Highly-efficient stable bio-doubling sewage treatment device

A sewage treatment device and biological multiplication technology, applied in biological treatment devices, biological water/sewage treatment, aerobic process treatment, etc., can solve the problem of small circulation volume of mixed liquid, poor adjustability of return ratio, and death of microorganisms without nutrient source starvation and other problems, to achieve the effect of increasing the hydraulic process and residence time, improving the resistance to shock load, and stabilizing the microbial growth environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

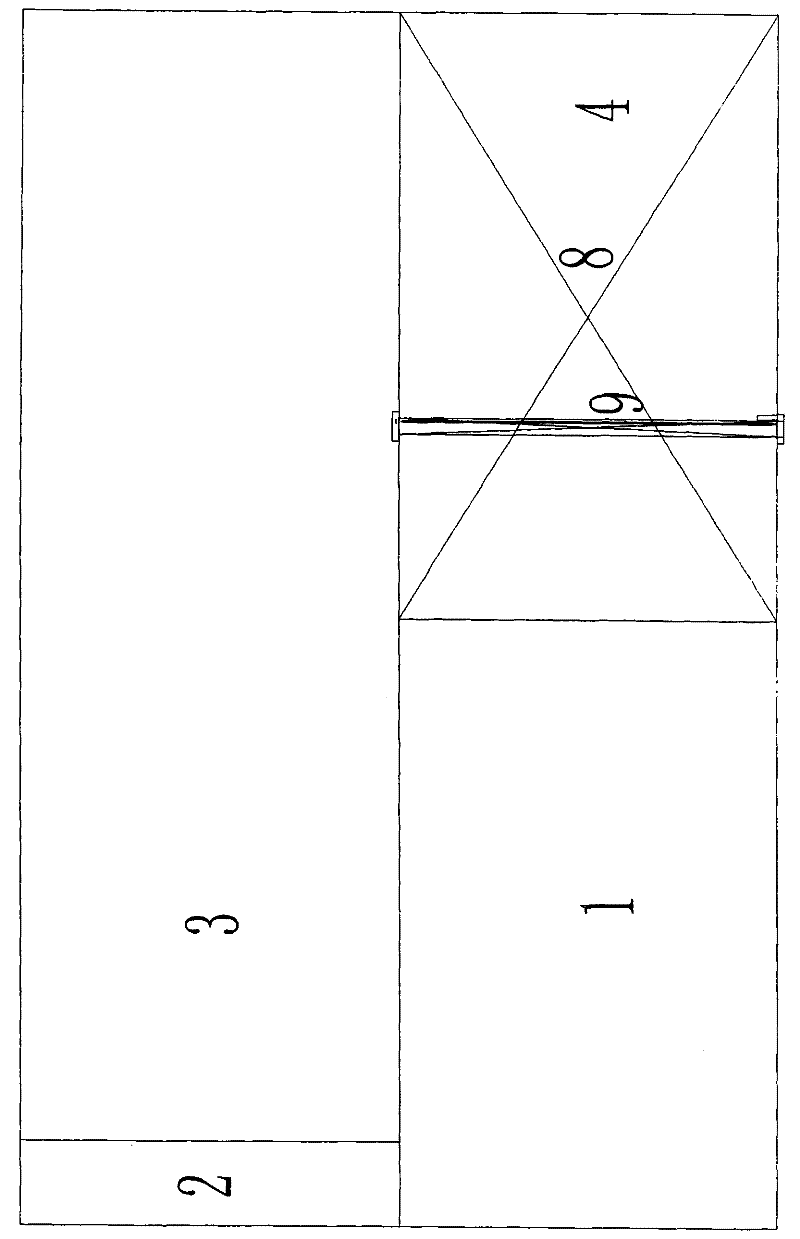

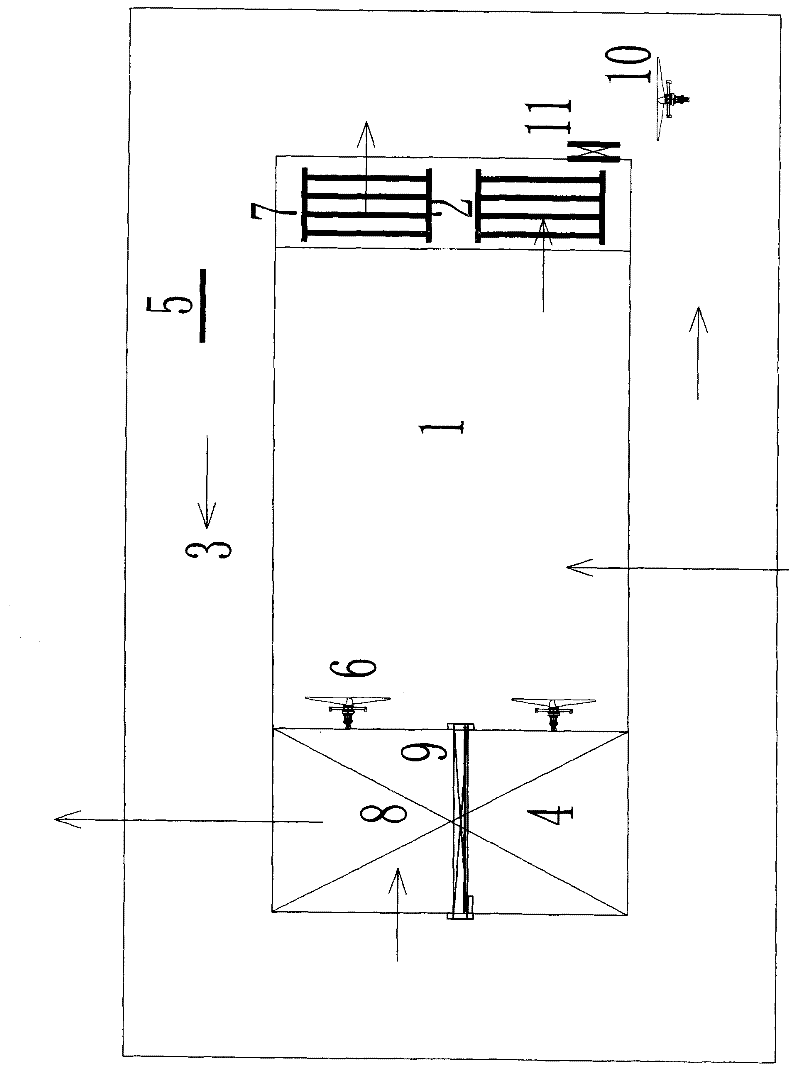

[0033] Example 1, see figure 2 , the efficient and stable biological multiplication process sewage treatment device of the present invention comprises a long strip-shaped hollow rectangular annular ditch 3, the bottom of which is provided with a microporous aerator 5 to form an aerobic treatment functional area, and the inner side of the annular ditch is adjacently arranged from left to right There are: a rectangular precipitation zone 4, an influent mixing reaction zone 1 and an air stripping zone 2. The sedimentation zone 4 is built with an inclined pipe 8 for accelerated sedimentation and separation with a width smaller than the pool width and a driving type scraper and suction machine 9; an underwater mixing propeller 6 is arranged in the influent mixing reaction zone 1 near the end of the sedimentation zone; the gas lift zone 2 is provided with a gas stripping device 7 . The pool wall shared by the airlift area 2 and the annular ditch 3 has a connected opening and a con...

Embodiment 2

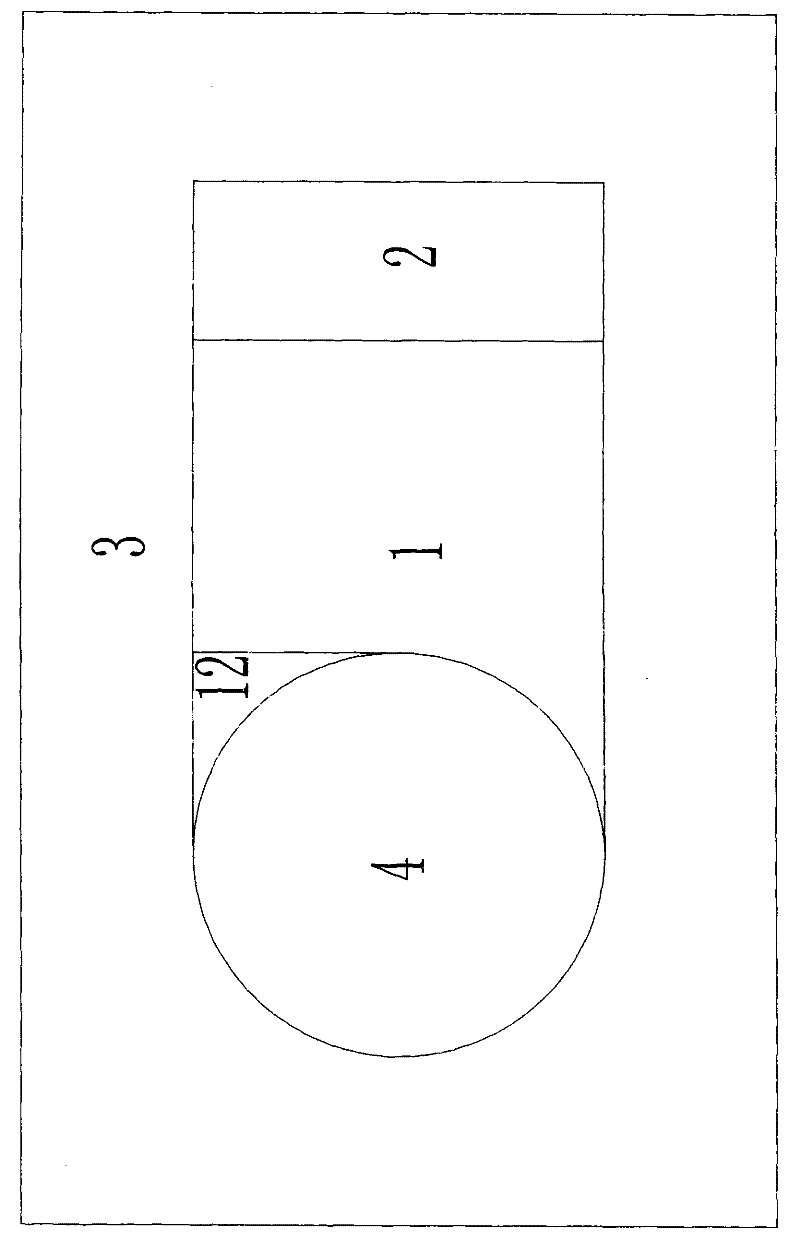

[0037] Example 2, see image 3 , as in Example 1, wherein the settling zone 4 is designed as a circular settling tank, and a sludge lift pump 12 is arranged near the settling tank 4 in the influent mixed reaction zone 1 (rotary scraper / suction machine can also be used in the settling tank) ).

Embodiment 3

[0038] Embodiment 3: see Figure 4 , as embodiment 2, annular ditch 3 changes elliptical track type into.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com