Microcapsule suspending agent prepared from carbosulfan, chlorpyrifos and abamectin by compounding

A microcapsule suspension, carbosulfan technology, applied in the direction of insecticides, acaricides, biocides, etc., to achieve the effect of reducing quantity and frequency, improving stability, and inhibiting volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

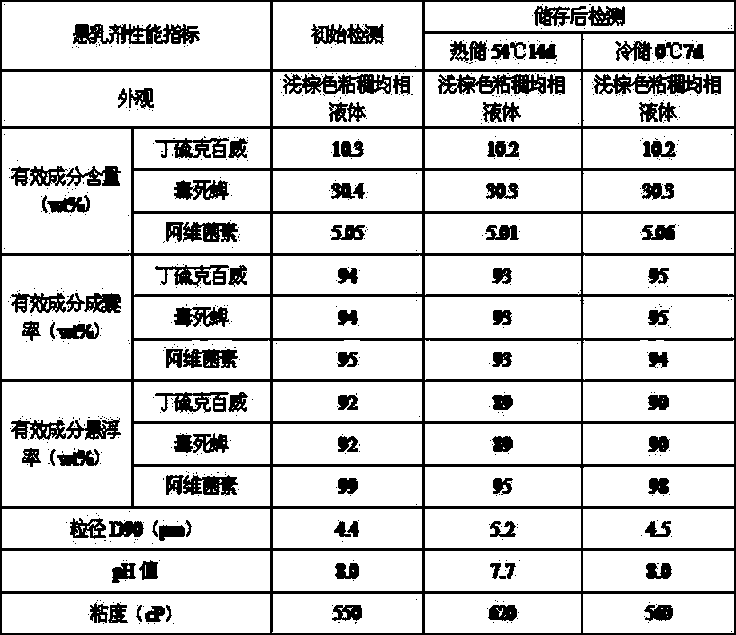

Embodiment 1

[0042] Carbosulfan 10kg, avermectin 0.5kg, chlorpyrifos 10kg, solvent oil Solvesso 200 5kg, rosin-based vegetable oil ND45 3kg, capsule skin material melamine polyisocyanate 0.5kg, cyclodextrin 2kg, emulsifier Calcium dodecylbenzenesulfonate 0.5kg, phenylethylphenol polyoxyethylene ether 0.5kg, ethylene oxide propylene oxide copolymer 1kg, dispersant calcium lignosulfonate Borresperse CASA 1kg, organosilane defoamer 0.05 kg, suspending agent magnesium aluminum silicate 1kg, xanthan gum 0.2kg, preservative benzoic acid 0.2kg, antifreeze agent ethylene glycol 5kg, water 59.55kg.

[0043] Production steps:

[0044] Step 1: (1) Dissolve the original drug carbosulfan and chlorpyrifos in solvent Solvesso 200, add emulsifier calcium dodecylbenzenesulfonate and phenylethylphenol polyoxyethylene ether and polyisocyanate as the capsule skin material Form an oil phase; (2) Dissolve calcium lignosulfonate and some antifoaming agents in some water to form a water phase; (3) Slowly drop th...

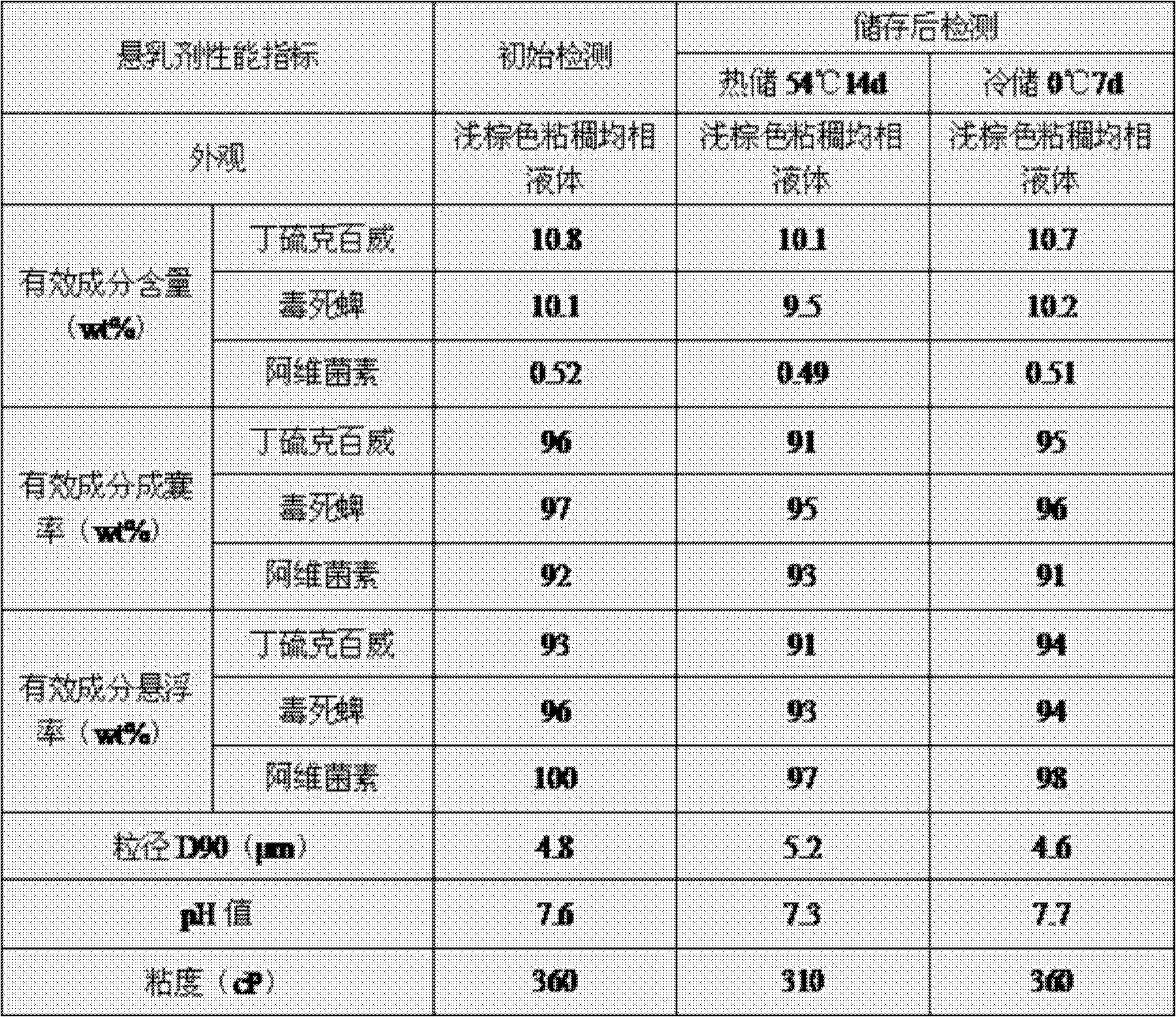

Embodiment 2

[0049] Carbosulfan 15kg, avermectin 1kg, chlorpyrifos 15kg, solvent oil Solvesso 200 7kg, rosin-based vegetable oil ND60 3kg, capsule skin material melamine polyisocyanate 0.8kg, cyclodextrin 4kg, emulsifier ten Calcium dialkylbenzenesulfonate 1kg, phenylethylphenol polyoxyethylene ether 1kg, ethylene oxide propylene oxide copolymer 2kg, dispersant calcium lignosulfonate Borresperse CASA 2kg, organosilane defoamer 0.05kg, auxiliary Suspending agent magnesium aluminum silicate 0.5kg, xanthan gum 0.15kg, preservative sodium benzoate 0.15kg, antifreeze agent propylene glycol 4kg, water 43.35kg.

[0050] Production steps:

[0051] Step 1: (1) Dissolve the original drug carbosulfan and chlorpyrifos in solvent Solvesso 200, add emulsifier calcium dodecylbenzenesulfonate and phenylethylphenol polyoxyethylene ether and polyisocyanate as the capsule skin material Form an oil phase; (2) Dissolve calcium lignosulfonate and some antifoaming agents in some water to form a water phase; (3)...

Embodiment 3

[0055] Weigh carbosulfan 15kg, avermectin 3kg, chlorpyrifos 20kg, solvent oil Solvesso 200 8kg, rosin-based vegetable oil ND100 5kg, capsule skin material melamine polyisocyanate 1kg, sodium alginate 3kg, cyclodextrin 2kg , emulsifier calcium dodecylbenzenesulfonate 1kg, phenethylphenol polyoxyethylene ether 1kg, ethylene oxide propylene oxide copolymer 2kg, dispersant calcium lignosulfonate Borresperse NA 1.5kg, organosilane defoaming Agent 0.05kg, suspending agent xanthan gum 0.1kg, preservative sodium benzoate 0.1kg, antifreeze agent propylene glycol 4kg, water 33.25kg.

[0056] Production steps:

[0057] Step 1: (1) Dissolve the original drug carbosulfan and chlorpyrifos in solvent Solvesso 200, add emulsifier calcium dodecylbenzenesulfonate and phenylethylphenol polyoxyethylene ether and polyisocyanate as the capsule skin material Form an oil phase; (2) Dissolve calcium lignosulfonate and some antifoaming agents in some water to form a water phase; (3) Slowly drop the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com