Manufacturing method of polyphenylene sulfide composite heat conduction material for light-emitting diode (LED)

A composite heat-conducting material, polyphenylene sulfide technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of narrow application range, unsatisfactory heat conduction, unsatisfactory impact resistance and process toughness, etc., to prevent electrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

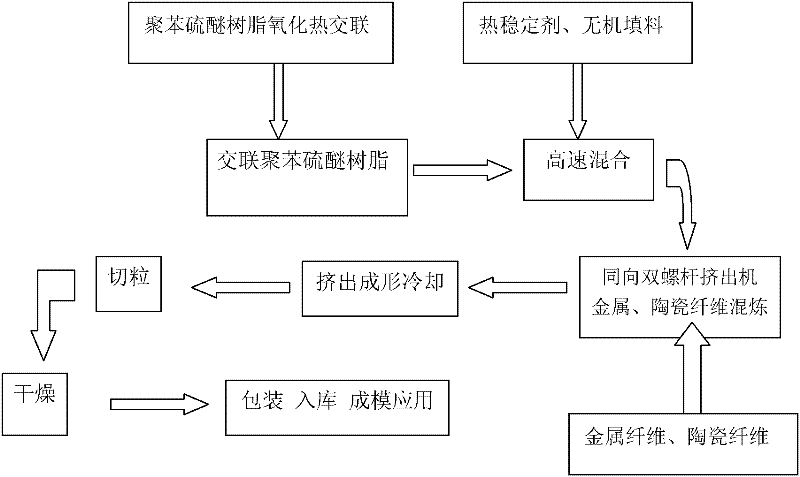

Method used

Image

Examples

Embodiment 1

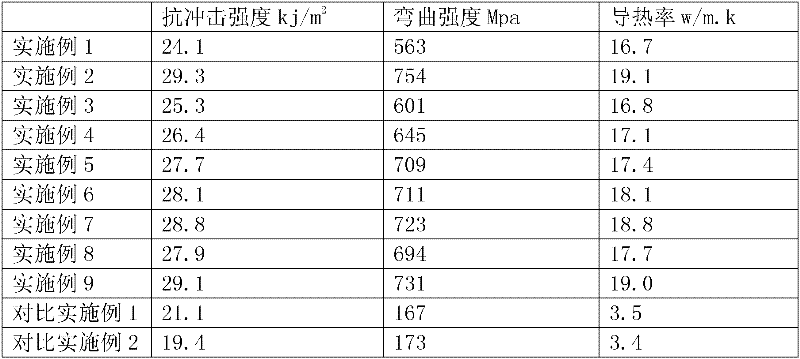

[0035] The linear polyphenylene sulfide resin with a weight average molecular weight of 30,000 and a melt index of 380g / 10min is at 240°C; after 4 hours of oxidative thermal crosslinking, the polyphenylene sulfide resin is 40kg, and the heat stabilizer nonyl triphenyl phosphite is 1.5 kg, pretreated calcium sulfate whiskers 12kg, whisker length of 50 μm, 6% w pretreated particle diameter of 10nm carbon black powder 6kg formula, adding to the blender and stirring at high speed for 3 hours, then pretreated 8 kg of good nano-scale copper heat-conducting metal fiber material, long fibers with a fiber diameter of 1 nm, 32.5 kg of pretreated 95% alumina ceramic fibers, and long fibers with a fiber diameter of 25 μm are input into the twin-screw extruder, and finally passed through the same direction Twin-screw extruder kneading and extruding, cooling, pelletizing, and packaging to produce a polyphenylene sulfide composite material as a heat-conducting material for LEDs

Embodiment 2

[0037]After the linear polyphenylene sulfide resin with a weight average molecular weight of 50,000 and a melt index of 330g / 10min has undergone oxidative thermal crosslinking, 60 kg of polyphenylene sulfide resin, 0.5 kg of nonyl phosphite as a heat stabilizer, and pretreated 7.5kg of calcium carbonate whiskers, 25μm whisker length, 4kg of pretreated carbon black powder with a particle size of 5nm, added to the mixer and stirred at high speed for 2.5 hours, and then the pretreated nano-scale aluminum heat-conducting metal 6kg of fiber material, long fiber with a fiber diameter of 5nm, 22kg of pretreated 95% alumina ceramic fiber, a long fiber twin-screw extruder with a fiber diameter of 10μm, and finally mixed and extruded by a co-rotating twin-screw extruder , cooling, pelletizing, and packaging, and a polyphenylene sulfide composite material as a heat-conducting material for LEDs is prepared

Embodiment 3

[0039] After the linear polyphenylene sulfide resin with a weight average molecular weight of 40,000 and a melt index of 337g / 10min has undergone oxidative thermal crosslinking, use 50kg of polyphenylene sulfide resin, 1.0kg of heat stabilizer nonyl phosphite, and pretreatment Magnesium carbonate whiskers 10kg, the whisker length is 30μm, the formula 5kg of the pretreated carbon black powder with a particle size of 6nm is added to the mixer and stirred at high speed for 3 hours, and then the pretreated nano-scale 304 stainless steel heat-conducting metal 7kg of fiber material, long fiber with a fiber diameter of 4nm, 27kg of pretreated 95% alumina ceramic fiber, a long fiber twin-screw extruder with a fiber diameter of 20μm, and finally mixed and extruded by a co-rotating twin-screw extruder , cooling, pelletizing, and packaging, and a polyphenylene sulfide composite material as a heat-conducting material for LEDs is prepared

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com