Gain photon crystal fiber waveguide and its device

A photonic crystal fiber and waveguide technology, applied in optical waveguide light guides, laser parts, lasers, etc., can solve the problems of not being able to meet practical application requirements, the mode field is greatly improved, and the laser power loss is large. Good self-heat dissipation characteristics, improved quality, improved numerical aperture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

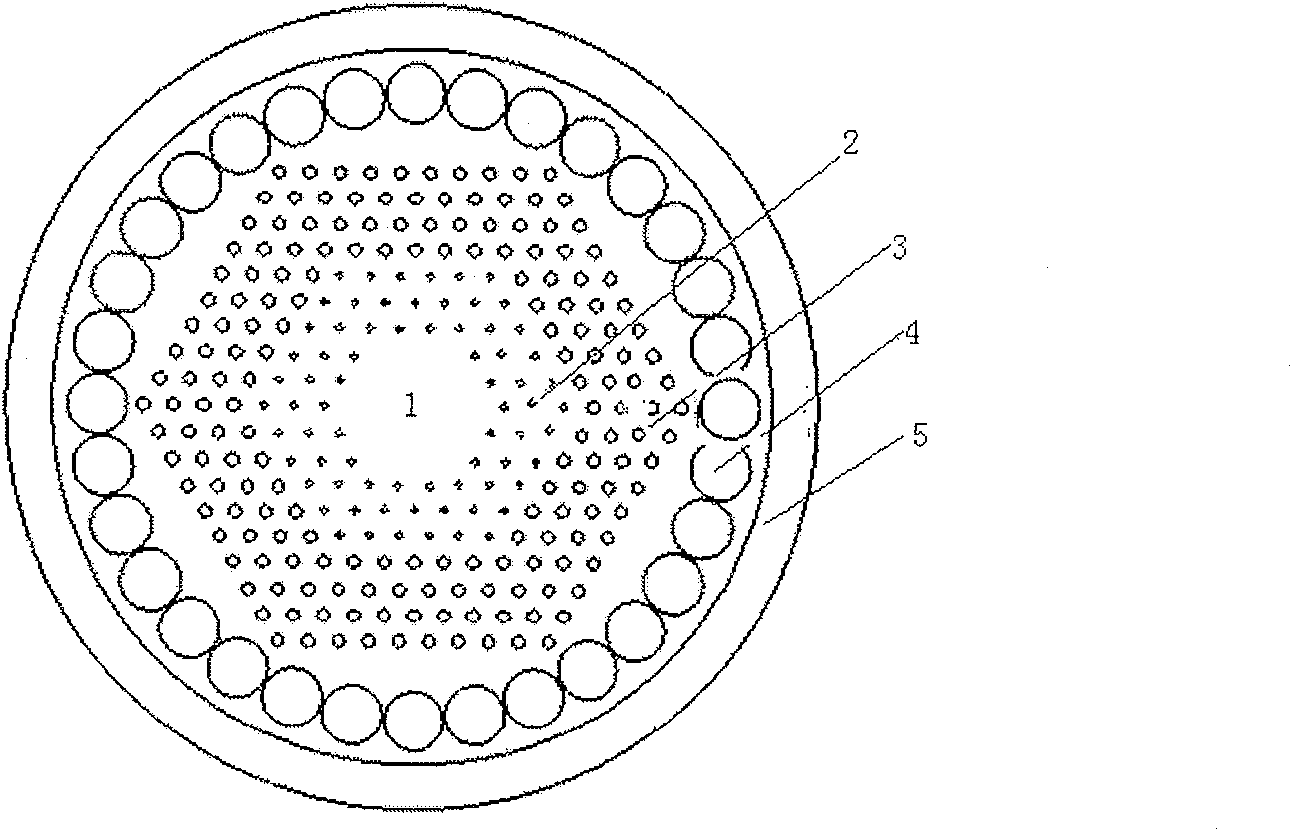

[0048] The improved chemical vapor deposition (MCVD) process is used to manufacture ytterbium ion (thulium, neodymium, holmium, praseodymium, erbium, lanthanum and other rare earth ions can also be doped) optical fiber core rod, and the rare earth doping concentration is above 6000ppm. Then, a 400±10 μm rare earth-doped quartz glass cylinder is made by drawing at a high temperature of about 2200 ° C on a wire drawing tower. The relative refractive index difference of the rare earth-doped part is between 0.61% and 2.2%, in this case it is 0.61% , The ratio of the diameter of the rare earth ion doped part to the diameter of the rare earth doped quartz glass cylinder is between 0.08 and 0.52, in this example it is 0.18. Plasma Chemical Vapor Deposition (PCVD) technology is used to manufacture high-purity quartz glass rods, and then drawn into 800±10μm high-purity quartz glass cylinders at a high temperature of 2200°C on a wire drawing tower. Use the PCVD process to prepare a germ...

Embodiment 2

[0050] The improved chemical vapor deposition (MCVD) process is used to manufacture ytterbium ion (can also be doped with thulium, neodymium, holmium, praseodymium, erbium, lanthanum and other rare earth ions) optical fiber core rod, the rare earth doping concentration is above 8000ppm, and then in wire drawing A rare earth-doped quartz glass cylinder of 400±10 μm is made by pulling down at a high temperature of about 2200°C on the tower. The relative refractive index difference of the rare earth-doped part is between 0.61% and 2.2%, in this case it is 0.61%. Doped with rare earth ions The ratio of the partial diameter to the diameter of the entire cylinder is between 0.08 and 0.52, in this case 0.32. Plasma Chemical Vapor Deposition (PCVD) technology is used to manufacture high-purity quartz glass rods, and then drawn into 800±10μm high-purity quartz glass cylinders at a high temperature of 2200°C on a wire drawing tower. A germanium-doped quartz glass rod with a core relativ...

Embodiment 3

[0052] The improved chemical vapor deposition (MCVD) process is used to manufacture ytterbium ion (can also be doped with thulium, neodymium, holmium, praseodymium, erbium, lanthanum and other rare earth ions) optical fiber core rod, the rare earth doping concentration is above 8000ppm, and then in wire drawing A rare earth-doped quartz glass cylinder of 400±10 μm is made by pulling down at a high temperature of about 2200°C on the tower. The relative refractive index difference of the rare earth-doped part is between 0.61% and 2.2%, in this case it is 0.98%. Doped with rare earth ions The ratio of the partial diameter to the diameter of the entire cylinder is between 0.08 and 0.52, in this case 0.39. Plasma Chemical Vapor Deposition (PCVD) technology is used to manufacture high-purity quartz glass rods, and then drawn into high-purity quartz glass cylinders of 410±10 μm on a wire drawing tower at a high temperature of 2200 °C. A germanium-doped quartz glass rod with a core re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com