Preparation method for composite carbon fiber based on graphene/ polyacrylonitrile

A technology of composite carbon fiber and polyacrylonitrile, applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, wet spinning method, etc., to achieve good strength and toughness, easy operation, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The steps of the preparation method of graphene / polyacrylonitrile composite carbon fiber are as follows:

[0025] 1) 1 part by weight of graphene or graphene oxide, 10-1000 parts by weight of solvent, 10-1000 parts by weight of acrylonitrile monomer, add 0.01-10 parts by weight of initiator under nitrogen protection, and heat to 50-95 °C, react for 1-60 hours, precipitate, centrifuge, wash, and dry to obtain polyacrylonitrile-grafted graphene;

[0026] 2) Add 1 part by weight of polyacrylonitrile-grafted graphene to 5-150 parts by weight of an organic solvent, and process ultrasonically at 5-50 KHz at 30-80 °C for 0.1-10 hours to obtain polyacrylonitrile-grafted graphene spinning lyosol;

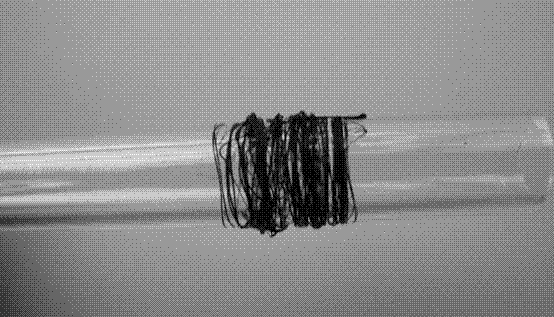

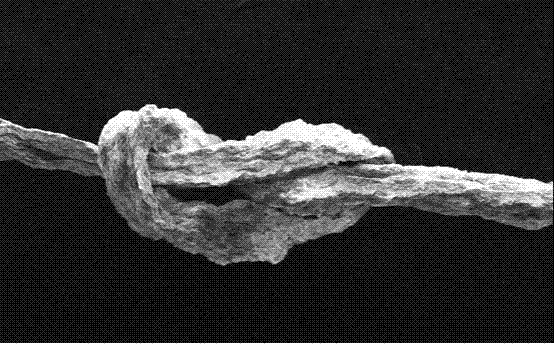

[0027] 3) Pass the polyacrylonitrile-grafted graphene spinning solution sol through a spinning capillary with a diameter of 5-500 μm at an extrusion speed of 1-100 mL / h, and stay in the coagulation solution at 10-80°C for 1-100s Solidified into filaments, collected by a winder, and ...

Embodiment 1

[0037] 1) Add 20 mg of graphene oxide, 20 mL of N, N-dimethylformamide (DMF), 15 g of acrylonitrile monomer, add 0.01 g of initiator by weight under nitrogen protection, and heat to 60 °C , reacted for 48 hours, through precipitation, centrifugation, washing, drying, to obtain graphene grafted with polyacrylonitrile;

[0038] 2) Add 50 mg of polyacrylonitrile-grafted graphene to 10 mL of N, N-dimethylacetamide, and process it at 30 °C with 25KHz ultrasonic for 5 hours to obtain polyacrylonitrile-grafted graphene spinning solution Sol;

[0039] 3) The polyacrylonitrile-grafted graphene spinning solution sol was passed through a spinning capillary with a diameter of 30 μm at an extrusion speed of 10 mL / h, and mixed with water and dimethyl sulfoxide (DMSO) at 20 °C Stay in the medium for 50 s to solidify into filaments, collect them with a winder, and obtain graphene oxide fibers after drying.

[0040] 4) The graphene fiber was reduced in hydroiodic acid for 10 h, washed and dr...

Embodiment 2

[0043] 1) Add 20 mg of graphene oxide, 20 mL of N, N-dimethylformamide (DMF), 10 g of acrylonitrile monomer, add 0.01 g of initiator by weight under nitrogen protection, and heat to 50 °C , reacted for 48 hours, through precipitation, centrifugation, washing, drying, to obtain graphene grafted with polyacrylonitrile;

[0044] 2) Add 50 mg of polyacrylonitrile-grafted graphene to 3 mL of butanol, and conduct ultrasonic treatment at 30 °C for 5 hours at 30KHz to obtain polyacrylonitrile-grafted graphene spinning solution sol;

[0045] 3) The polyacrylonitrile-grafted graphene spinning solution sol was passed through a spinning capillary with a diameter of 30 μm at an extrusion rate of 10 mL / h, and was solidified in a mixture of water and tetrahydrofuran at 20 °C for 50 s. The filaments were collected using a winder and dried to obtain graphene oxide fibers.

[0046] 4) Place the graphene fiber in an inert gas protection, raise the temperature to 500°C at 20°C / min, keep the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com