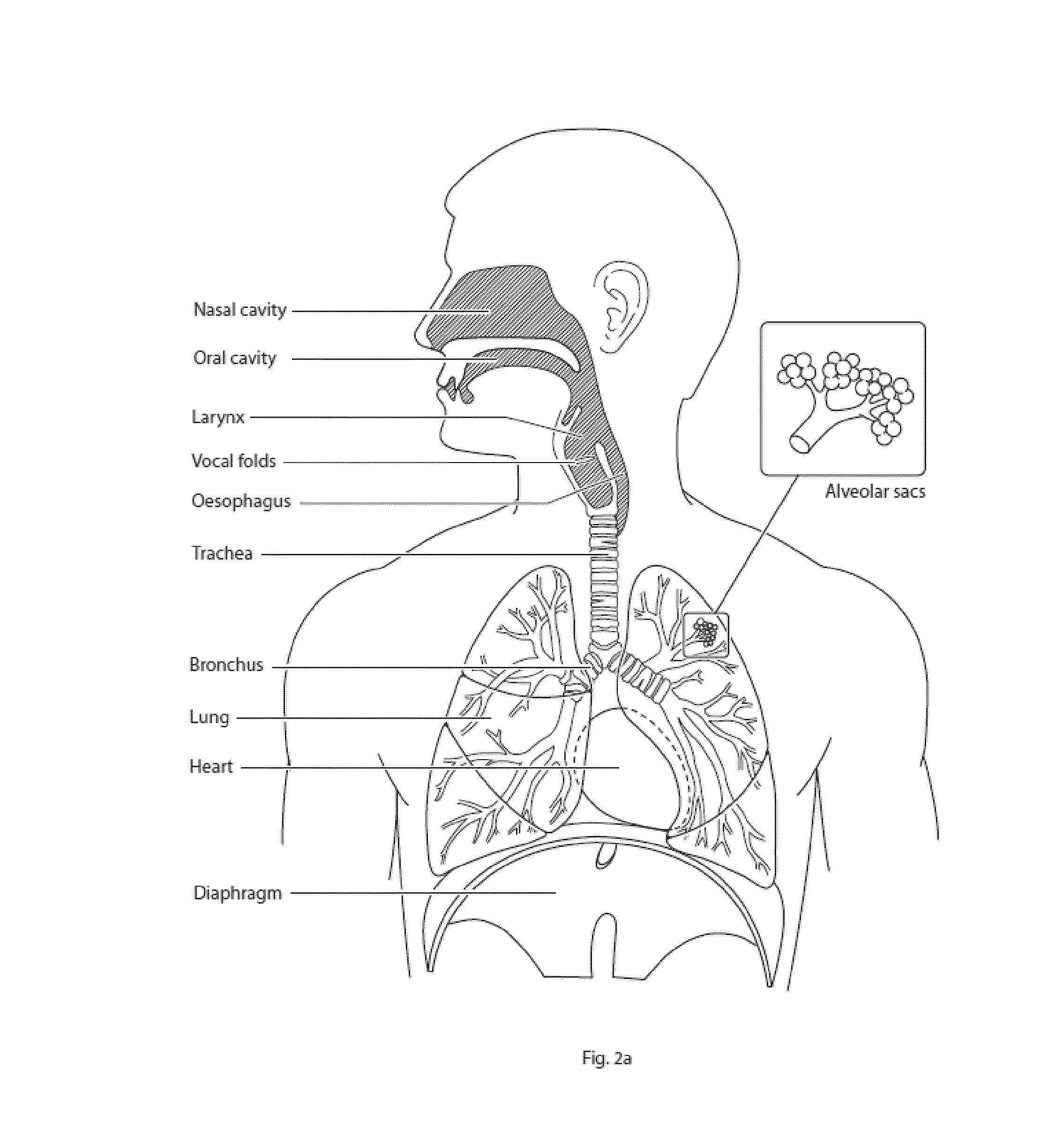

When there is an obstruction to the passage of air through the back of the mouth and nose, the soft palate and the bell collide, producing a vibration called snoring. There are various ways of reducing or eliminating snoring, nasal masks introducing air pressure to the throat (CPAP), surgery of the throat (OPPBA) and devices that are introduced into the mouth to cause a mandibular advancement what increases the oropharyngeal area, improving ventilation, among other solutions. The present invention disclosure an intraocclusal removable device in the form of a “U” that is placed covering all of the upper jaw teeth, wherein two steps, one in each extreme of the lower part of the element, which impede the mandible be closed completely on its normal occlusion, forcing it to produce a forward displacement of the lower jaw.

Owner:HEINE ANDRES

Method and apparatus for mandibular osteosynthesis

InactiveUS6423068B1Enhanced bending easeWiden the optionsInternal osteosythesisBone platesEngineeringSymphysis

An apparatus for osteosynthesis of a mandible. An elongated plate has a plurality of apertures. The plate has a first portion, a second portion, and a central portion intermediate the first and second portions. Each of the apertures within the first portion and within the second portion are disposed in relatively close spaced relationship, and each of the apertures within the central portion are disposed in relatively widely spaced relationship. The width of the plate between apertures is less in the central portion than in the first portion. The plate is more easily bent within the central portion than within the first portion, and can be bent to a relatively small radius in the central portion without distorting the apertures within the central portion. The central portion is sized and located to overlie the symphysis of the mandible.

Owner:ZIMMER BIOMET CMF & THORACIC

Method and apparatus for mandibular osteosynthesis

InactiveUS20020062127A1Quickly and easily contoursCooperate accuratelySuture equipmentsLigamentsBody of mandibleEngineering

A system for mandibular reconstruction generally includes an elongated locking plate having a plurality of internally threaded apertures and a plurality of fasteners. Each fastener includes a main body portion having an upper threaded shaft and a lower threaded shaft. The lower threaded shaft is adapted to engage the mandible. Each fastener further includes a removable head portion internally threaded for engaging the upper shaft portion and externally threaded for engaging a selected one of the internally threaded apertures of the locking plate. In the preferred embodiment, the thread leads of the head portion and lower shaft of the main body portion are identical. A method of mandibular osteosynthesis utilizes the system of osteosynthesis and generally comprises the steps of temporarily securing the elongated locking plate to the mandible with at least one fastener by engaging the threads of the lower portion with the mandible and threadably engaging the head with the locking plate, unthreading the head portion from the main body of the fastener to thereby allow displacement of the locking plate from the mandible without removing the fasteners from the mandible, performing a surgical procedure (e.g., removal of a cancerous growth), and re-securing the elongated plate to the fastener with the removable head portion.

Owner:BIOMET MICROFIXATION

Oral apparatuses and methods for mandibular jaw manipulation

An oral apparatus for mandibular jaw manipulation which in some embodiments may include: an upper tray configured to receive a plurality of maxillary teeth and which may have a first upper anchor member coupled to a first side of the upper tray and a second upper anchor member coupled to a second side of the upper tray; a lower tray configured to receive a plurality of mandibular teeth and which may have a first lower anchor member coupled to a first side of the lower tray and a second lower anchor member coupled to a second side of the lower tray. The first upper anchor member may be configured to contact the first lower anchor member and the second upper anchor member may be configured to contact the second lower anchor member to adjust the positional relationship between the mandible and the maxilla of a mouth.

Owner:ROSS GREGORY K

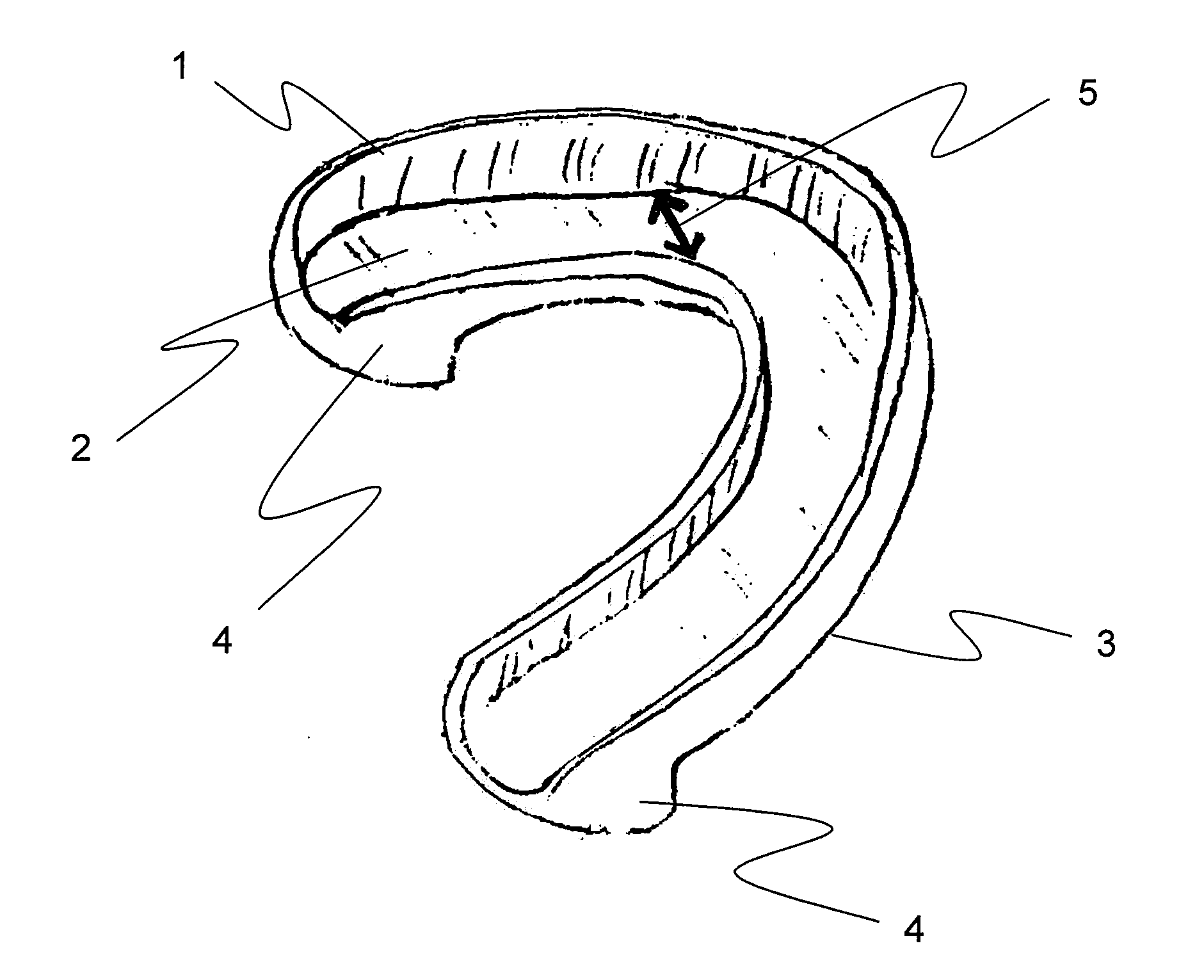

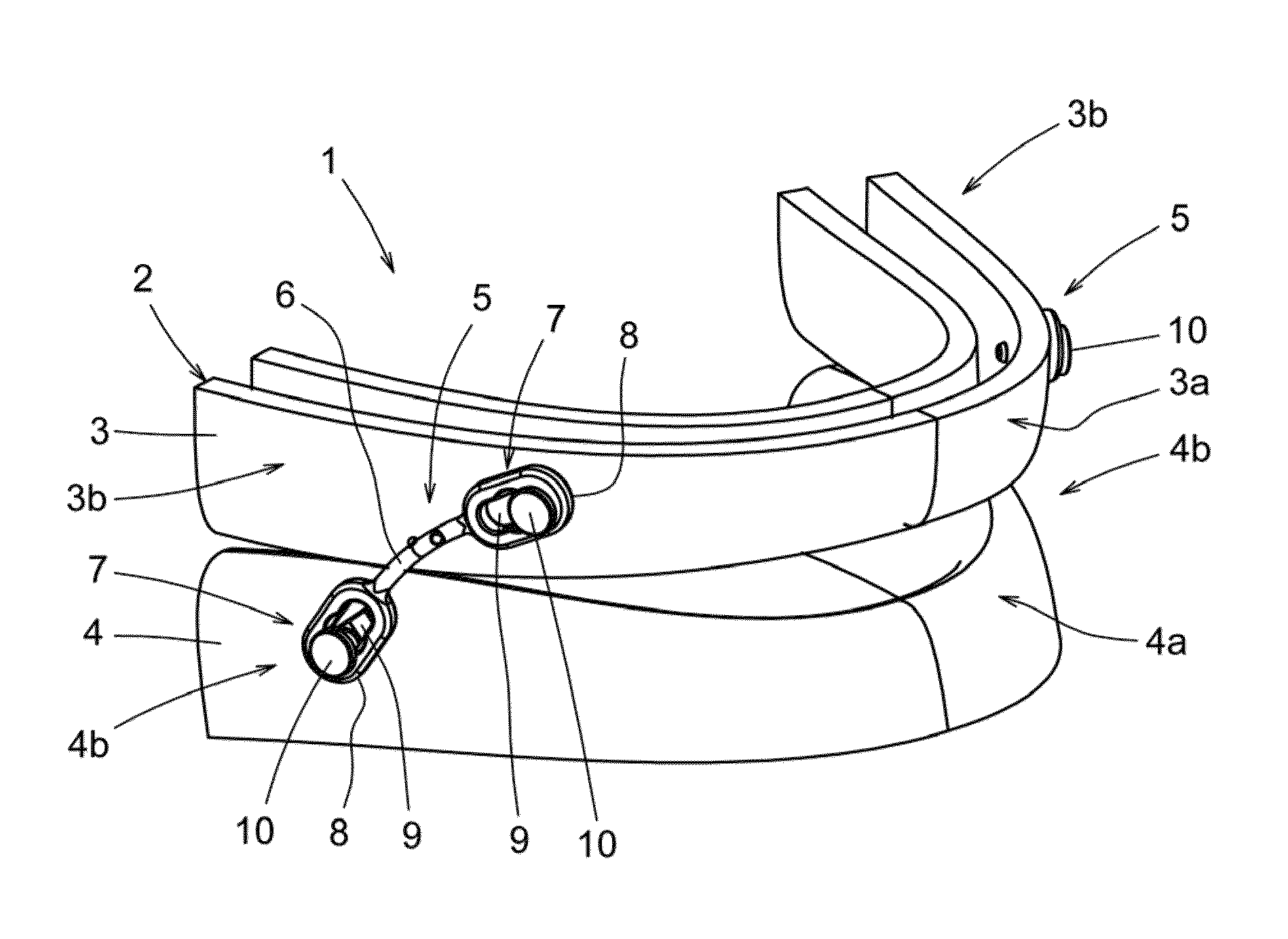

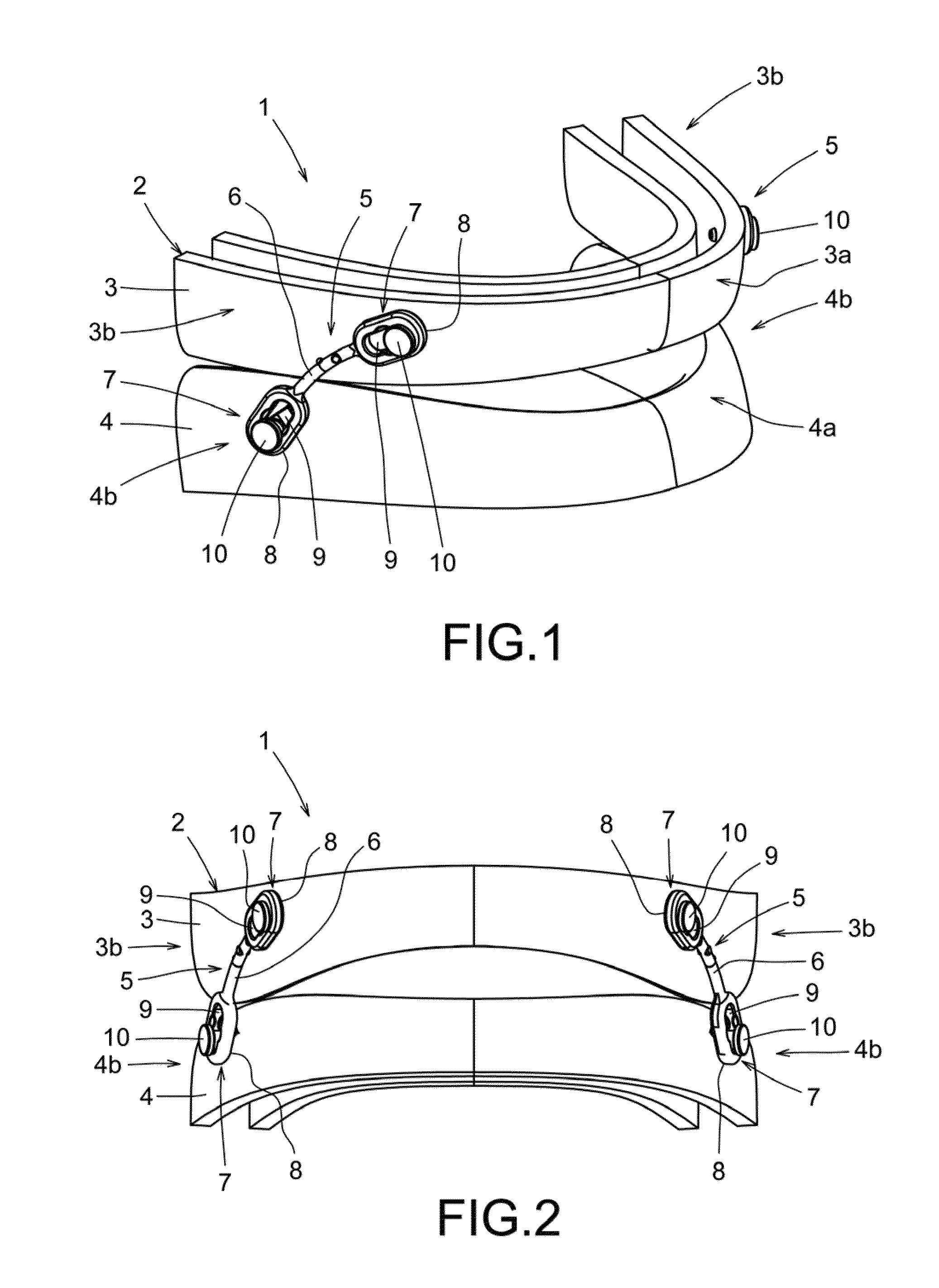

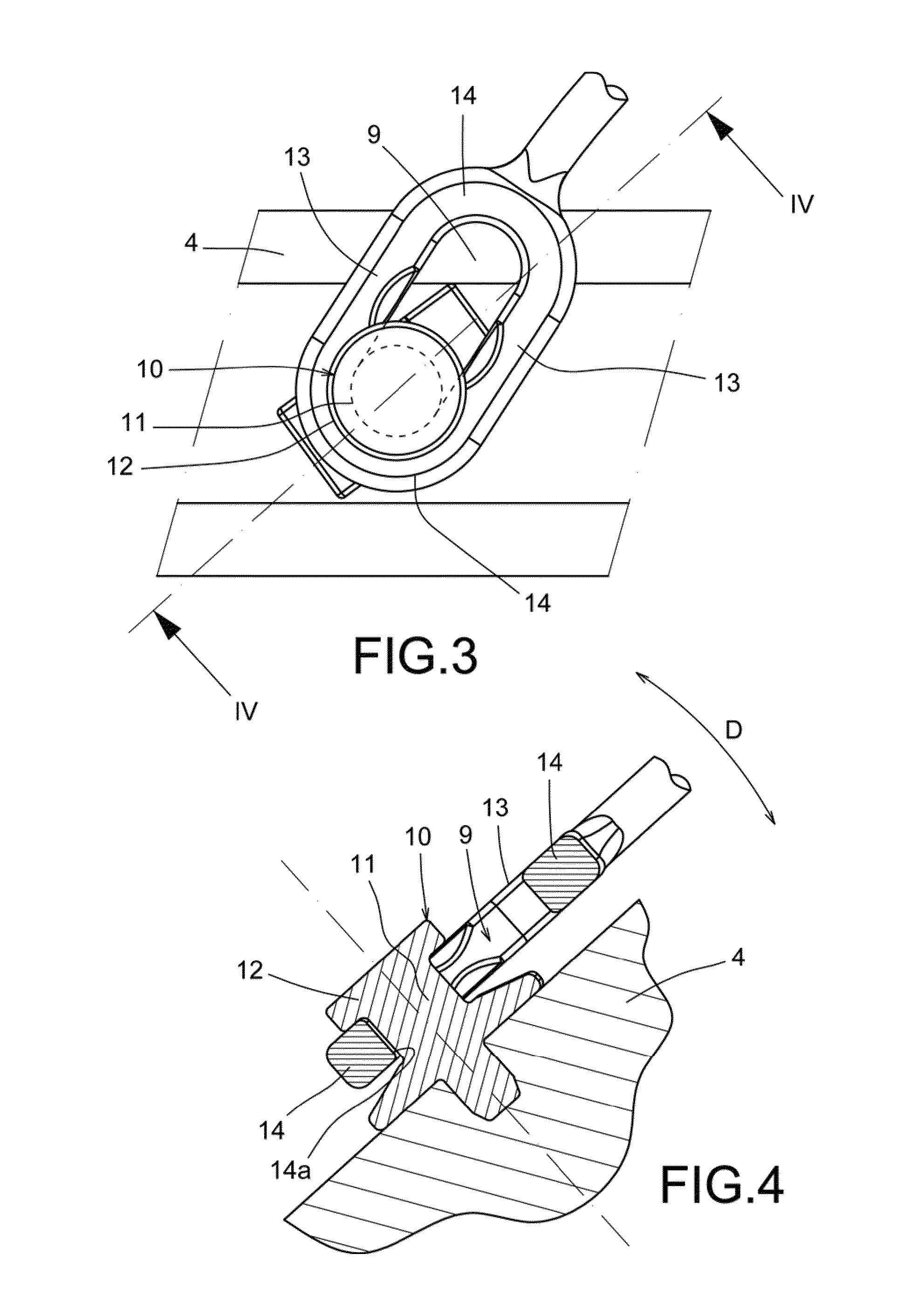

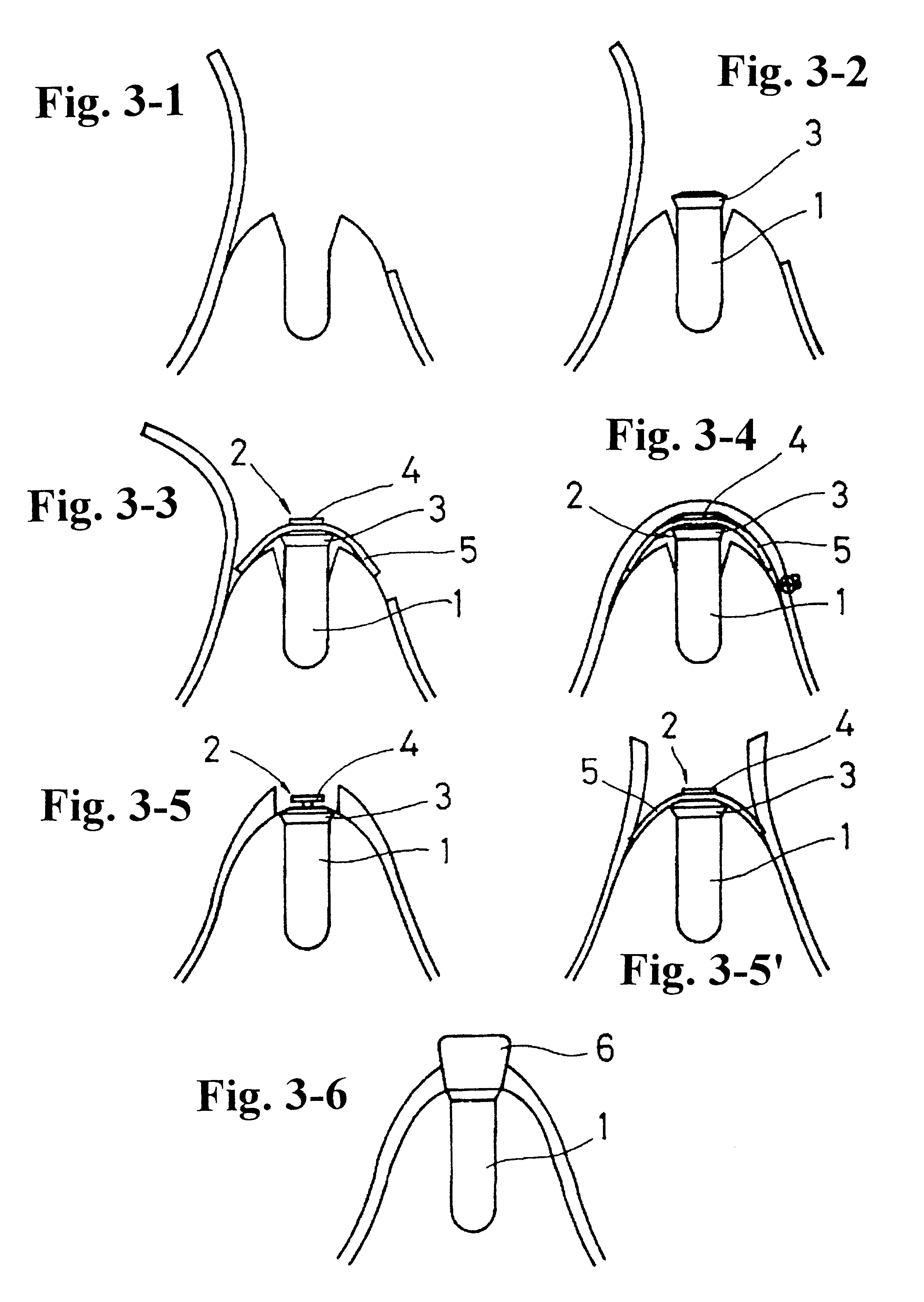

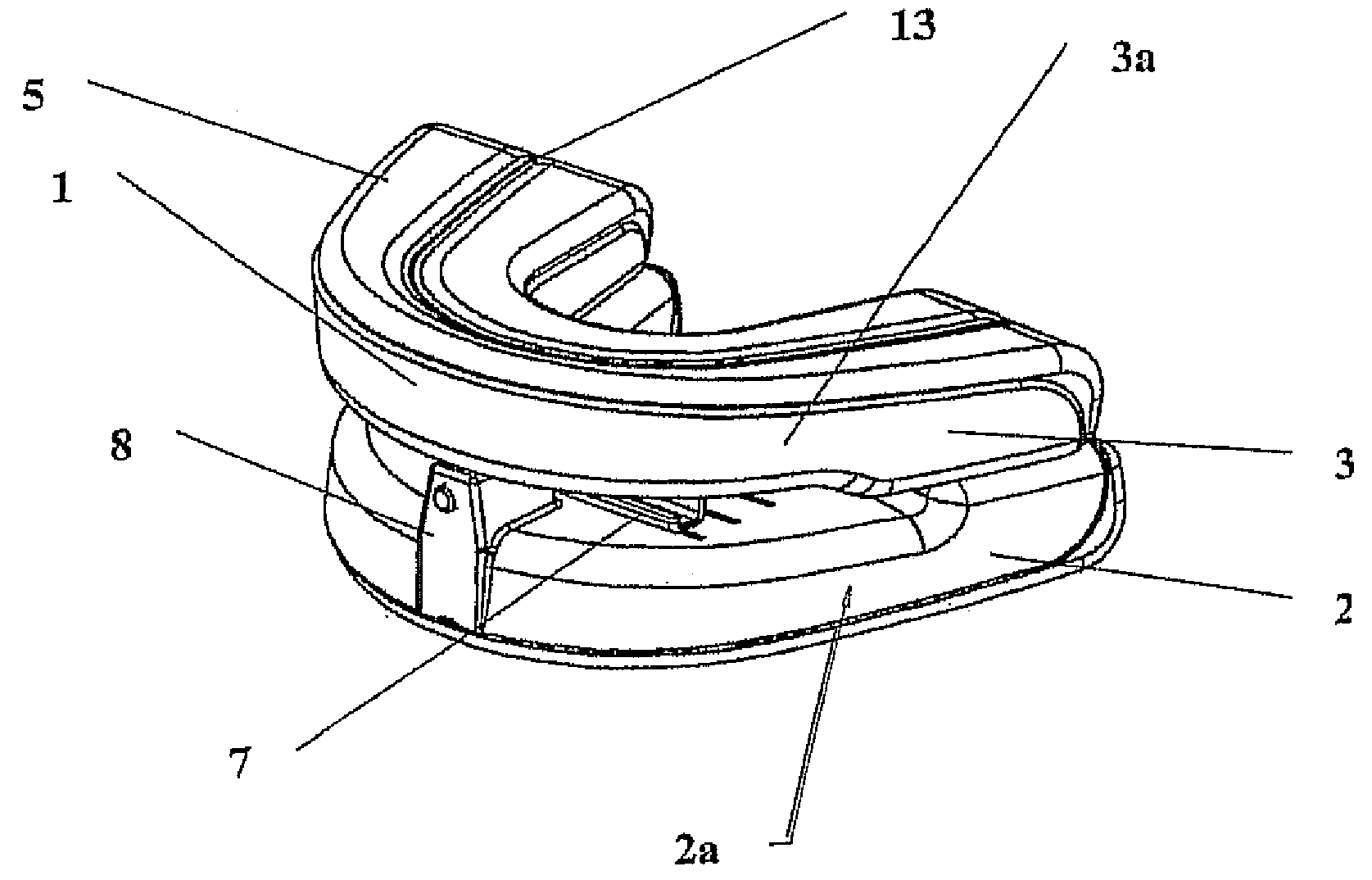

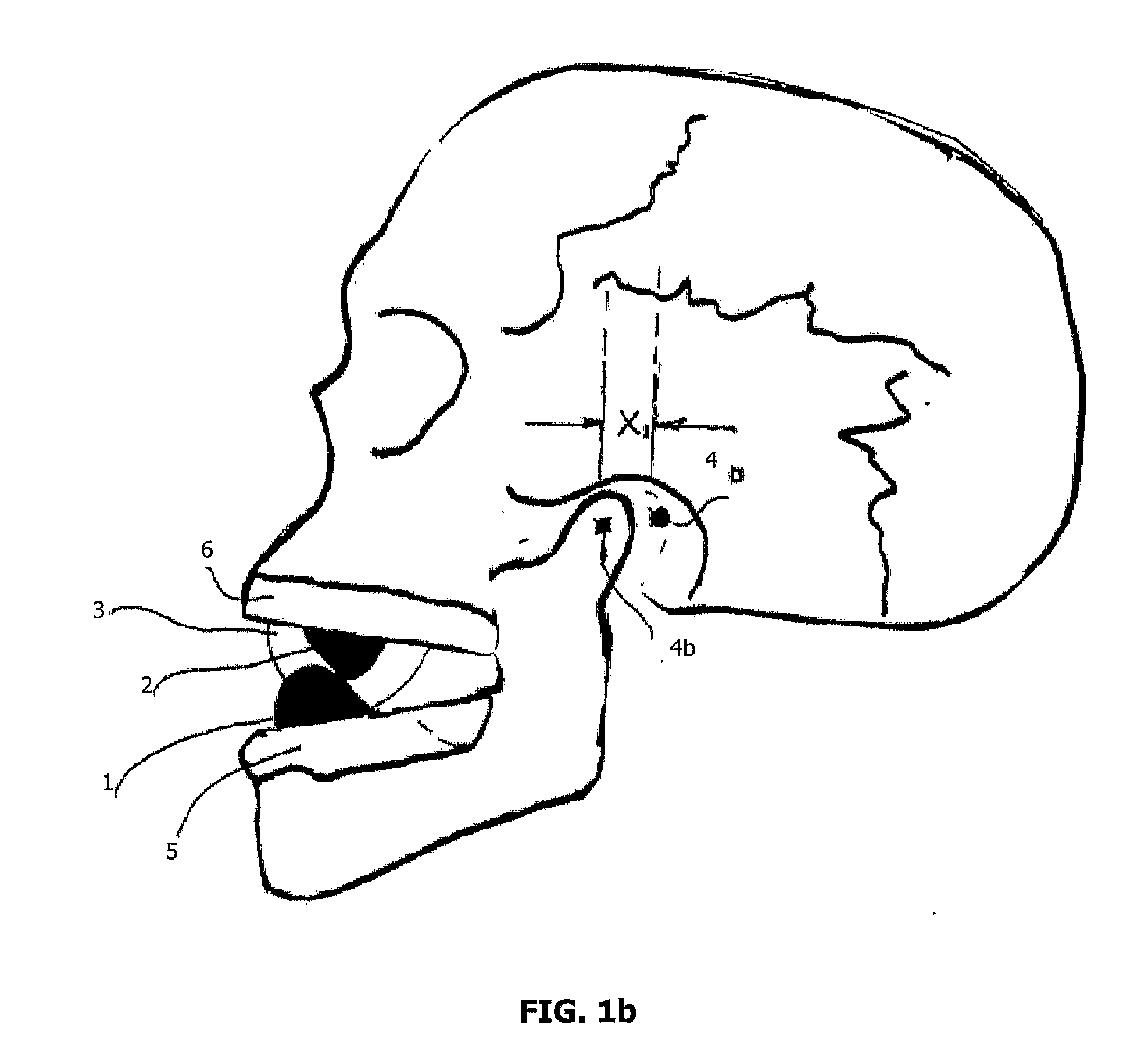

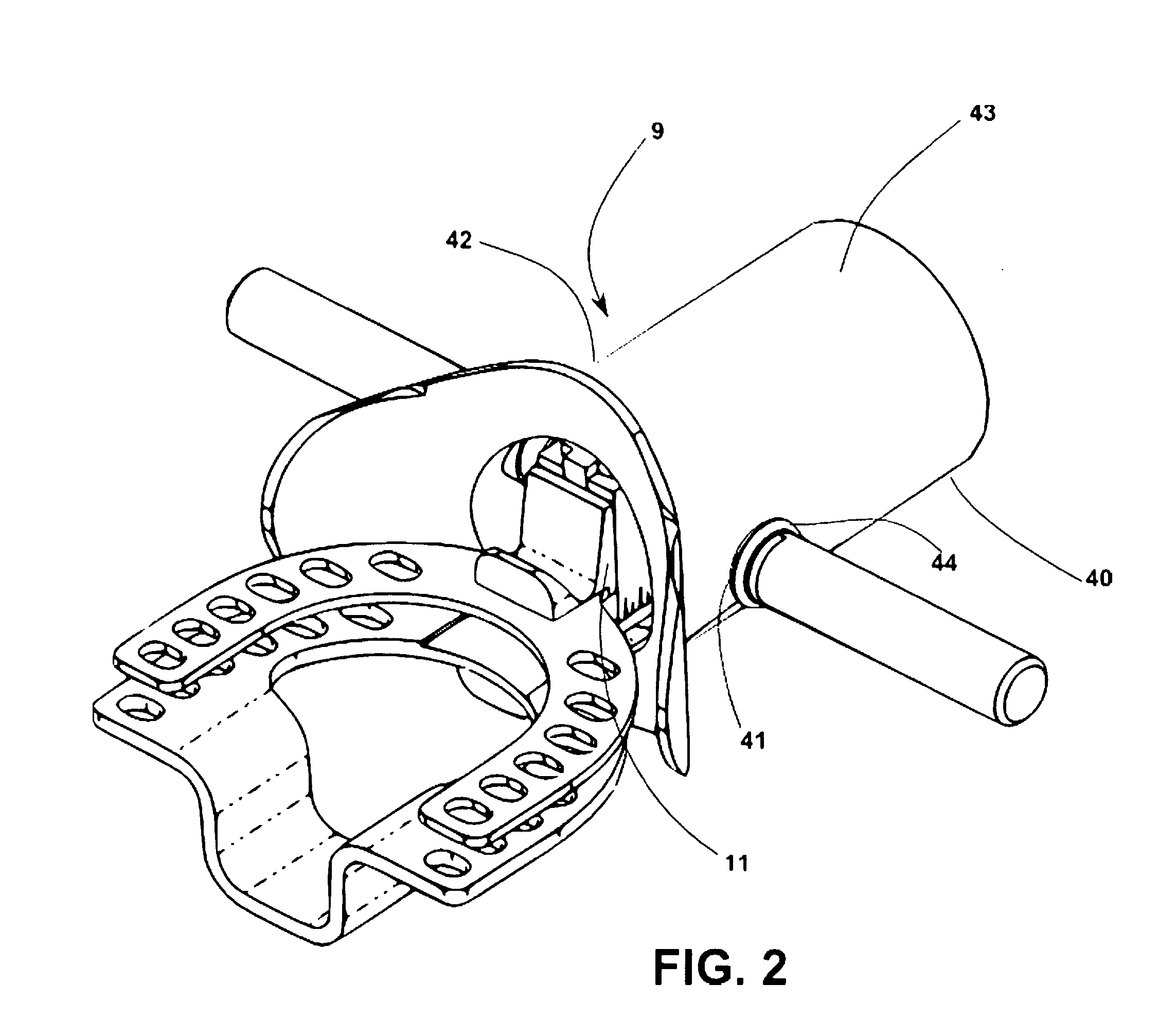

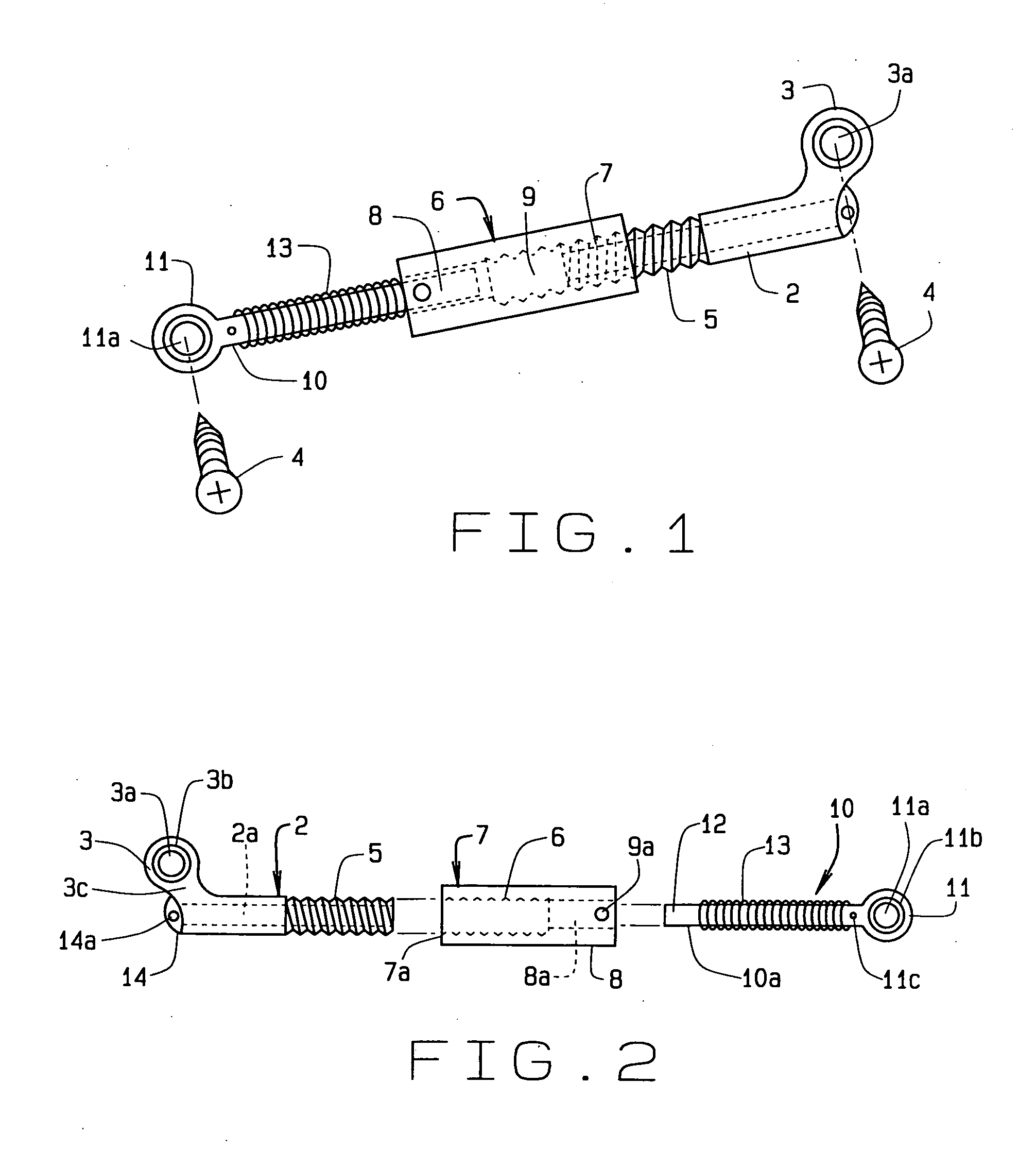

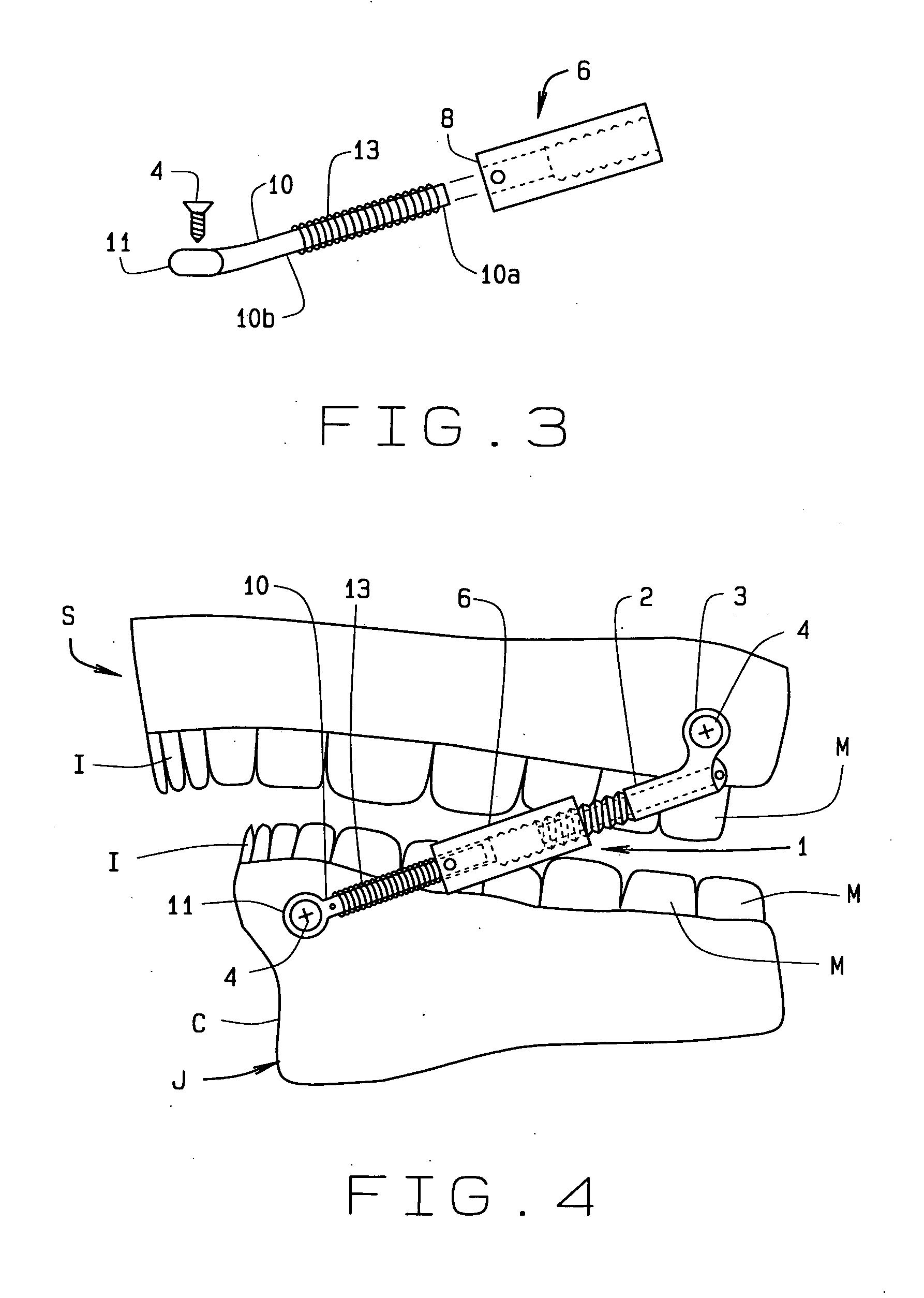

Mandibular advancement device, and a method and kit for preparing said device

InactiveUS20150216716A1Effective treatmentImprove comfortOthrodonticsSnoring preventionEngineeringLateral protrusion

Mandibular advancement device (1; 20) and a device preparation method and kit, comprising a mouthpiece (2) and at least one plastic strap (5; 21) with two ends (7) fitted with a slot (9) that is connected articulately to a respective cylindrical portion (11) of a lateral protrusion (10) of the mouthpiece (2). The slot (9) is closed and is longer in length than the diameter of the cylindrical portion (11), which can move along the slot (9). The strap (5; 21) acts by traction between the cylindrical portions (11) of the mouthpiece (2) to prevent the free return of the lower portion (4) with respect to the upper portion (3) of the mouthpiece (2) and therefore treats apnea, whilst allowing some advancement and lateral movement of the lower portion (4), making it comfortable for the user.

Owner:BIOTECHNOLOGY INST I MAS D SL

Mandibular advancement device

InactiveUS8136529B2Less rigidImprove comfortOthrodonticsSnoring preventionVertical displacementDental lamina

A mandibular advancement device including upper and lower dental plates which operatively fit over at least part of the upper and lower teeth of a user, said upper and lower dental plates being made from a flexible material, the lower dental plate having two pairs of spaced apart pillars, each pair consisting of an anterior and posterior pillar, said pairs being on opposing sides of the lower dental plate, two removably attachable horizontal displacement inserts, mounted in the buccal region on opposite sides of the upper dental plate, two removably attachable vertical displacement inserts mounted in the lower dental plate, placed in a manner to provide correct vertical registration of the teeth, such that operatively each horizontal displacement insert is retained between the respective anterior and posterior pillars to maintain an advancement of the mandible. A method for production of the mandibular advancement device is also claimed.

Owner:BODY BALANCING PTY LTD

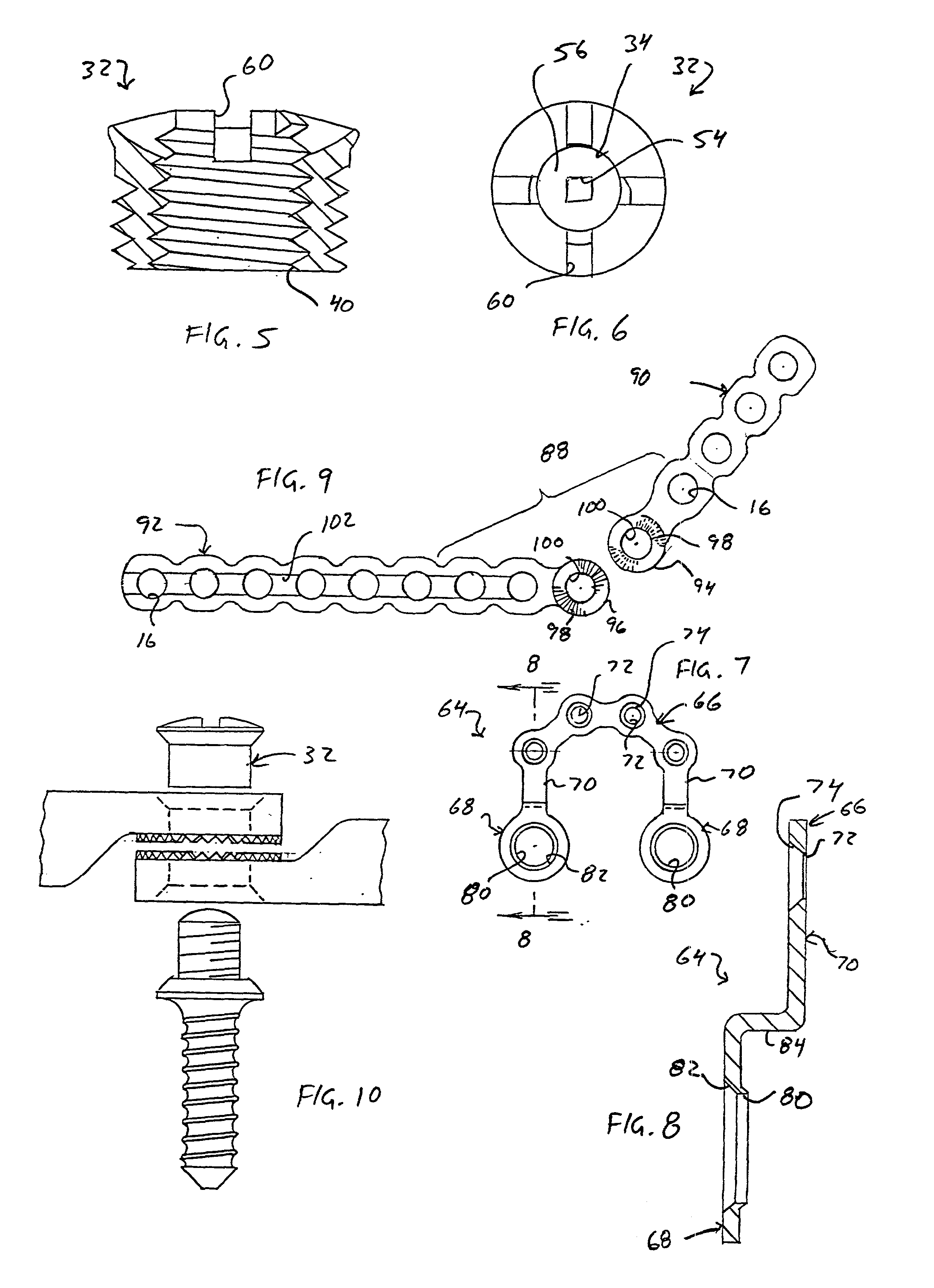

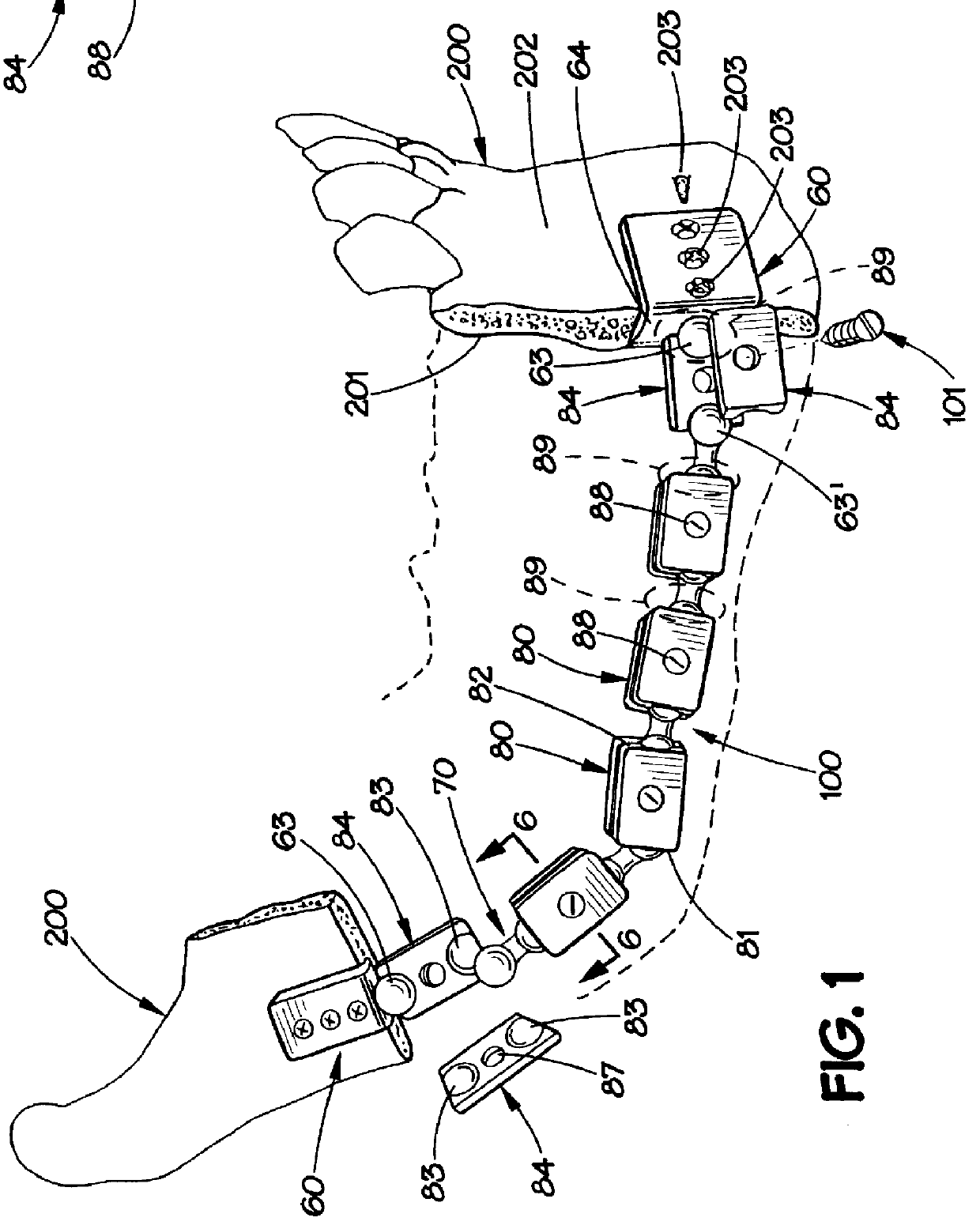

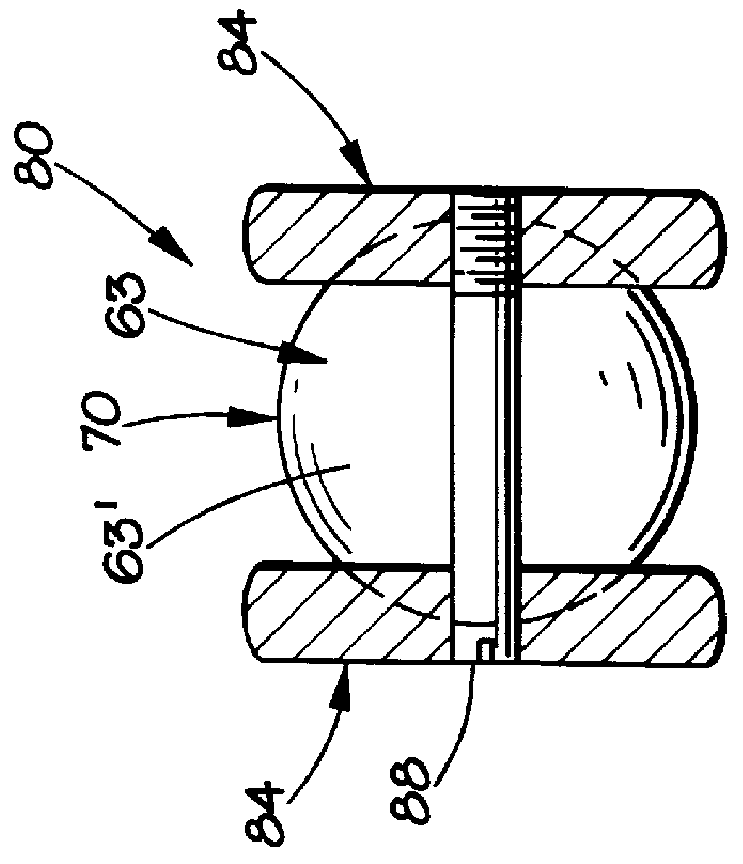

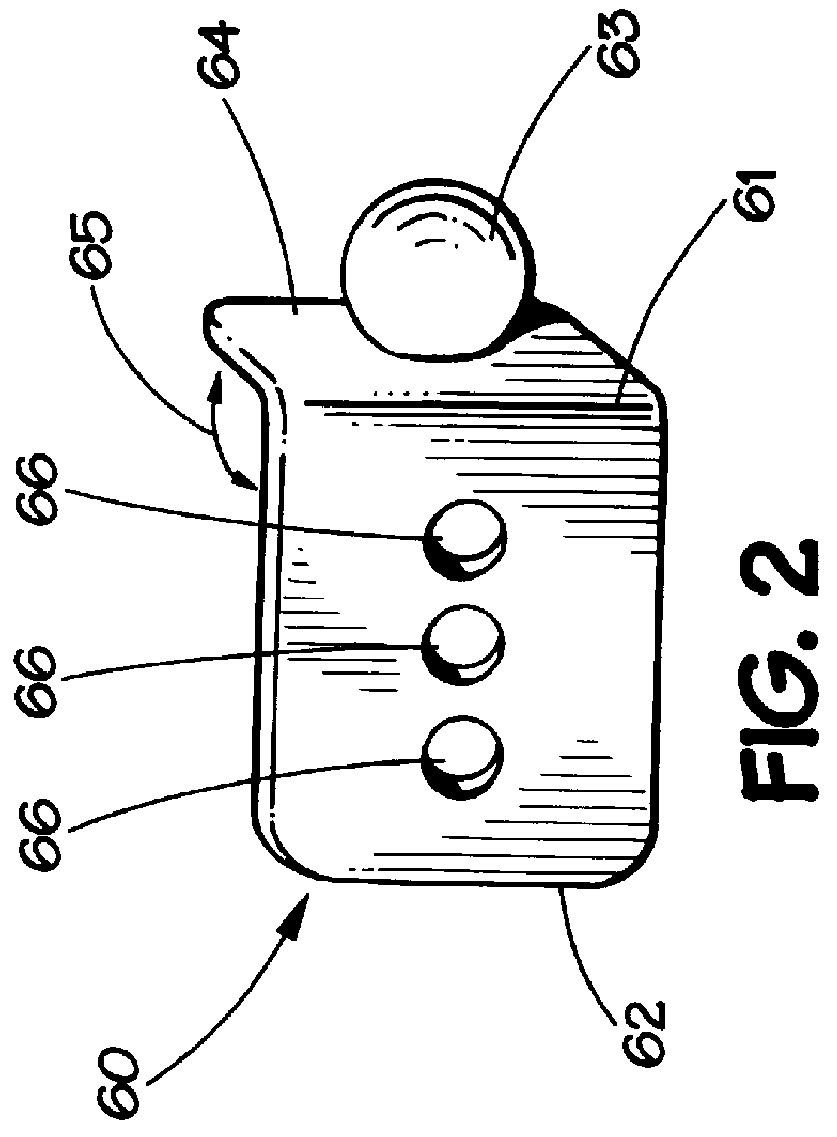

Modular mandibular prosthesis

InactiveUS6060641AEasy to adjustCorrecting occlusionInternal osteosythesisDiagnosticsCouplingEngineering

The invention relates to a modular mandibular prosthesis for use after the resection of a patient's mandible. The modular mandibular prosthesis includes a pair of anchor plates and at least one connector member. Each anchor plate has first and second ends. The second end of each anchor plate is adapted to be attached to a portion of the patient's mandible. At least one connector member is disposed between the pair of anchor plates. Each connector member includes first and second ends. The first end of a connector member is connected to the first end of an anchor plate thereby defining a connection. The second end of a connector member is connected to the first end of the other anchor plate. Additional connector members may be disposed between the anchor plates wherein the first end of the additional connector member is attached to the second end of an adjacent connector member thereby defining a connection and the second end of the additional connector member is connected to the first end of an adjacent connector member thereby defining a connection. Each connection defines a swivel coupling which permits three dimensional movement at each connection thereby facilitating orientation and installation of the modular mandibular prosthesis.

Owner:BAYLOR COLLEGE OF MEDICINE

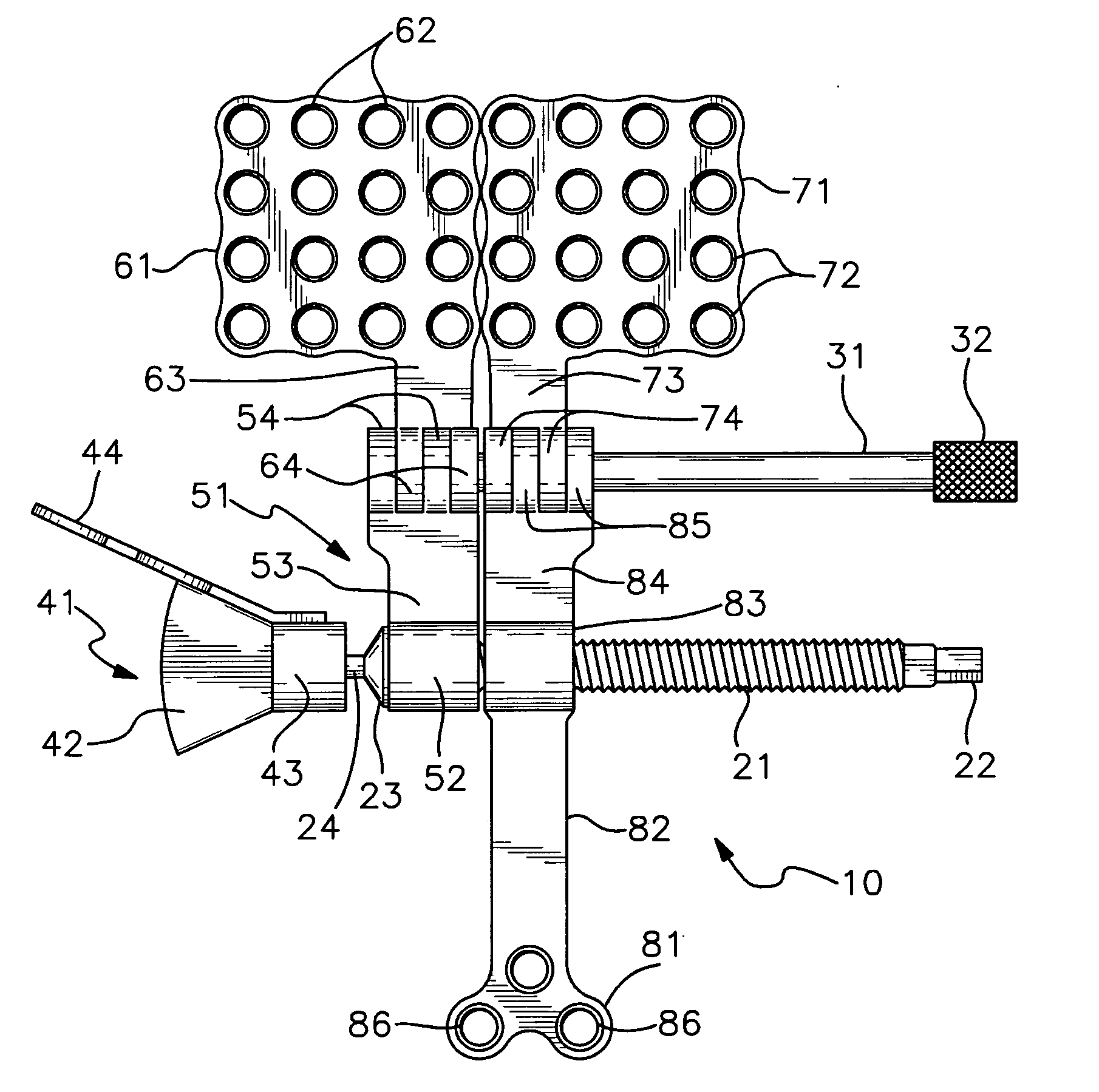

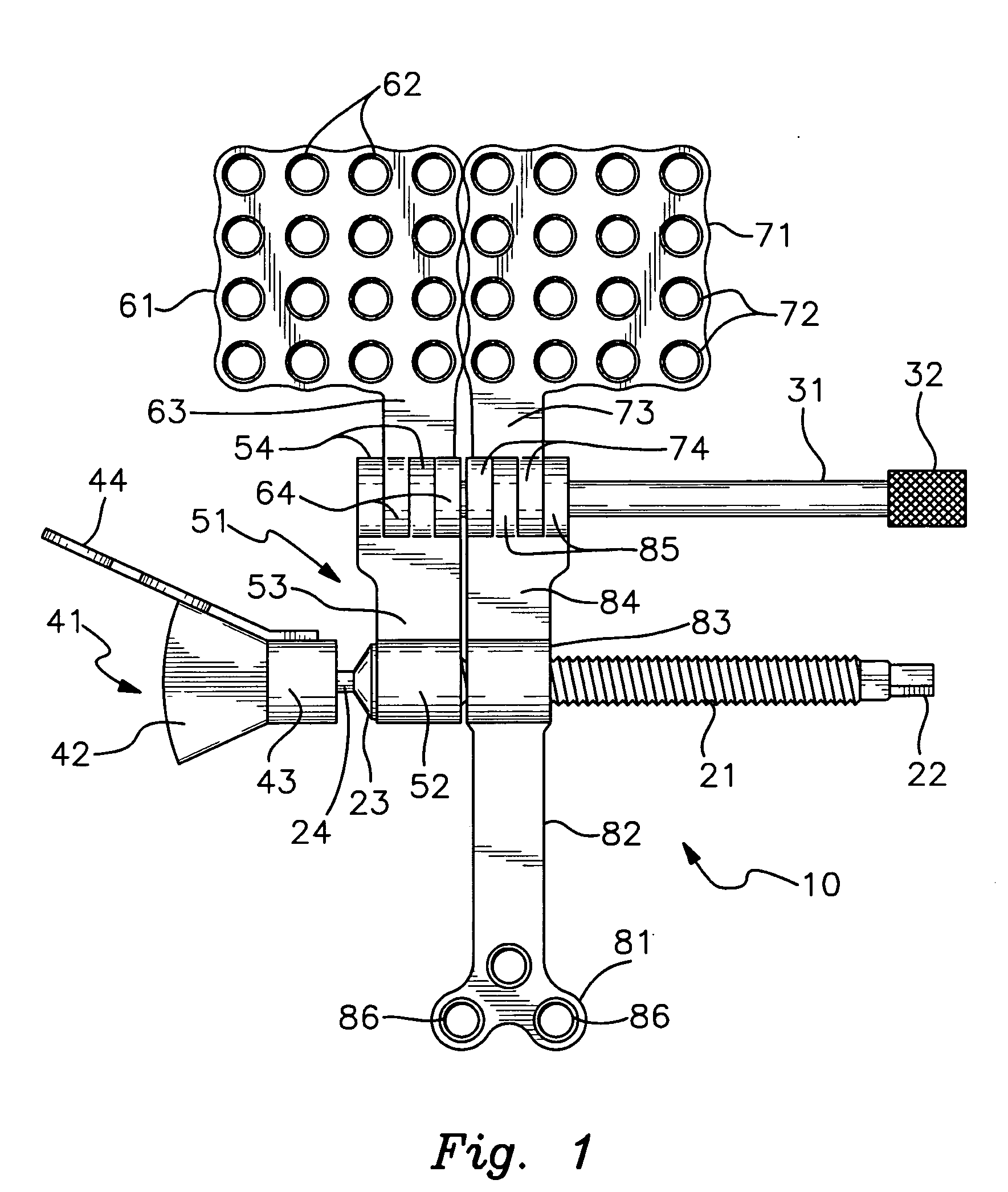

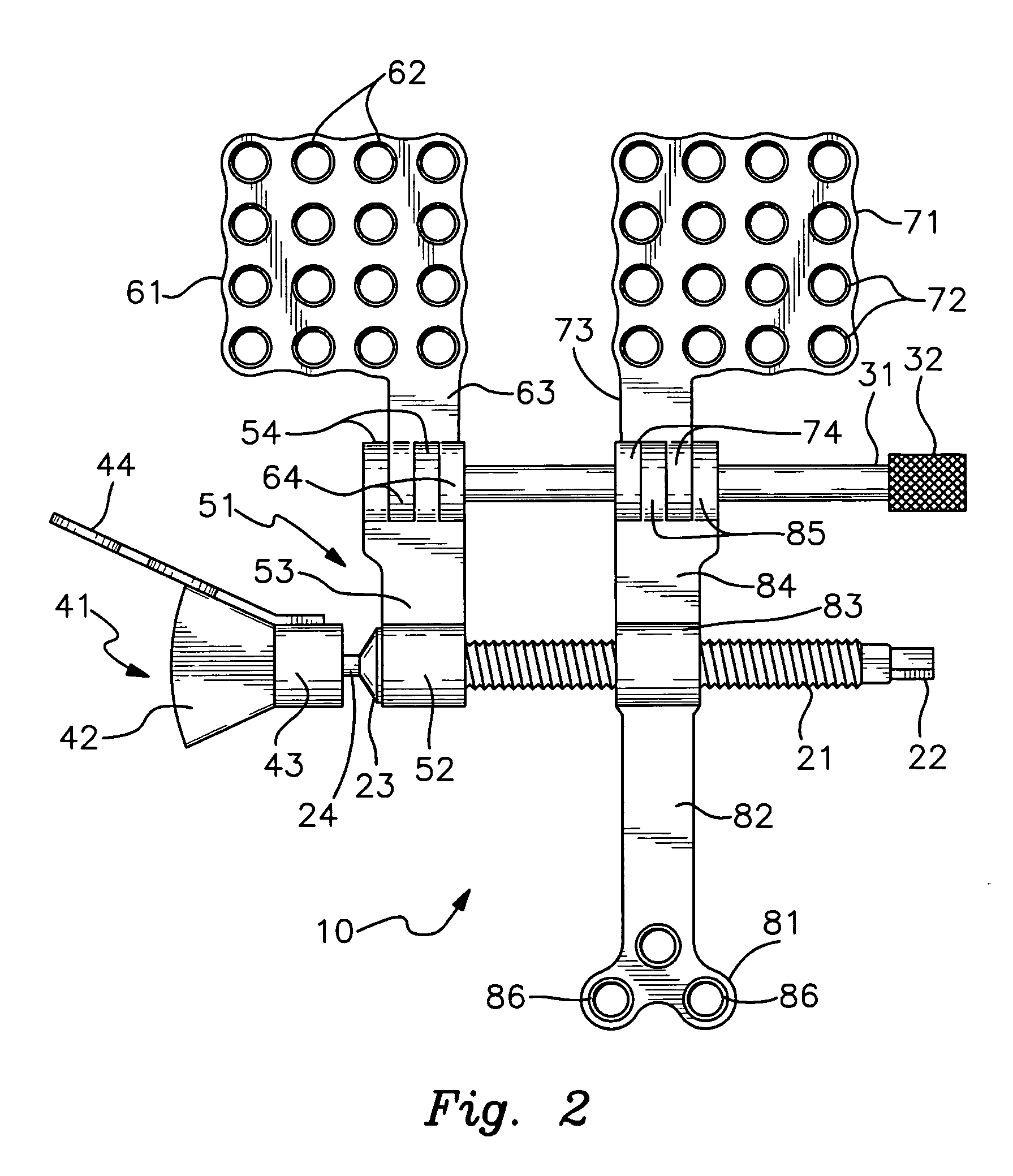

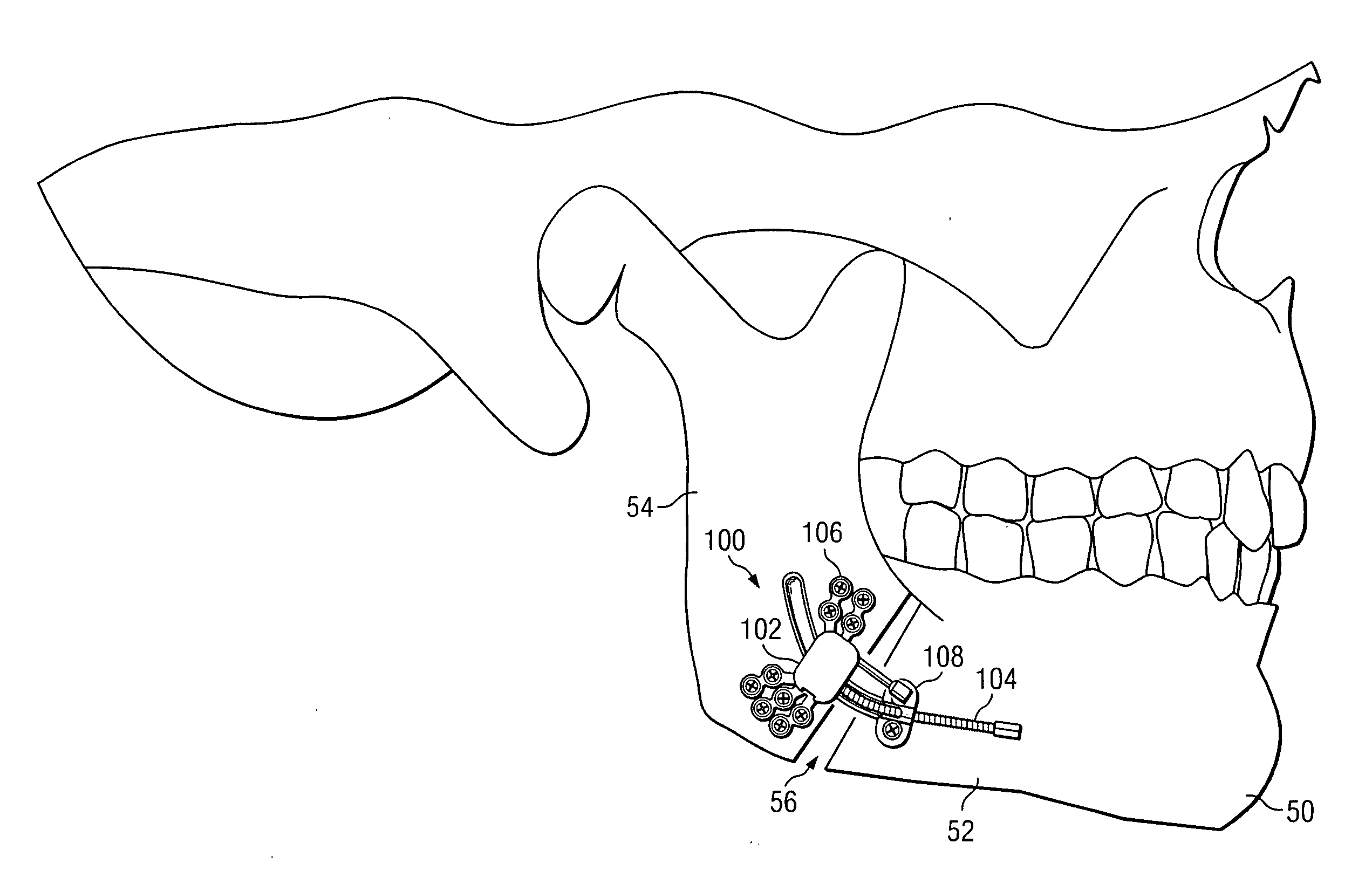

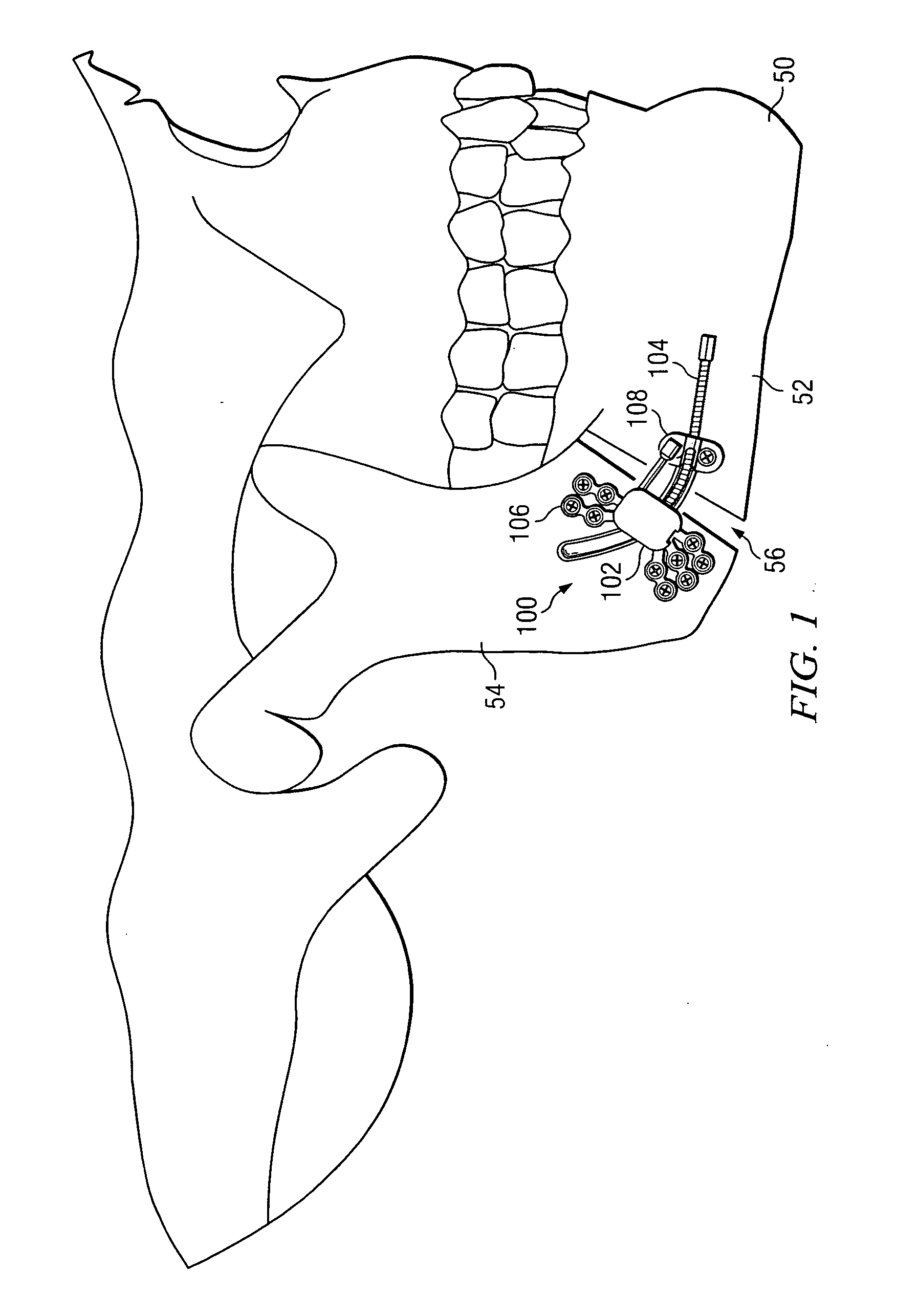

Bone distractor and method

InactiveUS20050256526A1Quick releaseJoint implantsExternal osteosynthesisMaxilla/MaxillaryAnterior maxilla

A bone distractor having four bone plate attachment members for affixation to the posterior and anterior maxilla and / or zygomatic buttress and to the posterior and anterior mandible, the attachment members mounted onto a pair of parallel rods, one rod being a threaded drive rod and the other being a releasable guide rod, whereby rotation of the drive rod causes dimensional separation of the anterior attachment members from the posterior attachment members. The guide rod can be quickly removed such the superior attachment members joined to the maxilla and / or zygomatic buttress are physically separated from the inferior attachment members joined to the mandible such that the jaw can be opened.

Owner:KLS MARTIN LP

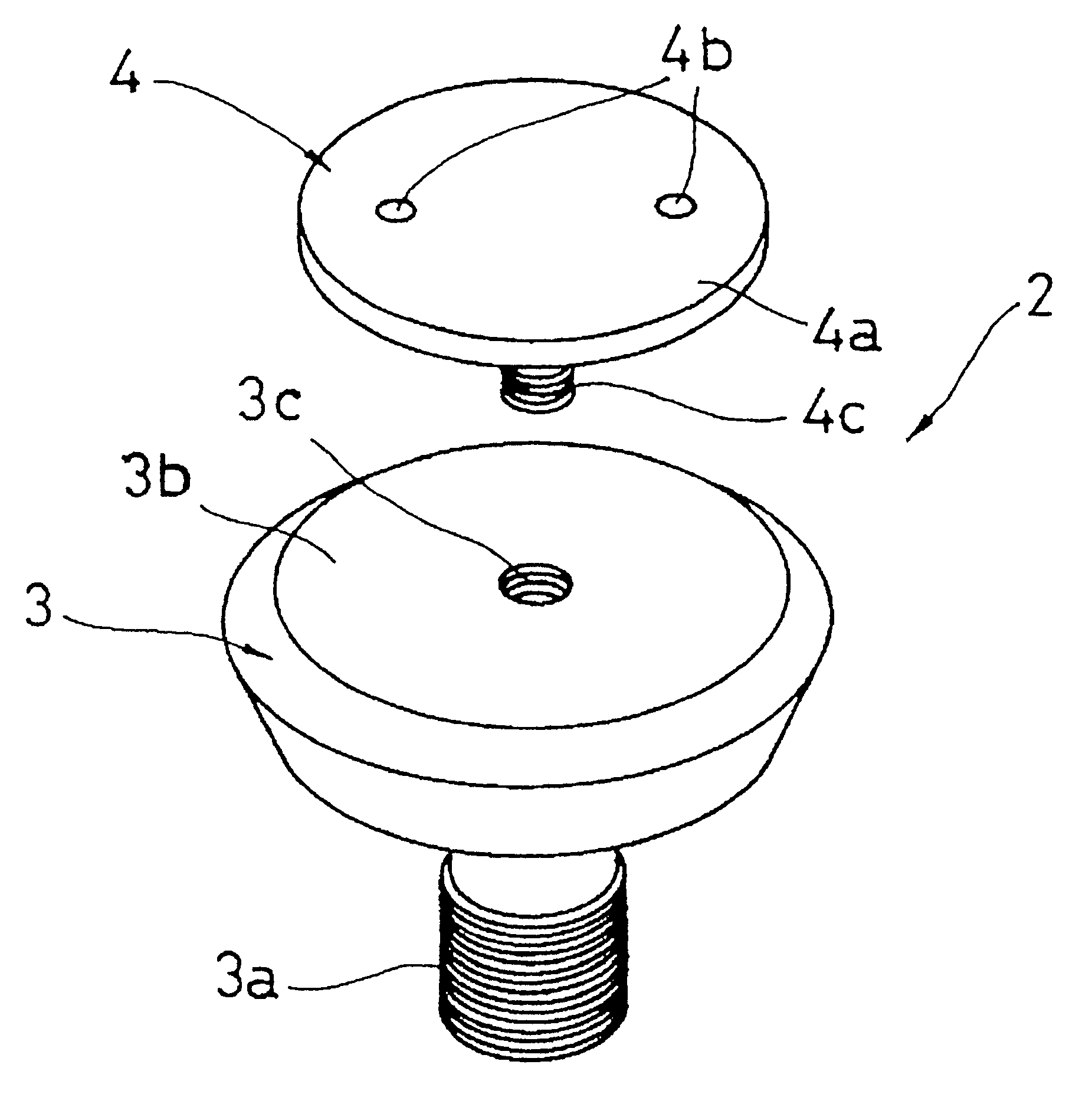

Cover screw for dental implant

A cover screw for a dental implant seals a threaded hole of an implant fixture formed in a mandible or maxilla. The cover screw is formed of a main body and a membrane fixing screw, and is attached to the implant fixture until the implant fixture is thoroughly connected to the mandible or maxilla in an implantation hole. The main body includes a first male screw to be screwed into the threaded hole of the implant fixture, an outer face formed on a side opposite to the male screw and facing an oral cavity, and a threaded hole formed on a side of the outer face. The threaded hole has a diameter smaller than that of the male screw and extends parallel to the male screw. The membrane fixing screw has a head, and a second male screw to be screwed in the threaded hole. A barrier membrane is properly held between the main body and the head.

Owner:GC CORP

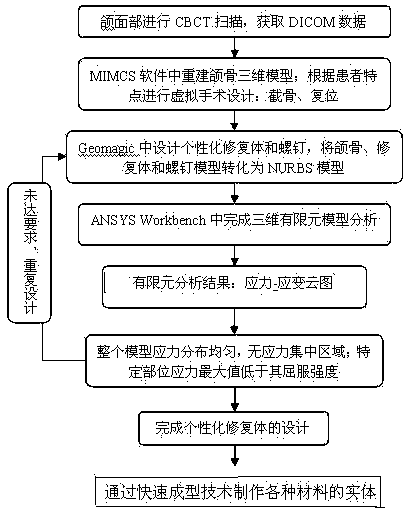

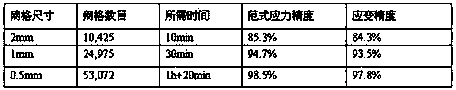

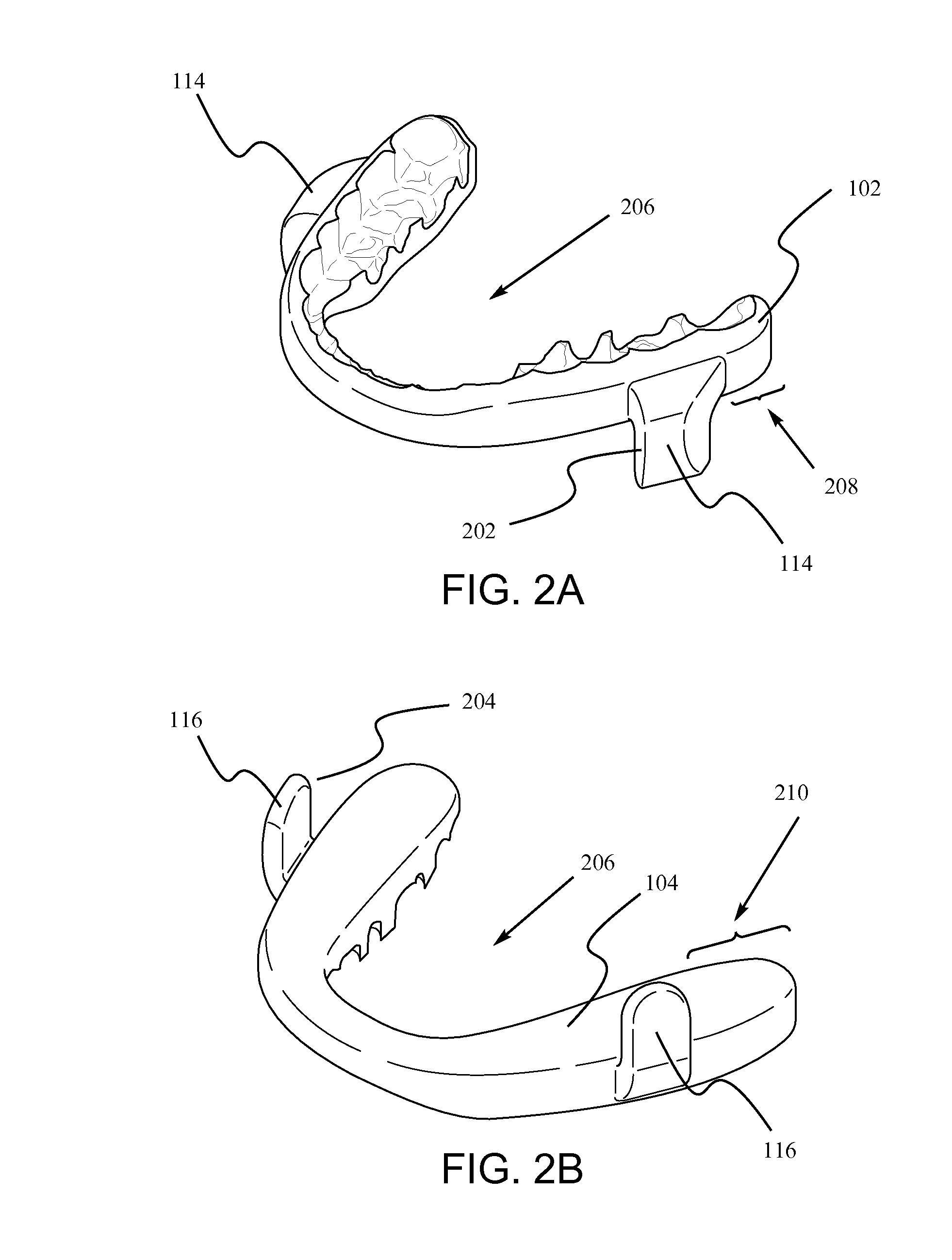

Manufacturing method for jaw defect individual restoration

ActiveCN103919631AHigh breaking strengthIncrease stressBone implantSurgeryBiomechanicsComputer-aided

The invention relates to the fields of computer-aided technology and maxillofacial plastic medical apparatus and instruments, in particular to an optimal design and manufacturing method for a jaw defect individual restoration. The optimal design and manufacturing method is characterized by comprising the following steps: conducting CBCT scanning on the maxillofacial part of a patient, obtaining DICOM data, guiding the data into three-dimensional modeling software-MIMICS (Materialise, Belgium) to reconstruct a jaw three-dimensional model, designing the individual restoration, designing models of a plurality of virtual screw according to the size of retention screws supposed to be adopted, then moving the models to the appropriate positions of the jaw to simulate the situation to the screw retention restoration, obtaining Von Mises stress and a strain nephogram, and manufacturing entities of various materials through the fast forming technology. The jaw defect individual restoration made through the manufacturing method for the jaw defect individual restoration has good performance in biomechanical properties including breaking strength, stress-strain distribution, the service life and the like. So far, a patient with upper and lower jaw defects accepting an implanting operation is observed for two years, and no bad complications of fracture, exposure and the like happen.

Owner:SICHUAN UNIV

Mandibular advancement device

ActiveUS20160184129A1Reducing partial constriction of airwayOthrodonticsSnoring preventionDentitionConstriction

Disclosed herein are mandibular advancement devices comprising an upper splint and a lower splint, where the upper splint comprises one or more upper fins, where each upper fin is located at a distance UD from back of the upper splint; the lower splints comprise one or more lower fins, where each lower fin is located at a distance LD from back of the lower splint; where the position of the upper and lower fins is unchangeable. Also disclosed are methods of reducing partial constriction of airway during sleep for a patient, the method comprising identifying a patient in need thereof; and administering to the patient the disclosed mandibular advancement device. Also disclosed are methods of manufacturing a mandibular advancement device, the method comprising obtaining measurements from a patient's dentition; digitally designing a mandibular advancement device; and milling the mandibular advancement device.

Owner:PROSOMNUS SLEEP TECH INC

Mandibular repositioning device

ActiveUS20140326253A1Improve comfortImprove gripProgramme controlImage enhancementEngineeringMaxilla/Maxillary

Owner:RESMED SAS

Continously adjustable mandibular protrusion splint for treating snoring and obstructive sleep apnoea

ActiveUS20090090371A1Positive effect wearing comfortDeep and uniform impressionSnoring preventionDental toolsMaxilla/MaxillaryReady to use

Owner:YILDIZ FAHRI DR

Mandibular occlusal inhibitor

A device for maintaining a patient's mouth in an open position during a medical procedure is provided. The device includes a cylindrical body configured to be received in the patient's mouth. A flange extending from an edge of the body is configured to engage the face of the patient, and preferably, the device includes a retainer for retaining the body in the patient's mouth.

Owner:THE CHILDRENS HOSPITAL OF PHILADELPHIA

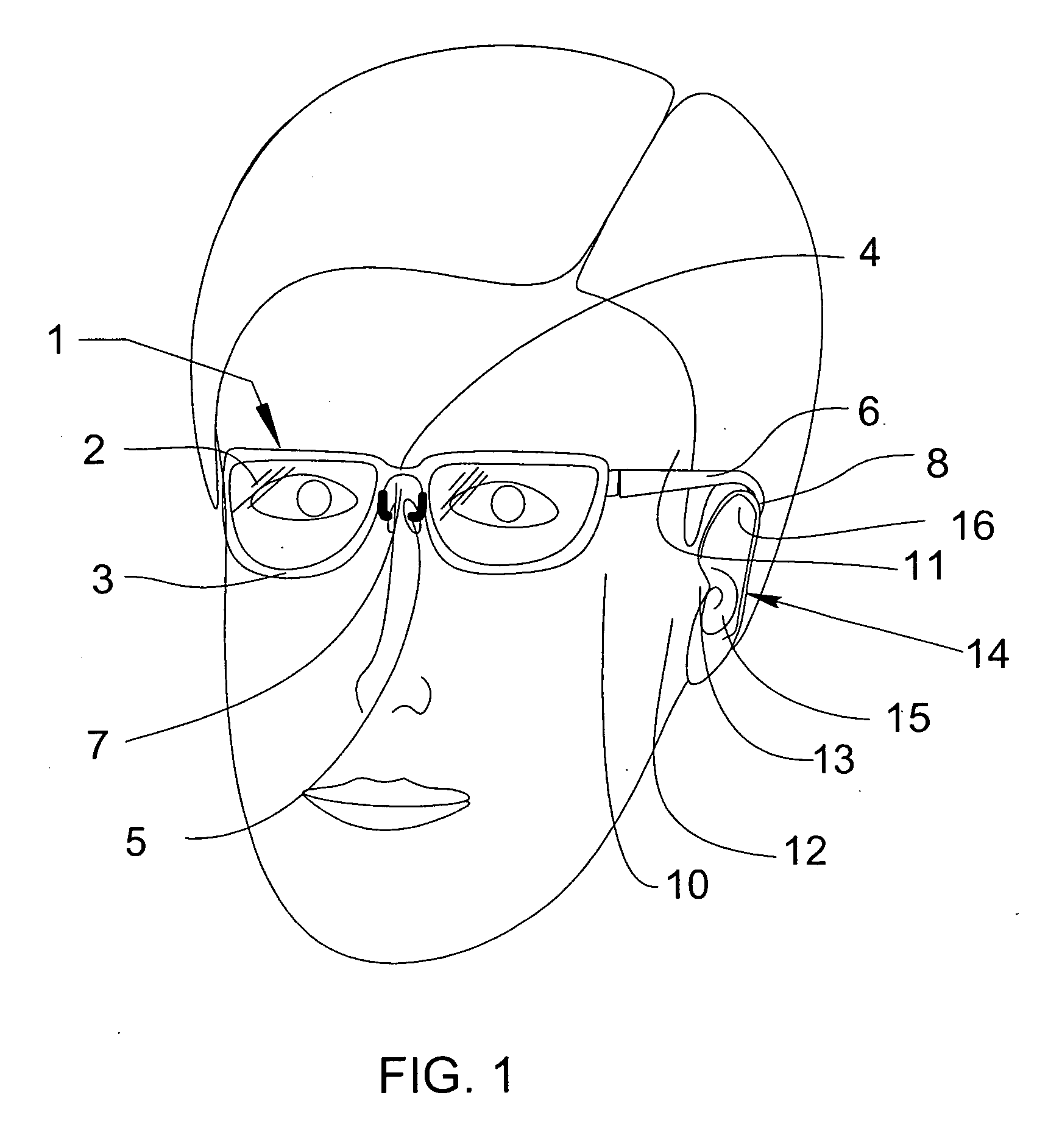

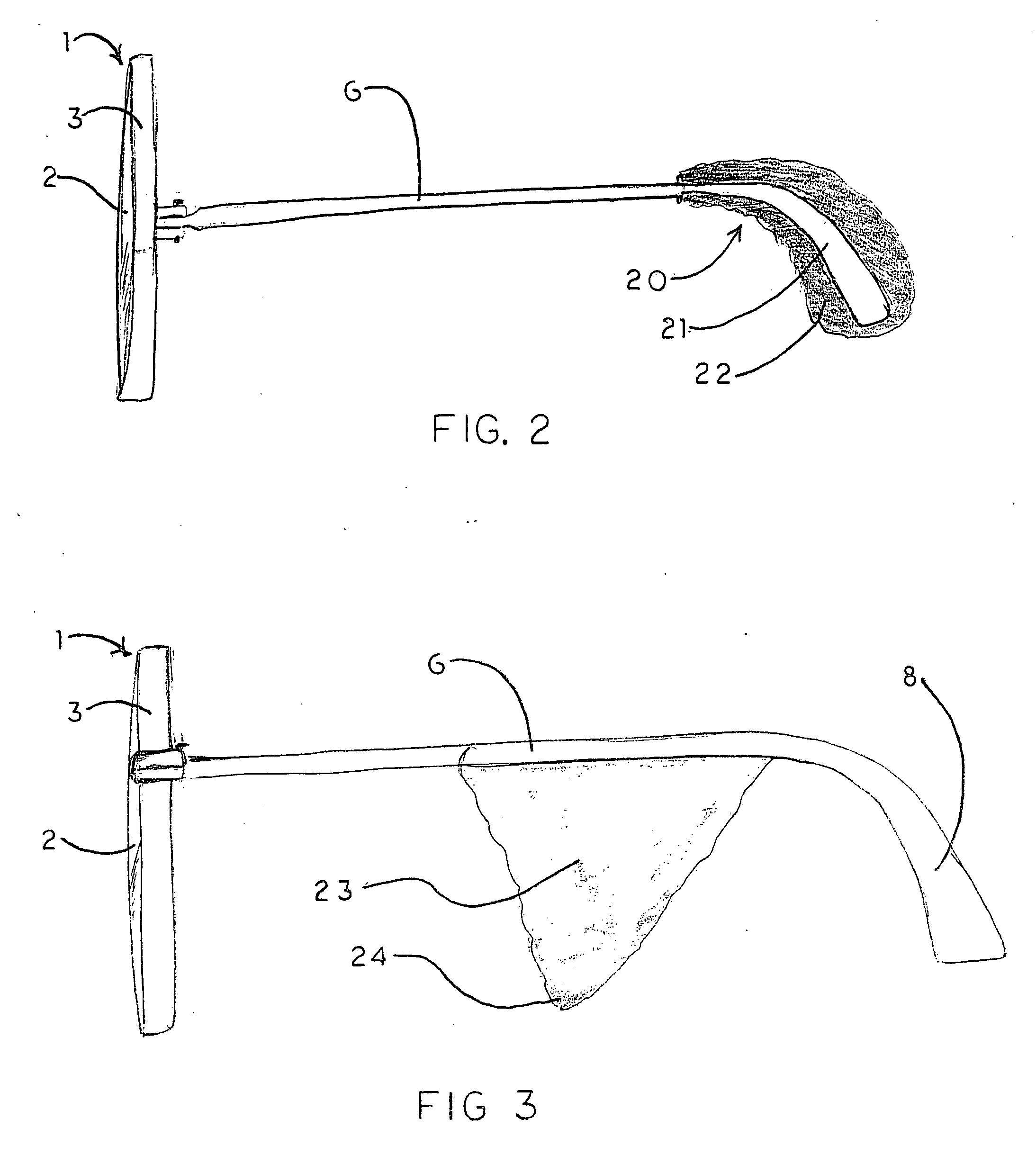

Eyeglasses with temple arm supports

InactiveUS20060098160A1Improve disadvantagesNon-optical adjunctsNon-optical partsNoseSurgery procedure

Eyeglasses with additional temple arm supports for supporting the frame of a pair of eyeglasses off of and above the nose and nasal bone. The glasses are used by patients recovering from rhinoplasty surgery but who must still have use of eyeglasses which do not contact the nasal bone or nose. In one embodiment, the frame is suspended above the nose by an enhanced counterweighed ear loop. In another embodiment, a stanchion is provided supported by the zygomatic arch to elevate the temple arm. Several embodiments support the temple arm with additional mandibular and temple rests extending orthogonally from the temple. Several additional embodiments replace the conventional ear loop with a pair of support pads at the end of a shortened temple arm. The support pads press against the two bony protuberances on the side of the wearer's head. These protuberances include the zygomatic arch, the mandibular condyle, and the temple. Pressure by the support pads against two of these protuberances provides sufficient support for the entire weight of the eyeglasses. Another embodiment is comprised of a support hoop disposed on the temple arm. The upper arc of the hoop is supported by the temple while the lower arc is supported by the mandible.

Owner:JAMIE SHAHROOZ S +1

Mandibular Advancement Device

InactiveUS20100300458A1Prevent fallingEnhances jaw protrusionSnoring preventionNon-surgical orthopedic devicesEngineeringCam

A mandibular advancement device is proposed which comprises both an upper and a lower base plate, whereby engagement of the plates during closing of the jaws causes protrusion of the mandible and allows relative lateral movement between the jaws. In one particular form the invention relates to a device for positioning upper and lower jaws, including a cam associated with one of the jaws and a follower associated with the other jaw, the follower having an engagement surface which translates across the cam to advance one of the jaws relative to the other as the jaws are closed.

Owner:AIROSPACE ENTERPRISES

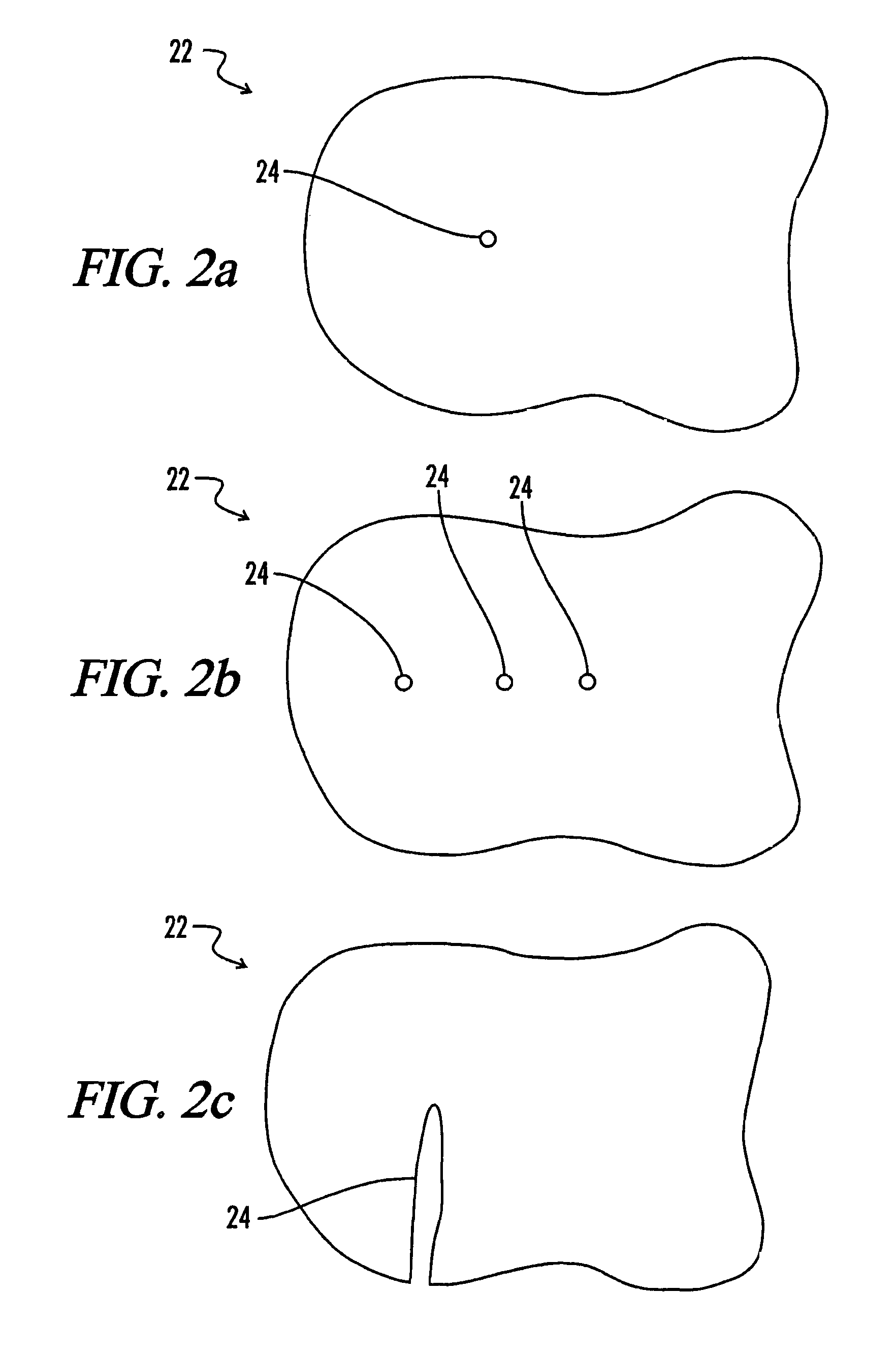

Mandibular bone transport reconstruction plate

This device can be used to create new bone to fill a gap in the mandible after surgical excision. It uses a bone reconstruction plate as a distraction device. The reconstruction plate fixes the bone stumps on both sides of the bone gap. In the middle segment of the plate overlying the bone gap, the transport bone disc is carried on a transport unit that moves along a rail on the outer surface of the reconstruction plate.

Owner:CRANIOTECH ACR DEVICES

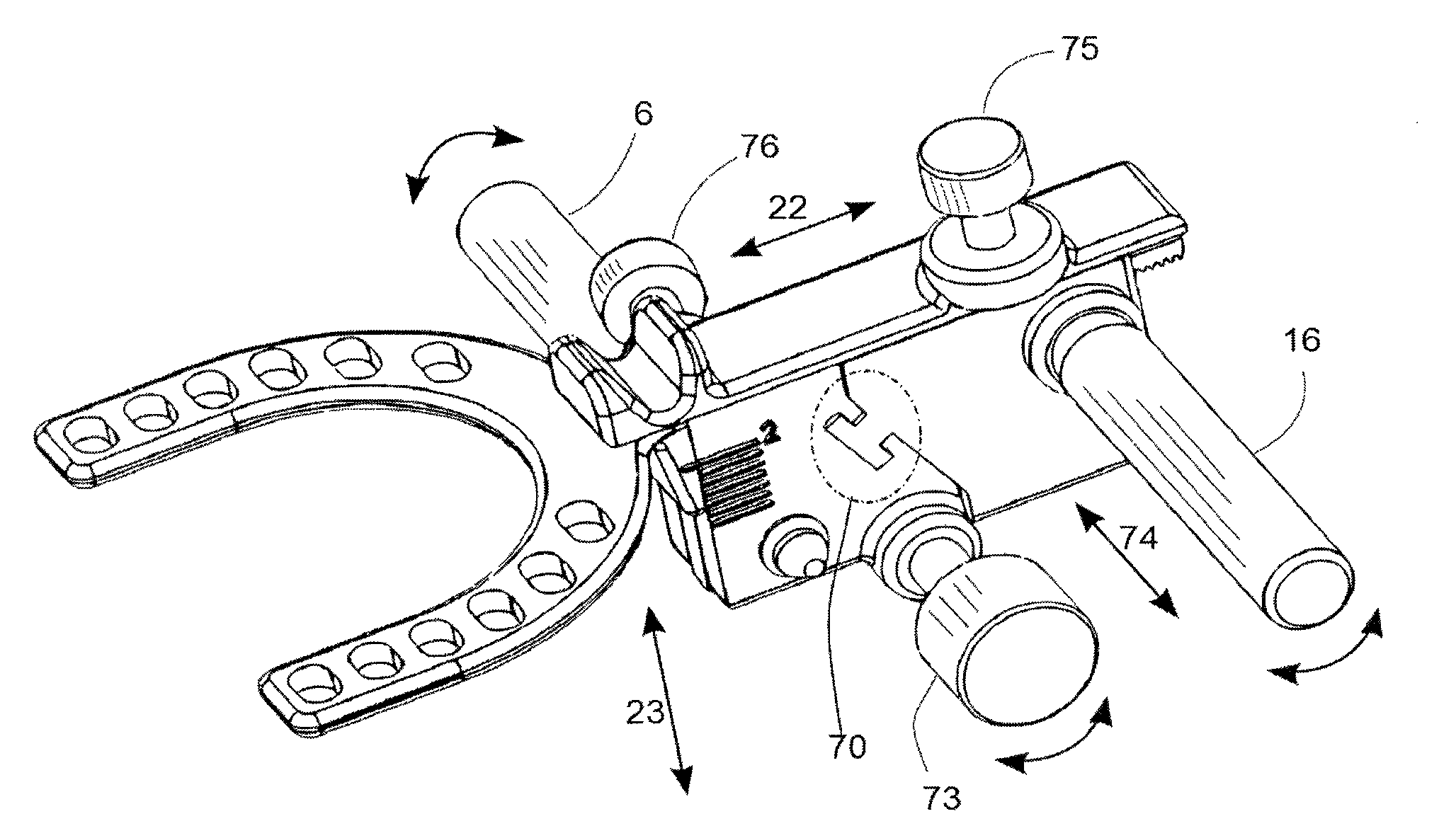

Curve linear and straight mandibular distractor with occlusion correction feature

InactiveUS20070162045A1Precise occlusion alignmentDisadvantages and of reduced eliminatedProsthesisExternal osteosynthesisDistractionOverbite

In accordance with one embodiment of the present invention, an osteodistraction device includes a flexible rod having a threaded portion. A distraction arm that includes a rod guide is coupled to the threaded portion of the flexible rod through a threaded hole near one end of the distraction arm. The rod guide of the distraction arm is operable to slide through a pivoting guide that is coupled to the distraction arm. An adjustment screw is coupled to the pivoting guide and is operable to rotate the distraction arm from a first to a second orientation. The flexible rod is operable to change the position of the rod guide relative to the pivoting guide.

Owner:OSTEOMED

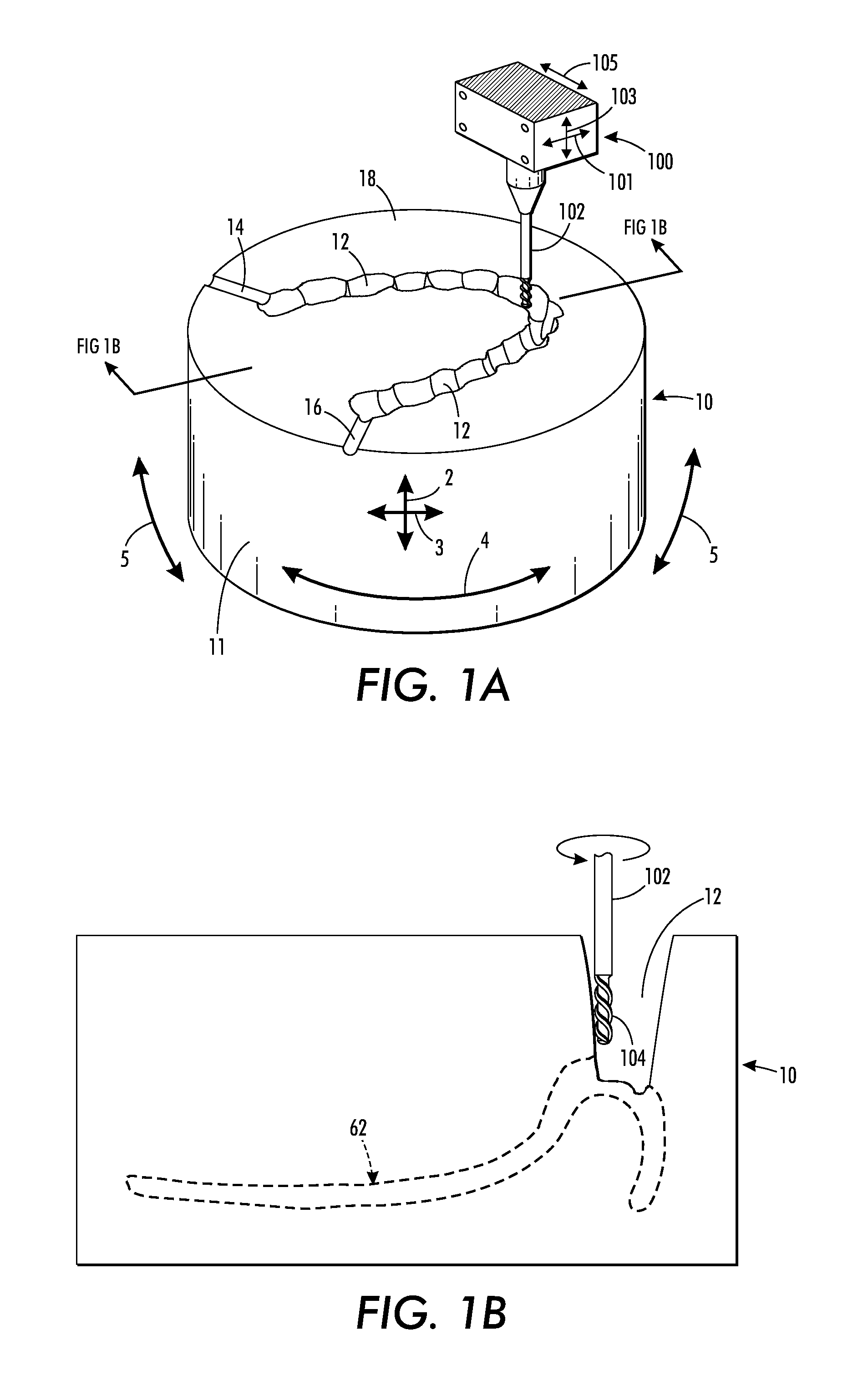

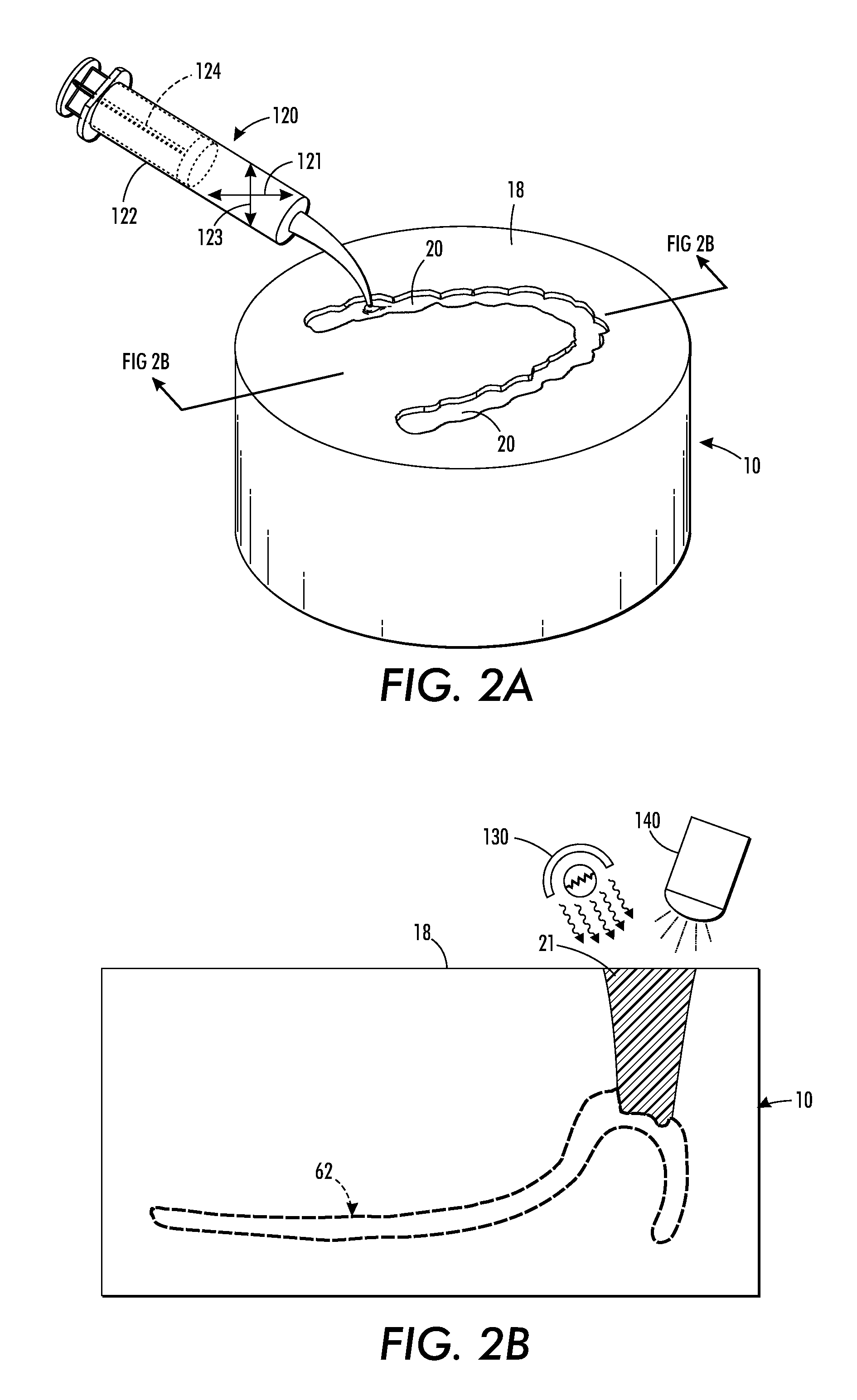

Denture and method and apparatus of making same

ActiveUS8641938B2Minimal number of stepMinimal manual laborAdditive manufacturing apparatusImpression capsNatural toothDentures

A method for making a denture comprising a base and a plurality of teeth joined thereto. The method comprises forming a first cavity in a block of a denture base material, the first cavity being formed to match the contour of natural teeth as arranged on maxillae or on a mandible; filling the first cavity with a first fluid synthetic tooth material and solidifying the first fluid synthetic tooth material into a first solid synthetic tooth material; removing a portion of the first solid synthetic tooth material to form the plurality of teeth; and removing a portion of the block of denture base material to form the denture base. The steps of the method may be implemented by a computer. An apparatus for making the denture according to certain embodiments of the method, and a denture comprised of a base and artificial teeth are also disclosed.

Owner:GLOBAL DENTAL SCI

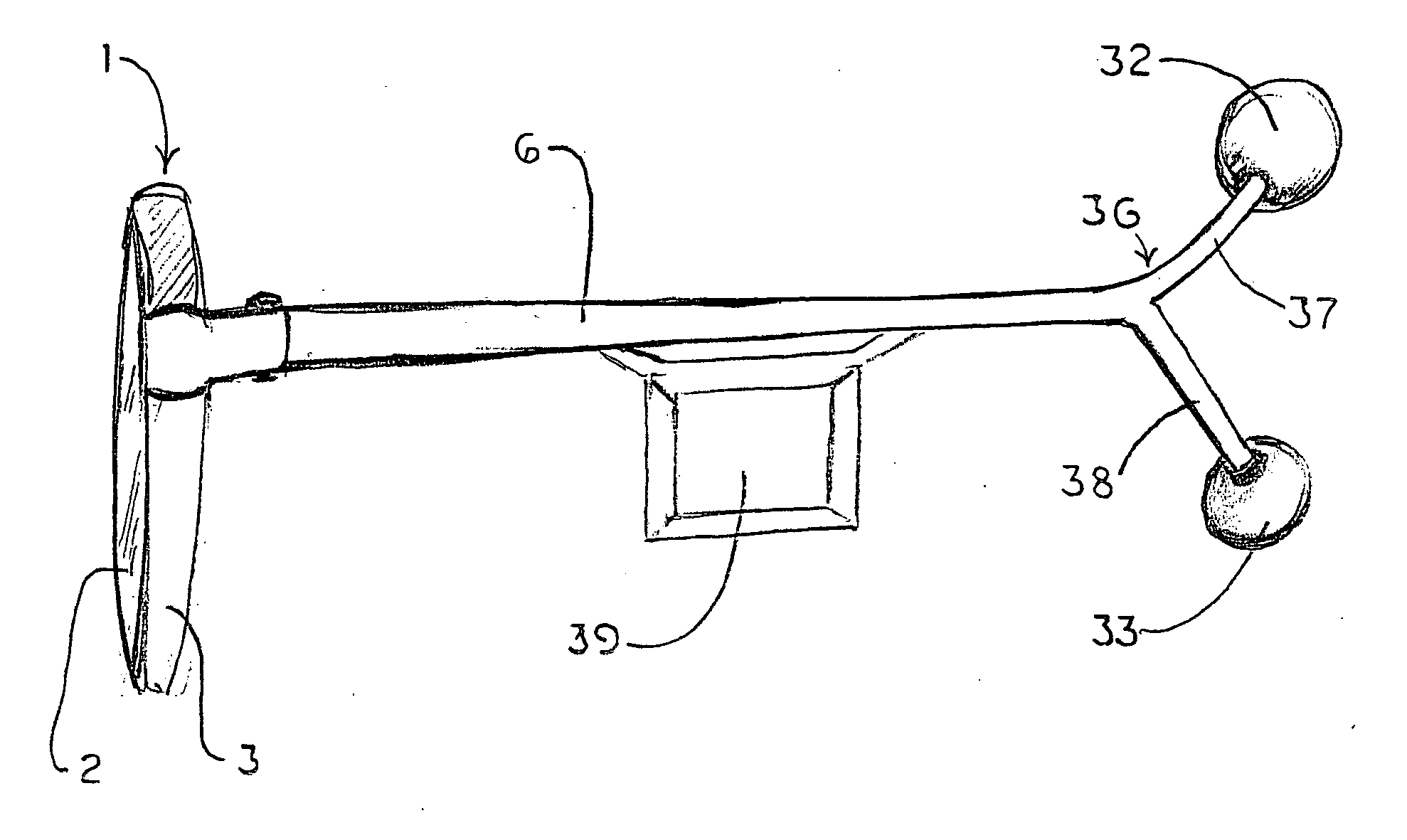

Mandibular manipulator

InactiveUS8226407B2Quantitative precisionAccurate measurementTeeth fillingSnoring preventionGear wheelEngineering

A mandibular manipulator instrument used as a standalone tool or with associated mouthpiece that includes two interlocking laterally sliding frames which interlock to create a movable upper and a lower incisor pull driven by a pair of pinion shafts and shaped for receiving a patient's central incisor teeth. A screw thread is used to provide a precise lateral motion for the sagittal measurement. The mouthpiece is constructed of resilient rubber. The mandibular manipulator may be positioned and held in a resilient flexible mouthpiece by the two pinions protruding through acoustically tight apertures respective to each pinion's position. The manipulator can be used for other application in an embodiment without the mouthpiece and / or in combination with a bite registration shape that is part of the manipulator frame.

Owner:KOSMO TECH

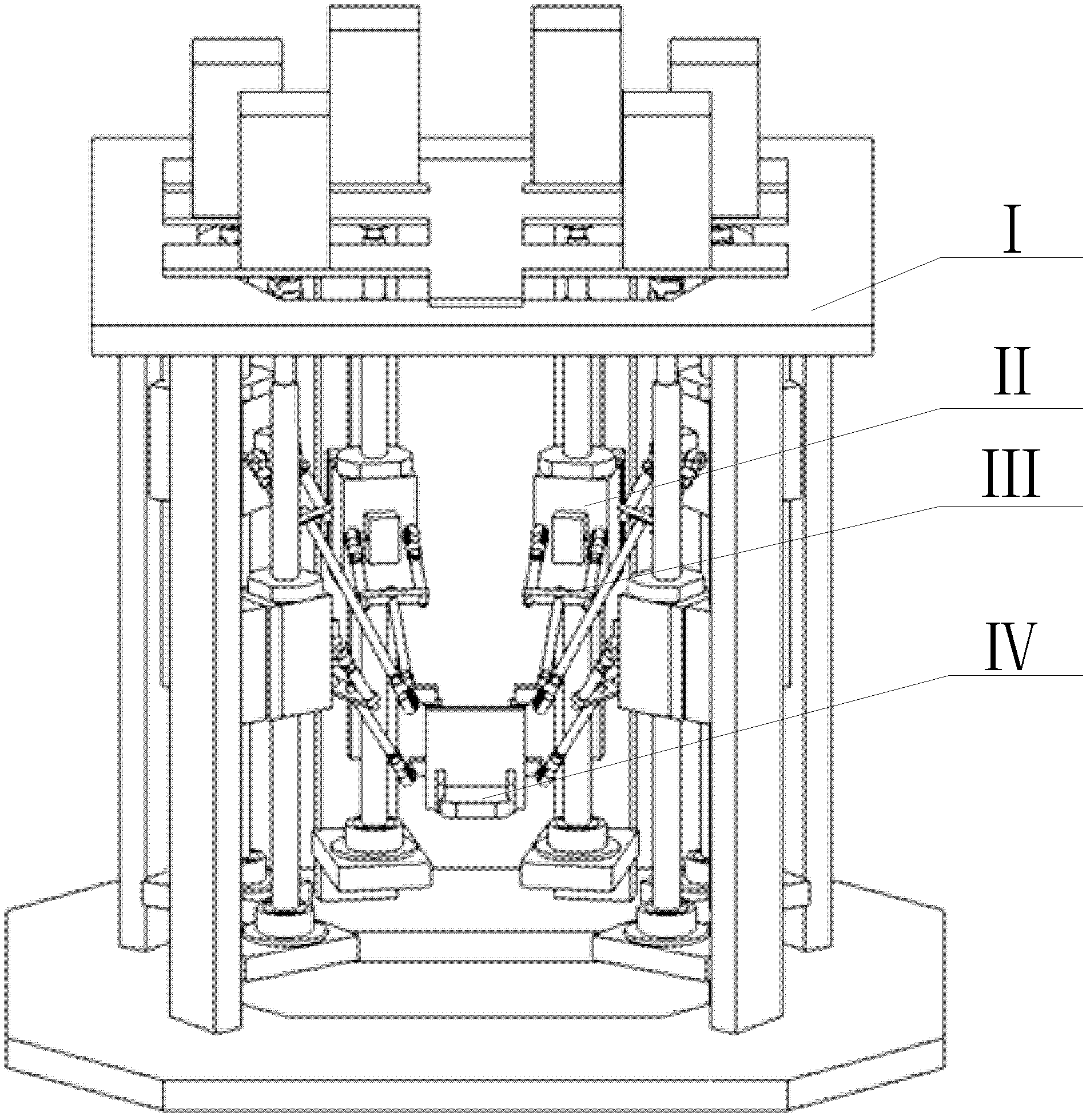

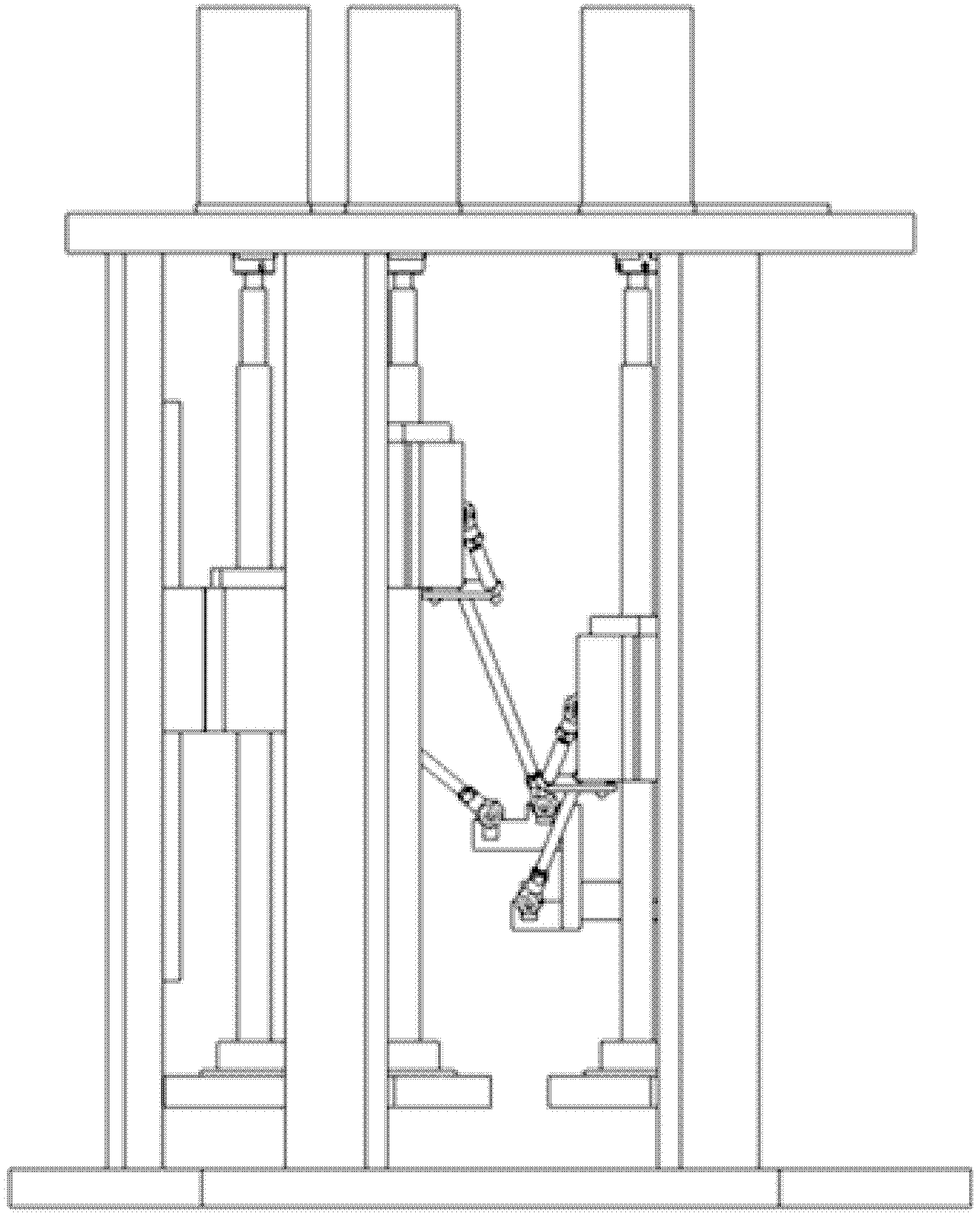

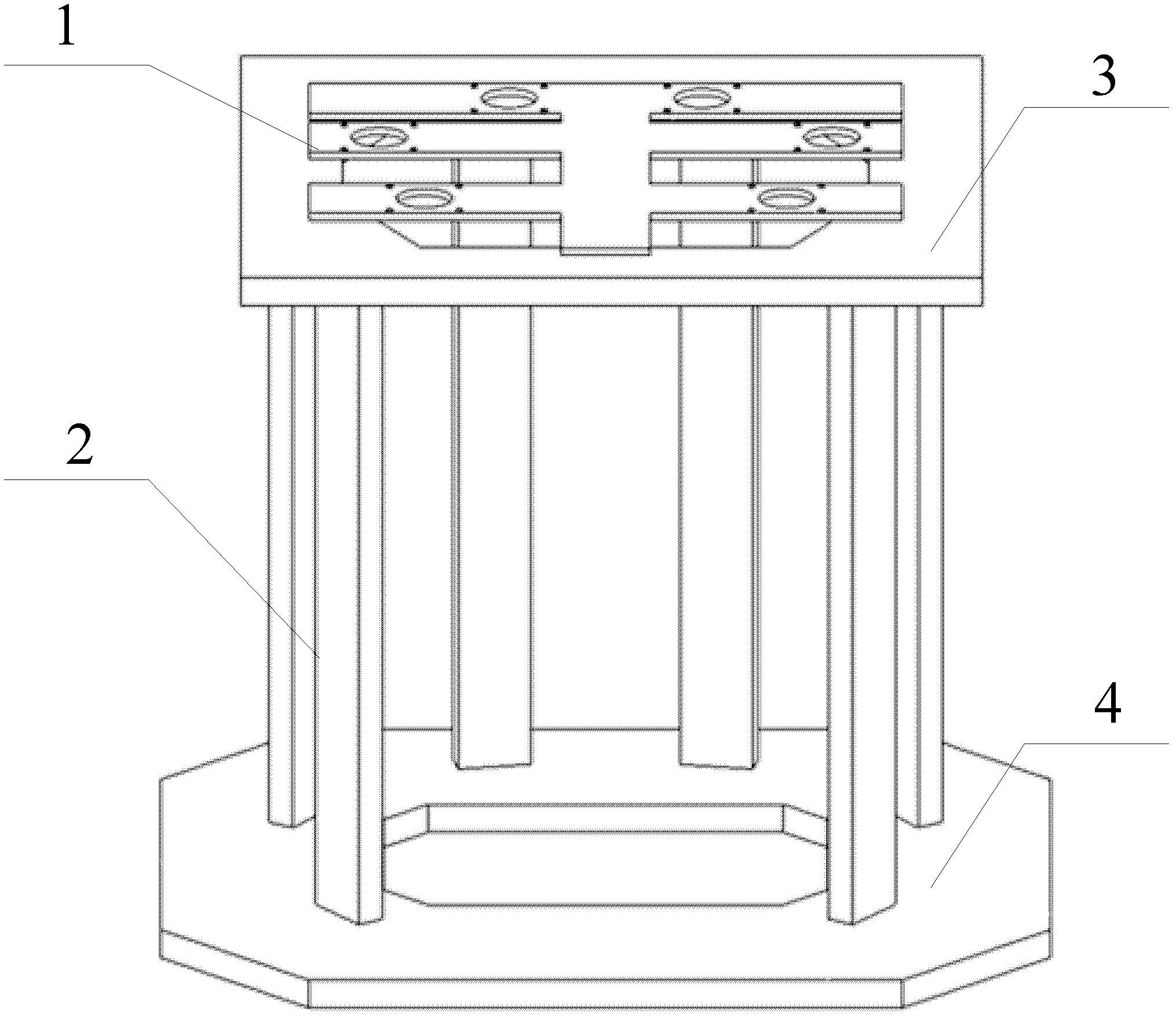

Mandibular movement imitating robot

ActiveCN102626348ARealistic reproduction of human jaw movement trajectoryHigh degree of bionic designDental articulatorsEducational modelsHuman bodyBall screw

The invention discloses a mandibular movement imitating robot, which belongs to the technical field of bionic robots and can provide a scientific means for the research of the dentistry, the food science and the biomechanics. The mandibular movement imitating robot comprises a static platform, six driving devices, six movable branched chains and a mandibular platform, wherein the driving devices consist of motors and ball screw pair transmission systems and are used for driving the six movable branched chains to realize movement of the mandibular platform in a three-dimensional space. The mandibular movement imitating robot has the advantages that the dimension diameters of a human body mandibular system and the biomechanical characteristics of a mandibular muscle driving system are synthetically considered, the movement function and a chewing environment of a human mandible can be truly reproduced, and the requirements of realness in movement locus and rationality in occlusion strength are satisfied.

Owner:DALIAN UNIV OF TECH

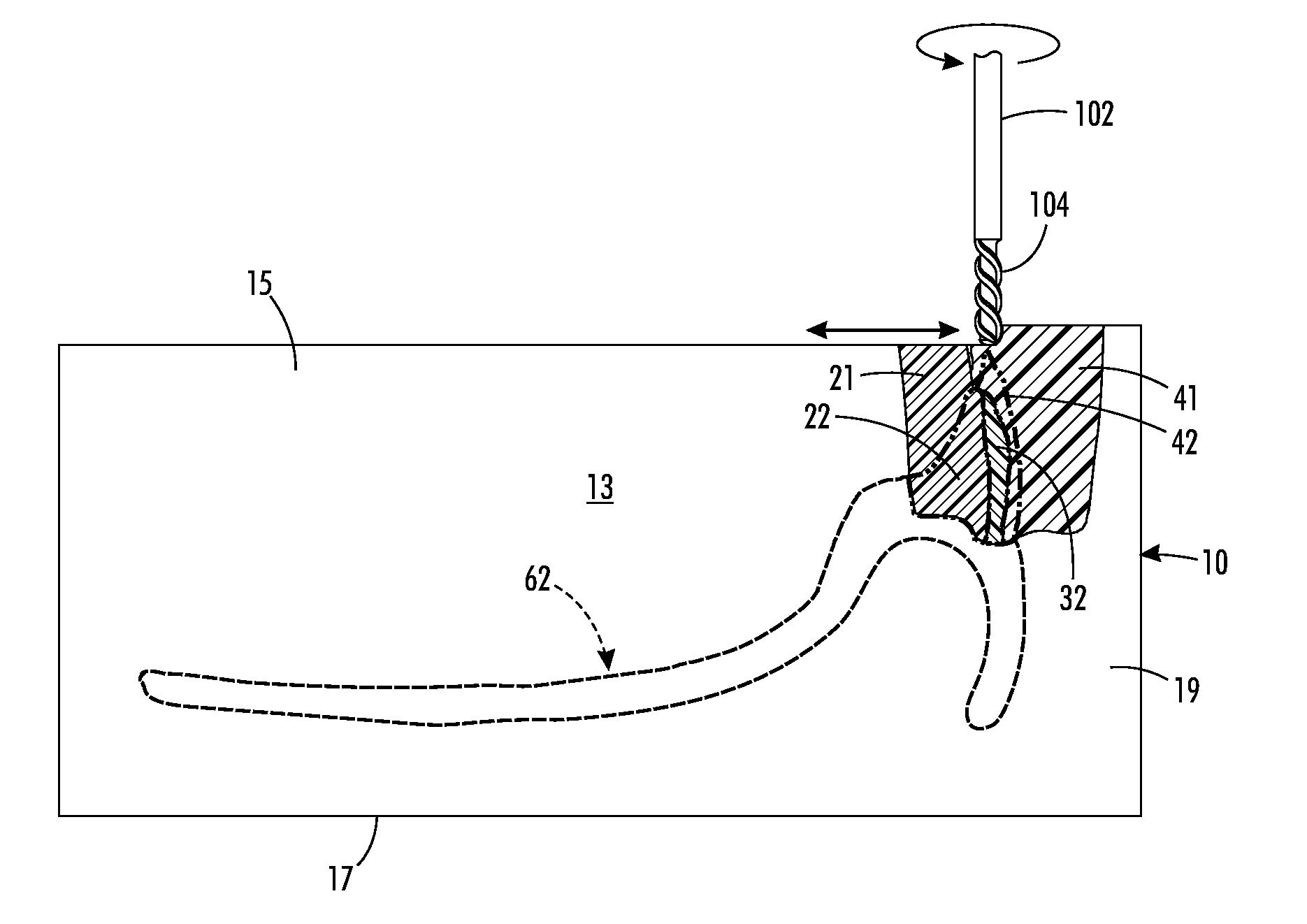

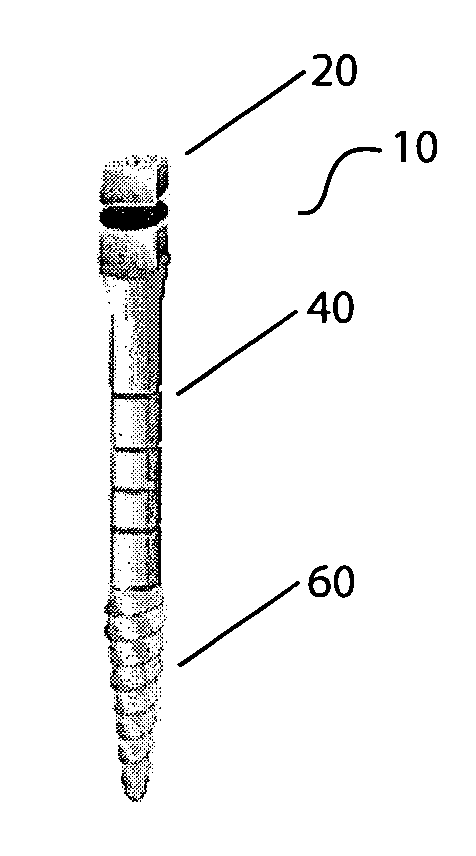

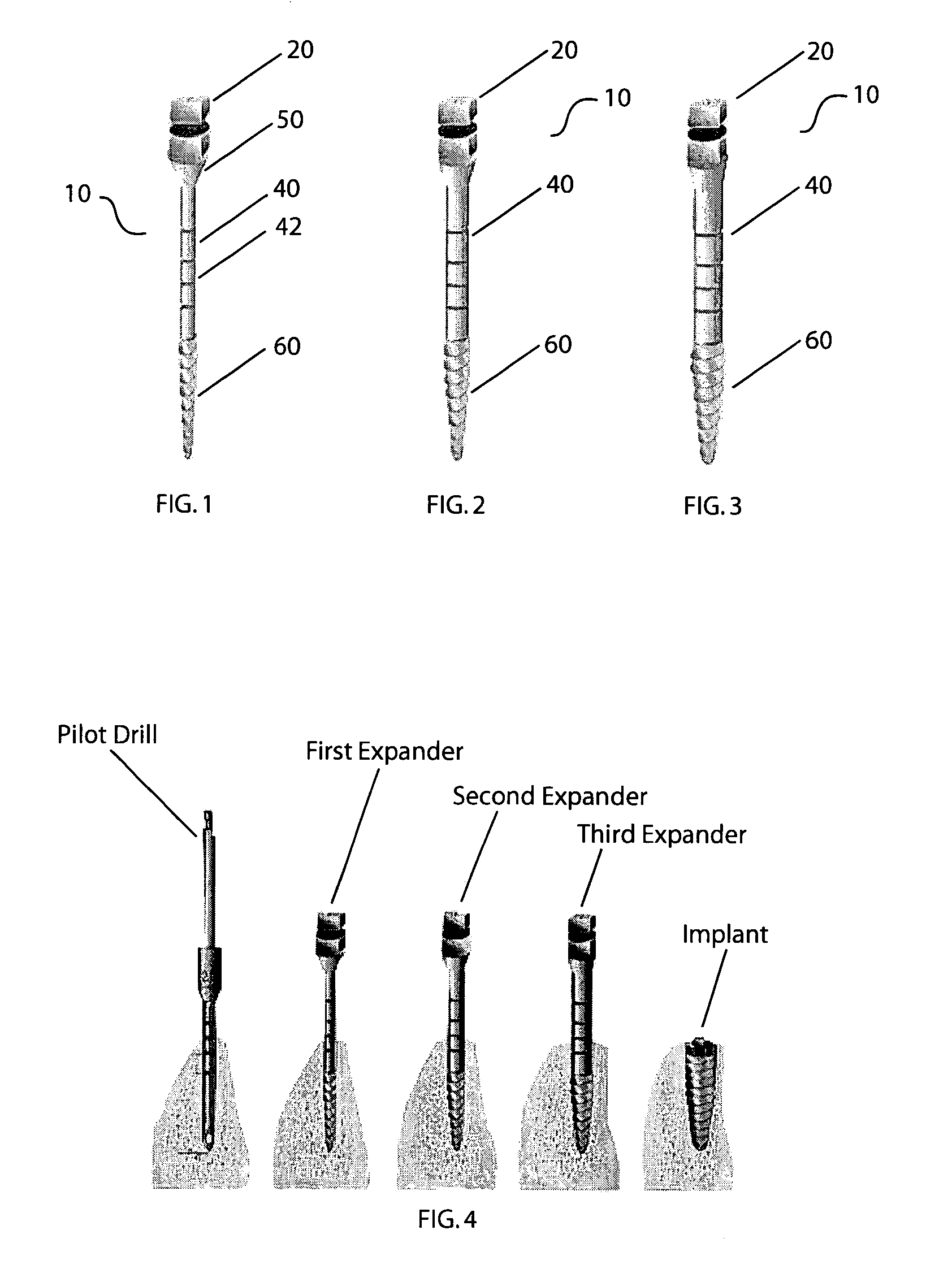

Method of bone expansion and compression for receiving a dental implant using threaded expanders

InactiveUS7241144B2Bite into and uniformly engage with surrounding bone tissueGentle expansionDental implantsDental toolsBone tissueDental implant

A method and devices for bone tissue expansion and compression for receiving a dental implant are disclosed. The method includes the steps of creating an initial osseotomy site in the maxilla or the mandable using a pilot drill; screwing a first threaded expander into the site to expand the site laterally; and allowing the expander staying in the site for a short time to impress the interior wall of the osseotomy site; then retrieving the first expander. These steps are repeated using a second, and / or third threaded expander having an increasing outer diameter to further expand the osseotomy site to a final diameter which is complementary, but narrower than the diameter of the dental implant so that expanded osseotomy site enables uniform engagement of the implant with the bone tissue. A preparation drilling to extend osseotomy site only at cortical level can be incorporated for hard bone and larger implants.

Owner:EVOLLUTION IP HLDG

Mandibular occlusal inhibitor

A device for maintaining a patient's mouth in an open position during a medical procedure is provided. The device includes a cylindrical body configured to be received in the patient's mouth. A flange extending from an edge of the body is configured to engage the face of the patient, and preferably, the device includes a retainer for retaining the body in the patient's mouth.

Owner:THE CHILDRENS HOSPITAL OF PHILADELPHIA

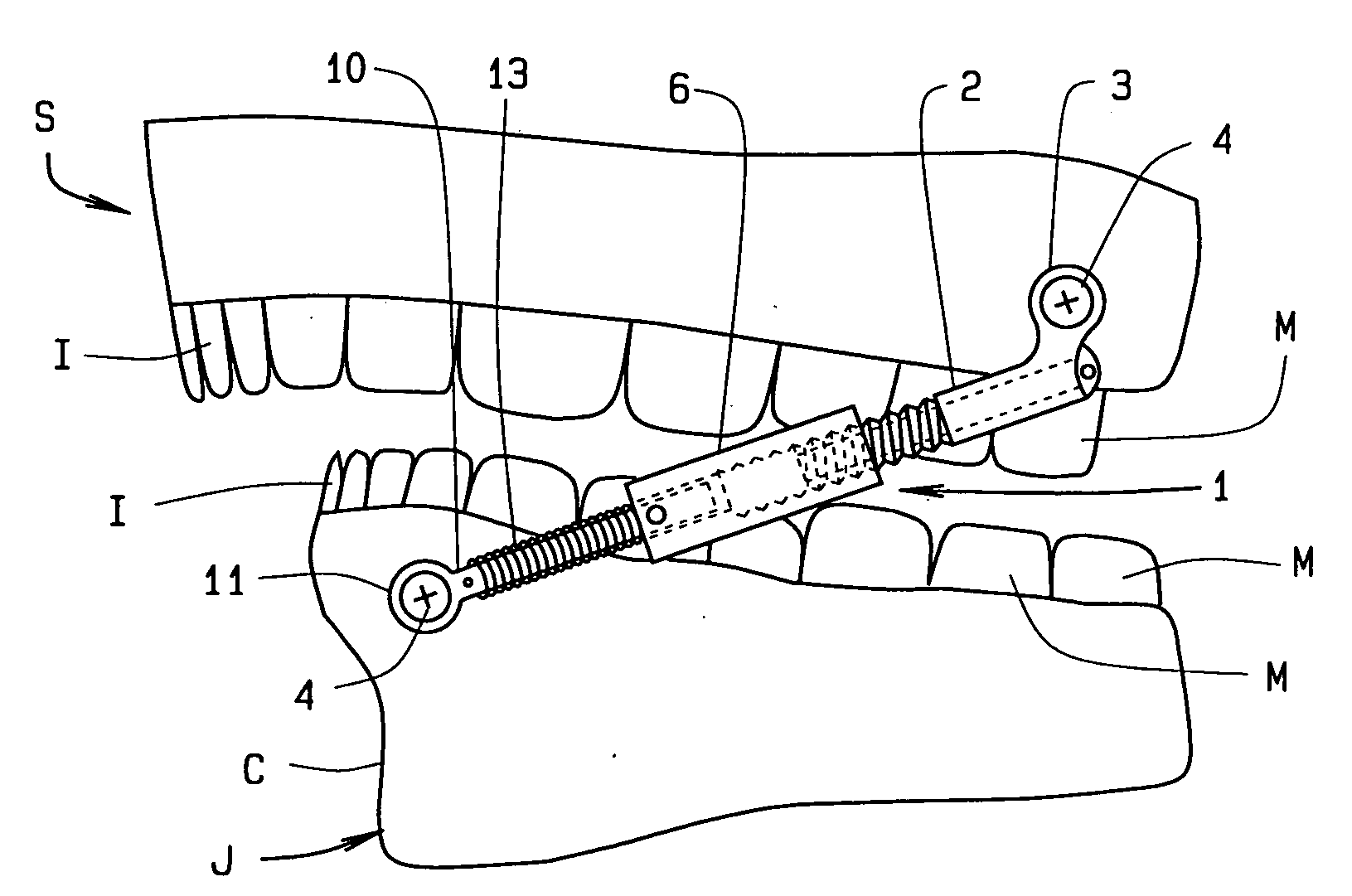

Jaw advancer connected to bone

A jaw advancer connects to the skull, maxilla jaw, and the jawbone, mandibular jaw, without contacting the teeth of a patient. Each advancer, of a pair, has a hollow upper member with a head to admit a screw into the maxilla and an opposite threaded end, a socket having a threaded end that admits the upper member and an opposite smooth bore, and a lower member with a head to admit a screw into the mandible and an opposite smooth end that fits into the smooth bore. The lower member has a coaxial spring that provides an expansive force to the lower jaw and that cushions the socket. The lower member slides within the hollow portion of the upper member when the patient moves the advancer. The head of the upper member attaches proximate the molars of the maxilla to advance the mandible and attaches proximate to the incisors of the maxilla to retract the mandible. Alternatively, the lower member has a slight curve to separate it from the teeth.

Owner:WILLIAMS MICHAEL O

Inferior alveolar nerve block guide

InactiveUS8257341B1Accurate locationFine surfaceInternal osteosythesisFastening prosthesisInferior alveolar nerveBody contour

A guide for administering an injection including a guide body contoured for a human mandible; and at least one needle indexing guide on the guide body for the insertion of a needle there through, the guide use to provide a predictable and repeatable way of administering an injection to block a nerve.

Owner:FLETCHER JACK MAURICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com