Method and device for producing fuel ethanol by solid state fermentation of fiber raw materials

A cellulosic raw material and solid-state fermentation technology, applied in the field of microbial fermentation, to achieve the effects of reducing production costs, making it easy, and overcoming uneven temperature and humidity distribution of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

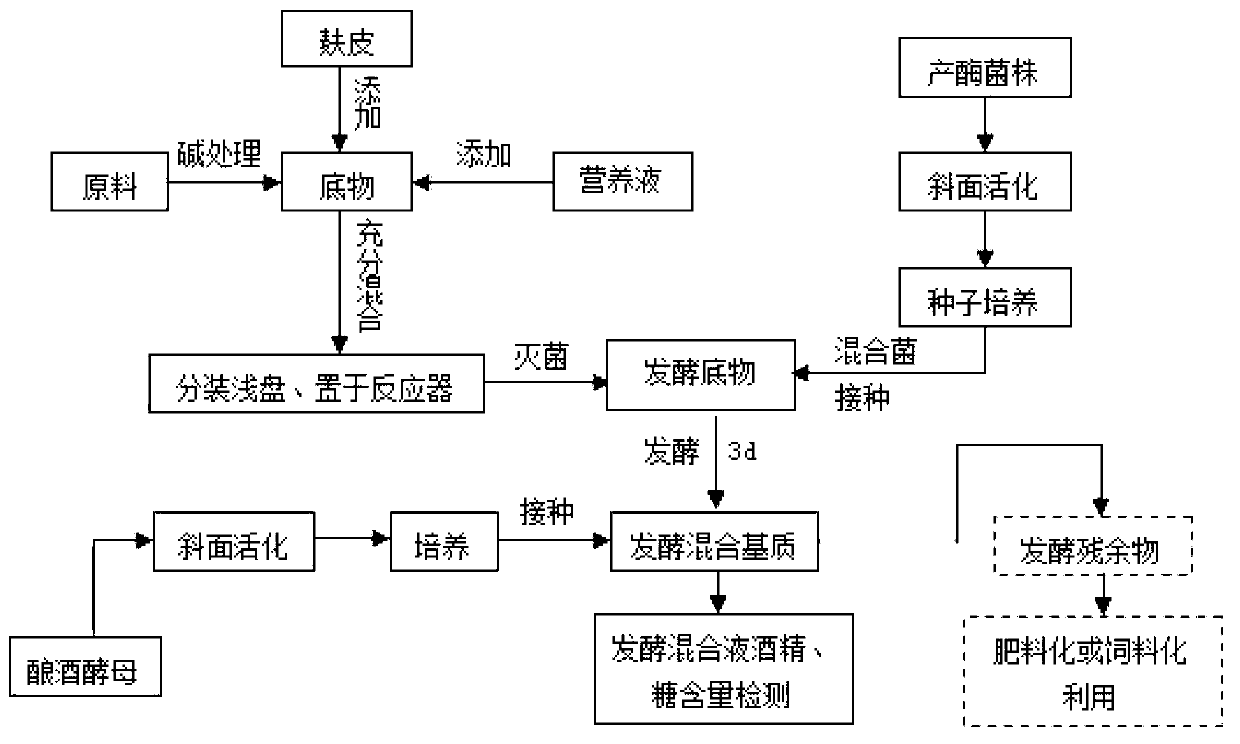

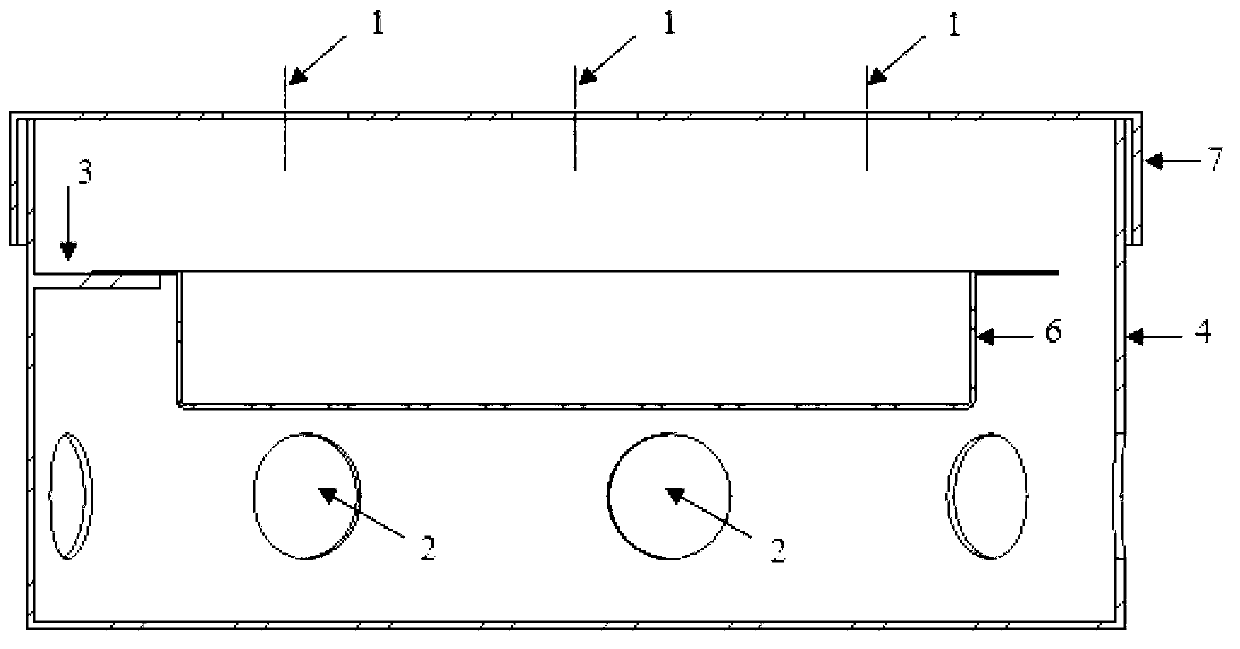

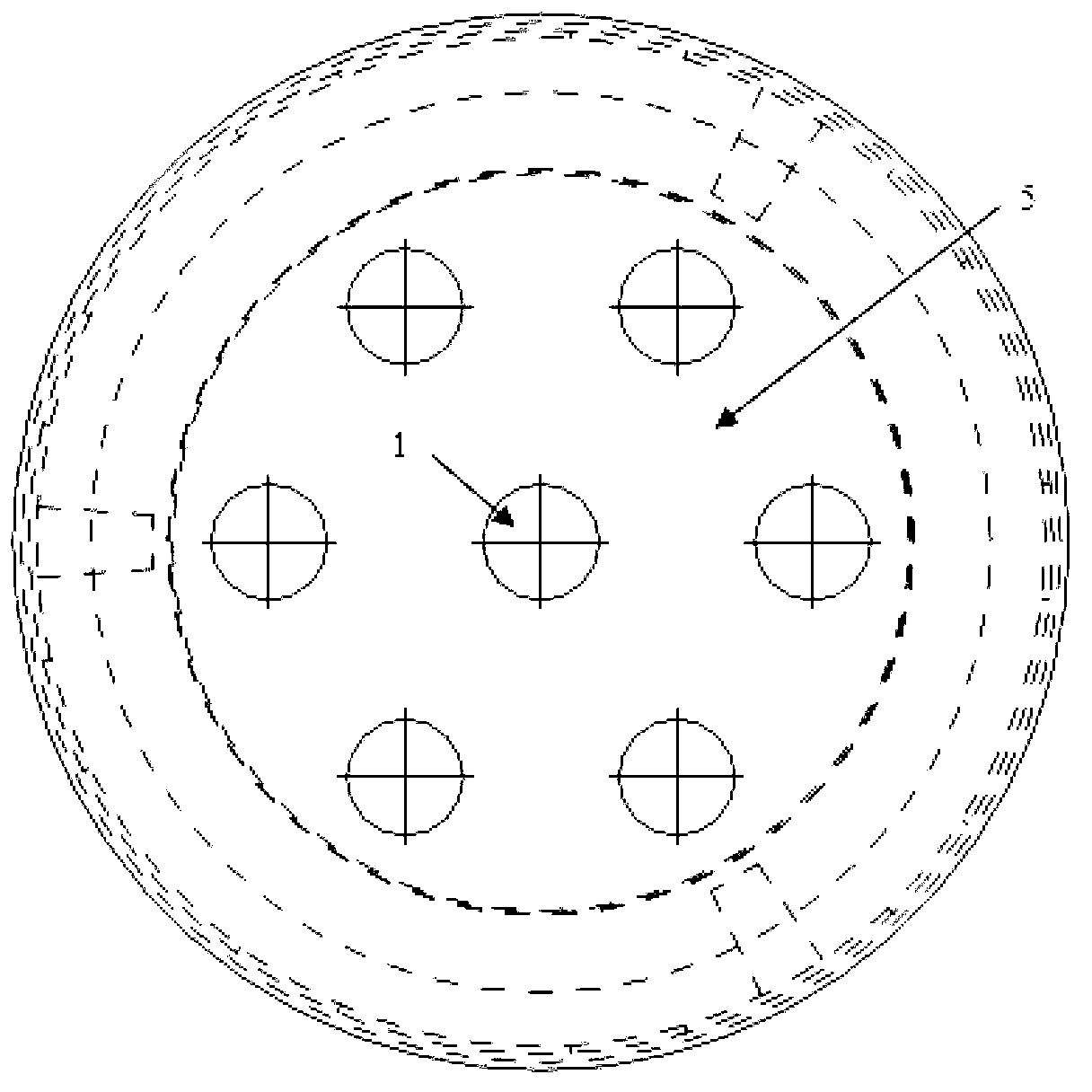

[0034] The schematic diagram of the process is as figure 1As shown, the bagasse was crushed and sieved to collect raw materials with a particle size of 60 mesh, and then carried out low-temperature alkaline pretreatment to remove most of the lignin components in the raw materials that hinder the degradation of cellulose and hemicellulose, and to improve the growth and metabolism of microorganisms. The substrate provides favorable conditions, and the specific process of alkaline pretreatment is as follows: Weigh 100 g of crushed and sieved bagasse raw material (dry basis), mix it with 0.5 mol / L NaOH solution at a solid-liquid mass ratio of 1:20, and mix it with 0.5 mol / L NaOH solution for 80 Stir the reaction in a water bath at ℃ for 2 hours. After the reaction, separate the solid from the liquid, wash the solid until the pH is neutral, and dry it at 50 ℃ until it has a constant weight (completely anhydrous) and store it as a fermentation raw material; in the bagasse raw materia...

Embodiment 2

[0036] Referring to Example 1, the difference is that the mixed bacteria in the spore suspension are Trichoderma reesei CICC40359 and Penicillium decumbens CICC40361, and the volume ratio of the inoculation of the two is 1:2, and the fermentation reactor after inoculation is placed in a constant temperature and humidity In the box, the fermentation temperature is controlled at 28°C and the air humidity is 92%. After 72 hours of fermentation, the sugar content in the substrate has the maximum value. Samples are added to 30mL sterile water at 30°C and 150rpm to dilute and dissolve for 1 hour. After centrifugation, the total sugar concentration is detected. Transfer the parallel sample mixed substrates (including undegraded substrates, sugars produced by fermentation and effective complex enzymes synthesized by microorganisms in the process of degrading substrates) from the 3d fermentation to a 50mL Erlenmeyer flask, and add 30mL0.2M pH5.0 10% (V / V) activated yeast seed solution w...

Embodiment 3

[0038] With reference to Example 1, the difference is that the fermented cellulosic raw material is rice straw powder, and after it is configured through the solid-state fermentation medium configuration process identical to Example 1, according to 8% (Trichoderma reesei CICC40359: Penicillium decumbens LSM-1 is 1:3) (V / V) inoculum amount inoculated and fermented through the same process. After 3 days of mixed bacteria fermentation, the contents of glucose and xylose in the substrate were 10.035g / L and 6.928g / L respectively, and the total sugar concentration reached 20.209g / L; the highest alcohol concentration reached 5.675g / L after 24 hours of fermentation, which was 39.79% of the theoretical alcohol conversion rate. After the fermentation, the solid and liquid are separated, and the solid residue can be recycled and processed into organic fertilizer or feed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com