New clean method for producing xylitol and arabinose

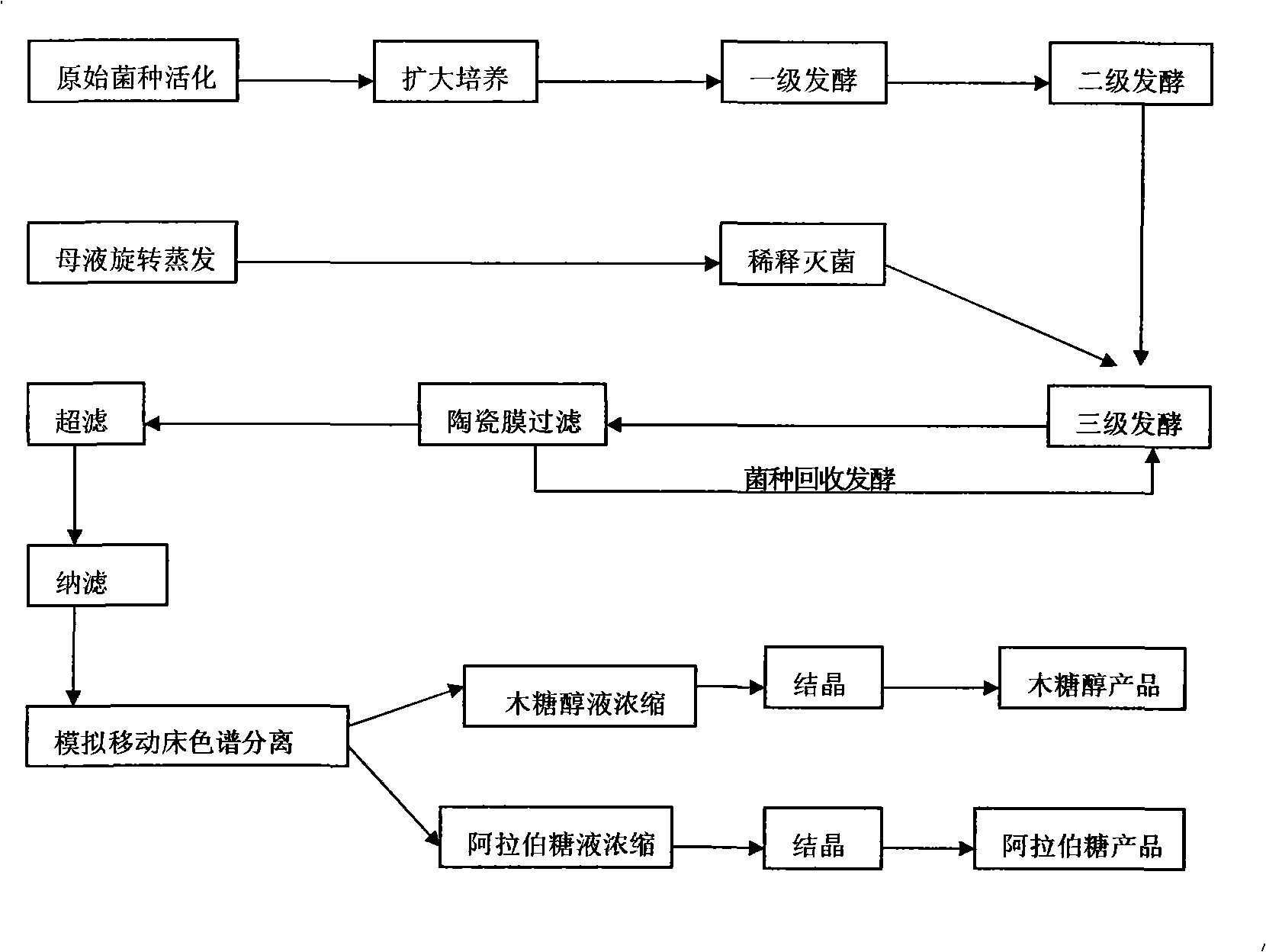

A technology for arabinose and clean production, applied in chemical instruments and methods, monosaccharides, sugar derivatives, etc., can solve the problems of high energy consumption, large pollution, and difficult chromatographic separation, etc., and achieve the improvement of xylitol yield, The effect of reducing production cost and shortening fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Activation of the original strain

[0052] The original strains are xylitol fermentation strains provided by ATTC or China Microorganism Culture Collection Center, mainly Candida tropicalis. For strains with a conversion rate of 75%-97% to xylitol, the original strains are inoculated in a solid enrichment medium on a slope, the culture temperature is 28°C-32°C, and the culture time is 72 hours-96 hours;

[0053] (2) Expansion of training

[0054] Inoculate the activated strain on the enrichment medium for cultivation, the cultivation temperature is 28°C-32°C, the shaking frequency is 150-220 times / min, and the cultivation time is 24 hours;

[0055] (3) Primary fermentation culture

[0056] The seeds cultivated by shake flask vibration are inoculated into 50 liters of primary fermenter according to the inoculum amount of 5%. -350 rpm, fermentation temperature 28°C-32°C, fermentation time 18-24 hours, no bacteria after microscopic examination, can be transferred to...

Embodiment 2

[0078] (1) Activation of the original strain

[0079] The original strains are xylitol fermentation strains provided by ATTC or China Microorganism Culture Collection Center, mainly Candida tropicalis. For strains with a conversion rate of 75%-97% to xylitol, the original strains are inoculated in a solid enrichment medium on a slope, the culture temperature is 28°C-32°C, and the culture time is 72 hours-96 hours;

[0080] (2) Expansion of training

[0081] Inoculate the activated strain on the enrichment medium for cultivation, the cultivation temperature is 28°C-32°C, the shaking frequency is 150-220 times / min, and the cultivation time is 24 hours;

[0082] (3) Primary fermentation culture

[0083] The seeds cultivated by shake flask vibration are inoculated into 100 liters of primary fermenter according to the inoculum size of 5%. -350 rpm, fermentation temperature 28°C-32°C, fermentation time 18-24 hours, no bacteria after microscopic examination, can be transferred to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com