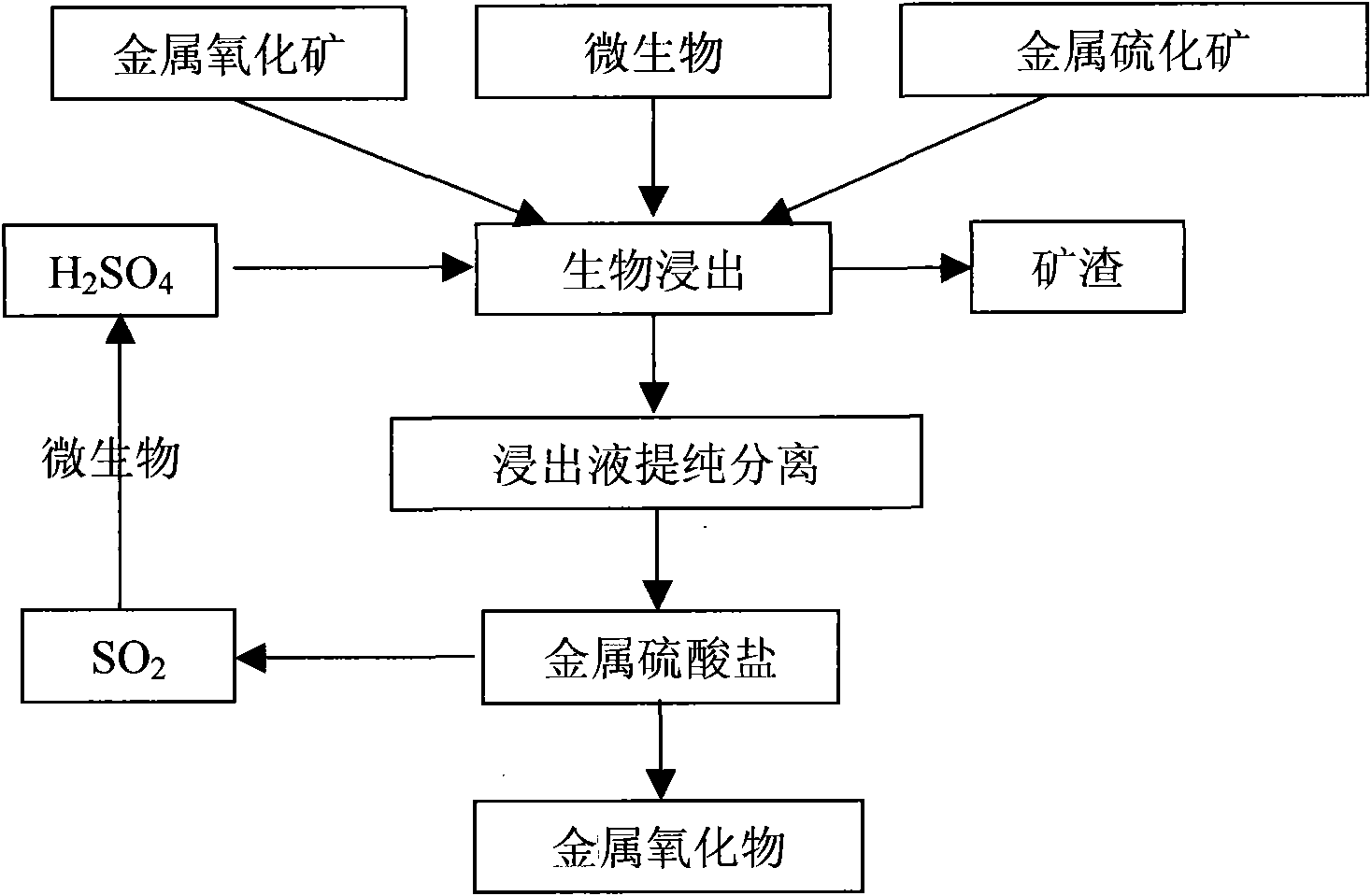

Biological-chemical metallurgy method by jointly utilizing oxidized ore and sulfide ore

A technology of chemical metallurgy and sulfide ore, which is applied in the return leaching stage of sulfur dioxide biological oxidation to sulfuric acid, oxidative leaching of sulfide ore, and metal sulfate reduction pyrolysis. Yield impact and other issues, to achieve good promotion value, easy control, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

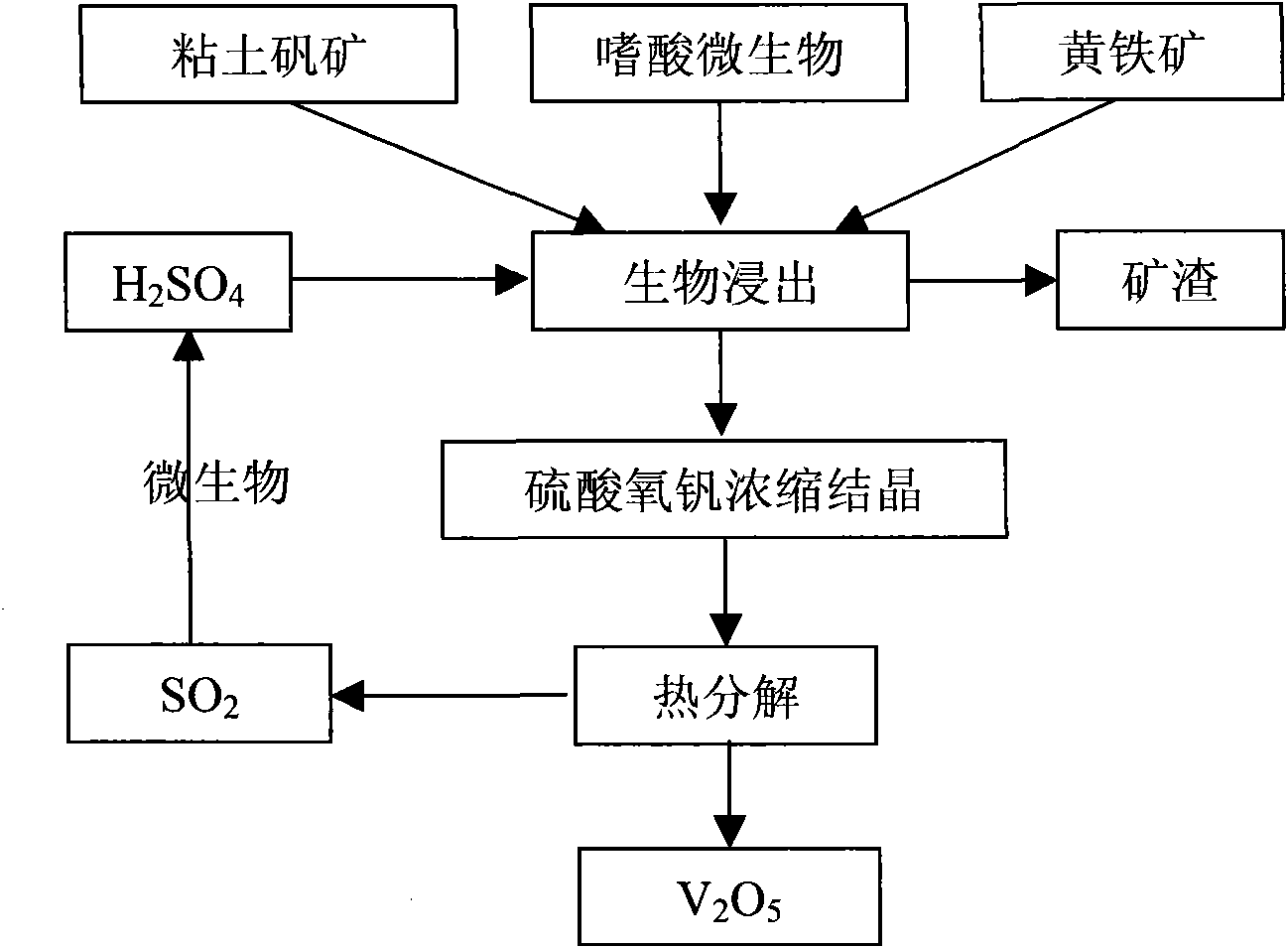

[0046] Example 1 Co-leaching of clay-type vanadium ore and pyrite

[0047] Clay vanadium ore is based on SiO 2 The clay-type vanadium pentoxide mineral used as the matrix is currently used in the process of sodium roasting and water immersion extraction, which has high energy consumption and low efficiency. In particular, the reaction process produces a large amount of toxic chlorine gas, which is extremely harmful to the environment and workers' health. By using the method, firstly, the oxidized vanadium pentoxide ore is pre-sorted into granular and fine-grained minerals. Fine-grained minerals are subjected to tank leaching, and massive minerals are subjected to heap leaching to be leached together with pyrite. T.f ore leaching microorganisms are selected, and the acidic environment is adjusted under normal temperature and pressure, and the vanadium pentoxide ore is reduced and leached. During the leaching process, microorganisms reduce the insoluble pentavalent vanadium...

Embodiment 2

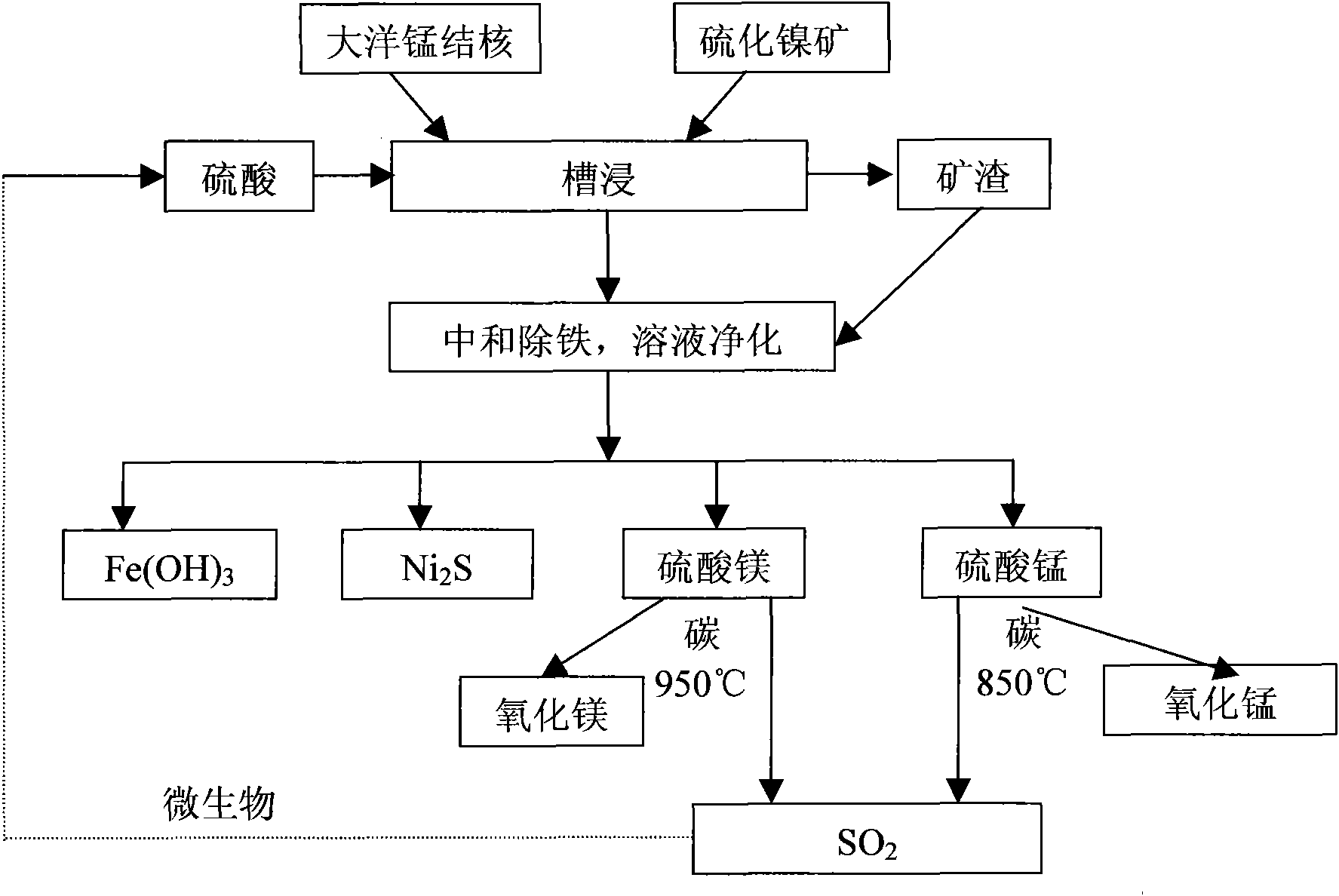

[0071] Oceanic manganese nodules are widely distributed on the seabed at a water depth of 5,000 to 6,000 meters. They are oxidized minerals and contain more than 70 elements. The average grades of nickel and manganese are (%): nickel 1.30, manganese 25.00, and have high economic value. It is a mineral resource that can be replaced by human beings. China Jinchuan Group currently owns hundreds of millions of tons of low-grade nickel sulfide ore. By adopting the technology of the invention, the two kinds of minerals can be used together, and the safety of strategic metals can be greatly improved.

[0072] 1) Raw material preparation

[0073] Oceanic manganese nodules were collected in the eastern Pacific Ocean by China's "Ocean No. 1" voyage DY105-13. According to detection and analysis, oceanic manganese nodules are a multi-mineral aggregate, mainly manganese minerals, iron minerals and aluminosilicate minerals. , Copper, cobalt, nickel and other metals exist in the crystal la...

Embodiment 3

[0094] Waste molasses, a by-product of the sucrose industry, is mainly used in the production of alcohol, yeast, organic acids (monosodium glutamate, citric acid), etc. About 15 tons of waste liquid is discharged for every ton of alcohol produced. At present, the annual discharge of such waste liquid in my country is more than 6 million tons. Select the representative manganese ore rich in Guilin, Guangxi in China, use sphalerite as the reducing agent, and add organic waste (molasses alcohol waste liquid) as the reducing agent and culture medium for bacteria, and mix in T.f, T.t and L.f Under the action of bacteria and heterotrophic microorganism Geobacter metallireducens, the manganese is leached and recovered, and the organic waste liquid is treated.

[0095] 1) Raw material preparation

[0096] Manganese ore is taken from a mine in Guangxi, the manganese ore grade is 25.8%, sphalerite is taken from a mine in China, the zinc grade is: Zn51.15%. Grind the two ores to -200 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com