Preparation method of sustained and controlled release coated material from polymer micro-nano particles employing embedding method

A coating material and polymer technology, which is applied in the field of polymer micro-nanoparticle embedding method to prepare slow and controlled release coating materials, can solve the problems of inaccurate control, uneven particle size of inorganic minerals, etc., and achieve good film-forming properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

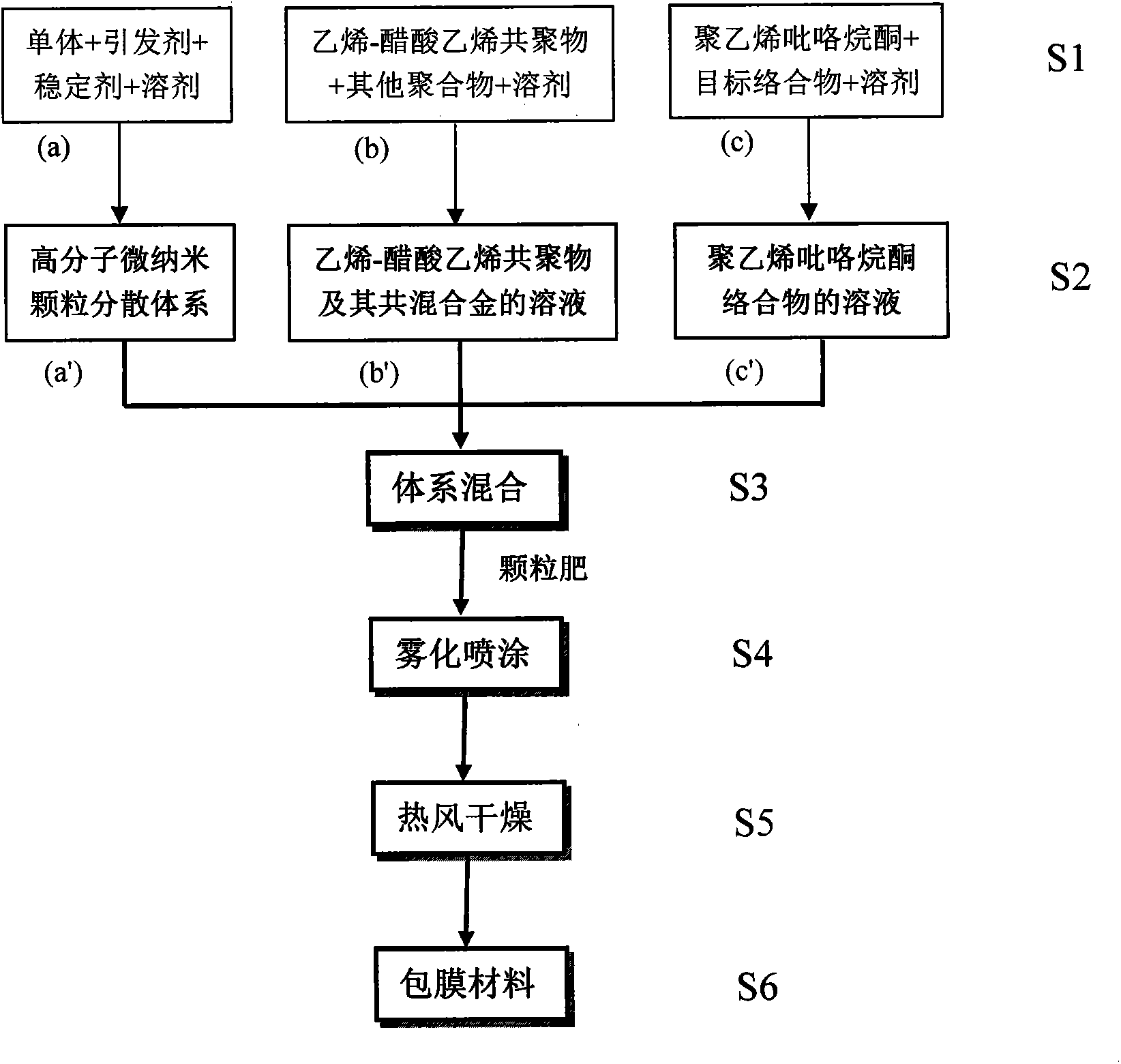

Method used

Image

Examples

Embodiment 1

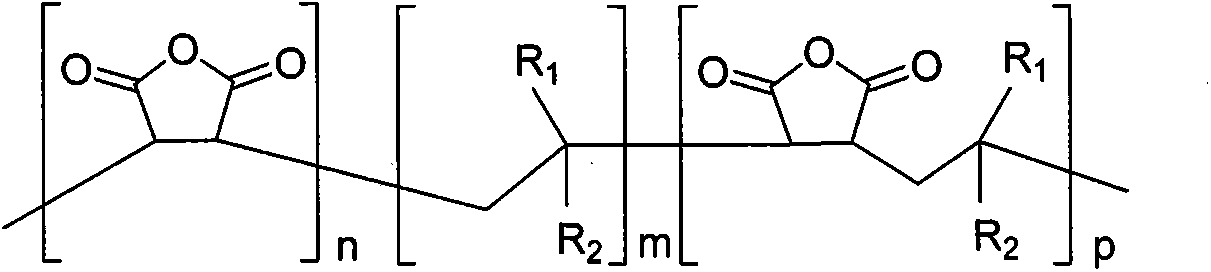

[0060] (1) Preparation of reaction solution: 10% maleic anhydride, 12% vinyl acetate, 0.5% benzoyl peroxide, 3.5% hydroxypropyl cellulose, and butyl acetate as solvent; Nitrogen deoxygenation for 20min; Water bath Polymerization was initiated by heating at a temperature of 75°C for 150 minutes; the reaction product was separated with a centrifuge at 3000 rpm, washed three times with butyl acetate, and redispersed in butyl acetate by ultrasonic vibration to obtain a dispersion system of polymer micro-nano particles;

[0061] (2) Preparation of polymer solution: 8% ethylene-vinyl acetate copolymer, 2% polyvinyl acetate, dissolved in butyl acetate, temperature 95°C, stirring speed 800rpm, time 150min;

[0062] (3) Preparation of complex solution: polyvinylpyrrolidone (number average molecular weight 45000) 15%, dissolved in butyl acetate, temperature 80°C, stirring speed 850rpm, time 120min; complex manganese, iron, zinc, α-naphthalene Acetic acid, auxin, Avermectin;

[0063] (4...

Embodiment 2

[0066] (1) Preparation of reaction solution: 25% maleic anhydride, 25% methyl acrylate, 1% azobisisobutyronitrile, 4% dextrin, and isoamyl acetate as solvent; Nitrogen deoxygenation for 60 minutes; Water bath heating Initiate the polymerization reaction at a temperature of 45°C and a time of 240 minutes; the reaction product is separated by a centrifuge at 1000 rpm, washed 5 times with isoamyl acetate, and redispersed in isoamyl acetate by ultrasonic vibration to obtain a dispersion system of polymer micro-nano particles ;

[0067] (2) Preparation of polymer solution: ethylene-vinyl acetate copolymer 12%, polymethyl methacrylate 4%, dissolved in isoamyl acetate, temperature 150°C, stirring speed 1000rpm, time 60min;

[0068] (3) Preparation of complex solution: polyvinylpyrrolidone (number average molecular weight 58000) 10%, dissolved in isoamyl acetate, temperature 100°C, stirring speed 400rpm, time 60min; complex boron, selenium, auxin, Jinggang Mycin, Wuyiencin;

[0069]...

Embodiment 3

[0072] (1) Preparation of reaction solution: maleic anhydride 0.5%, styrene 0.5%, cumene hydroperoxide 0.05%, polyethylene glycol 0.5%, methyl benzoate as solvent; Nitrogen deoxygenation 10min; Water bath Polymerization reaction is initiated by heating at a temperature of 120°C for 30 minutes; the reaction product is separated at 2500 rpm by a centrifuge, washed 4 times with methyl benzoate, and redispersed in methyl benzoate by ultrasonic vibration to obtain a dispersion of polymer micro-nano particles system;

[0073] (2) Preparation of polymer solution: ethylene-vinyl acetate copolymer 15%, polystyrene 5%, dissolved in methyl benzoate, temperature 120 ° C, stirring speed 1000 rpm, time 240 min;

[0074] (3) Prepare complex solution: polyvinylpyrrolidone (number average molecular weight 36000) 15%, be dissolved in methyl benzoate, temperature 75 ℃, stirring speed 1000rpm, time 180min; Complex calcium, iron, copper, zinc, Gibberellin, abscisic acid, Jinggangmycin, artesunate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com