Graphene/conducting polymer composite electrode material

A conductive polymer, composite electrode technology, applied in battery electrodes, hybrid capacitor electrodes, circuits, etc., can solve the problems of graphene performance advantages that cannot be exerted, easy to agglomerate, etc., to reduce the impact, the preparation process is simple, and it is easy to scale. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] According to the mass ratio of 1:4, the specific surface area is 2200m 2 / g, graphene and polyaniline with a pore size of 3-8nm. Put the graphene into the ball mill tank of the ball mill, add a small amount of ethanol and stir for 2 minutes to make the graphene completely wet, add polyaniline and continue stirring for 1 hour, take out the mixed material, dry at 60°C to remove the ethanol, and obtain polyaniline / graphene The composite electrode material and the binder are made into pole pieces according to the mass ratio of 95:5, which can be used as supercapacitor electrodes.

Embodiment 2

[0020] Weigh the specific surface area as 2200m 2 / g, graphene with a pore size of 3-8nm, sonicate in methanol for 1h, add pyrrole monomer and sodium dodecylbenzenesulfonate, stir, control the reaction temperature below 0°C, and slowly add an aqueous solution of ferric chloride dropwise After reacting for 5 hours, the product was washed with deionized water and acetone, and dried to obtain a composite electrode material with a mass ratio of graphene and polypyrrole of 1:8, and a pole piece was made with polyvinylidene fluoride at a mass ratio of 90:10, which can be used as Li-ion battery electrodes.

Embodiment 3

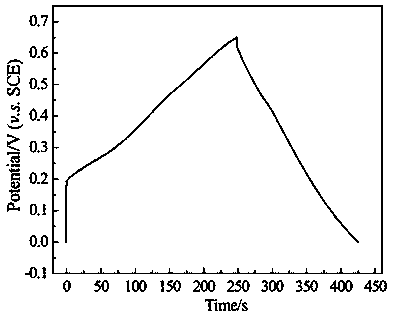

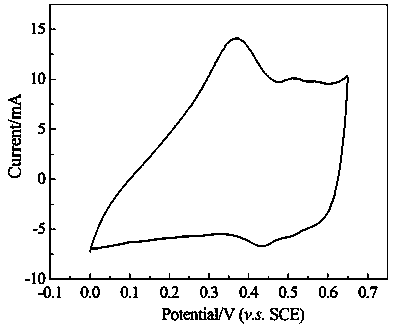

[0022] A layer of graphene dispersion is coated on the indium tin oxide glass electrode by spin coating method, and the specific surface area of graphene used is 2200m 2 / g, the pore size is 3-8nm; polythiophene is prepared by constant current electropolymerization, 0.1M imidazole tetrafluoroborate ionic liquid of ethylenedioxythiophene monomer is used as electrolyte, platinum electrode is auxiliary electrode, and silver wire is reference electrode , at room temperature, the current is 0.1mA / cm 2 Polymerization, controlling the polymerization time, so that the mass ratio of graphene and polythiophene is 1:1, and the obtained graphene / polythiophene composite material can be used as an active material for solar cell electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com