Preparation method of titanium dioxide/active carbon composite nanofibrous membrane

A technology of composite nanofibers and titanium dioxide, applied in chemical instruments and methods, oxidized water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve uneven dispersion of TiO, low photocatalytic activity and adsorption capacity, and blockage Nozzle and other problems, to achieve high application value, simple method, and improve the effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

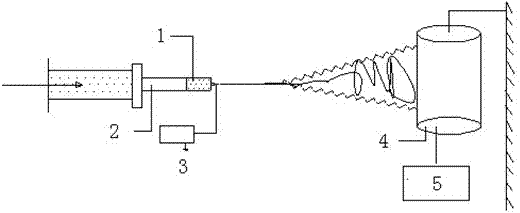

Method used

Image

Examples

Embodiment 1

[0029] (1) Under the condition of magnetic stirring, dissolve 8.5mL tetra-n-butyl titanate and 2.4mL glacial acetic acid in 17mL absolute ethanol, stir for 30 minutes to mix well, and slowly drop into the mixed solution of 5mL ethanol and 0.5mL distilled water , control the dropping rate of the burette to 1 drop / 3 seconds, seal and stir for 1 hour to obtain a light yellow transparent sol of titanium hydroxide, and let it stand for aging.

[0030] (2) Slowly add 2g of polyacrylonitrile powder into 15mL N,N-dimethylformamide solvent to obtain a polyacrylonitrile solution with a concentration of 11.7wt%, stir until it swells completely, and then place it in a water bath Slowly heat to 40°C and stir for 30 minutes to dissolve completely. Mix the prepared solution with the above prepared titanium hydroxide sol at a volume ratio of 1:4, and magnetically stir until uniformly mixed to obtain a transparent solution for power spinning.

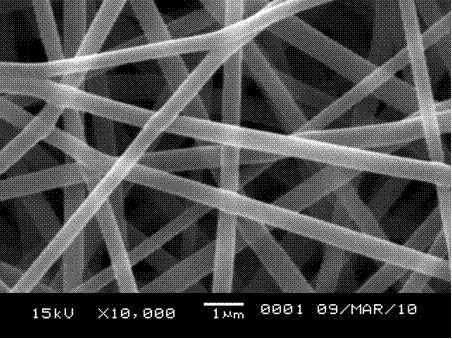

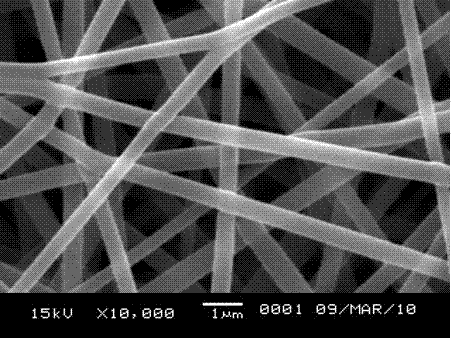

[0031] (3) Take about 15mL of the above polymer so...

Embodiment 2

[0036] (1) Under the condition of magnetic stirring, dissolve 8.5mL tetra-n-butyl titanate and 2.4mL glacial acetic acid in 17mL absolute ethanol, stir for 30 minutes to mix well, and slowly drop into the mixed solution of 5mL ethanol and 0.5mL distilled water , control the dropping rate of the burette to 1 drop / 3 seconds, seal and stir for 1 hour to obtain a light yellow transparent sol of titanium hydroxide, and let it stand for aging.

[0037] (2) Slowly add 2.5g of polyacrylonitrile powder into 17.5mL N,N-dimethylformamide solvent to obtain a polyacrylonitrile solution with a concentration of 12.5wt%, stir until it swells completely, and place Heat slowly to 40°C in a water bath, stir for 30 minutes to dissolve completely. The prepared solution and the prepared titanium hydroxide sol were magnetically stirred at a volume ratio of 2.5:17.5:2 until uniformly mixed to obtain a transparent solution for power spinning.

[0038] (3) Take about 15mL of the above polymer solution...

Embodiment 3

[0043] (1) Under the condition of magnetic stirring, dissolve 8.5mL tetra-n-butyl titanate and 2.4mL glacial acetic acid in 17mL absolute ethanol, stir for 30 minutes to mix well, and slowly drop into the mixed solution of 5mL ethanol and 0.5mL distilled water , control the dropping rate of the burette to 1 drop / 3 seconds, seal and stir for 1 hour to obtain a light yellow transparent sol of titanium hydroxide, and let it stand for aging.

[0044] (2) Slowly add 3g of polyacrylonitrile powder into 17mL N,N-dimethylformamide solvent to obtain a polyacrylonitrile solution with a concentration of 15wt%, stir until it swells completely, and then place it in a water bath for slow Heat slowly to 40°C and stir for 30 minutes to dissolve completely. Magnetically stir the prepared solution and the prepared titanium hydroxide sol at a volume ratio of 3:17:3 until uniformly mixed to obtain a transparent solution for power spinning.

[0045] (3) Take about 15mL of the above polymer soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com