Method for carrying out alkaline pretreatment on plant fiber raw materials for preparing ethanol through enzymolysis and fermentation

A plant fiber and ethanol production technology, which is applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve the problem of low utilization rate and ethanol yield, obvious inhibitory effect of inhibitors, inconsistent ethanol tolerance, etc. problems, to achieve the effect of reducing the cost of enzymes, adapting to industrialization and environmental protection, and reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Pretreatment of corn stalks

[0025]Crush corn stalks to 2-5cm, use 8% (w / w) alkali, 40% sulfide, and 1:6 (w / v) solid-to-liquid ratio. After idling at 60°C for 0.5h, raise the temperature To 140°C, keep warm for 1h. The corn stalks pretreated by green liquor are washed with water to remove residual chemicals, and the material is refined and squeezed dry to serve as the substrate for subsequent enzymatic hydrolysis. The substrate is analyzed for moisture, cellulose content, and total recovery and glycan recovery are calculated.

[0026] The results showed that the moisture content of 1000g absolute dry corn stalks was 76.90%, 55.39% (dry basis) and 25.43% xylan after green liquor pretreatment, washing and squeezing, and the total recovery rate of green liquor pretreatment was The recovery rate of dextran was 63.31%, the recovery rate of glucan was 91.95%, and the recovery rate of xylan was 63.42%, realizing the effective recovery of polycan.

Embodiment 2

[0027] Example 2 Effect of Substrate Concentration on Enzymatic Hydrolysis of Corn Stalk Cellulose

[0028] Weigh 5.41, 10.82, 16.23, 21.65, 27.06, 32.47g of the green liquor pretreated corn stalks of Example 1 (1.25, 2.50, 3.75, 5.00, 6.25, 7.50g respectively) in six 250mL Erlenmeyer flasks In each Erlenmeyer flask, add 2.5mL of 1mol / L citric acid buffer solution, and pretreat corn stalks with 13.94FPIU / g green liquid according to the amount of cellulase (25FPIU / g dextran, cellulase: β-glucose Glucosidase: xylanase = 1:1.15:6.61) Add corresponding enzymes to each Erlenmeyer flask, add appropriate amount of distilled water to each Erlenmeyer flask to make the total volume of water in the enzymolysis system 50mL, use a glass rod Mix the reaction system well, cover it, and perform enzymatic hydrolysis in a constant temperature shaker at 150 rpm and 50°C for 48 hours. After the hydrolysis, the hydrolyzate was centrifuged at 4000 rpm for 10 min, and the supernatant was taken to m...

Embodiment 3

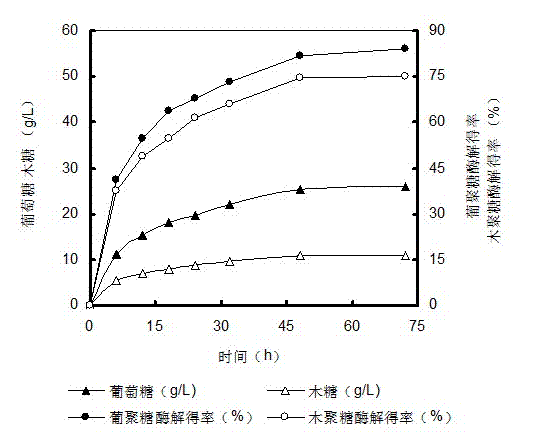

[0032] Example 3 Cellulase hydrolysis of pretreated corn stalks at 5% substrate concentration (solid-to-liquid ratio 1:20)

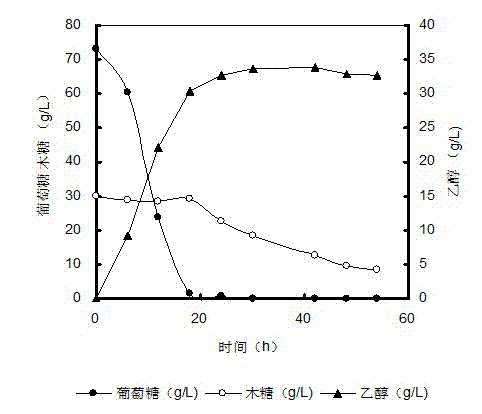

[0033] Sterilize 5648.1 mL of distilled water at 121°C for 15 minutes, and add it into a 10 L biochemical reactor that has been sterilized after being cooled. Take 1515.2 g of the corn stalk green liquid pretreatment corn stalks in Example 1 (350 g of absolute dry weight, 1165.2 g of moisture, 193.9 g of cellulose), add it into a 10L biochemical reactor while stirring, and use a small amount of solid hydrogen to Sodium oxide neutralizes to pH 4.8. The temperature of the reaction system was raised to 50°C, 41.42g of cellulase, 12.00g of β-glucosidase and 133.32g of xylanase were added, and hydrolyzed at 48-50°C for 48 hours. After 48 hours of hydrolysis, the hydrolyzate was centrifuged at 7000 rpm for 10 minutes (the centrifuge tube was sterilized beforehand), and the supernatant was used for subsequent concentrated fermentation of the hydrolyzed sugar s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com