Method for preparing xylose and arabinose by hydrolyzing lignocellulose

A technology of lignocellulose and arabinose, applied in the field of bioengineering, can solve the problems of high toxicity of trifluoroacetic acid and trifluoromethanesulfonic acid, no catalyst recovery and reuse, and difficult industrial application, etc., achieving significant economic and social value, Reduced equipment investment and fewer side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

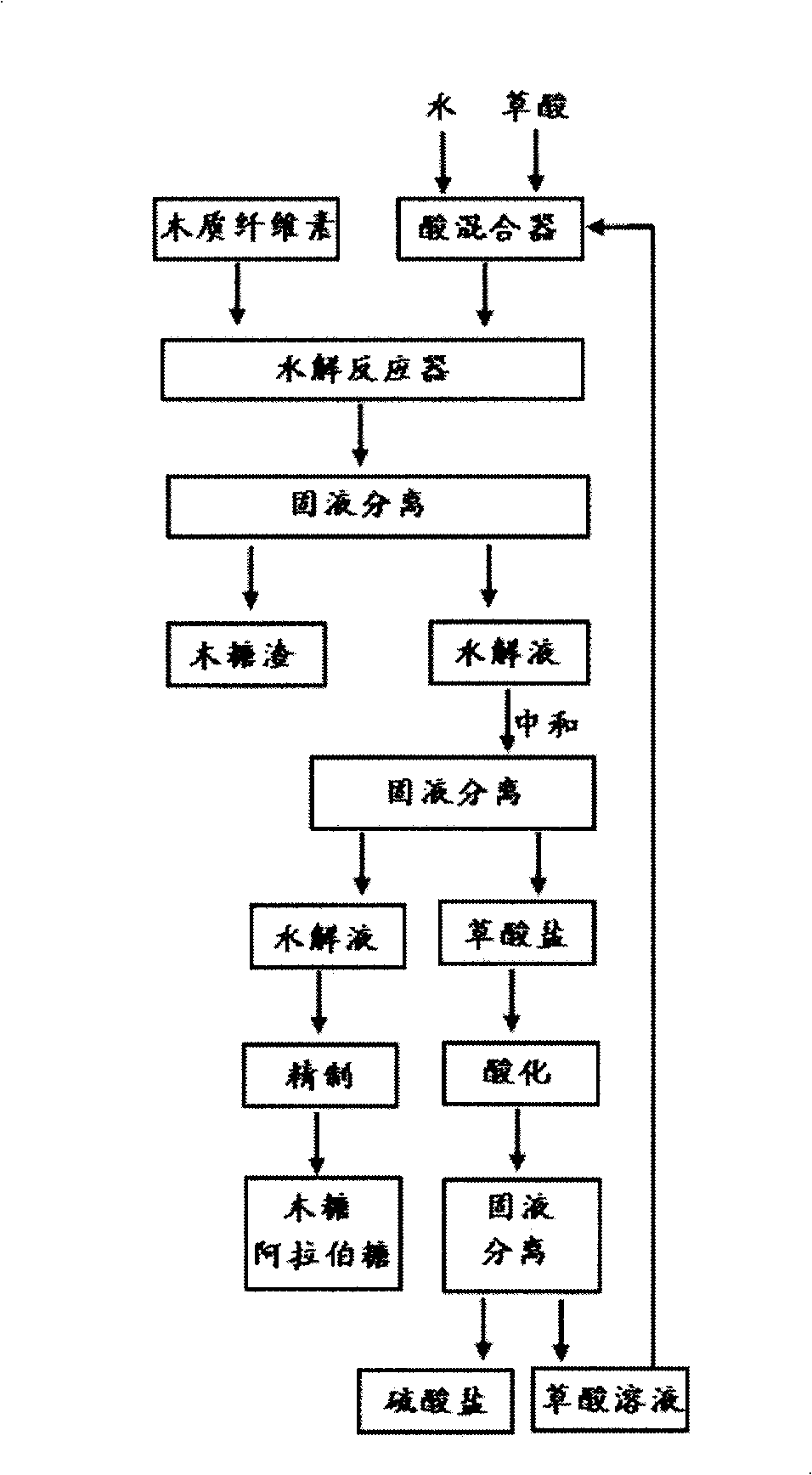

Method used

Image

Examples

Embodiment 1

[0028] Get dry corn cob (containing hemicellulose 36%, cellulose 41.2%, lignin 6.1%, other composition 16.7%), cross 20 mesh standard sieves after pulverizing, get 4g corn cob powder and join in the hydrolysis reactor, then Add 30mL of 3% oxalic acid solution, stir and mix, heat up to 125°C, and react for 120min. Filtrate with a Bush funnel to obtain 24.3 mL of hydrolyzate, and analyze the concentrations of xylose and arabinose to be 3.15% and 0.88% respectively; wash the filter cake 5 times, further recover xylose, arabinose and oxalic acid remaining in the xylose residue, and analyze the filtrate After concentration, the yields of xylose and arabinose were calculated to be 17.07% and 3.31%, respectively.

[0029] Add 0.73g of calcium hydroxide to the hydrolyzate in the neutralization tank to generate calcium oxalate precipitate, filter and wash 3 times, further recover the residual xylose and arabinose in the xylose residue, and then add the filter cake to 30mL of 3.3% Stir...

Embodiment 2

[0032] Take dry sweet sorghum slag (containing 34.57% of hemicellulose, 39.07% of cellulose, 13.29% of lignin, and 13.07% of other components), pass through a 20-mesh standard sieve after crushing, and add 4g of sweet sorghum straw powder into the hydrolysis reactor , and then add 20 mL of 5% oxalic acid solution, stir and mix, heat up to 130° C., and react for 50 min. Filtrate with a Bush funnel to obtain 14.7 mL of hydrolyzate, and analyze the concentrations of xylose and arabinose to be 2.14% and 0.53% respectively; wash the filter cake 5 times, further recover xylose, arabinose and oxalic acid remaining in the xylose residue, and analyze the filtrate After concentration, the yields of xylose and arabinose were calculated to be 15.2% and 1.71%, respectively.

[0033] Add 0.82g of calcium hydroxide to the hydrolyzate in the neutralization tank to generate calcium oxalate precipitate, filter and wash 3 times to further recover the residual xylose and arabinose in the xylose r...

Embodiment 3

[0036] Take 3g of corncob powder and add it into the hydrolysis reactor, then add 30mL of 4% oxalic acid solution, stir and mix, raise the temperature to 140°C, and react for 35min. Filtrate with a Bush funnel to obtain 24.4 mL of hydrolyzate, and analyze the concentrations of xylose and arabinose to be 3.45% and 0.94% respectively; wash the filter cake 5 times, further recover xylose, arabinose and oxalic acid remaining in the xylose residue, and analyze the filtrate After concentration, the yields of xylose and arabinose were calculated to be 18.67% and 3.55%, respectively.

[0037] Add 0.75g of calcium hydroxide to the hydrolyzate in the neutralization tank to generate calcium oxalate precipitate, filter and wash 3 times to further recover the residual xylose and arabinose in the xylose residue, then add the filter cake to 3.3% Stir and react in 30 mL of sulfuric acid solution for 0.5 h, filter and wash the filter cake 3 times to further recover the residual oxalic acid in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com