Fibrous supercapacitor and preparation method thereof

A supercapacitor, fibrous technology, applied in the field of capacitors, can solve problems such as toxicity and environmental pollution, and achieve the effects of high specific capacity, good conductivity and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of preparation method of fibrous supercapacitor, described preparation method is carried out according to the following steps:

[0024] a Soak the washed fabric and fabric fiber in 0.2mol / L∽1.0mol / L polymer monomer, 0.01mol / L∽1.0mol / L dopant and 0.0001mol / L∽0.001mol / L surfactant In the mixing system, and stirred on a magnetic stirrer for 1h, then slowly dropwise added 0.1mol / L∽0.5mol / L oxidation initiation solution to it, after the dripping, continued to stir for 2h∽4h, after the reaction, Wash with absolute ethanol and distilled water, and then dry at 50°C to obtain a skin electrode of a fibrous supercapacitor.

[0025] b Soak the skin electrode 1 and core electrode 2 obtained by in-situ polymerization in the electrolyte solution for 10 min.

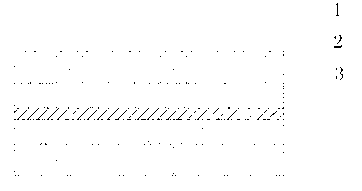

[0026] c. The core electrode 2 treated in step a is tightly coated with the electrolyte layer 3, and then the skin electrode 1 is tightly coated on the outer surface of the electrolyte layer 3 to form a fibrous supe...

Embodiment 1

[0031] According to the above preparation method, take the cleaned spandex fiber and cotton fabric, under room temperature, ferric trichloride and deionized water are made into 100mL0.5mol / L oxidation initiation solution, and the pyrrole monomer obtained by distillation is mixed with Miscellaneous agent sodium dodecylbenzenesulfonate, surfactant cetyltrimethylammonium bromide, and deionized water are made into 100mL monomer mixed solution, wherein, the concentration of pyrrole monomer is 1.0mol / L, mixes The impurity concentration is 0.5mol / L, and the surfactant concentration is 0.0001mol / L; soak the treated spandex fiber and cotton cloth in the monomer mixed solution, stir on a magnetic stirrer, and slowly add Oxidation initiating solution, in-situ polymerization of pyrrole monomer and oxidation initiating system, after dripping, continue to stir on a magnetic stirrer for 2 hours to generate conductive polypyrrole, polypyrrole is deposited on spandex fiber and cotton cloth to f...

Embodiment 2

[0033] According to the above preparation method, take the washed cotton fiber and hemp fabric, and at room temperature, ammonium persulfate and deionized water are made into 100mL of 1.0mol / L oxidation initiating solution, and the distilled aniline monomer, doped Agent toluenesulfonic acid, surfactant dodecyl dimethyl benzyl ammonium chloride and deionized water are made into 100mL monomer mixed solution, wherein, the concentration of aniline monomer is 1.0mol / L, and dopant concentration is 1.0mol / L, the surfactant concentration is 0.001mol / L; soak the treated cotton fiber and hemp fabric in the monomer mixed solution, stir on a magnetic stirrer, and slowly add the oxidation initiating solution, aniline In situ polymerization of the monomer and the oxidation initiating system, after dripping, continue to stir on a magnetic stirrer for 4 hours to generate conductive polyaniline, which is deposited on cotton fibers and linen fabrics to form composite conductive fibers and conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com