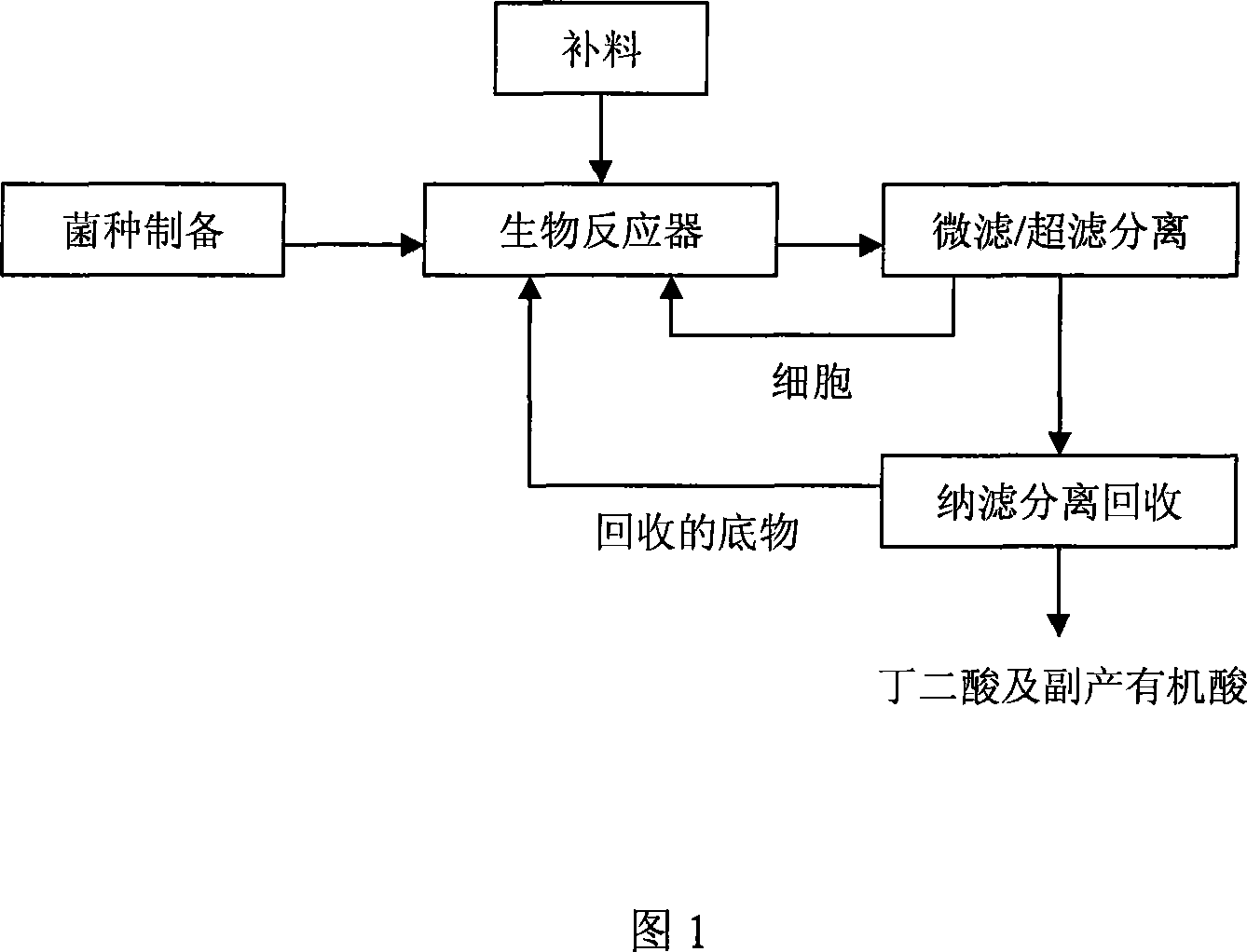

Method for preparing succinic acid by coupling fermentation and film separation unit

A succinic acid and membrane separation technology, applied in the field of bioengineering, can solve the problems of substrate and other nutrient element loss, difficult separation of product and substrate, consumption of large acid-base regeneration resin, etc., to achieve easy automatic control and industrial The effects of modernization, significant social and economic benefits, and increased production intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Seed medium: glucose 10g / L, yeast extract 5g / L, peptone 5g / L, NaCl 1g / L, NaHCO 3 10g / L, Na 2 HPO 4 9~15g / L,KH 2 PO 4 4~12g / L, (add agar 20g / L when cultivating on a slant), pass through N 2 :CO 2 = 4:1 mixed gas for 2 minutes, sterilized at 121°C for 20 minutes, and cooled;

[0035] (2) Fermentation medium: glucose 40g / L, yeast extract 10-50g / L, peptone 10-50g / L, MnCl 2 0.05g / L, FeCl 2 0.05g / L, CaCl 2 0.05g / L, K 2 HPO 4 2.0g / L, vitamins added folic acid 5mg / L, biotin 5mg / L, vitamin B 12 5mg / L, lipoic acid 5mg / L, niacin 5mg / L, pantothenic acid 5mg / L, thiamine 5mg / L, vitamin B 6 5mg / L, pH 7.0;

[0036] (3) After the Actinobacillus succinogenes strain whose preservation number is CGMCC No.1716 is streaked on the seed slant medium, it is cultivated in an anaerobic incubator, and the ratio of mixed gas in the control incubator is: N 2 :CO 2 :H 2 =8: 1: 1, the bacterial strain after cultivating 36h is connected in the 100ml serum bottle that contains...

Embodiment 2

[0040] (1) Seed culture medium and fermentation medium are all the same as in Example 1.

[0041] (2) Prepare fermented seeds from the Actinobacillus succinogenes strain with the preservation number CGMCC No.1716, and the method is the same as in Example 1. When using a 5L fermenter for cultivation, the liquid volume of the medium is 3L, the inoculum size is 4% (v / v), the stirring speed is at 300rpm, 37°C, the pH is adjusted to 6.8 with 280g / L sodium carbonate, and the ventilation rate of carbon dioxide in the fermenter It is 1.0L / min. After 11 hours of fermentation, the production intensity of succinic acid has reached 2.2g / L h. At the end of the logarithmic growth phase of bacterial growth, the total concentration of succinic acid, formic acid and acetic acid accumulated in the system has reached 29g / L. At this time, the fermentation The glucose concentration in the liquid is 11g / L, and at this time, it is ready to be coupled with an ultrafiltration membrane for semi-contin...

Embodiment 3

[0046] The preservation number is the bacterial strain of CGMCC No.1716 adopting the same method as Example 1 to prepare fermenter seeds. When cultivating in a 5L fermenter, the liquid content of the medium is 3L, and the concentration of glucose in the fermentation medium is 25g / L. With embodiment 1, adopt 10N sodium hydroxide to adjust pH 6.80, pass into CO 2 , the ventilation rate is 0.75L / min, the anaerobic environment of the fermentation system is maintained, the inoculum size is 5% (v / v), the rotation speed is 250r / min, and after culturing at 37°C for 10.5 hours, the production intensity of succinic acid has reached 1.7 g / L·h, the total concentration of succinic acid, formic acid, and acetic acid accumulated in the system has reached 23g / L, and the concentration of glucose is only 2g / L. It is ready to be coupled with a microfiltration membrane for continuous fermentation.

[0047] Adopt the tubular ceramic microfiltration membrane of 0.14 μm through 4% sodium hydroxide d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com