Production of engineering corrugated honeycomb with fire-retarding and mould-proof functions

A production process, anti-mildew technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems of high drying energy consumption, unreasonable mechanical structure, poor synchronization of energy consumption efficiency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

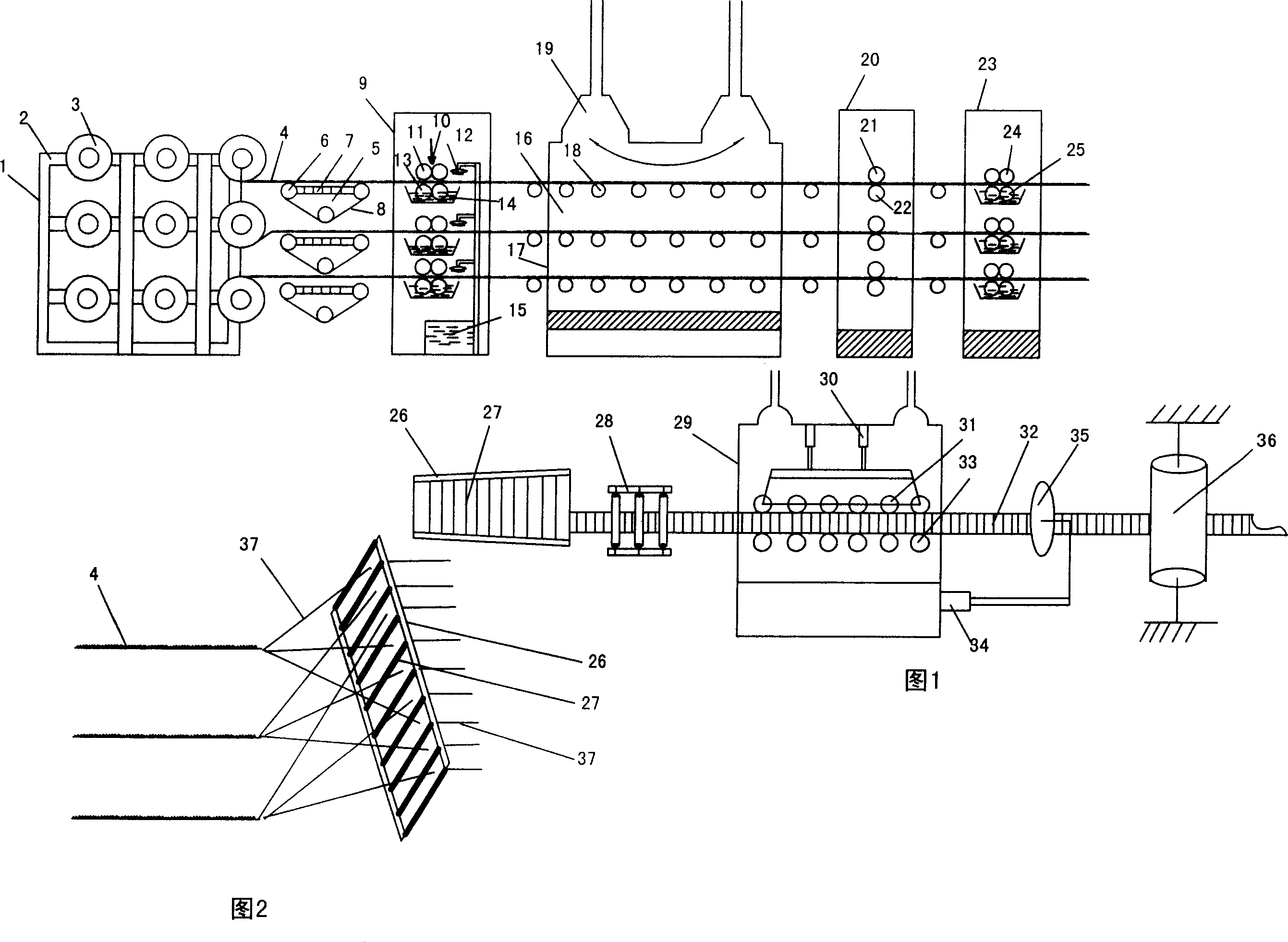

Image

Examples

Embodiment 1

[0052] The working width of single-faced corrugated cardboard is 1.6m, made of 170g / m2 high-strength corrugated paper, the corrugation pitch is 5mm high, the modulus is 8.4mm, rolled into a single-faced corrugated roll paper with a diameter of 2.5m, and then the roll paper is rolled Put it into the corresponding permeable cage mold, immerse it in the prepared boron salt or ammonium salt water-based flame retardant dipping pool, drip off the flame retardant after soaking, and put it in a drying room to dry, the room temperature is 40 ~ 200 ℃, the most Good natural or forced convection along the corrugated honeycomb holes. The drying room is equipped with a moisture exhaust fan and a temperature control system. When the room temperature is 85~95℃, the drying time is generally 3~4 hours, and the moisture content is 8~13% (mass percentage). ).

[0053] When the temperature of the roll paper impregnated with flame retardant is above 20℃ in summer, it can be dried naturally in the open ...

Embodiment 2

[0060] According to the same production process as in Example 1, the flame retardant is composed of 5-8% ammonium sulfate, 5-6% sodium tetraborate, 4-5% ammonium molybdate and the balance of water in terms of weight percentage.

[0061] The fireproof glue is composed of 80-90% sodium silicate with a Baume degree of 35-60°C, 5-15% starch derivatives, 1-1.5% sodium stearate and 3-5% ethylene glycol according to weight percentage.

[0062] As the adhesive, commonly known products are used.

[0063] The thickness of the corrugated honeycomb composite is 100mm and the density is 200kg / m3. Test plane compressive strength 3.1mpa, thermal conductivity: 0.055W / M·K, sound insulation RW≥36dB, in line with the A-level (sandwich) non-combustible material GB8624 standard.

Embodiment 3

[0065] According to the process of Example 1, the flame retardant is composed of ammonium chloride 3-6%, ammonium molybdate 4-5%, ammonium polyphosphate 4-8%, calcium propionate 2-3% and the balance in weight percentage. Water composition.

[0066] The fireproof adhesive is composed of sodium silicate 85-98%, glycerol 1-14% and sodium stearate 1-1.5% by weight percentage.

[0067] A publicly-known product is used as the adhesive.

[0068] Using the prepared corrugated honeycomb composite to produce the wooden fire door, its thickness is 50mm. The main technical indicators: fire resistance rating ≥ 1.2h, composite material is A2 grade (composite sandwich material GB8624-97), flat compressive strength ≥ 2.5mpa , Thermal conductivity: 0.068W / M·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fire resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com