Method of preparing simvastatin sustained-release microsphere carried series

A technology of slow-release microspheres and simvastatin, applied in the biological field, can solve the problems that have not yet been studied and reported on simvastatin sustained-release microsphere preparations, and achieve improved bioavailability, controllable particle size, and adjustment range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 0.09 gram of polylactic acid (molecular weight 0.2 million) in 3ml of dichloromethane to make a homogeneous mixture, slowly add it to 30ml of PVA aqueous solution (containing 0.6ml of Tween80) with a mass concentration of 1.5% stirred at a speed of 700rpm , continue to stir for 1.5 hours, 37 ° C vacuum rotary evaporation for 1 hour, remove the organic solvent, centrifuge at 18,000 rpm, wash with deionized water 3 times, and vacuum dry for 48 hours to obtain about 0.078 grams of polylactic acid blank microsphere powder. The average particle size of the microspheres is 2100nm.

[0030] Microspheres of different particle sizes obtained by applying polylactic acid of other molecular weights and other biodegradable polymer materials according to the above steps, the average particle size ranges from 358nm to 2100nm, and the results are shown in Table 1, which can meet the requirements for preparing drug-loaded microspheres with different degradation rates. need.

...

Embodiment 2

[0035] (1) A mixture of PLA (0.05 grams, molecular weight 1.0w) and simvastatin (0.01 grams) with a mass ratio of 5:1 was dissolved in 3 milliliters of dichloromethane to make a uniform mixture;

[0036] (2) Slowly add the above mixed solution into 30ml of PVA aqueous solution with a mass concentration of 1.5% (containing 0.6ml of Tween80, 0.3g of sodium chloride, used after stirring at 700rpm for 15 minutes) in stirring (700rpm), and continue stirring for 1.5 hours ;

[0037] (3) Rotary evaporation under reduced pressure at 37°C for 1 hour to remove the organic solvent; centrifuge at 18,000 rpm for 10 minutes, wash with water, and dry in vacuum for 48 hours to obtain about 0.06 g of simvastatin-loaded microsphere powder with an average particle size of 102 nm. The sealing rate is 20.89%.

[0038]Get dry loaded simvastatin microsphere powder 0.03g, add 1 milliliter of acetonitrile and 2 milliliters, 0.1M phosphate buffer saline, after 24 hours, ultraviolet spectrophotometer d...

Embodiment 3

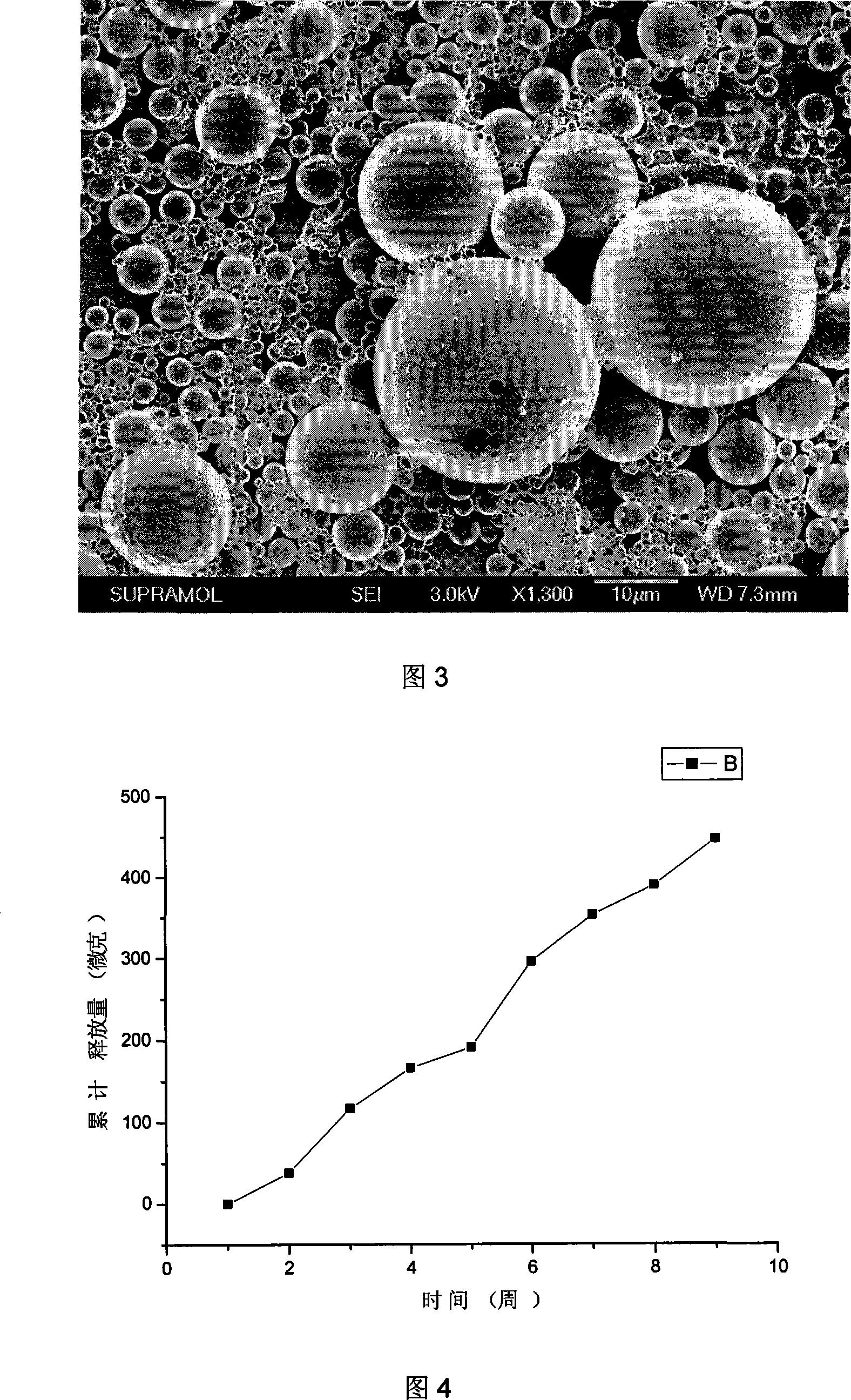

[0042] A mixture of PLGA7525 (0.05 gram, molecular weight 2w) and simvastatin (0.01 gram) with a mass ratio of 5:1 was dissolved in 3 milliliters of dichloromethane to make a homogeneous mixture, which was slowly added to the stirring (700 rpm) in 30 milliliters of PVA aqueous solution with a mass concentration of 1% (containing 0.6 milliliters of Tween80, 0.3 grams of sodium chloride, used after stirring at 700 rpm for 15 minutes), continued stirring for 1.5 hours, reduced pressure at 37 ° C, and rotary evaporated for 1 hour , remove the organic solvent; centrifuge at 18000rpm for 10 minutes, wash with water, and dry in vacuum for 48 hours to obtain 0.062 g of simvastatin-loaded microsphere powder, with an average particle diameter of 1400 nm and an encapsulation efficiency of 35.27%.

[0043] Change the stirring speed and prepare microspheres under other conditions unchanged, in order to explore the influence of stirring speed on the preparation of microspheres. A series of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com