Surface modification treatment method of battery diaphragm

A battery diaphragm and surface modification technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of insufficient hydrophilicity and heat resistance of the diaphragm, high stress and pore blockage, and low coating stress. Achieve the effect of improving hydrophilicity and heat resistance, reducing internal stress and reducing brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]The surface modification of a commercially available polyolefin battery separator was carried out using an ion-assisted electron beam evaporation coating device equipped with an e-type electron gun evaporation coating system and a Hall ion source system. In order to monitor the thickness and deposition rate of the coating, the ion-assisted electron beam evaporation coating device is equipped with a crystal oscillator film thickness monitor. In this embodiment, silicon dioxide particles with a purity of not less than 99.99% are used as the raw material for the inorganic oxide coating, argon with a purity of not less than 99.99% is used as the discharge gas, and hexamethyl di Siloxane as an organic monomer specifically comprises the following steps:

[0032] In the step where the inorganic oxide raw material is heated, evaporated and deposited on the surface of the battery separator to form an oxide coating:

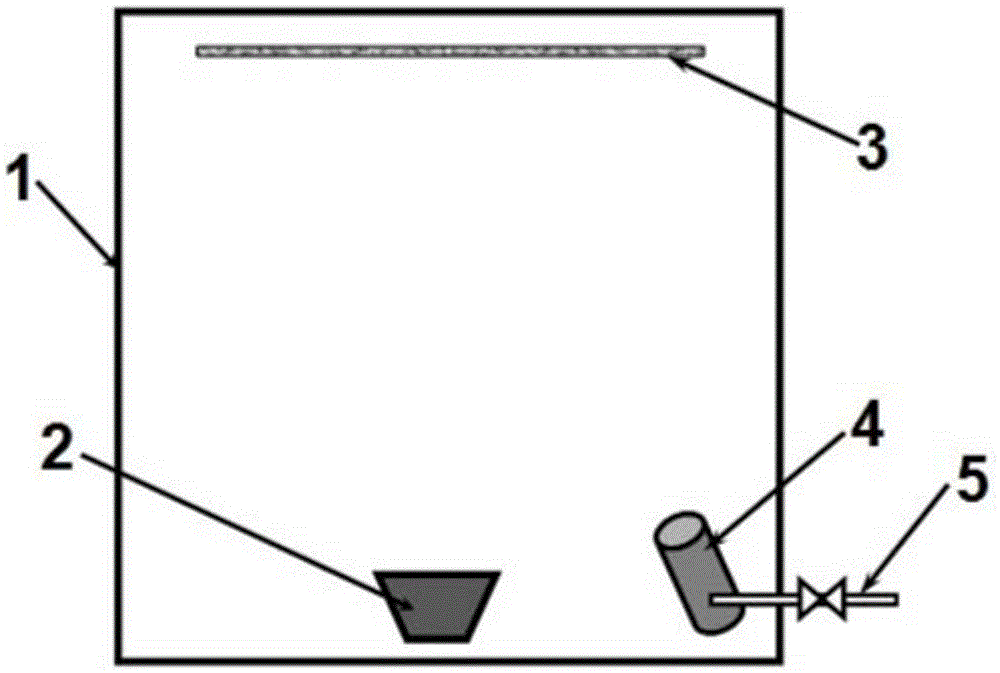

[0033] ①Put the battery diaphragm 3 and silicon dioxide respec...

Embodiment 2

[0047] The surface modification treatment method of the battery separator in this example is basically the same as the treatment steps in Example 1, the only difference is that the raw material of the inorganic oxide is aluminum oxide, and the siloxane organic monomer is octamethylcyclotetrafluoroethylene silicone.

[0048] Since the evaporation and gasification stability of aluminum oxide is better than that of silicon dioxide, and it is not easy to lose oxygen due to heat, a higher deposition rate than silicon oxide can be used. However, the hardness of the aluminum oxide coating is higher than that of the silicon oxide coating, so the total thickness of the aluminum oxide coating should not exceed 120nm.

[0049] The intake flow rate of octamethylcyclotetrasiloxane is lower than that of hexamethyldisiloxane, and the ionization voltage of the ion source should be increased to ensure a better ionization effect.

Embodiment 3

[0051] The surface modification treatment method of the battery diaphragm in this example is basically the same as the treatment steps in Example 1, the only difference being that silicon monoxide and zirconia are used as raw materials for inorganic oxides, and the ion source 4 is a Kaufmann ion source.

[0052] Because silicon monoxide and zirconium dioxide are used at the same time, the evaporation and gasification stability of the inorganic oxide raw materials is better than that of Example 1, and it is not easy to lose oxygen due to heat, and a higher deposition rate is adopted, but the hardness of the two coatings is lower than that of Example 1. It is higher than Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com