Device and method for machining high-density aluminum oxide by plasma

A plasma and aluminum oxide technology, which is applied in the coating process and coating of metal materials, can solve the problems of slow production rate, influence of sapphire quality or yield, uneven quality of products, etc., and achieve the effect of uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

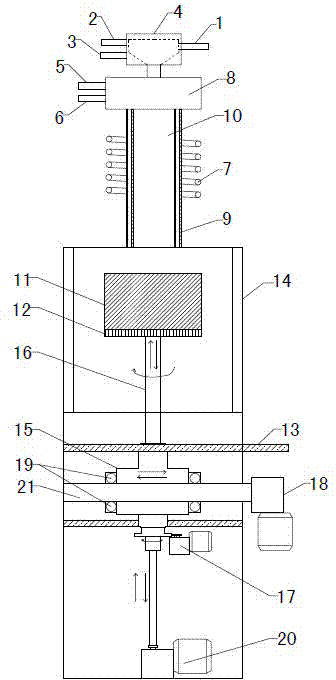

[0035] a. Use the mixed gas of nitrogen and hydrogen with a volume ratio of 97:3 as the plasma generation gas, and use the radio frequency plasma generator 8 to emit the plasma generation gas. The plasma generation gas enters the plasma torch 10 and emits it at the high frequency induction coil 7 Ionization occurs under the action of a high-frequency magnetic field and the temperature is continuously raised to 10,000°C.

[0036] b. The impurity content of alumina powder with a particle diameter of 0.3-50 μm is detected by glow discharge mass spectrometry: 11 ppm silicon, 5 ppm iron, 10 ppm sodium, 5 ppm manganese, 6 ppm zinc, 5 ppm copper, and 6 ppm calcium , magnesium 4 ppm; the aluminum oxide powder is continuously passed through the radio frequency plasma generator 8 into the plasma torch 10 from the water-cooled feeding funnel 4 at a feeding rate of 400 g / min, and the aluminum oxide powder is heated by plasma at 10000 ° C during the falling process. Instantly melted, molte...

Embodiment 2

[0039] a. Use the mixed gas of helium and hydrogen with a volume ratio of 90:10 as the plasma generating gas, and use the radio frequency plasma generator 8 to emit the plasma generating gas. After entering the plasma torch 10, the plasma generating gas passes through the high frequency induction coil 7 Ionization occurs under the action of the emitted high-frequency magnetic field and the temperature continues to rise to 10,000°C.

[0040] b. The impurity content of alumina powder with a particle diameter of 0.5-50 μm is detected by glow discharge mass spectrometry: silicon 30 ppm, iron 20 ppm, sodium 40 ppm, manganese 10 ppm, zinc 11 ppm, copper 9 ppm, calcium 13 ppm, magnesium 9 ppm; the alumina powder is continuously passed through the radio frequency plasma generator 8 into the plasma torch 10 from the water-cooled feeding funnel 4 at a feeding rate of 350g / min, and the alumina powder is heated by plasma at 10,000°C during the falling process Instantaneous melting occurs ...

Embodiment 3

[0043] a. Use the mixed gas of argon and hydrogen with a volume ratio of 93:7 as the plasma generating gas, and use the radio frequency plasma generator 8 to emit the plasma generating gas. After entering the plasma torch 10, the plasma generating gas passes through the high frequency induction coil 7 Under the action of the emitted high-frequency magnetic field, ionization occurs and the temperature continues to rise to 10000 °C;

[0044] B, use the aluminum oxide powder of embodiment 1; The aluminum oxide powder enters the plasma torch 10 continuously through the radio frequency plasma generator 8 with the feed rate of 450g / min from the water-cooled feeding funnel 4, and the aluminum oxide powder passes through 10000 in the process of falling. The plasma heating at ℃ produces instant melting, and the molten aluminum oxide is deposited on the deposition table 12;

[0045] c. The deposition table 12 maintains a rotating speed of 225r / min while collecting the falling fused alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com