Method for preparing rare earth doped silica glass microstructure optical fiber by laser melting technology

A microstructure optical fiber, rare earth doping technology, applied in glass manufacturing equipment, manufacturing tools and other directions, to achieve the effect of improving stability, reducing hydroxyl content, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

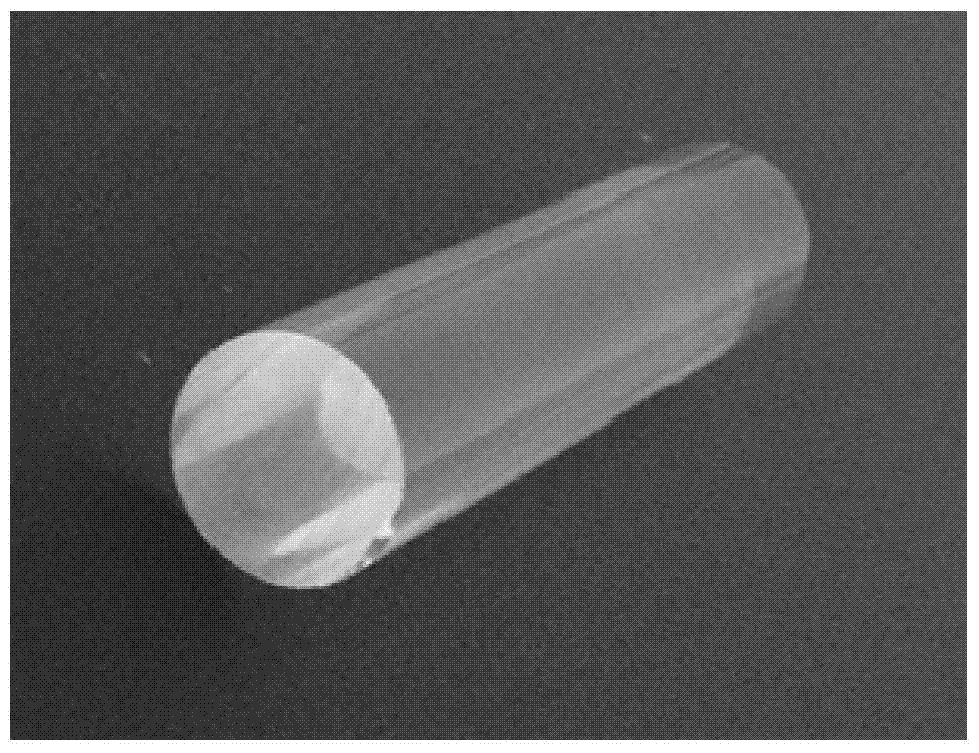

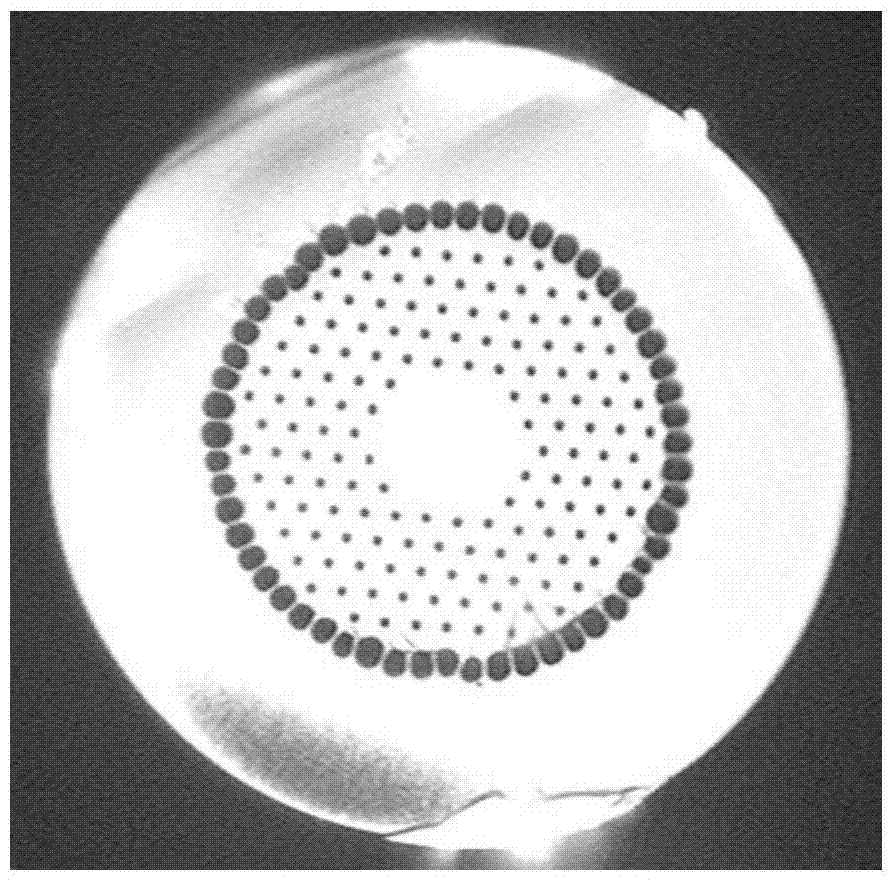

[0044] 3) Treatment of doped rods and preparation of optical fiber preforms: the prepared doped quartz rods are cut into rods with a length of 10-30 cm, and after grinding and polishing, uniform doped silica rods with an outer diameter of 5-30 mm can be made. Miscellaneous quartz rod; as the core of the microstructured optical fiber preform, the method for preparing the microstructured optical fiber preform by stacking: selecting a quartz tube with an outer diameter of 15-50mm, an inner diameter of 10-35mm, and a length of 20-100cm as the outer casing, Quartz capillaries are periodically arranged around the center of the doped quartz rods in the inner holes, so as to prepare preformed rods of doped microstructure optical fibers;

[0045] 4) Drawing of rare earth-doped silica glass microstructure optical fiber: install the microstructure optical fiber preform prepared in the previous step on the fiber drawing tower, and finally draw out the outer diameter of 100- 2000 μm rare e...

Embodiment 1

[0055] The composition of the doping powder is (mass percentage): Yb 2 o 3 : 1.28%, Al 2 o 3 : 2.49%, SiO 2 : 96.23%; the amount of raw materials used to prepare the doped powder is determined by the composition; select some of the following precursors to prepare ytterbium-doped quartz glass: ytterbium chloride hexahydrate, aluminum chloride hexahydrate, silicon tetrachloride (solution). Choose deionized water as the solvent. Add deionized water into a quartz glass beaker, dissolve aluminum chloride hexahydrate and ytterbium chloride hexahydrate in the deionized water, and stir for 30 minutes to prepare a doping solution. Then use dry oxygen as the carrier gas (carrier gas flow rate: 0.1-4.8 m 3 / h) Carry silicon tetrachloride (the amount of silicon tetrachloride introduced is 1-4 times the mass of the doping solution) into the doping solution, and keep stirring to form a gel-like material. The material was then heated at a temperature of 200 degrees to remove excess wat...

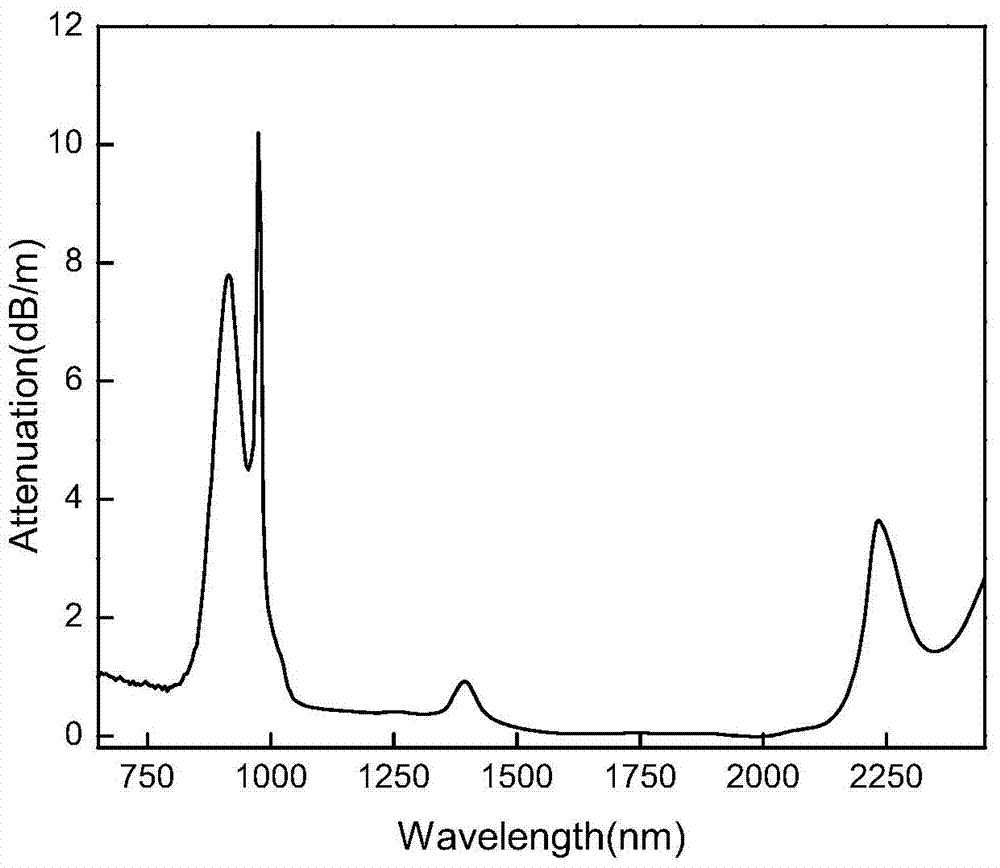

Embodiment 2

[0065] The composition of the doping powder is (mass percentage): Yb 2 o 3 : 2.53%, Er 2 o 3 : 0.61%, Al 2 o 3 : 2.46%, SiO 2 : 94.40%; the amount of raw materials used to prepare the doping powder is determined by the composition; add deionized water to a quartz glass beaker, dissolve aluminum chloride hexahydrate, erbium chloride, and ytterbium chloride hexahydrate in deionized water to form erbium ytterbium The solution was co-blended and the solution was stirred at room temperature for 30 minutes. Then use dry oxygen as the carrier gas (carrier gas flow rate: 0.1-4.8 m 3 / h) Carry silicon tetrachloride (the amount of silicon tetrachloride introduced is 1-4 times the mass of the doping solution) into the doping solution, and keep stirring to form a gel-like material. The material was then heated at 200 degrees to remove excess moisture, and after 6 hours, a dry doped powder was obtained. Then the dry powder was heated under a chlorine atmosphere at a high temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com