Three-dimensional porous chitosan/gelatine microsphere, preparation method thereof and application in liver cell culture

A three-dimensional porous and chitosan technology, which is applied in the preparation of microspheres, tumor/cancer cells, animal cells, etc., can solve the problems of increasing the risk factor, not keeping the shape well, and the surface and the interior are not connected, so as to increase Effects of specific surface area, improved exchange, and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

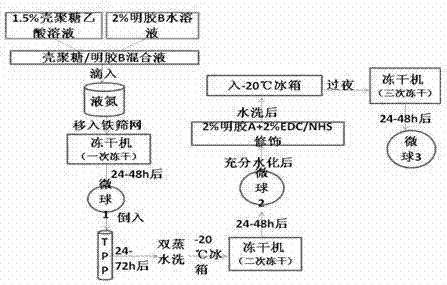

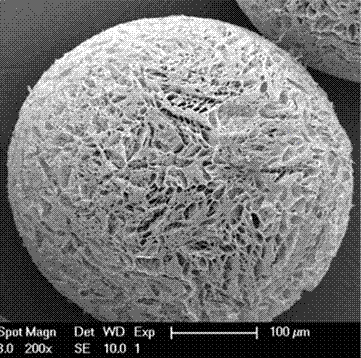

[0059] Preparation of a Three-dimensional Porous Chitosan / Gelatin Microspheres

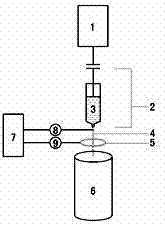

[0060] (1) Preparation of primary freeze-dried microspheres

[0061] Prepare 1.5% chitosan (prepared with 1% acetic acid) and 2% gelatin B (prepared with double distilled water) respectively. : 1 phase mixed, after removing air bubbles, inhale into a 5ml syringe with a needle inner diameter of 0.7mm, and connect the microcapsule generator-electrostatic device (such as figure 1 Shown), in a high-voltage electrostatic environment (voltage U=60, frequency F=90, pulse width PW=6: high-voltage pulse microcapsule forming instrument, University of Shanghai for Science and Technology) drop into liquid nitrogen, wait for the microspheres to sink to the liquid nitrogen tank After bottoming, remove the microspheres and put them on an iron screen soaked in liquid nitrogen, put them on the freeze dryer, control the freeze drying temperature at -60°C to -80°C, turn off the freeze dryer after 24-48 hours and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com