Fluorinated conjugated microporous polymer absorption material and application thereof

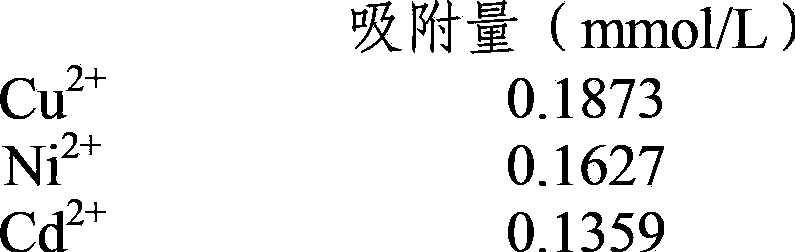

A technology of conjugated micropores and adsorption materials, applied in the direction of adsorption of water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of poor kinetic adsorption performance, long adsorption equilibrium time, and low adsorption capacity. Achieve the effect of large adsorption capacity, good kinetic adsorption performance and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

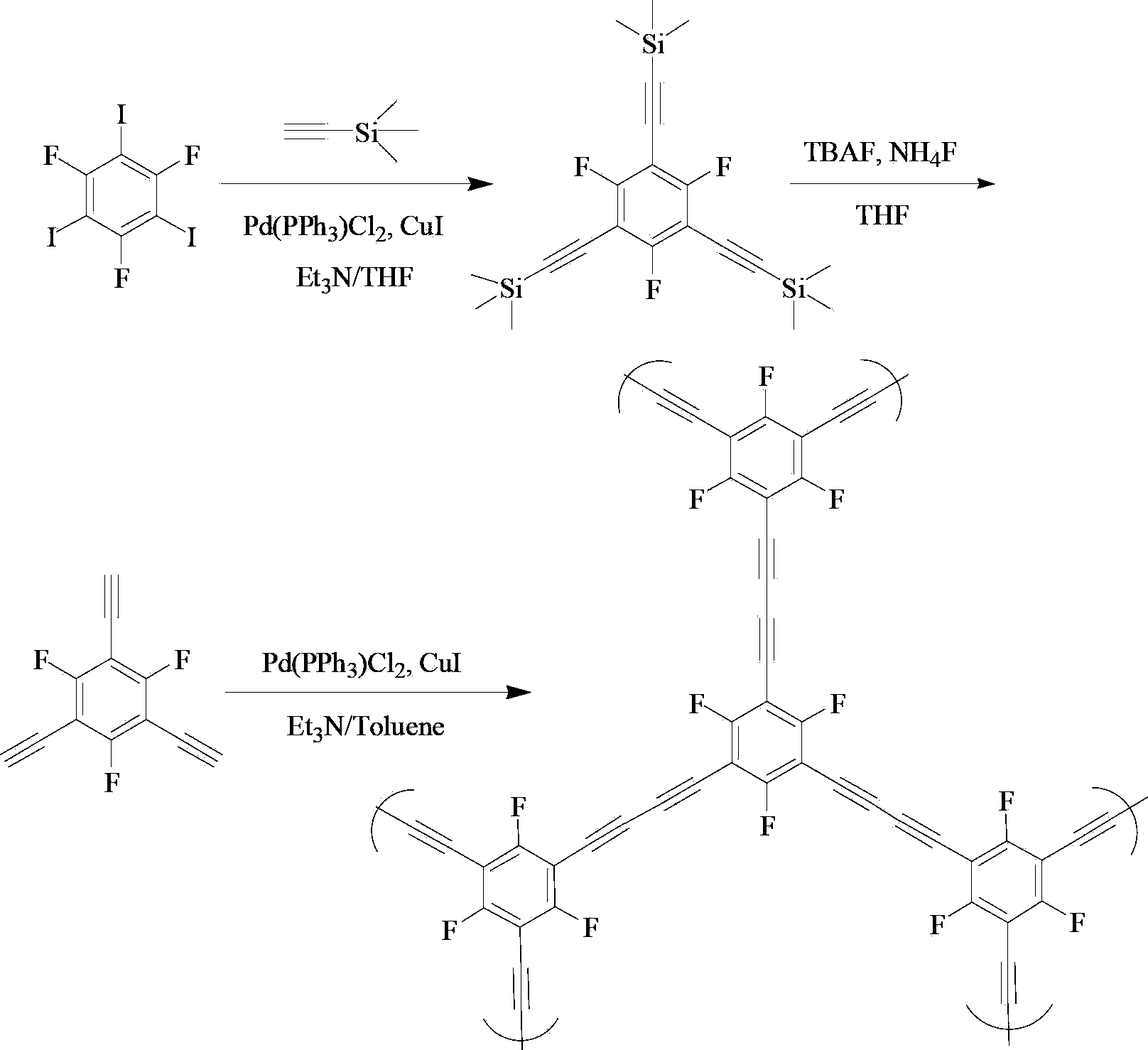

[0020] (1) Synthesis of 1,3,5-trifluoro-2,4,6-tris(trimethylsilylethynyl)benzene

[0021] Add 300mg of 1,3,5-trifluoro-2,4,6-triiodobenzene, 16.8mg of bis(triphenylphosphine)palladium dichloride and 6.19mg of cuprous iodide into a mixed solution of 10mL of triethylamine and 5mL of tetrahydrofuran , the whole system was placed in an argon atmosphere, and after stirring at room temperature for 30 minutes, 0.49 mL of trimethylsilylacetylene was dropped into the above system with a syringe, and refluxed at 50° C. for 48 hours. The solvent was removed, and the desired 1,3,5-trifluoro-2,4,6-tris(trimethylsilylethynyl)benzene compound was obtained through separation and purification by column chromatography. 1 H NMR(400MHz):δ=0:26(s,27H).

[0022] (2) Synthesis of 1,3,5-trifluoro-2,4,6-triethynylbenzene

[0023] Dissolve 1.3g of 1,3,5-trifluoro-2,4,6-tris(trimethylsilylethynyl)benzene, 810mg of ammonium fluoride and 130mg of tetra-n-butylammonium fluoride in 20mL of tetrahydrofuran...

Embodiment 2

[0029] Dissolve 900 mg of 1,3,5-triethynylbenzene, 127.5 mg of bis(triphenylphosphine)palladium(II) dichloride and 33 mg of cuprous iodide into a mixed solution of 6 mL of toluene and 6 mL of triethylamine , under an argon atmosphere, heated to 70°C while stirring. After 36 hours of reaction, the product was filtered and washed with chloroform, methanol, water and acetone in turn, and then the product was put into a Soxhlet extractor, and methanol was used as the After solvent extraction for 3 days, the product was baked at 100° C. for 24 hours to constant weight to obtain a conjugated microporous polymer product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com