Patents

Literature

41results about How to "Improve logistics distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

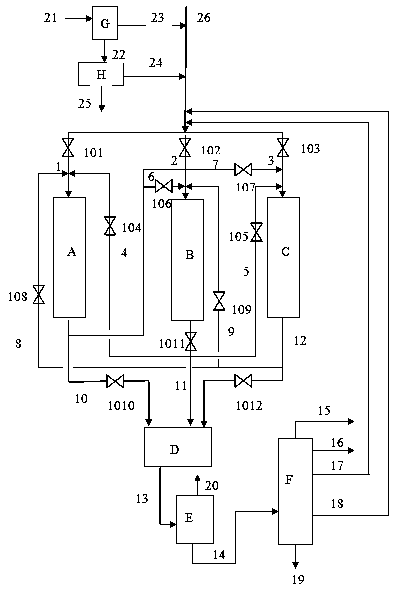

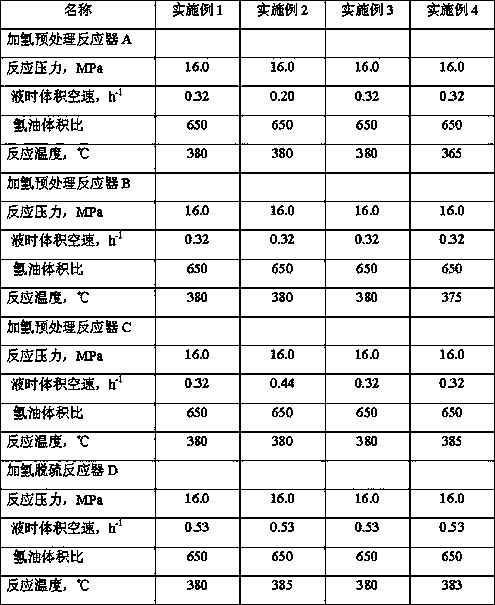

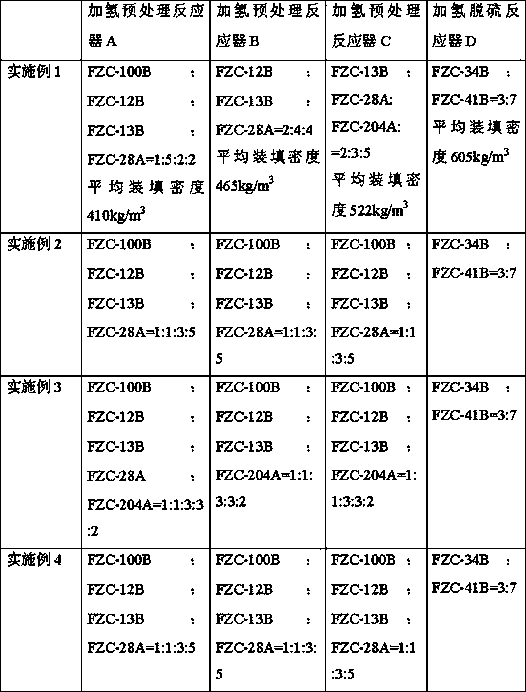

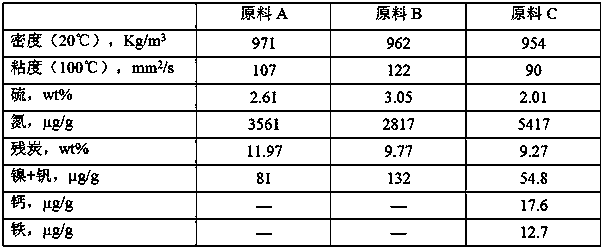

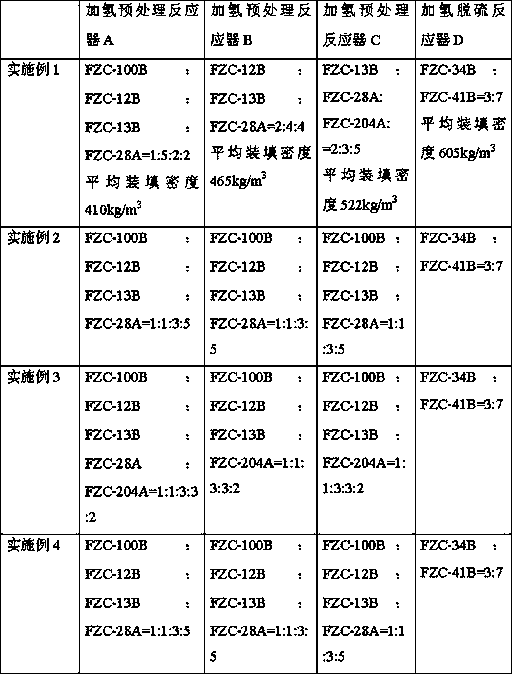

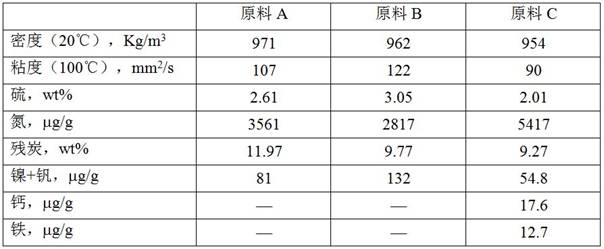

Process for treating inferior oil product

ActiveCN106701190AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesChemistryPre treatment

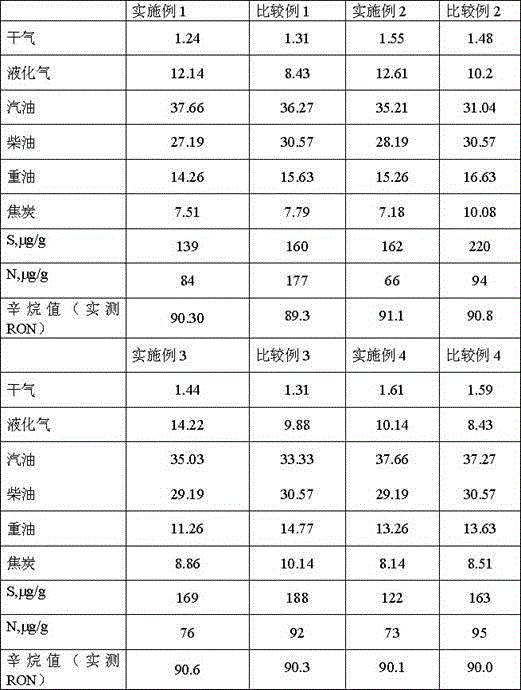

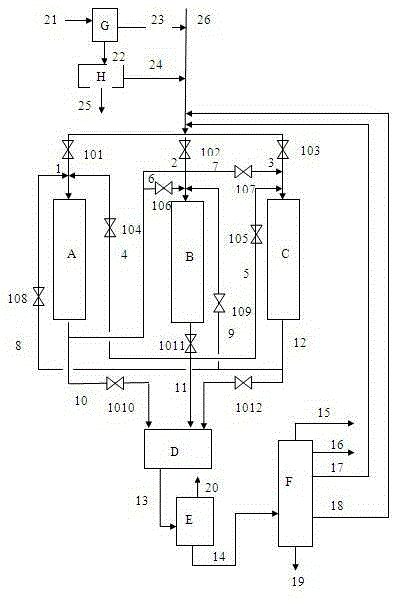

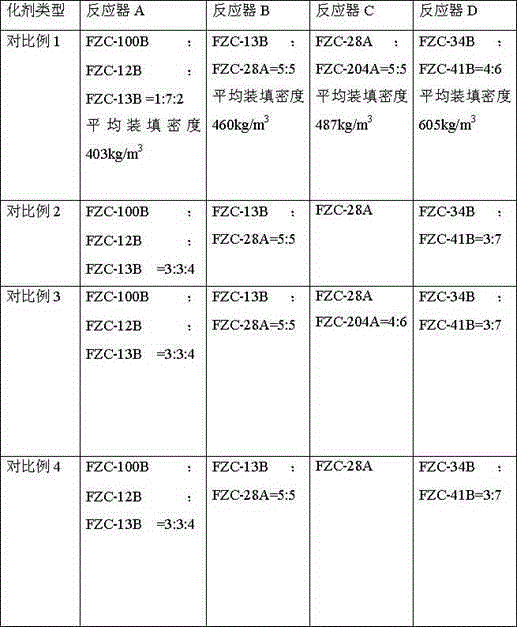

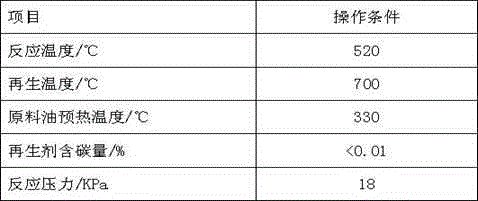

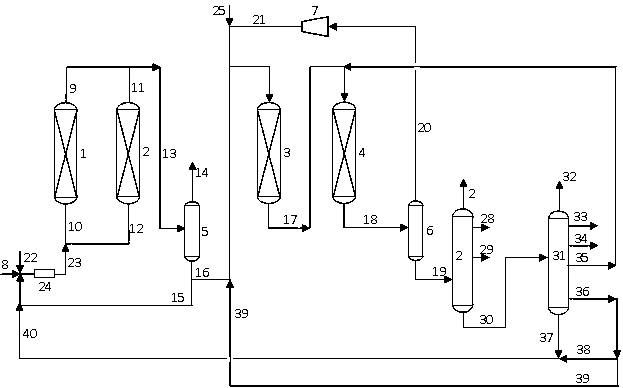

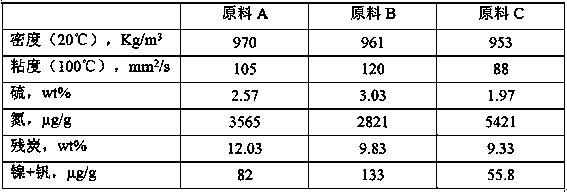

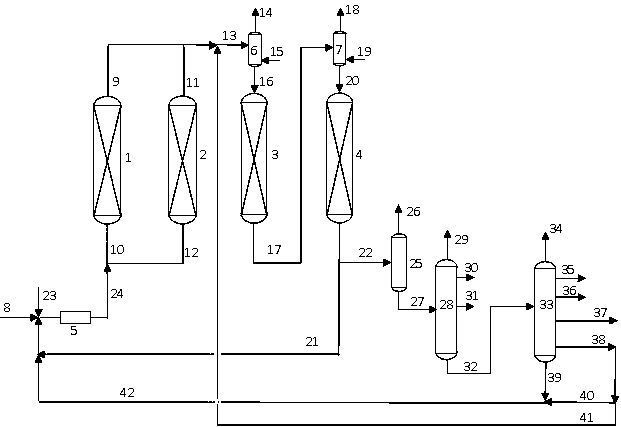

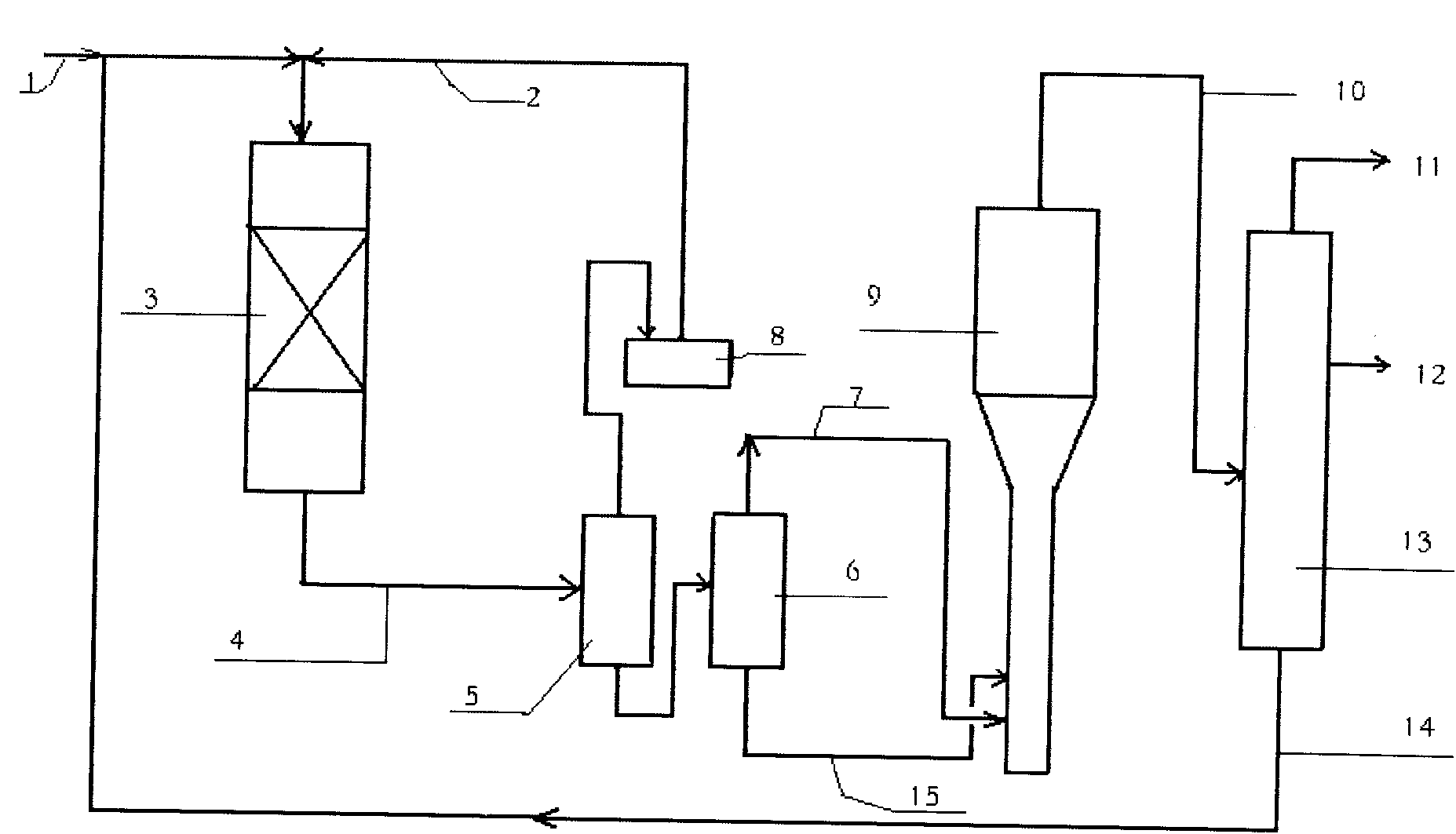

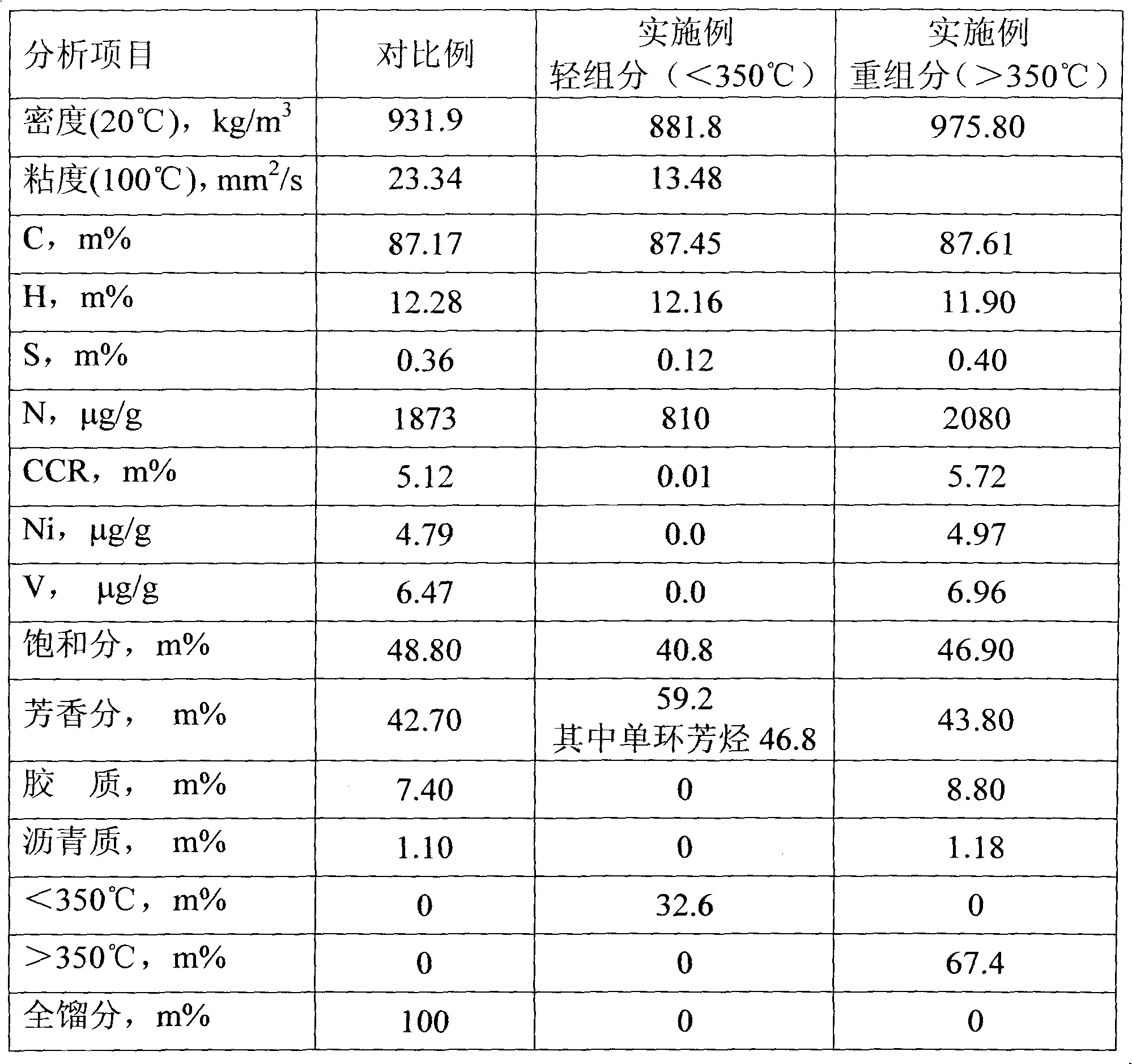

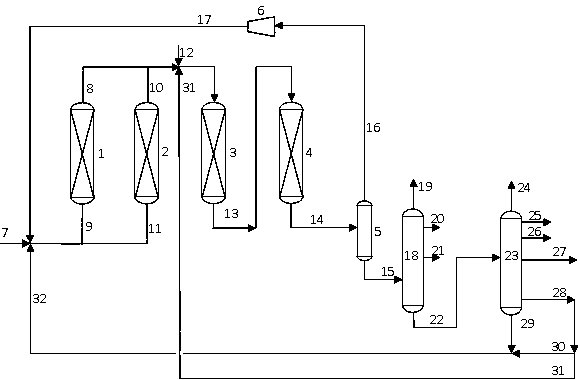

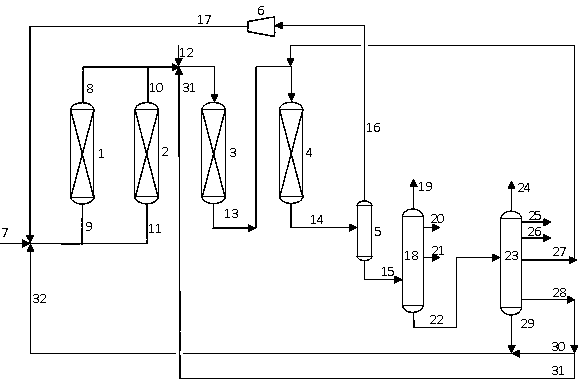

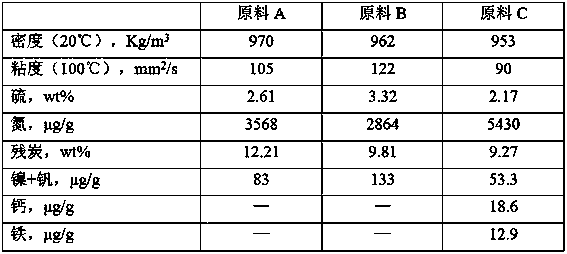

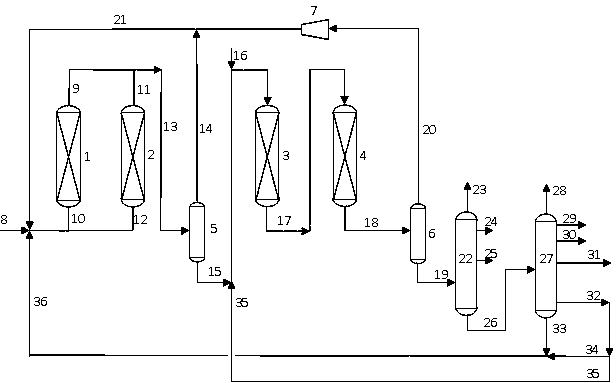

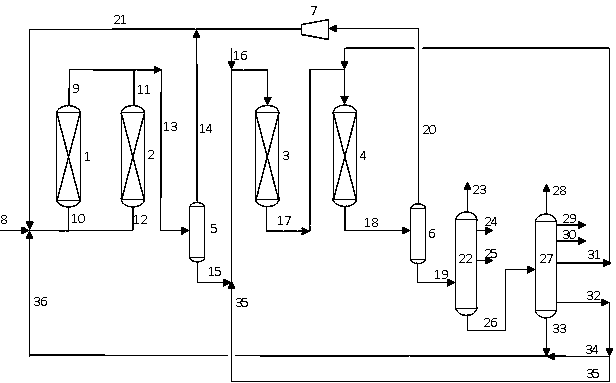

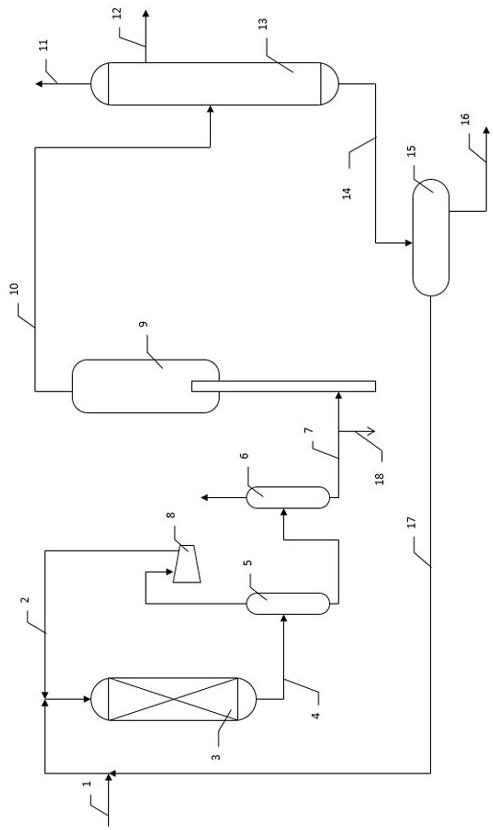

The invention discloses a process for treating an inferior oil product. The process comprises a hydropretreating reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone. The process comprises the following contents: mixing a residual oil raw material and hydrogen, then successively allowing the mixture to pass through the hydropretreating reaction zone and the hydrotreating reaction zone which are connected in series, subjecting a reaction effluent of the hydrotreating reaction zone to gas-liquid separation, allowing a gas phase to recycle back to the hydropretreating reaction zone and / or the hydrotreating reaction zone, allowing a liquid phase to directly enter the catalytic cracking reaction zone and carrying out a catalytic cracking reaction, and separating a catalytic cracking reaction effluent so as to obtain dry gas, liquefied gas, catalytically cracked gasoline fraction, catalytically cracked diesel fraction, catalytically cracked heavy recycle oil and catalytically cracked slurry oil, wherein the catalytically cracked diesel oil, the catalytically cracked heavy recycle oil and the slurry oil are partially or completely recycled back to the hydrotreating reaction zone for a hydrotreating reaction. The method provided by the invention can prolong the cycle of stable operation of equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Residual oil hydrotreating-catalytic cracking combined process method

ActiveCN106701189AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

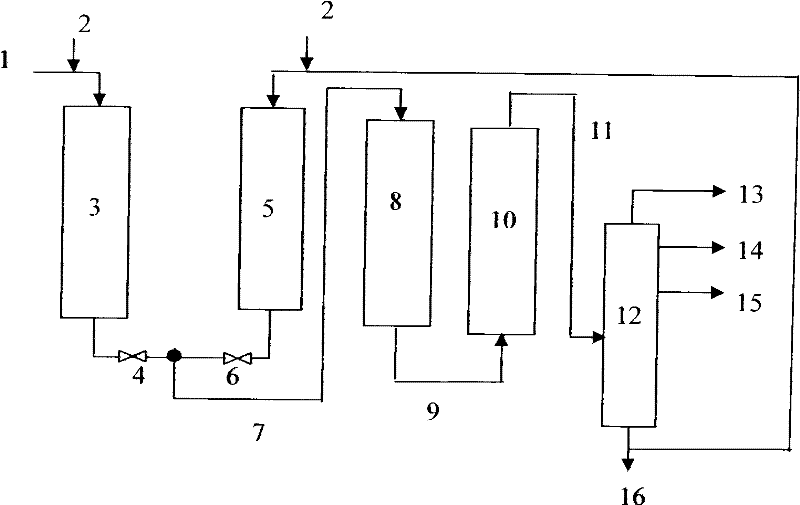

The invention discloses a residual oil hydrotreating-catalytic cracking combined process method which includes a hydropretreating reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone; the process method includes the following contents: a residual oil raw material, at least part of a catalytic cracking diesel oil fraction and hydrogen are mixed, and in turn pass through the hydropretreating reaction zone and the hydrotreating reaction zone which are in series connection, after gas-liquid separation of a hydrotreating reaction zone reaction effluent, a gas phase is recycled back to the hydropretreating reaction zone and / or the hydrotreating reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for catalytic cracking reaction, a catalytic cracking reaction effluent is separated to obtain a dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel oil fraction, catalytic cracking heavy cycle oil and catalytic cracking oil slurry, and the catalytic cracking diesel oil is partially or totally recycled back to the hydrotreating reaction zone for hydrotreating reaction. The method can prolong the stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreatment and catalytic cracking combined method of heavy hydrocarbon raw material

ActiveCN102876377AReduce the amount of mixed hydrogenStable temperatureTreatment with hydrotreatment processesFluid phaseHydrogenation reaction

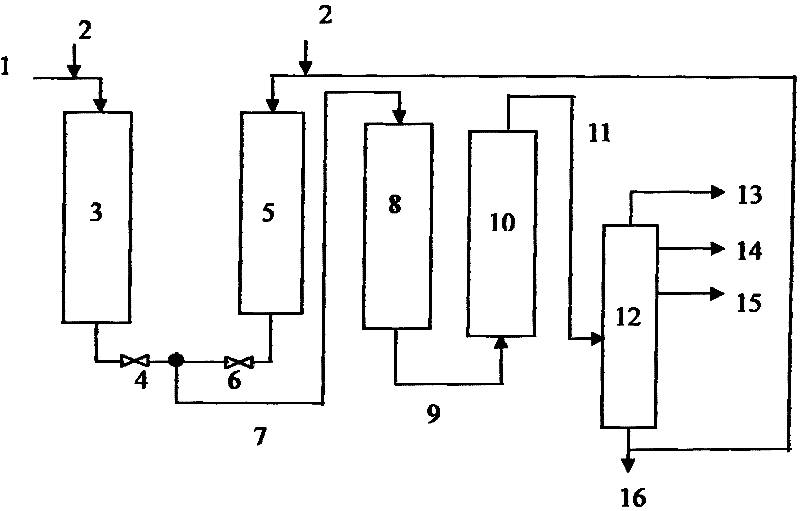

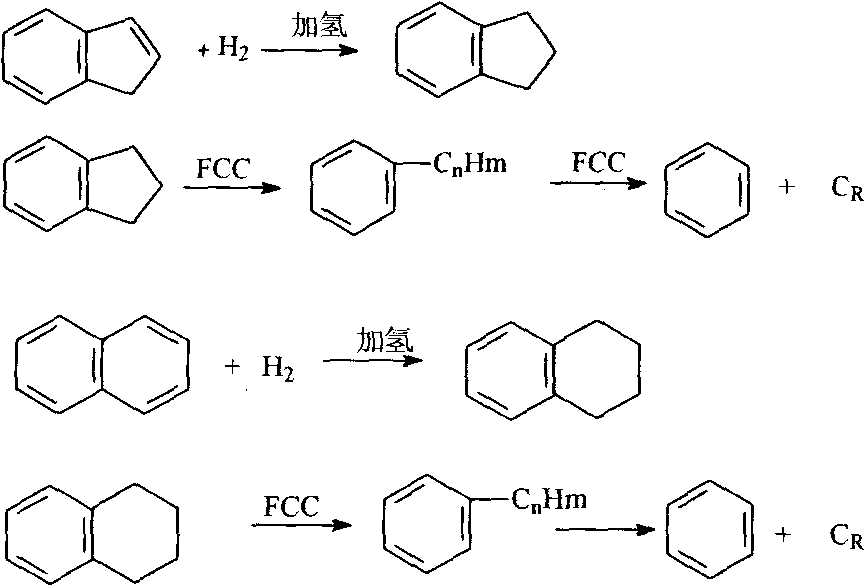

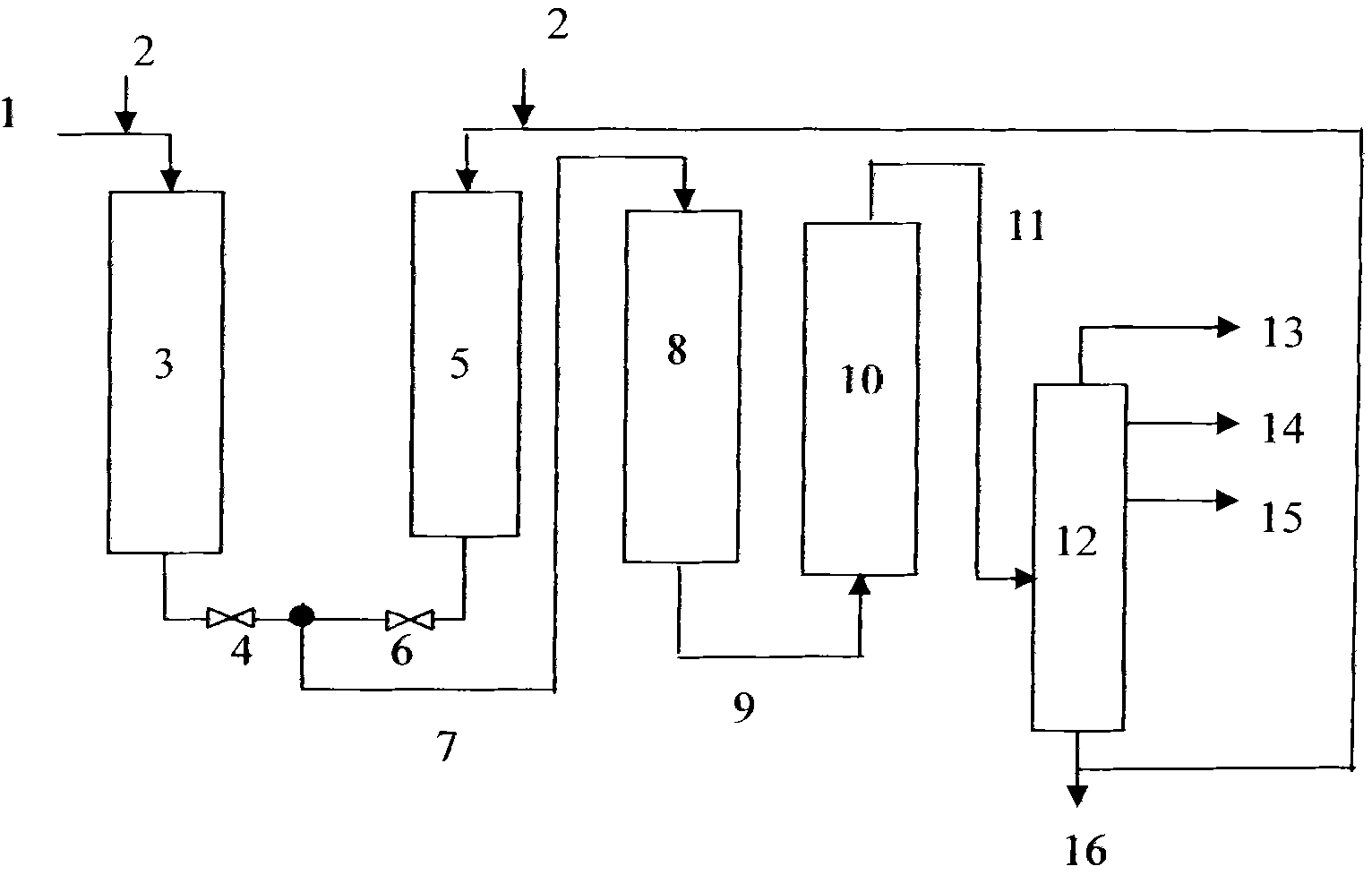

The invention discloses a hydrotreatment and catalytic cracking combined method of a heavy hydrocarbon raw material. According to the invention, an upflow reactor is at least connected in series with a downflow fixed bed reactor. The heavy hydrocarbon raw material passes through UFR and is mixed with a catalytic cracking heavy fraction, and the mixture enters the downflow fixed bed reactor. A hydrogenation reaction effluent is separated so as to obtain a liquid phase, and the liquid phase is subjected to catalytic cracking. The obtained catalytic cracking heavy fraction returns to an inlet of the downflow fixed bed reactor. According to the method, the catalytic cracking heavy distillate oil, which is introduced into the inlet of the fixed bed reactor, is beneficial to hydrogenation reaction and can significantly improve temperature rising of the bed when used as cutback oil and can minimize the amount of hydrogen injected through the inlet when used as a hydrogen donor, thus further raising cooperative effect of combined flow equipment and prolonging the running period as well.

Owner:CHINA PETROLEUM & CHEM CORP +1

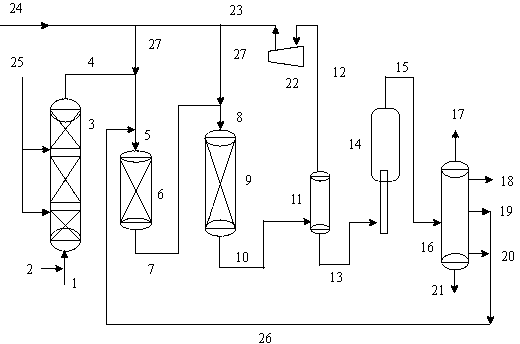

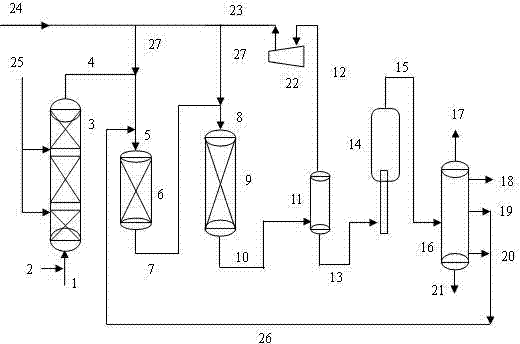

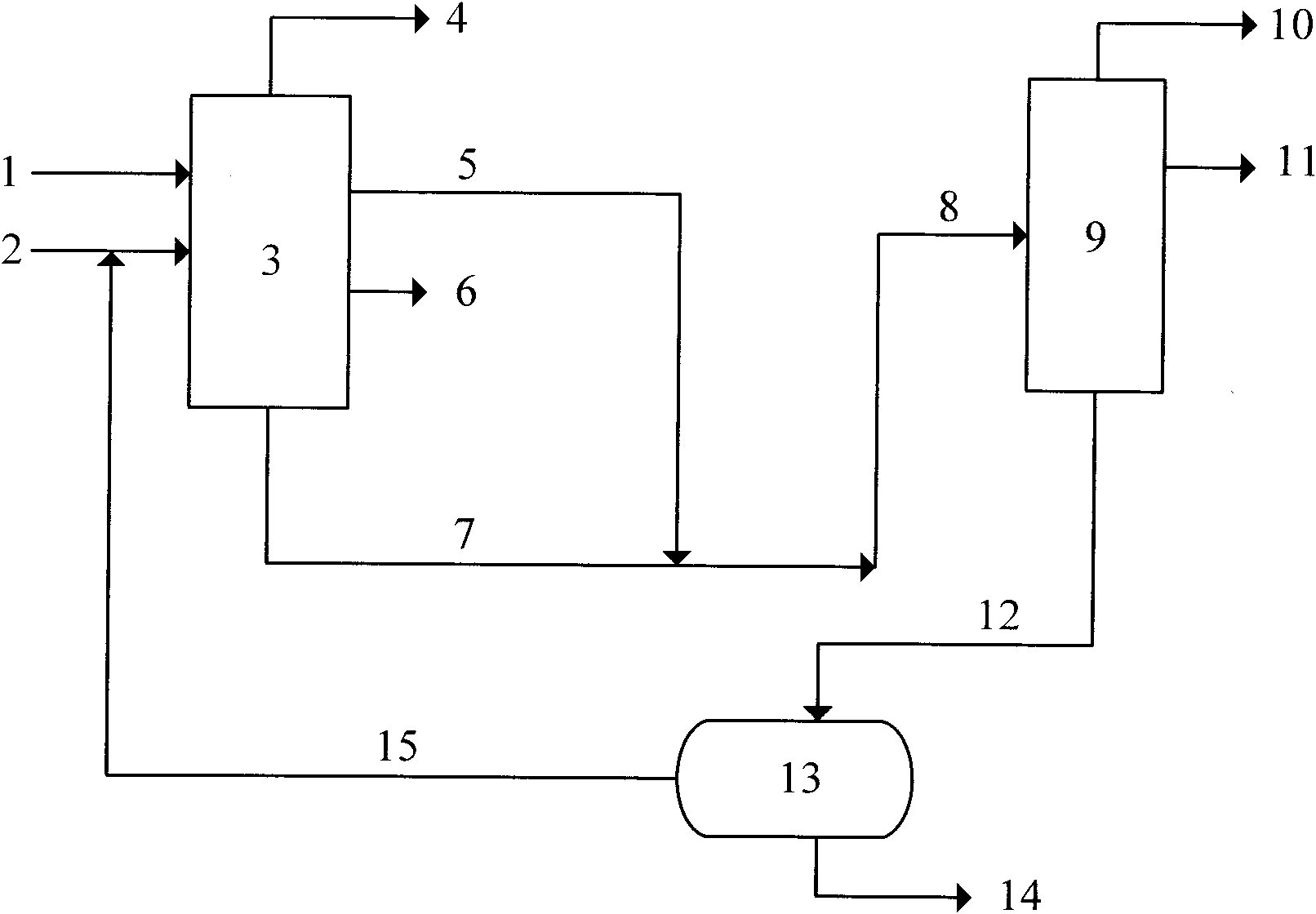

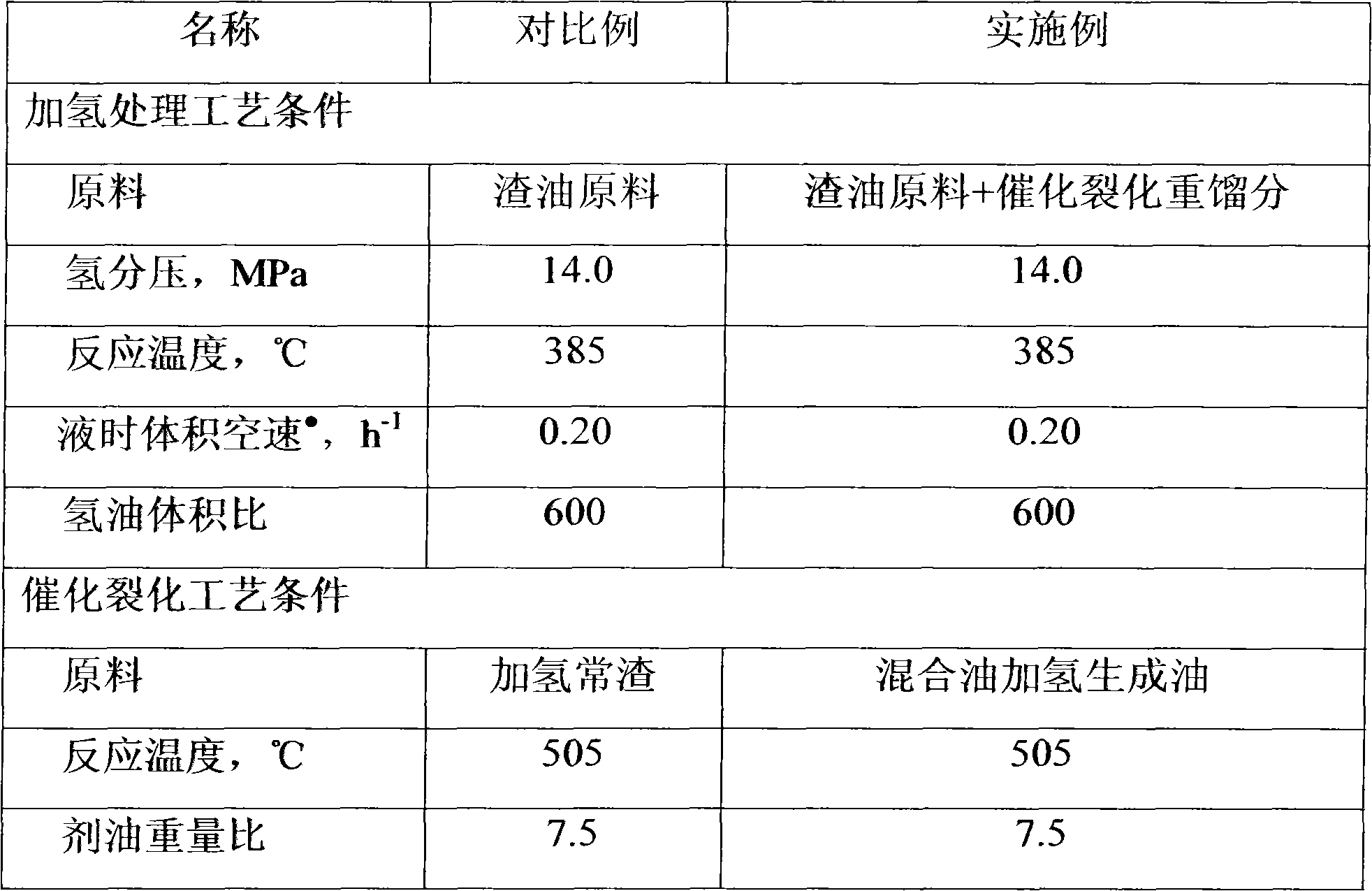

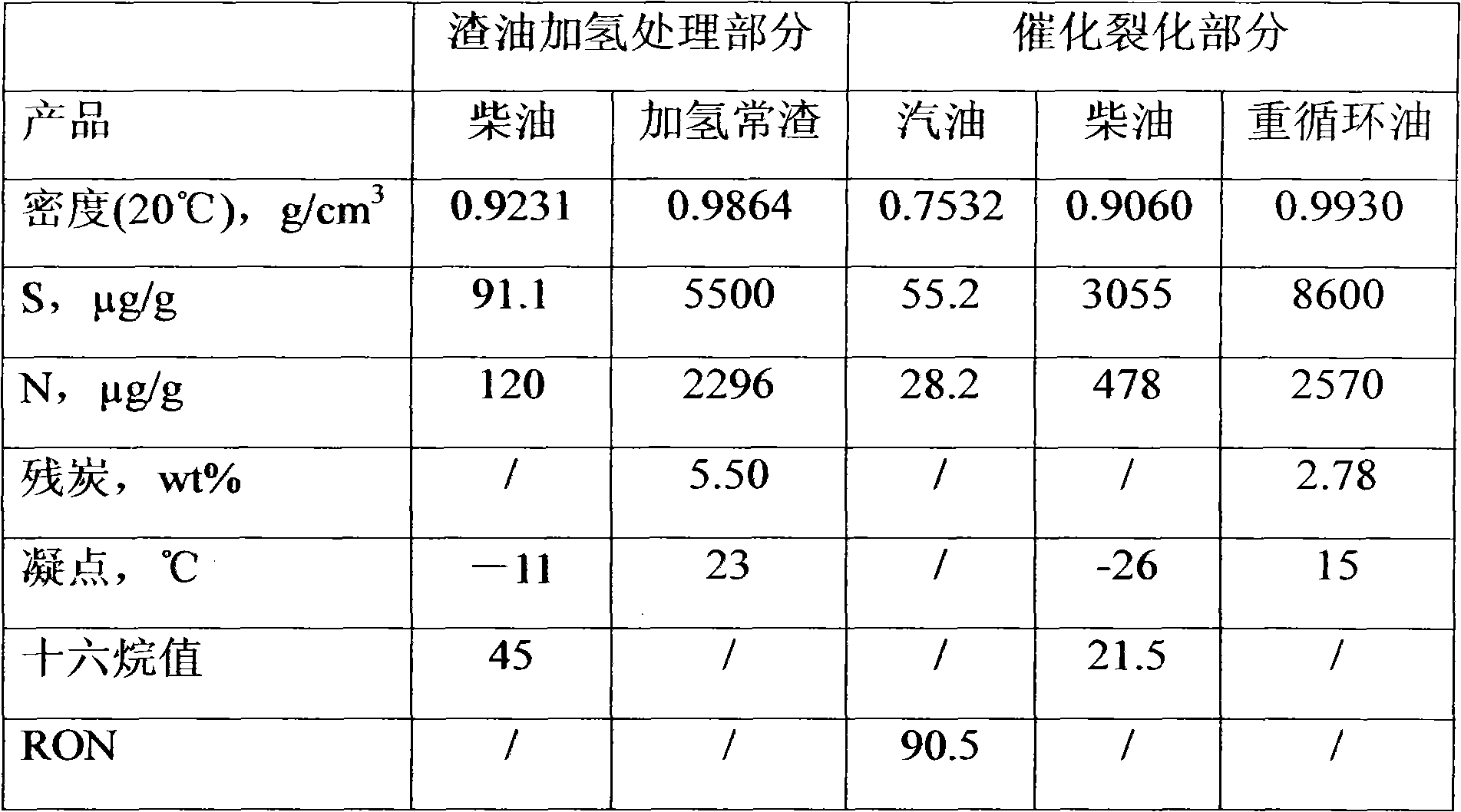

Hydrotreatment and catalytic cracking combined method for residuum

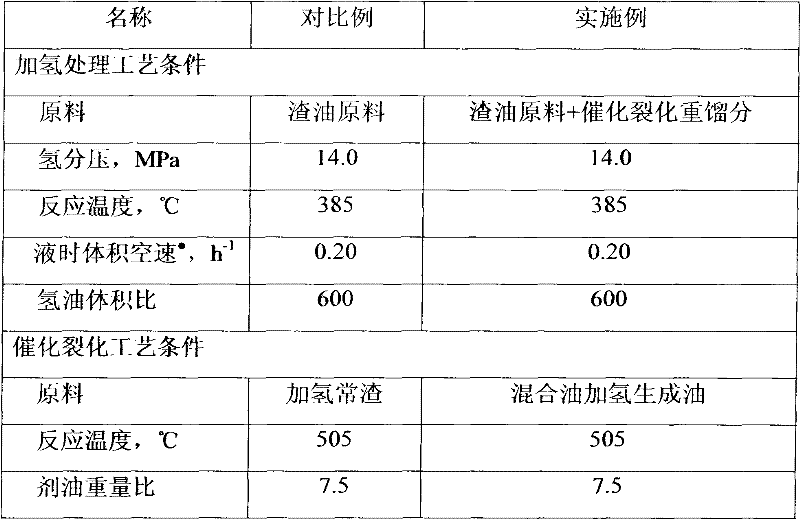

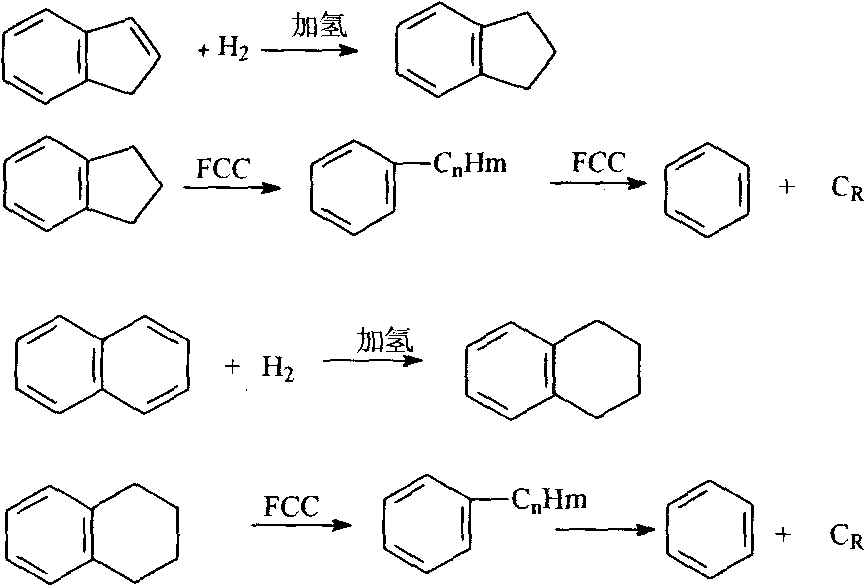

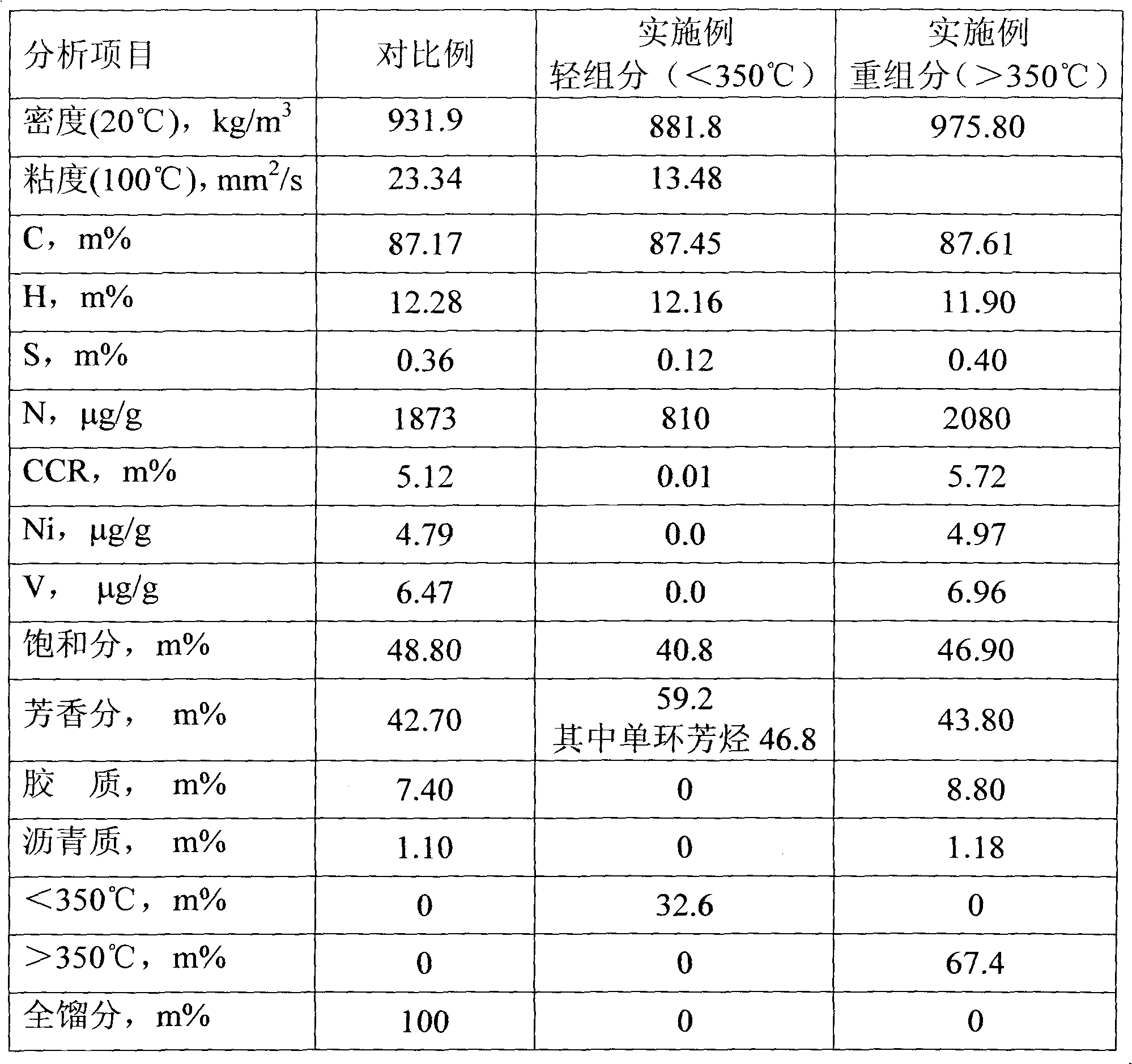

InactiveCN102732314AHigh aromatic contentHigh content of impurities such as sulfurTreatment with hydrotreatment processesPtru catalystGasoline

The invention discloses a hydrotreatment and catalytic cracking combined method for residuum. The hydrotreatment and catalytic cracking combined method for residuum comprises the following steps that a residuum raw material and at least part of a catalytically cracked diesel fraction undergo a hydrotreatment reaction in the presence of hydrogen and a hydrotreatment catalyst in a hydrotreatment device; a hydrotreatment reaction effluent is subjected to gas-liquid separation; a gas phase is circularly used for a hydrotreatment reaction and a liquid phase directly enters into a catalytic cracking device without passing through a fractionation device and then undergoes a catalytic cracking reaction; a catalytic cracking reaction effluent is treated by the fractionation device so that dry gas, liquefied gas, a catalytically cracked gasoline fraction, a catalytically cracked diesel fraction, catalytically cracked recycle oil and catalytically cracked slurry are separated out; a part or all of the catalytically cracked diesel fraction is fed back to the hydrotreatment device and then undergoes a hydrotreatment reaction; and the catalytically cracked recycle oil is fed back to the catalytic cracking device and then undergoes a catalytic cracking reaction. Compared with the prior art, the hydrotreatment and catalytic cracking combined method for residuum can realize maximum-yield production of gasoline, save an equipment investment, fully utilize reaction heat and reduce production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for treating inferior oil

ActiveCN106701175AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesCycle oilChemistry

The invention discloses a process for treating inferior oil, the process includes a hydropretreating reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone; the process includes the following contents: a residual oil raw material and hydrogen are mixed, and in turn pass through the hydropretreating reaction zone and the hydrotreating reaction zone which are in series connection, after gas-liquid separation of a hydrotreating reaction zone reaction effluent, a gas phase is recycled back to the hydropretreating reaction zone and / or the hydrotreating reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for catalytic cracking reaction, a catalytic cracking reaction effluent is separated to obtain a dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel oil fraction, catalytic cracking heavy cycle oil and catalytic cracking oil slurry, and the catalytic cracking diesel and the catalytic cracking heavy cycle oil are partially or totally recycled back to the hydrotreating reaction zone for hydrotreating reaction. The method can prolong the stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreatment and catalytic cracking deeply-combined method for residuum

InactiveCN102732315AQuality improvementIncrease productionTreatment with hydrotreatment processesPtru catalystGasoline

The invention discloses a hydrotreatment and catalytic cracking deeply-combined method for residuum. The hydrotreatment and catalytic cracking deeply-combined method for residuum comprises the following steps that a residuum raw material, at least part of catalytically cracked heavy recycle oil and at least part of catalytically cracked slurry undergo a hydrotreatment reaction in the presence of hydrogen and a hydrotreatment catalyst in a hydrotreatment device; a hydrotreatment reaction effluent is subjected to gas-liquid separation; a liquid phase directly enters into a catalytic cracking device without passing through a fractionation device and then undergoes a catalytic cracking reaction; a catalytic cracking reaction effluent is treated by the fractionation device so that dry gas, liquefied gas, a catalytically cracked gasoline fraction, a catalytically cracked diesel fraction, catalytically cracked heavy recycle oil and catalytically cracked slurry are separated out; and a part or all of the catalytically cracked heavy recycle oil and the catalytically cracked slurry are fed back to the hydrotreatment device and then undergo a hydrotreatment reaction. Compared with the prior art, the hydrotreatment and catalytic cracking deeply-combined method for residuum can realize maximum-yield production of gasoline, save an equipment investment, fully utilize reaction heat and reduce production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating residual oil with hydrogenation treatment and catalytic cracking processes

ActiveCN106701191AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a method for treating residual oil with hydrogenation treatment and catalytic cracking processes. A hydrogenation pretreatment reaction zone, a hydrogenation treatment reaction zone and a catalytic cracking reaction zone are contained; the method comprises steps as follows: a residual oil material and hydrogen are mixed and sequentially pass the hydrogenation pretreatment reaction zone and the hydrogenation treatment reaction zone which are connected in series; a reaction effluent in the hydrogenation treatment reaction zone is subjected to gas-liquid separation, a gas phase is recycled back to the hydrogenation pretreatment reaction zone and / or the hydrogenation treatment reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for a catalytic cracking reaction, a catalytic cracking effluent is separated, and dry gas, liquefied gas, catalytic cracking gasoline fractions, catalytic cracking diesel fractions, catalytic cracking heavy cycle oil and catalytic cracking oil slurry are obtained, wherein parts of or all of catalytic cracking diesel and catalytic cracking oil slurry are recycled back to the hydrogenation treatment reaction zone for a hydrogenation treatment reaction. By means of the method, the stable operation cycle of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method of residual oil

ActiveCN106701185AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a treatment method of residual oil, which comprises a solvent deasphalting device, a hydrogenation pretreatment reaction area, a hydrogenation treatment reaction area and a catalytic cracking reaction area. The method comprises the following steps that the raw residual oil is fractionated to obtain a light fraction and a heavy fraction; the heavy fraction is treated in the solvent deasphalting device to obtain deasphalted oil and deoiled asphalt; the light fraction, the deasphalted oil and hydrogen are mixed and then sequentially pass through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series; gas-liquid separation is performed on a reaction effluent of the hydrogenation treatment reaction area; a gas phase cycles back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area; a liquid phase directly enters the catalytic cracking reaction area to perform a catalytic cracking reaction; and a catalytic cracking reaction effluent is separated to obtain dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel fraction, catalytic cracking heavy cycle oil and catalytic cracking slurry oil. The method can prolong a stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

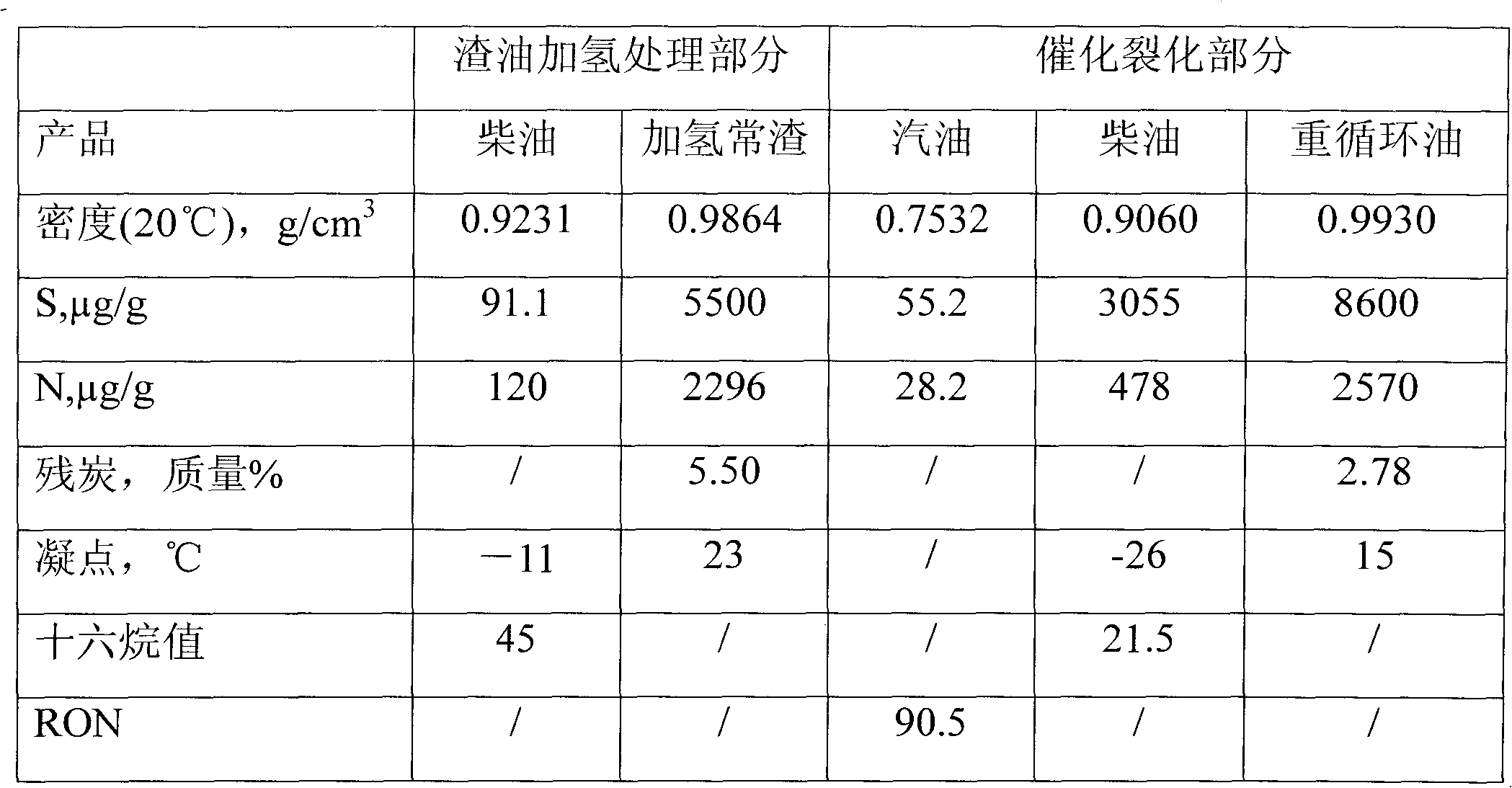

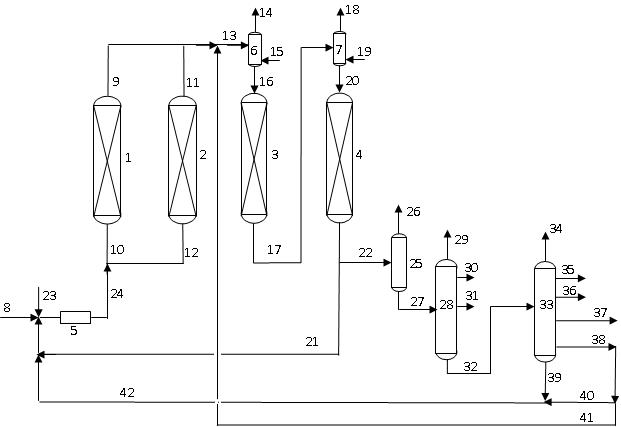

Residual oil hydrogenation treatment and catalytic cracking combination method

ActiveCN102453544AHigh aromatic contentLow cetane numberTreatment with hydrotreatment processesGas phaseFractionation

The present invention discloses a residual oil hydrogenation treatment and catalytic cracking combination method. According to the method, the residual oil hydrogenation treatment process comprises two hydrogenation protection reactors, wherein the two hydrogenation protection reactors are arranged in parallel connection, the feed material of the first hydrogenation protection reactor is the residual oil raw material, and the feed material of the second hydrogenation protection reactor is the catalytic cracking heavy fraction; the effluents of the two reactors are mixed, and the resulting mixture enters a hydrogenation treatment reaction zone to carry out a hydrogenation reaction; the effluent of the hydrogenation reaction is subjected to gas-liquid separation, wherein the resulting gas phase is circularly adopted for the hydrogenation reaction, and the liquid phase directly enters a catalytic cracking apparatus without fractionation; the effluent of the catalytic cracking reaction is separated to obtain dry gas, liquefied gas, catalytic cracking gasoline, and catalytic cracking heavy fraction after catalytic cracking of the gasoline, wherein the catalytic cracking heavy fraction is adopted as the feed material of the second hydrogenation protection reactor. With the method, the operating period of the residual oil hydrogenation apparatus can be prolonged, the maximum amount of the catalytic cracking gasoline can be produced, and the equipment investment can be saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Residual oil hydrogenation treatment and catalytic cracking combined processing method

ActiveCN102311798AIncrease processing costReduce investmentTreatment with hydrotreatment processesFiltrationGas phase

The invention discloses a residual oil hydrogenation treatment and catalytic cracking combined processing method, which comprises: performing the hydrogenation reaction of a residual oil raw material in the presence of hydrogen and a hydrogenation treatment catalyst, and performing gas-liquid separation of efflux of hydrogenation reaction, wherein a gas phase is circularly used in a hydrogenation reaction, and a liquid phase is fractioned to form a light component and a heavy component; allowing a light component to enter a reactor from the bottom of a catalytic cracking riser reactor, allowing a heavy component to enter the reactor as secondary feed of the catalytic cracking riser reactor and performing a catalytic cracking reaction; and separating a dry gas, a liquefied gas and a gasoline fraction from efflux of a catalytic cracking reaction, wherein the fractions of diesel are not separated and enter a residual oil hydrogenation device after filtration. Compared with the prior art, the method can produce high-octane number gasoline and high-added-value liquefied gas to a maximum degree; meanwhile, the method can fully utilizes reaction heat and reduces production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreatment and catalytic cracking combined method for residuum

InactiveCN102732311AQuality improvementIncrease productionTreatment with hydrotreatment processesPtru catalystGasoline

The invention discloses a hydrotreatment and catalytic cracking combined method for residuum. The hydrotreatment and catalytic cracking combined method for residuum comprises the following steps that a residuum raw material and at least part of catalytically cracked heavy recycle oil undergo a hydrotreatment reaction in the presence of hydrogen and a hydrotreatment catalyst in a hydrotreatment device; a hydrotreatment reaction effluent is subjected to gas-liquid separation; a gas phase is circularly used for a hydrotreatment reaction and a liquid phase directly enters into a catalytic cracking device without passing through a fractionation device and then undergoes a catalytic cracking reaction; a catalytic cracking reaction effluent is treated by the fractionation device so that dry gas, liquefied gas, a catalytically cracked gasoline fraction, a catalytically cracked diesel fraction, catalytically cracked heavy recycle oil and catalytically cracked slurry are separated out; and a part or all of the catalytically cracked heavy recycle oil is fed back to the hydrotreatment device and then undergoes a hydrotreatment reaction. Compared with the prior art, the hydrotreatment and catalytic cracking combined method for residuum can realize maximum-yield production of gasoline, save an equipment investment, fully utilize reaction heat and reduce production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

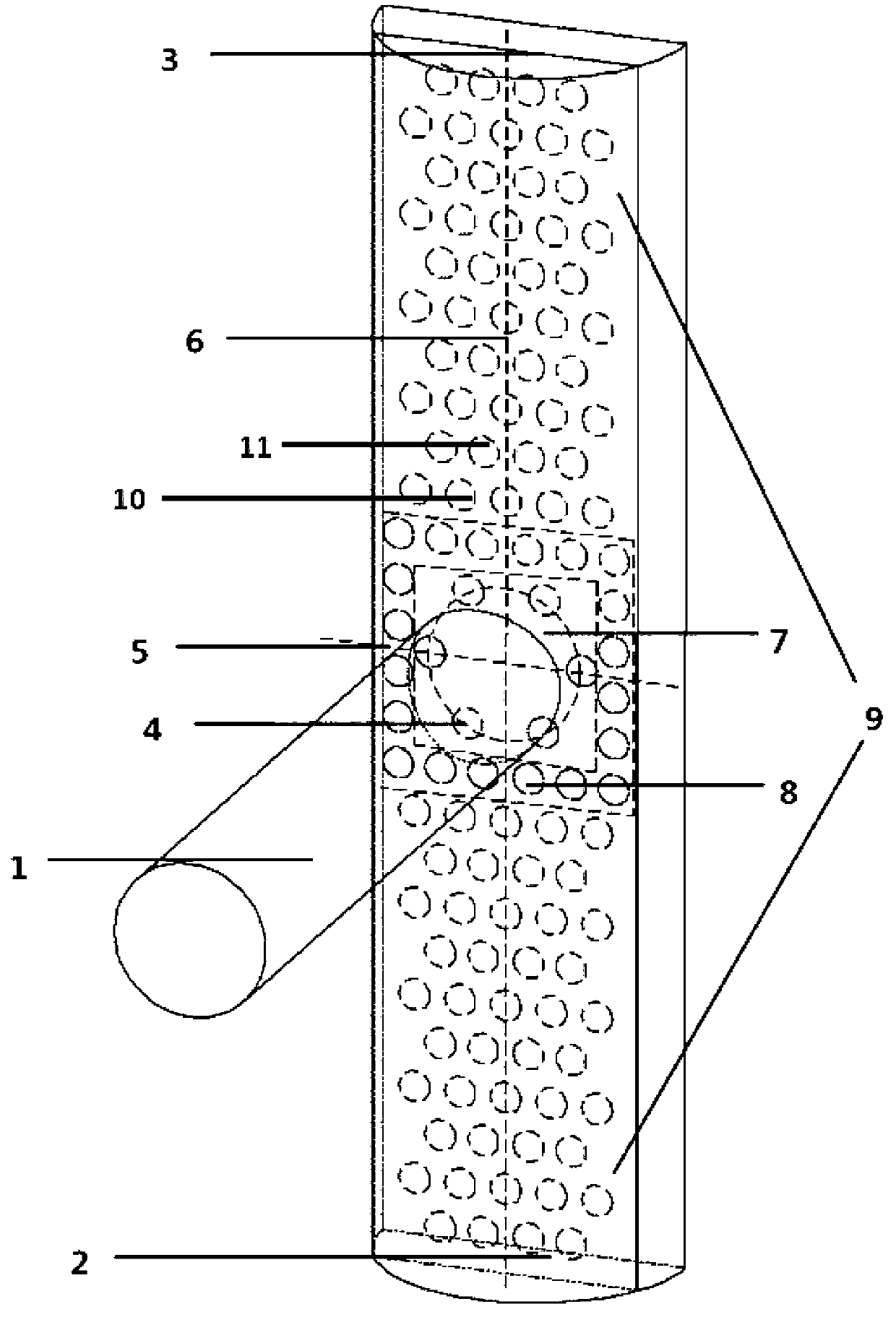

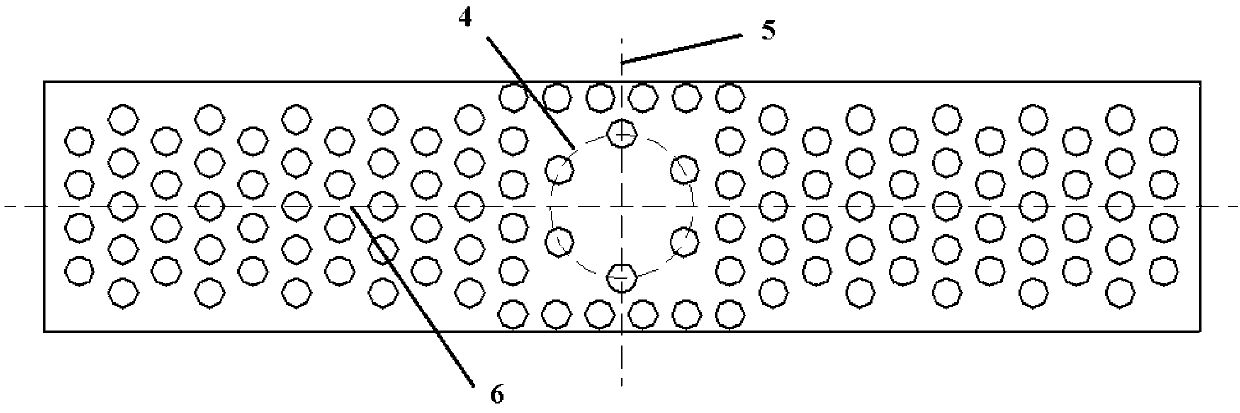

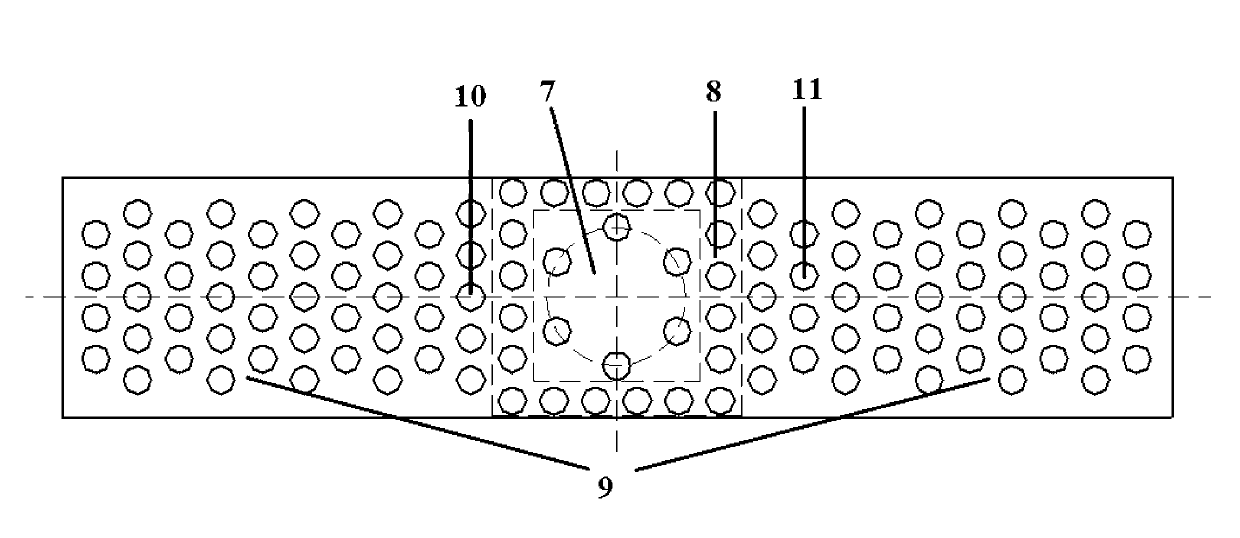

Head baffle of plate-fin heat exchanger

InactiveCN103017591AImprove logistics distributionImprove heat transfer effectHeat exchanger casingsEngineeringBilateral symmetry

The invention discloses a head baffle of a plate-fin heat exchanger. A head comprises a fluid inlet tube and an arc head. A baffle is disposed in the middle of arc structure of the arc head. 1-3mm of thickness of the baffle is recommended. The baffle is provided with a plurality of through holes. The diameter of each through hole is one fifth of that of the inlet tube. Spacing of both transverse and longitudinal holes is half of the hole diameter. The through holes arrayed on the baffle include three feature regions, namely an inlet tube projection region, a projection peripheral region and a bilateral symmetry region. The baffle structure is provided according to the logistical distribution feature of the traditional head. The diameter of the through holes is defined. The head baffle is simple and practical. Logistical distribution condition inside the head is improved effectively. The structural parameters of the baffle are defined according to the structural size of the head, so that the head baffle is universal, can be used as design basis and is important to improving heat exchange performance of the plate-fin heat exchanger.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Hydrotreatment and catalytic cracking combined method of heavy hydrocarbon raw material

ActiveCN102876377BReduce the amount of mixed hydrogenStable temperatureTreatment with hydrotreatment processesFluid phaseHydrogenation reaction

The invention discloses a hydrotreatment and catalytic cracking combined method of a heavy hydrocarbon raw material. According to the invention, an upflow reactor is at least connected in series with a downflow fixed bed reactor. The heavy hydrocarbon raw material passes through UFR and is mixed with a catalytic cracking heavy fraction, and the mixture enters the downflow fixed bed reactor. A hydrogenation reaction effluent is separated so as to obtain a liquid phase, and the liquid phase is subjected to catalytic cracking. The obtained catalytic cracking heavy fraction returns to an inlet of the downflow fixed bed reactor. According to the method, the catalytic cracking heavy distillate oil, which is introduced into the inlet of the fixed bed reactor, is beneficial to hydrogenation reaction and can significantly improve temperature rising of the bed when used as cutback oil and can minimize the amount of hydrogen injected through the inlet when used as a hydrogen donor, thus further raising cooperative effect of combined flow equipment and prolonging the running period as well.

Owner:CHINA PETROLEUM & CHEM CORP +1

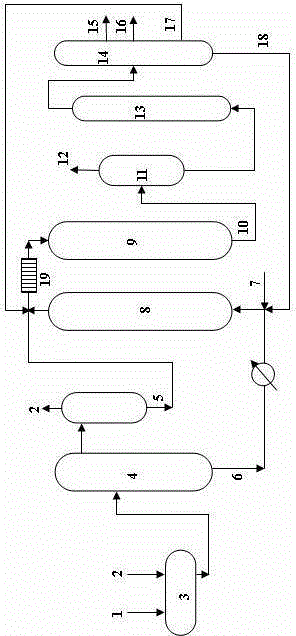

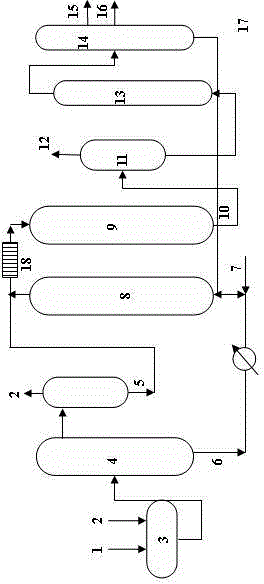

Combined process of hydrotreatment and light fraction-conversion for residual oil

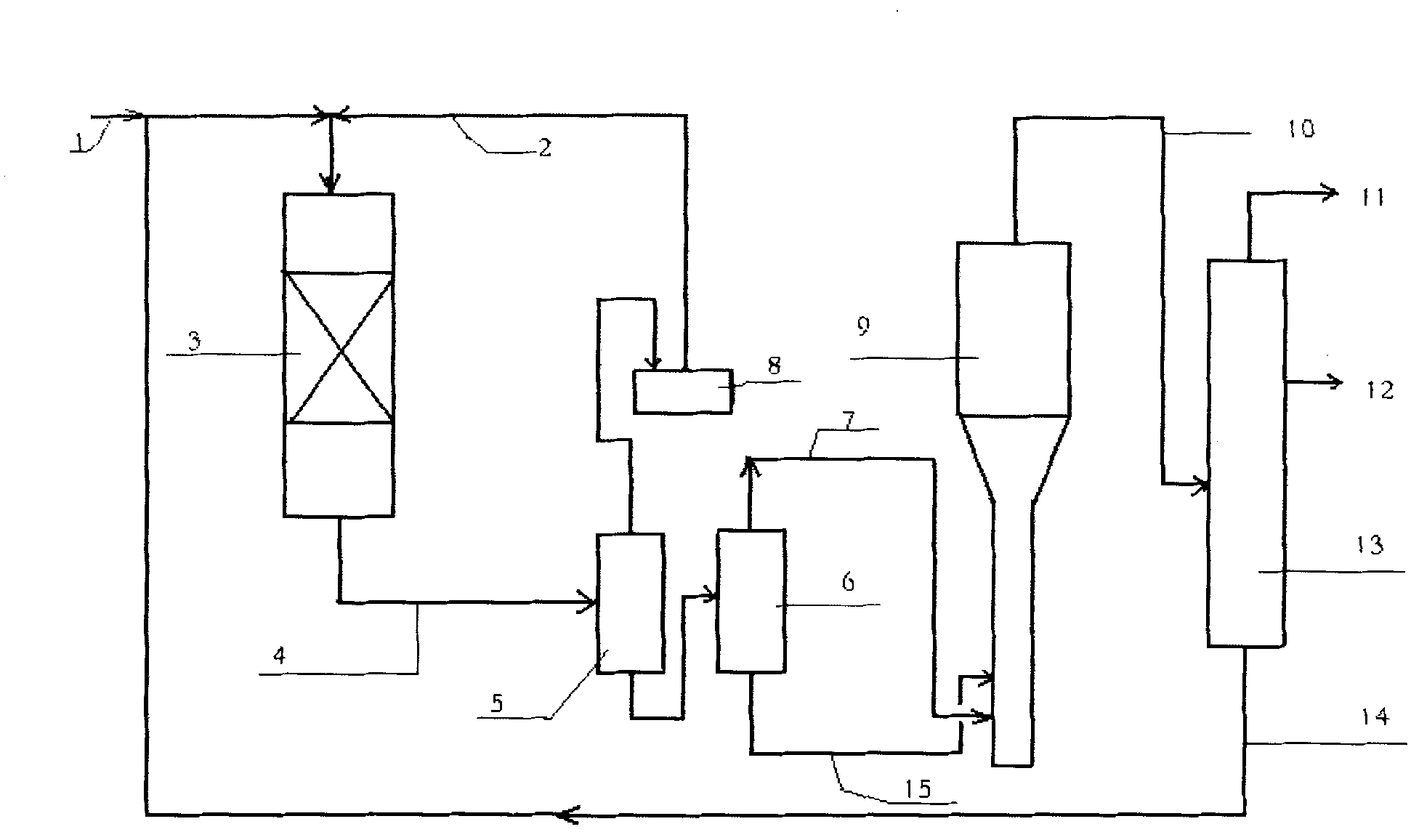

ActiveCN103102944BImprove the effect of hydrotreating reactionAct as a diluentTreatment with hydrotreatment processesFluidized bedFixed bed

The invention discloses a combined process of hydrotreatment and light fraction-conversion for residual oil. The combined process comprises the following steps: (1) allowing an inferior heavy oil feedstock to enter into a solvent deasphalting device so as to obtain deasphalted oil and de-oiled asphalt; (2) mixing the de-oiled asphalt obtained in step (1) with at least a part of oil slurry and allowing an obtained mixture to enter into a fluidized bed hydrotreatment unit for fluidized bed hydrotreatment; (3) mixing an effluent of fluidized bed hydrotreatment obtained in the step (2) with the deasphalted oil, adding at least a part of recycle oil of a catalytic cracking unit at the same time and allowing an obtained mixture to enter into a fixed bed hydrotreatment unit, wherein generated oil of an effluent of fixed bed hydrotreatment is used as a feedstock for the catalytic cracking unit; and (4) carrying out treatment in a fractionating tower of the catalytic cracking unit so as to obtain catalytic cracking reaction products including a gasoline fraction, a diesel oil fraction, recycle oil and oil slurry. Compared with the prior art, the combined process provided by the invention has the advantages of wide sources of the feedstocks, low equipment investment, stable operation, a long operation period and a good synergistic and coordination effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating inferior oil product by combined process

ActiveCN110408431AExtended operating cycleReduce poisonTreatment with hydrotreatment processesHydrogenReaction temperature

The invention discloses a method for treating an inferior oil product by a combined process. The method comprises the following steps: allowing an inferior oil raw material and hydrogen to enter a mixer for saturated hydrogen dissolution, and allowing an obtained mixture to pass through a hydropretreating zone; and separating a reaction effluent, allowing a separated reaction effluent and catalytic-cracked circulating oil to enter a hydrotreating reaction zone, separating an obtained reaction effluent, allowing obtained hydrotreated residual oil to undergo a catalytic cracking reaction, allowing obtained circulating oil and / or an oil slurry to be circulated to a hydropretreating reaction zone, and allowing a part of obtained circulating oil to be circulated to the hydrotreating reaction zone; wherein the reaction temperature t1 of the hydropretreating reaction zone is higher than the reaction temperature t2 of the hydrotreating reaction zone. The method provided by the invention can increase the utilization rate of a main hydrotreating catalyst, prolongs the operation cycle of a combined device, and increases the operation efficiency of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing gasoline and low-sulfur ship fuel

ActiveCN113046125AMaximize productionReduce investmentTreatment with hydrotreatment processesBio-feedstockHydrogenation reactionFluidized bed

The invention discloses a method for producing gasoline and low-sulfur ship fuel. The method comprises the following steps: hydrotreating a residual oil raw material through a fluidized bed hydrotreating reaction device and a fixed bed hydrotreating reaction device in sequence to obtain a hydrogenation reaction effluent; carrying out gas-liquid separation on the hydrogenation reaction effluent, not fractionating the obtained liquid phase, taking one part as low-sulfur ship combustion, and carrying out catalytic cracking on the remaining part; and returning a catalytic cracking heavy fraction in the effluent of the catalytic cracking reaction to be mixed with the residual oil raw material for hydrotreating. According to the combined process, high-octane catalytic cracking gasoline and low-sulfur ship fuel products can be produced to the maximum extent. Meanwhile, hydrogenation load is reduced, a catalytic cracking fractionation system is simplified, and equipment investment and operation energy consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of residual oil processing method

ActiveCN106701185BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a treatment method of residual oil, which comprises a solvent deasphalting device, a hydrogenation pretreatment reaction area, a hydrogenation treatment reaction area and a catalytic cracking reaction area. The method comprises the following steps that the raw residual oil is fractionated to obtain a light fraction and a heavy fraction; the heavy fraction is treated in the solvent deasphalting device to obtain deasphalted oil and deoiled asphalt; the light fraction, the deasphalted oil and hydrogen are mixed and then sequentially pass through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series; gas-liquid separation is performed on a reaction effluent of the hydrogenation treatment reaction area; a gas phase cycles back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area; a liquid phase directly enters the catalytic cracking reaction area to perform a catalytic cracking reaction; and a catalytic cracking reaction effluent is separated to obtain dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel fraction, catalytic cracking heavy cycle oil and catalytic cracking slurry oil. The method can prolong a stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating inferior residual oil by combined process

ActiveCN110408432AReduce poisonTake full advantage of activityTreatment with hydrotreatment processesHydrogenReaction temperature

The invention discloses a method for treating inferior residual oil by a combined process. The method includes the steps that after heavy oil raw oil is saturated and dissolved in hydrogen, firstly, hydrodemetallization and partial desulfurization are carried out in a hydrotreating pretreatment area; the reaction effluent is saturated and dissolved in hydrogen again and then enters a hydrotreatingreaction area for hydrodesulfurization and hydrodenitrification; the reaction temperature in the hydrotreating pretreatment reaction area is higher than that in the hydrotreating reaction area. According to the method, the hydrotreating pretreatment reaction area reacts at a higher temperature, most of metal impurities in materials can be removed, so that the deactivation reason of a desulfurization catalyst and / or denitrification catalyst in the hydrotreating reaction area is changed from previous metal deposition and carbon deposition deactivation to only carbon deposition deactivation, further the desulfurization catalyst and denitrification catalyst can be subjected to regeneration treatment after being used a cycle, the operation cycle of a hydrogenation unit is prolonged, and thus the operation efficiency of the unit is increased, and the economy is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Residual oil conversion combined process method

ActiveCN103102982BRealize comprehensive utilizationGuarantee normal productionTreatment with hydrotreatment processesFluidized bedFixed bed

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for treating residual oil by hydrotreating-catalytic cracking process

ActiveCN106701191BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a method for treating residual oil with hydrogenation treatment and catalytic cracking processes. A hydrogenation pretreatment reaction zone, a hydrogenation treatment reaction zone and a catalytic cracking reaction zone are contained; the method comprises steps as follows: a residual oil material and hydrogen are mixed and sequentially pass the hydrogenation pretreatment reaction zone and the hydrogenation treatment reaction zone which are connected in series; a reaction effluent in the hydrogenation treatment reaction zone is subjected to gas-liquid separation, a gas phase is recycled back to the hydrogenation pretreatment reaction zone and / or the hydrogenation treatment reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for a catalytic cracking reaction, a catalytic cracking effluent is separated, and dry gas, liquefied gas, catalytic cracking gasoline fractions, catalytic cracking diesel fractions, catalytic cracking heavy cycle oil and catalytic cracking oil slurry are obtained, wherein parts of or all of catalytic cracking diesel and catalytic cracking oil slurry are recycled back to the hydrogenation treatment reaction zone for a hydrogenation treatment reaction. By means of the method, the stable operation cycle of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

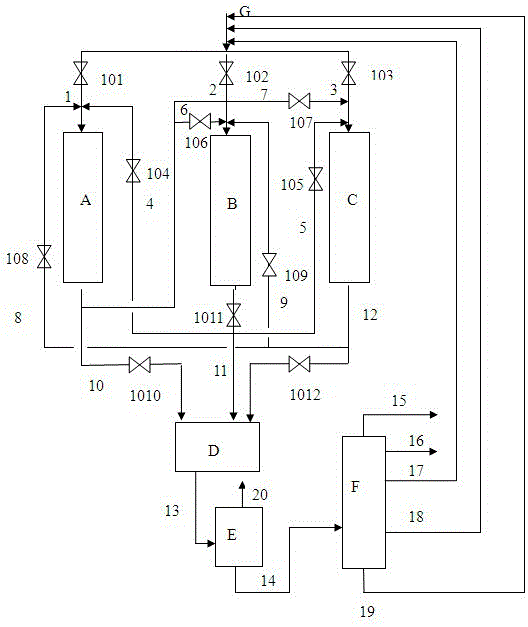

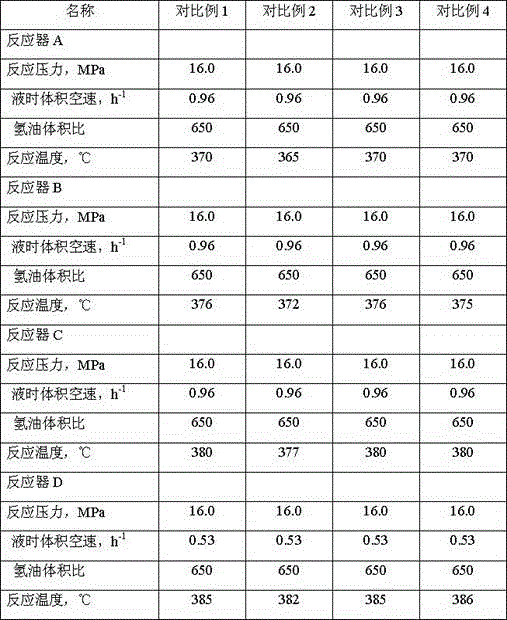

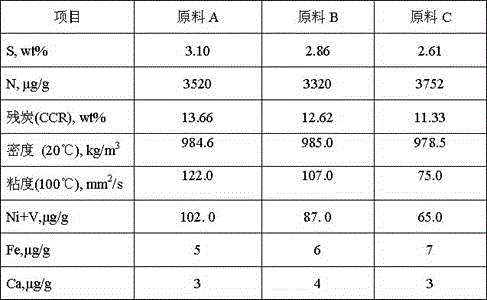

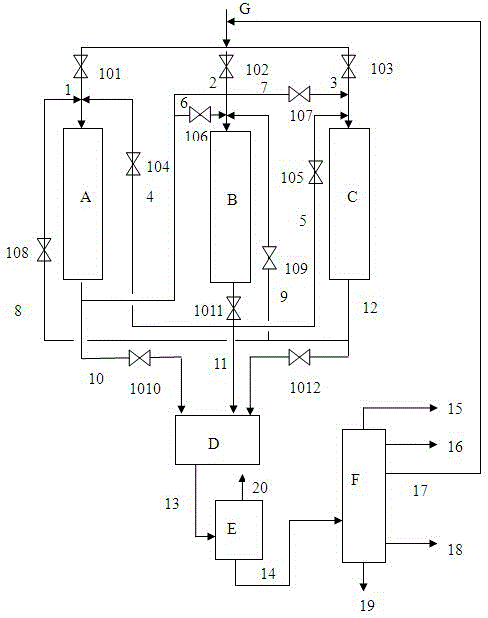

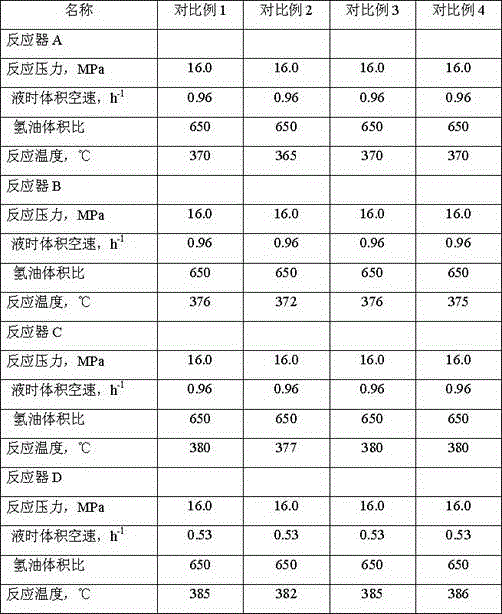

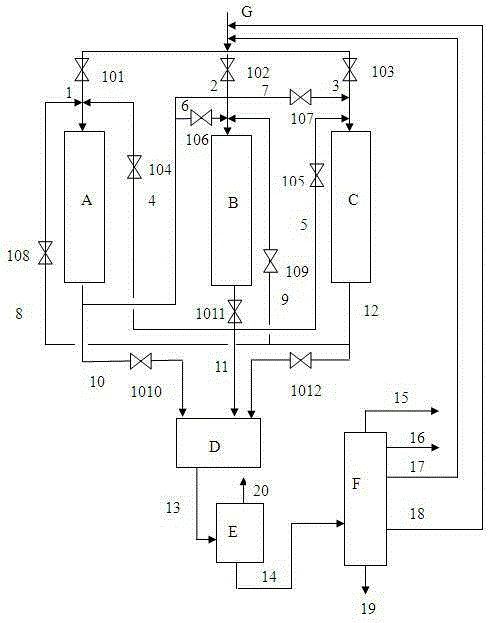

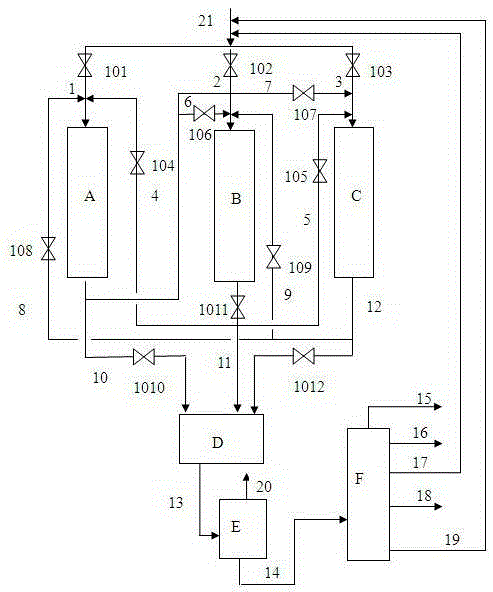

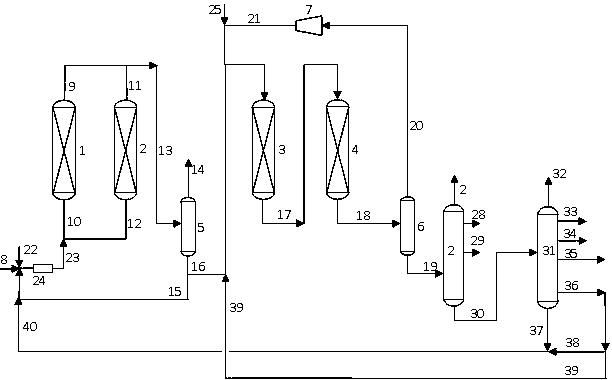

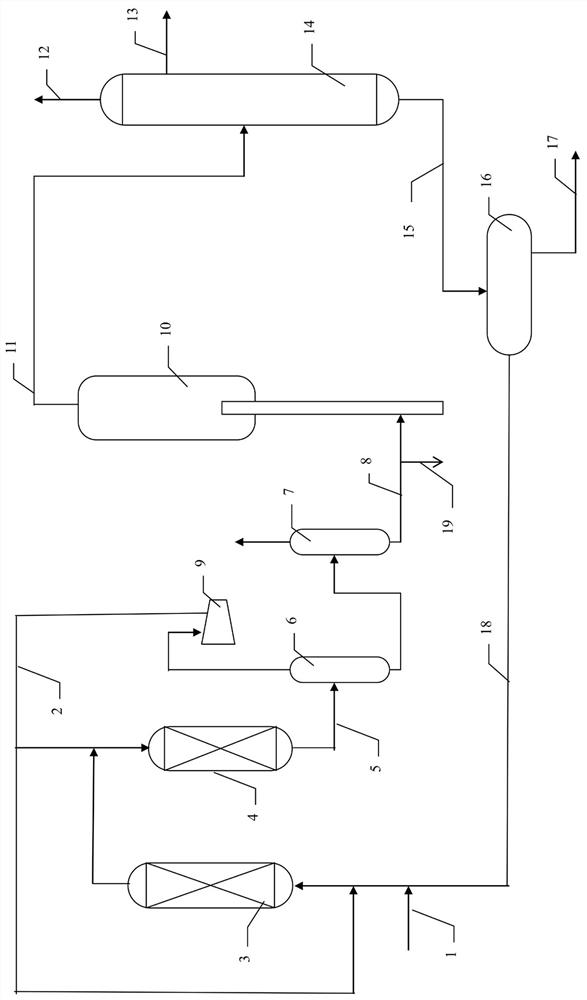

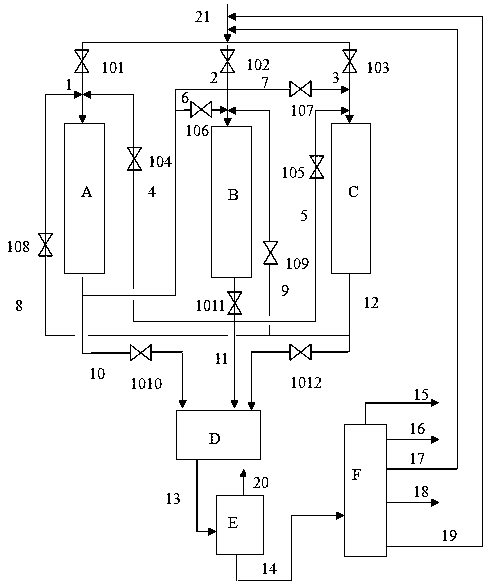

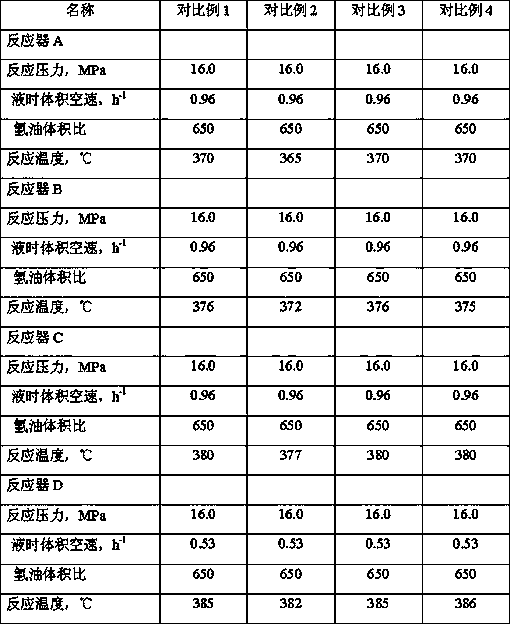

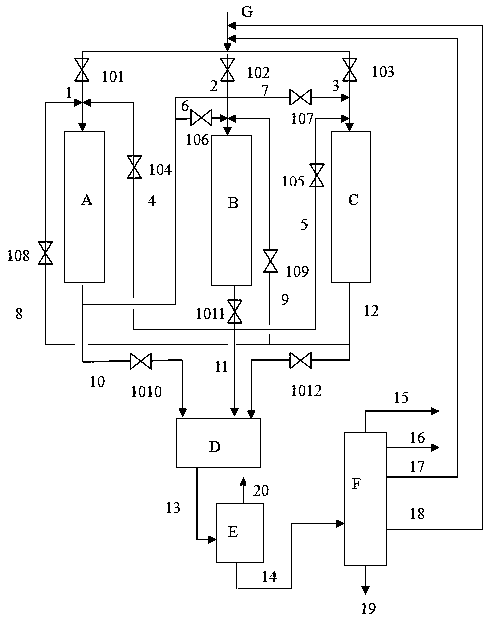

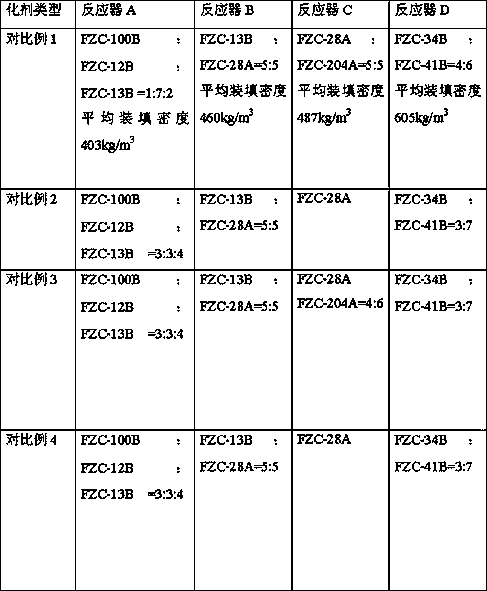

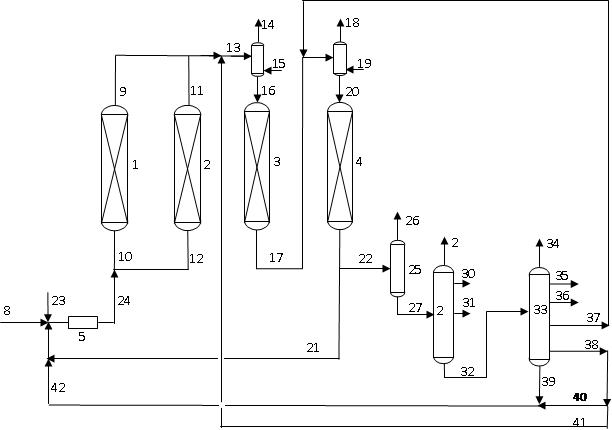

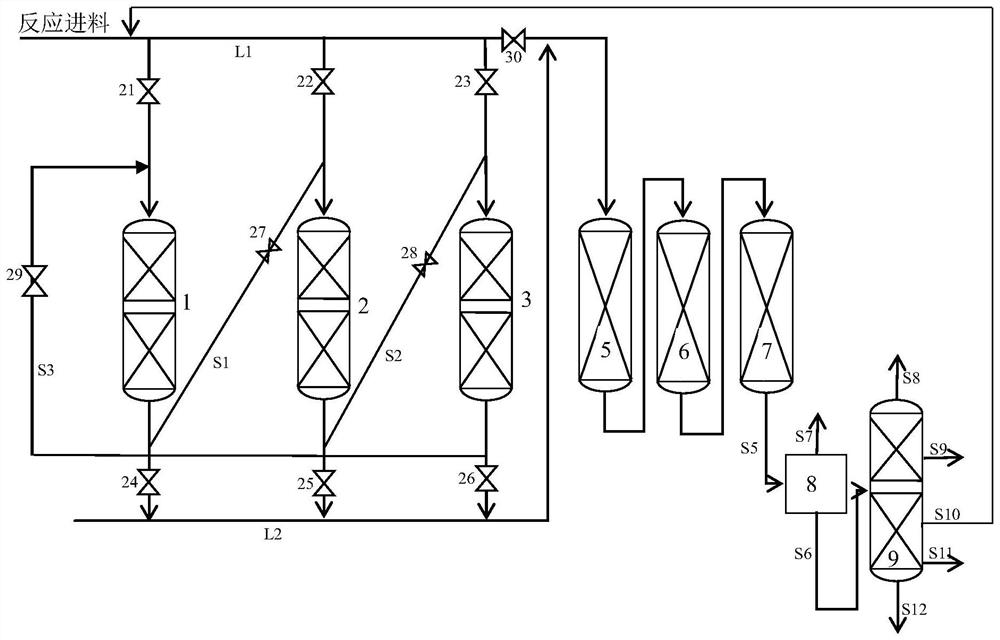

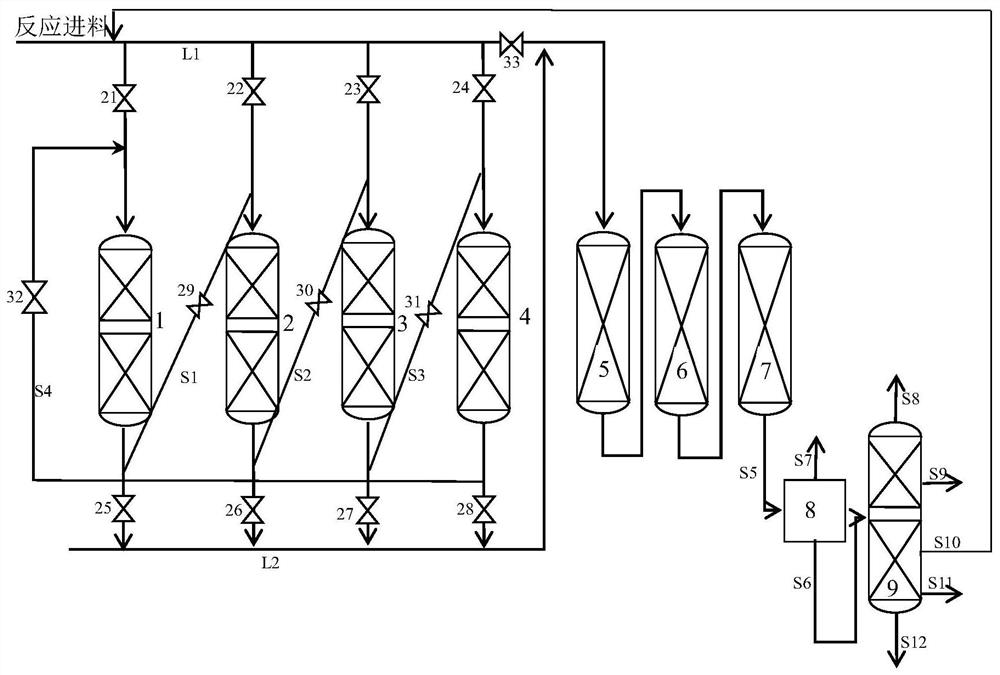

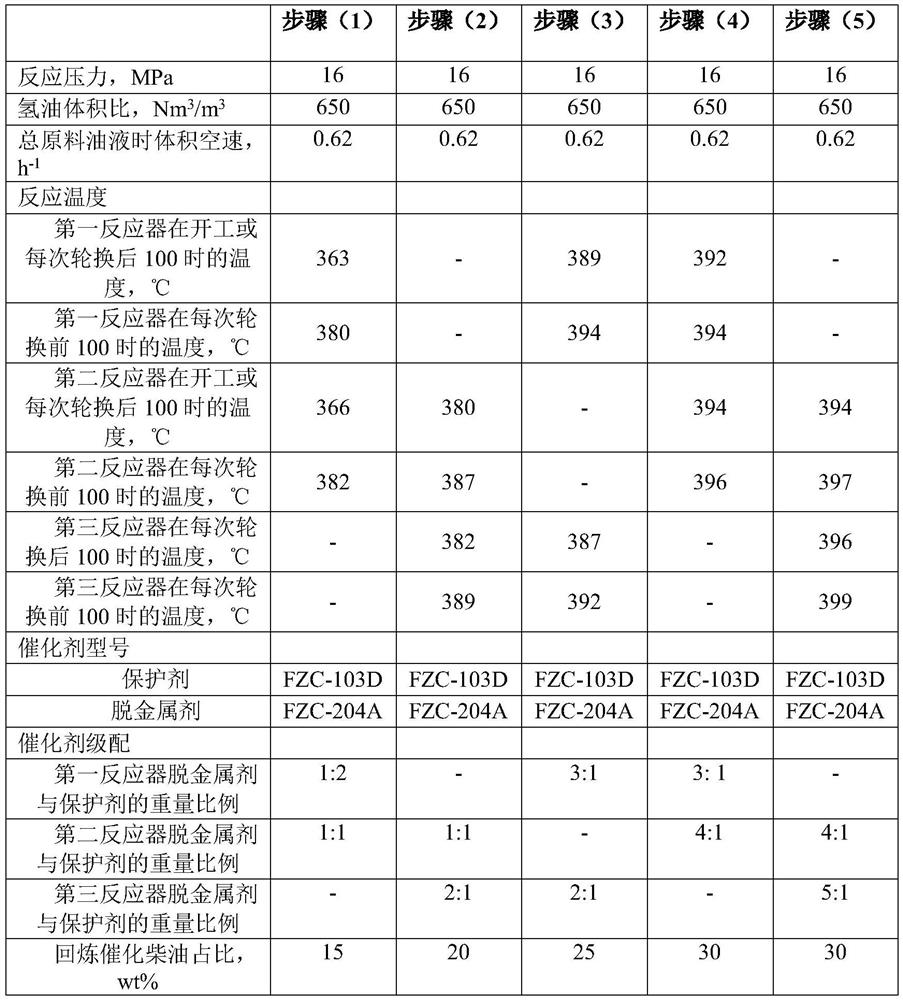

Series alternate residual oil hydrotreatment-catalytic cracking combined process method and system

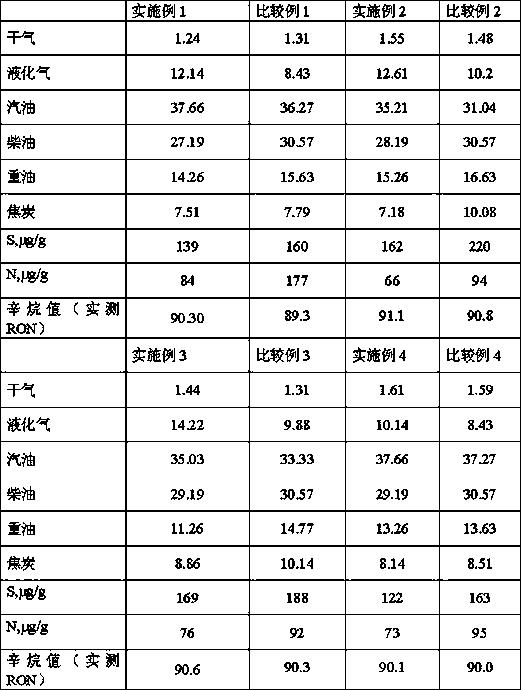

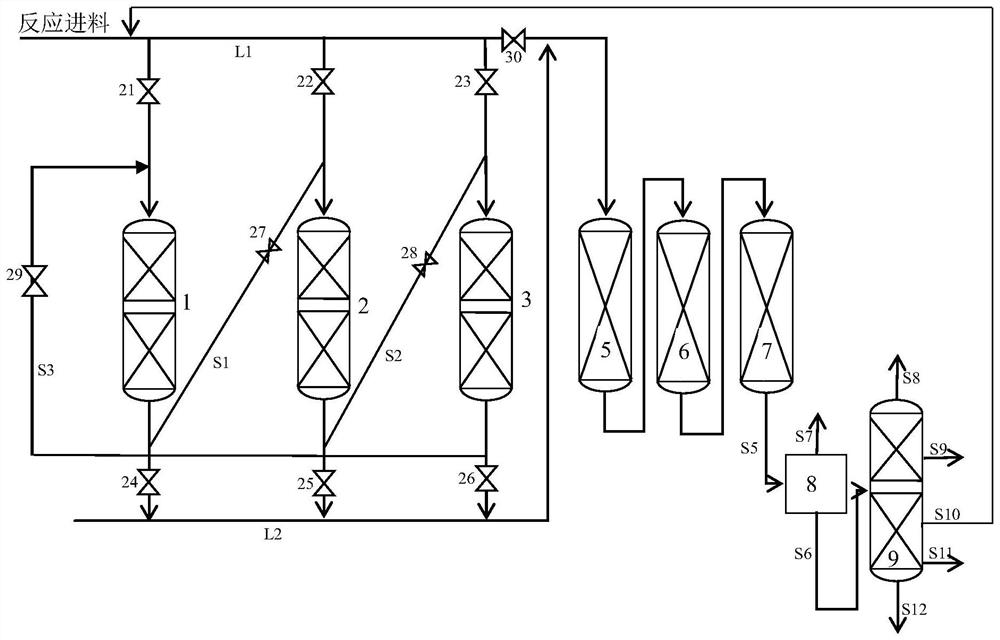

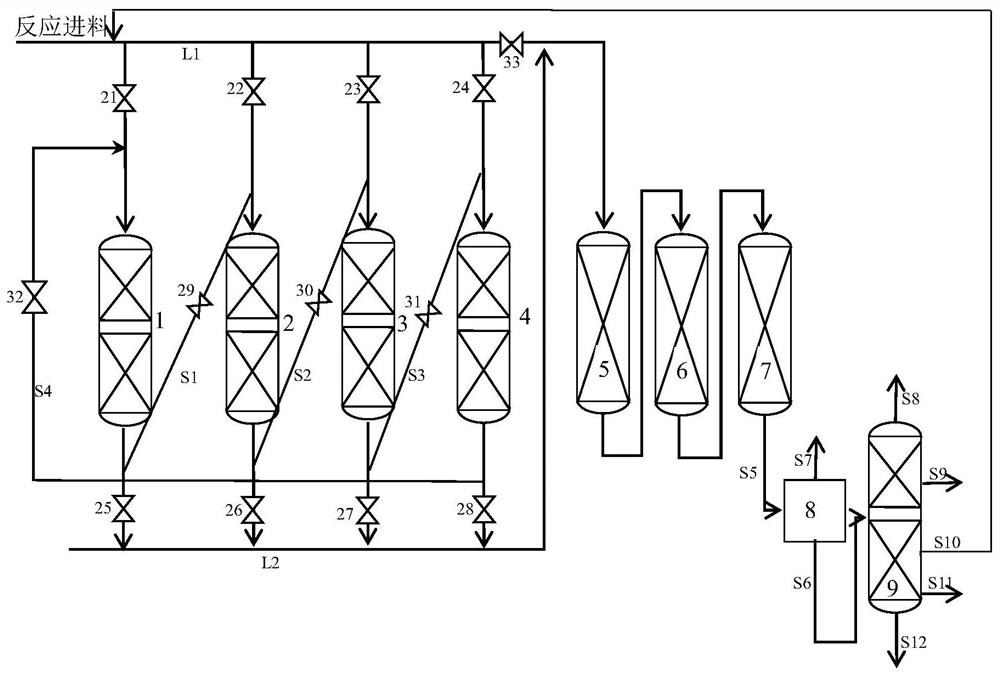

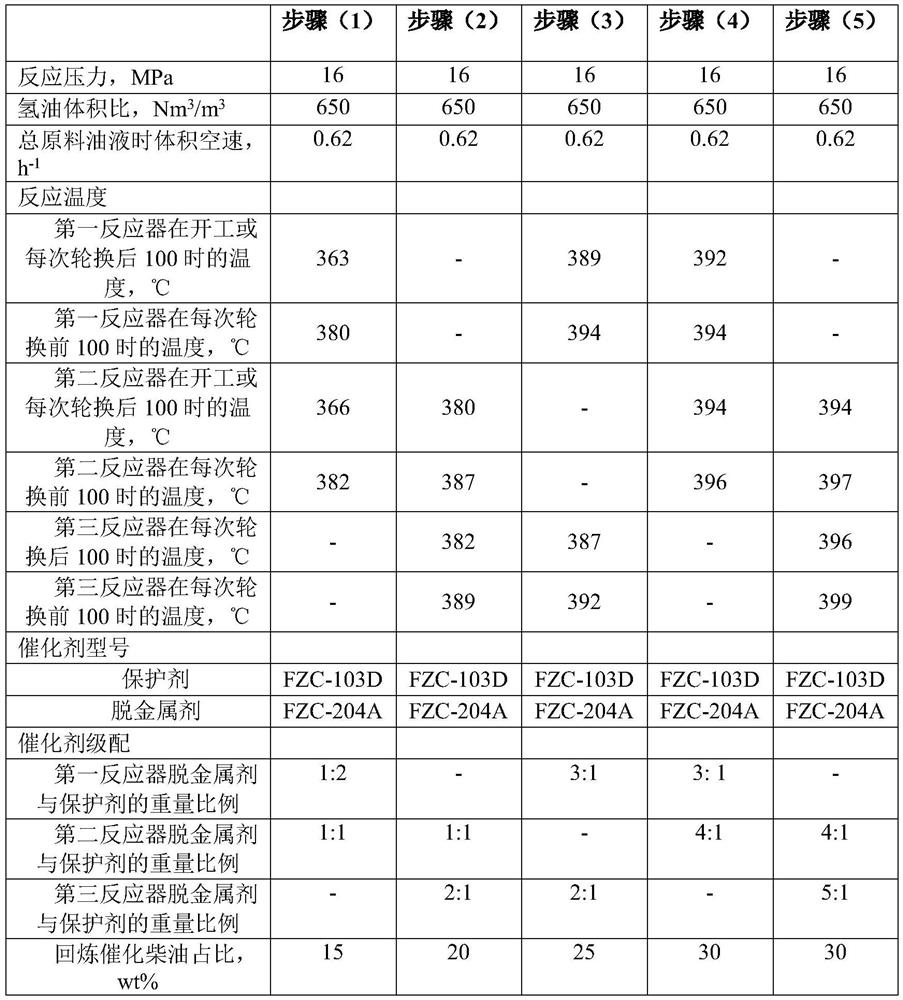

ActiveCN112210401ARealize long-term operationExtended run timeTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystProcess engineering

The invention discloses a series alternate residual oil hydrotreatment-catalytic cracking combined process method and system. The method comprises the following steps: mixing a residual oil raw material and at least part of a catalytically cracked diesel fraction with hydrogen, allowing the obtained mixture to sequentially pass through a hydrogenation pretreatment zone and a hydrotreating reactionzone which are connected in series, carrying out gas-liquid separation on the reaction effluent of the hydrotreating reaction zone, and allowing the separated liquid phase to directly enter a catalytically cracked reaction zone to carry out a catalytic cracking reaction. The hydrogenation pretreatment reaction zone comprises N hydrogenation pretreatment reactors, the first hydrogenation pretreatment reactor to the N-1th hydrogenation pretreatment reactor are sequentially connected in series and are used as N1-stage online hydrogenation pretreatment reactors, and the Nth hydrogenation pretreatment reactor is used as an offline hydrogenation pretreatment reactor. According to the method and the system, the operation time of the hydrotreating pretreatment process is long without shutdown, the stable exertion of the overall catalytic activity of the hydrotreating main catalyst is facilitated, reasonable and limited alternating times are ensured, and the operation time and the working efficiency of the hydrotreating reactor are prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Residual oil hydrogenation treatment and catalytic cracking combined method

ActiveCN102311801BEliminates repetitive processing stepsReduce investmentTreatment with hydrotreatment processesCombined methodLiquid gas

The invention discloses a residual oil hydrogenation treatment and catalytic cracking combined method, which comprises the following components: performing the hydrogenation treatment reaction of a residual oil raw material in the presence of hydrogen and a hydrogenation catalyst, separating product of the reaction to obtain a gas, hydrogenated naphtha, hydrogenated diesel and hydrogenated tail oil, wherein the gas is circularly used in a hydrogenation reaction, the hydrogenated naphtha and hydrogenated tail oil enter a catalytic cracking device to undergo a catalytic cracking reaction in the presence of a cracking catalyst; and separating the product of the reaction to obtain a dry gas, a liquefied gas, a gasoline fraction and a catalytic cracking heavy fraction, wherein the catalytic cracking heavy fraction is filtered to remove solid impurity and circulated to a hydrogenation treatment device. When the method is used, the quality of produced naphtha and diesel product can be improved; and particularly, the sulfur content in naphtha and diesel is lowered and the cetane number of diesel is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of low-quality oil treatment process method

ActiveCN106701175BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesOil processingGas phase

The invention discloses a process for treating inferior oil, the process includes a hydropretreating reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone; the process includes the following contents: a residual oil raw material and hydrogen are mixed, and in turn pass through the hydropretreating reaction zone and the hydrotreating reaction zone which are in series connection, after gas-liquid separation of a hydrotreating reaction zone reaction effluent, a gas phase is recycled back to the hydropretreating reaction zone and / or the hydrotreating reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for catalytic cracking reaction, a catalytic cracking reaction effluent is separated to obtain a dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel oil fraction, catalytic cracking heavy cycle oil and catalytic cracking oil slurry, and the catalytic cracking diesel and the catalytic cracking heavy cycle oil are partially or totally recycled back to the hydrotreating reaction zone for hydrotreating reaction. The method can prolong the stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Residual oil hydrogenation treatment and catalytic cracking combined processing method

ActiveCN102311798BIncrease processing costReduce investmentTreatment with hydrotreatment processesThermal energyGas phase

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating residual oil through combined technology

ActiveCN110408428AReduce poisonTake full advantage of activityTreatment with hydrotreatment processesCycle oilPre treatment

The invention discloses a method for treating residual oil through a combined technology. The method for treating the residual oil through the combined technology comprises the steps of after inferiorraw material oil and hydrogen are mixed, making an obtained mixture pass through a hydrogenation pre-treatment region at first; and separating a reaction effluent, which is obtained after a reactioneffluent and catalytic cracking circulating oil enter a hydrogenation treatment reaction region, to obtain residual oil subjected to hydrogenation, carrying out a catalytic cracking reaction to obtaincirculating oil and / or slurry oil, and circulating the obtained circulating oil and / or slurry oil to the hydrogenation pre-treatment reaction region, wherein reaction temperature t1 of the hydrogenation pre-treatment reaction region is higher than reaction temperature t2 of the hydrogenation treatment reaction region. By means of the method, the utilization rate of a main catalyst for hydrogenation treatment can be improved, a running period of an integrated device is prolonged, and the running efficiency of the device is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Residual oil hydrogenation treatment and catalytic cracking combination method

ActiveCN102453544BHigh aromatic contentLow cetane numberTreatment with hydrotreatment processesGas phaseFractionation

Owner:CHINA PETROLEUM & CHEM CORP +1

A combined process method for treating low-quality residual oil

ActiveCN110408432BReduce poisonTake full advantage of activityTreatment with hydrotreatment processesPtru catalystMetal impurities

The invention discloses a method for treating inferior residual oil with a combined process. After the heavy oil raw material is saturated with hydrogen, it first passes through the hydrogenation pretreatment zone for hydrodemetallization and partial desulfurization; the reaction effluent is saturated with hydrogen again and then enters the hydrotreatment reaction zone for hydrodesulfurization and hydrodenitrogenation Reaction; wherein the reaction temperature in the hydrogenation pretreatment reaction zone is higher than the reaction temperature in the hydrotreatment reaction zone. In the method of the present invention, the hydrogenation pretreatment reaction zone reacts at a higher temperature, which can remove most of the metal impurities in the material, so that the desulfurization catalyst and / or denitrogenation catalyst in the hydrogenation treatment reaction zone are deactivated The reason has changed from the previous metal deposition and carbon deposition deactivation to only carbon deposition deactivation, so that the desulfurization catalyst and denitrogenation catalyst can be regenerated after one cycle of use, prolonging the operation cycle of the hydrogenation unit, thereby increasing the capacity of the unit. The operating efficiency improves the economy.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating heavy oil by combined process

ActiveCN110408429AExtended operating cycleReduce poisonTreatment with hydrotreatment processesHydrogenReaction temperature

The invention discloses a method for treating heavy oil by a combined process. The method for treating the heavy oil by the combined process comprises the following steps: after mixing inferior raw oil with hydrogen, enabling the mixture to pass through a hydrogenation pretreatment zone at first; after separating reaction effluent, enabling the reaction effluent and catalytic cracking circulatingoil to enter a hydrotreating reaction zone; and separating the obtained reaction effluent to obtain hydrogenated residual oil, and carrying out catalytic cracking reaction on the hydrogenated residualoil to obtain circulating oil and / or oil slurry which are recycled to the hydrotreating reaction zone to obtain another part of circulating oil which is recycled to the hydrotreating reaction zone, wherein the reaction temperature t1 of the hydrotreating reaction zone is higher than the reaction temperature t2 of the hydrotreating reaction zone. According to the method, the utilization rate of ahydrotreating main catalyst can be increased, the running period of a combined device is prolonged, and the running efficiency of the device is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combination Process Method and System for Residual Oil Hydrotreating-FCC with Rotation in Series

ActiveCN112210401BRealize long-term operationExtended run timeTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystProcess engineering

The invention discloses a combined process method and system of series-rotatable residual oil hydrogenation treatment-catalytic cracking. The method comprises: the residual oil raw material and at least part of the catalytic cracking diesel fraction are mixed with hydrogen, and then sequentially pass through a hydrotreating pretreatment zone and a hydrotreating reaction zone arranged in series; the reaction effluent in the hydrotreating reaction zone is subjected to gas-liquid separation, The obtained liquid phase directly enters the catalytic cracking reaction zone for catalytic cracking reaction; the hydrogenation pretreatment reaction zone includes N hydrogenation pretreatment reactors, and the 1st to N-1th hydrogenation pretreatment reactors are successively They are connected in series in sequence and used as N‑1 online hydrogenation pretreatment reactors, and the Nth one is used as an off-line hydrogenation pretreatment reactor. The method and system can realize the operation time of the hydrogenation pretreatment process for a long time without stopping, which is beneficial to the stable performance of the overall catalytic activity of the main catalyst for hydrogenation treatment, ensures reasonable and limited rotation times, and prolongs the operation of the hydrogenation treatment reactor. time and work efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of gasoline and low-sulfur marine fuel

ActiveCN113046128AReduce investmentReduce operating energy consumptionTreatment with hydrotreatment processesPtru catalystHydrogenation reaction

The invention discloses a production method of gasoline and low-sulfur marine fuel. The production method comprises the following steps: (1) carrying out hydrogenation reaction on a residual oil raw material in the presence of hydrogen and a hydrotreating catalyst; (2) carrying out gas-liquid separation on an effluent of the hydrogenation reaction, circulating a gas phase to the hydrogenation reaction in the step (1), taking a liquid phase as mixed hydrogenation generated oil, not fractionating the mixed hydrogenation generated oil, throwing a part of the mixed hydrogenation generated oil as low-sulfur marine fuel, feeding the rest of the mixed hydrogenation generated oil into a catalytic cracking device, and carrying out catalytic cracking reaction; and (3) mixing a catalytic cracking heavy fraction obtained after dry gas, liquefied gas and catalytic cracking gasoline are separated from the effluent of the catalytic cracking reaction, used as heavy cycle oil, with the residual oil raw material in the step (1) for hydrogenation reaction. The combined process provided by the invention can be used for producing high-octane catalytic cracking gasoline and low-sulfur marine fuel products to the maximum extent. Meanwhile, hydrogenation load is reduced, a catalytic cracking fractionation system is simplified, and equipment investment and operation energy consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com