Drinking water electrochemical preoxidation device and method

A pre-oxidation and electrochemical technology, which is applied in the oxidation water/sewage treatment, electrolysis components, electrolysis process, etc., can solve the problems of unsatisfactory odor and odor removal, insufficient iron active sites, and high cost of chemicals, and achieves enhanced pre-oxidation. The effect of improving the oxidizing ability, improving the pre-oxidizing energy, and improving the coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: electrochemical generation hydrogen peroxide

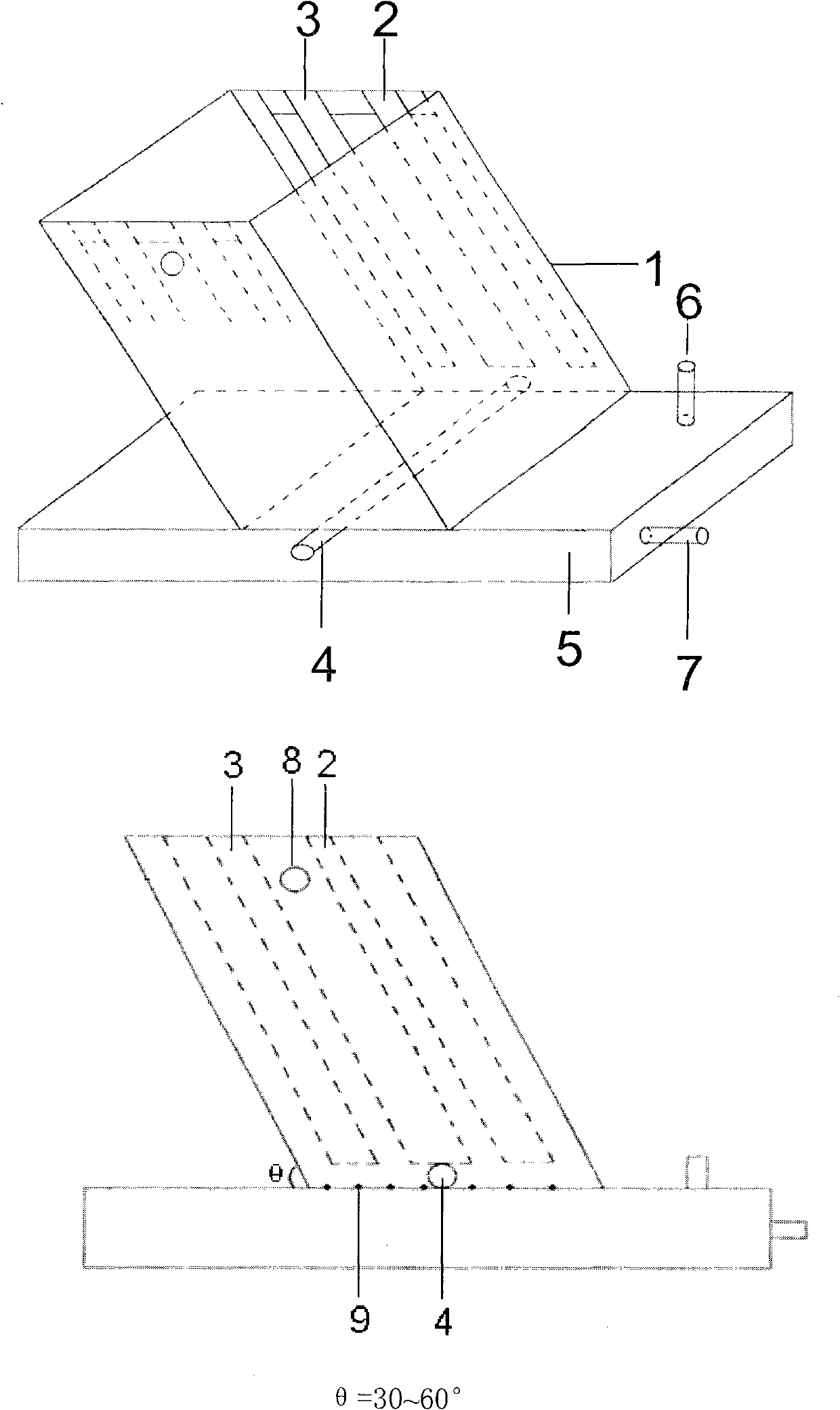

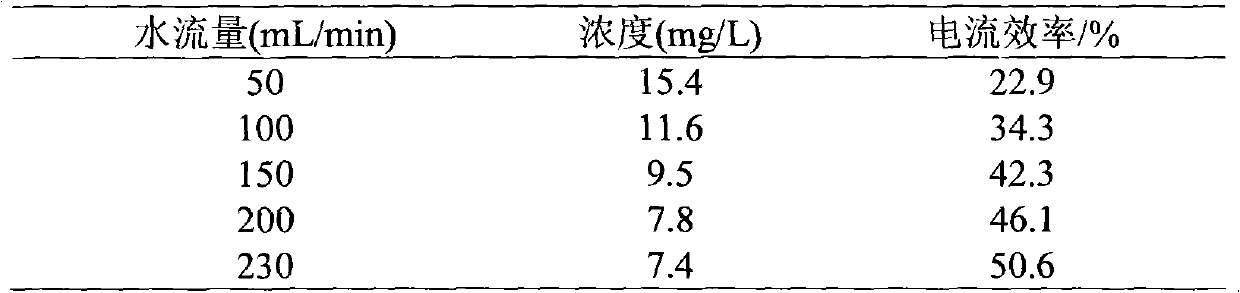

[0037] Using tap water in the laboratory, the test of electrochemically generating hydrogen peroxide was carried out without adjusting the pH value of the raw water and without adding electrolyte. Electrolysis conditions: electrode spacing 1cm, electrode inclination θ=60°, current density: 1.99mA / cm 2 , the amount of air introduced: 0.1m 3 / h, the water-gas volume ratio converted to air intake is 1:10~1:30, and the water flow corresponding to the applied current per ampere is 9~45L / h. The anode is a titanium ruthenium iridium mesh electrode, the cathode is a graphite felt cathode, and the apparent area of the electrodes is 160cm 2 . Sampling at the outlet of the electrolyzer to monitor the concentration of hydrogen peroxide in the water. Under different water flow conditions, the concentration of hydrogen peroxide in water is shown in Table 1.

[0038] Table 1 The variation of the concentration of elect...

Embodiment 2

[0041] Embodiment 2: Generation experiment of hydroxyl free radical under neutral condition

[0042] Test method: Under certain electrolysis conditions, the benzoic acid solution is electrolyzed and tested after passing through the iron-silicon filter column. Electrode inclination θ=60°, current density: 2mA / cm 2 , flow rate: 25mL / min, gas volume: 0.05m 3 / h, the water-gas volume ratio of air intake is about 1:30, the water flow rate corresponding to the applied current per ampere is about 5L / h, and the pole spacing: 1cm. Electrolyte: benzoic acid solution, initial concentration of benzoic acid: 20mg / L, pH=7. The filling height of the iron-silicon filter material is about 30cm, and the diameter of the filter column is 3cm. Sampling and testing method: benzoic acid concentration and fluorescence photometric test after 20 minutes of electrolysis on-line sampling, ① Determination of benzoic acid concentration: UV spectrophotometry, the maximum absorption wavelength is 221nm; ②...

Embodiment 3

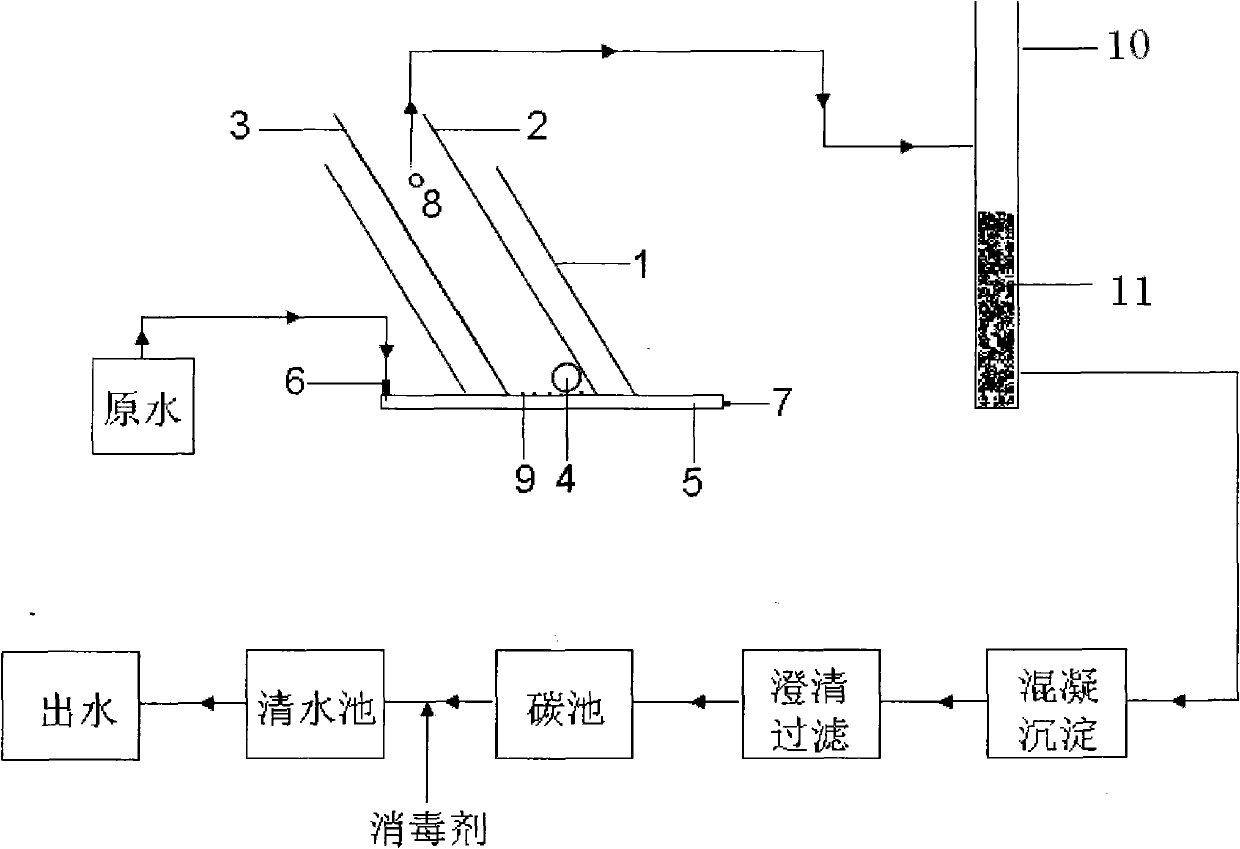

[0044] Example 3: Using electrochemical direct pre-oxidation technology to purify raw water

[0045] Experimental conditions: the titanium ruthenium iridium mesh electrode is used as the anode, the graphite felt is used as the cathode, and the apparent area of the electrodes is 160cm 2 , the electrode inclination angle θ=60°, the water flow rate is 100-400mL / min, and the ventilation volume is 0.1-0.5m 3 / h, the current density is 0.5~20mA / cm 2 , the volume ratio of water and air into the water is 1:4~1:17, and the water flow rate corresponding to the applied current per ampere is 9~75L / h. Table 2 shows the water quality parameters tested after the effluent from the electrolyzer was coagulated and precipitated, clarified and filtered. The coagulation parameters are as follows: add 30 mg / L polyaluminum chloride (PAC) to the water sample, first stir at a speed of 100 r / min for 1 min, then stir at a speed of 50 r / min for 15 min, and take the supernatant liquid after standing f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com