Degradable zwitterionic polymer with biological associativity and preparation method thereof

A zwitterion, bioassociation technology, which is applied in the types of packaging items, special packaging items, medical containers, etc., can solve the problems of hindering application, unable to have biocompatibility, degradability and bioassociation at the same time, To achieve the effect of mild conditions, excellent anticoagulant and biocompatibility, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

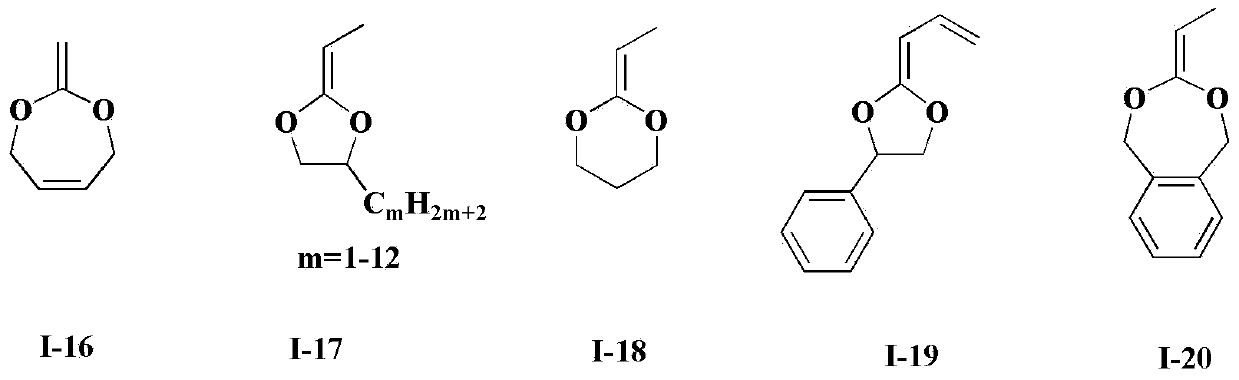

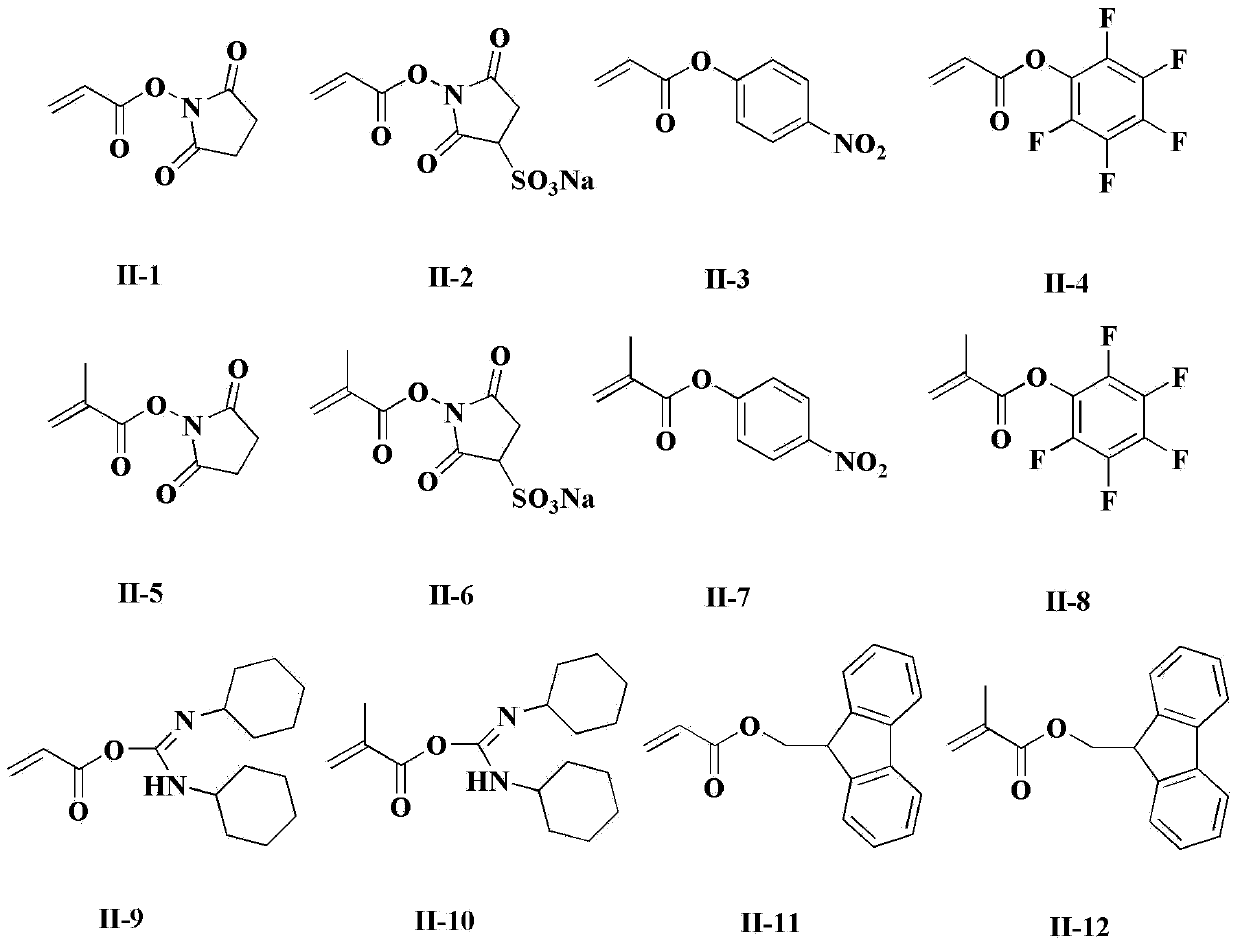

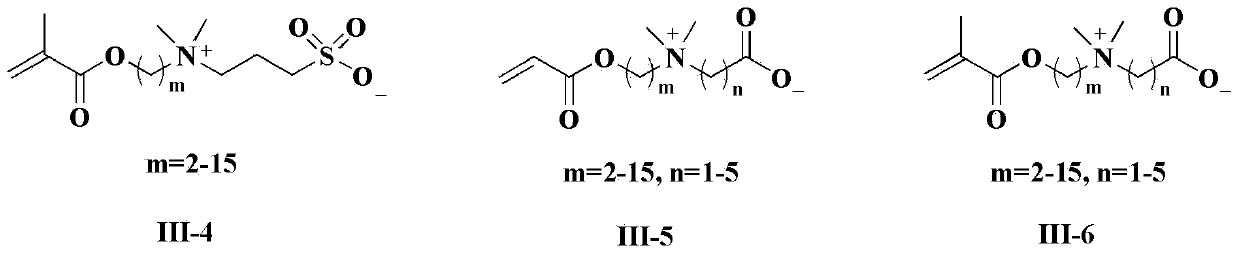

Method used

Image

Examples

Embodiment 1

[0037] Add 50mL of anisole and 20mL of methanol into the polymerization tube, then add 2.5g of 2-methacryloyloxyethylphosphorylcholine, 2.5g of N-hydroxysuccinimide methacrylate, 45g of 2-methylene- 1,3-Dioxetane and 5g of azobisisobutyronitrile, deoxygenated by nitrogen gas for 30 minutes, put into an oil bath at 60°C to react for 24 hours, after taking out, concentrate the solvent, and then precipitate with petroleum ether to obtain The product was dried in a vacuum oven at 40 °C for 24 h. The polymerization process is shown in the following formula:

[0038]

[0039] figure 1 The H NMR spectrum of the polymer prepared for this embodiment, the NMR characteristic peaks of each unit of the copolymer have been marked in the figure, which proves the successful synthesis of the polymer.

[0040] figure 2 The gel permeation chromatogram of the polymer prepared for this example shows that the molecular weight of the prepared polymer is 28000, and the molecular weight distrib...

Embodiment 2

[0042] Add 100mL of acetonitrile into the polymerization tube, then add 4.5g of [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfonic acid propyl)ammonium hydroxide, 2g of methacrylic acid N-hydroxy Succinimide ester, 60g of 2-methylene-1,3-dioxolane and 0.08g of di-tert-butyl peroxide, after deoxygenation by nitrogen gas for 30 minutes, put them in an oil bath at 150°C for 12 hours , after taking it out, concentrate the solvent, then precipitate with petroleum ether, and dry the obtained product in a vacuum oven at 40°C for 24h. The polymerization process is shown in the following formula:.

[0043]

Embodiment 3

[0045]Add 100mL of ethanol and 250mL of benzene into the polymerization tube, then add 40g of [2-(methacryloyloxy)propyl]dimethyl-(3-carboxylate ethyl) ammonium hydroxide, 10g of acrylic acid N-hydroxy Succinimide, 200g of 2-methylene-1,3-dioxycyclohexane and 5g of dimethyl azobisisobutyrate, after deoxygenation with nitrogen gas for 30 minutes, put them into an oil bath at 110°C for reaction After 8 hours, the solvent was concentrated and precipitated with petroleum ether, and the obtained product was dried in a vacuum oven at 40°C for 24 hours. The polymerization process is shown in the following formula:

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com