Polyaluminum silicate-acrylamide copolymer composite flocculant and preparation method thereof

A technology of acrylamide copolymerization and polyaluminum iron silicate, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of secondary pollution, improvement of water treatment effect, etc., achieve cost saving, strong coagulation ability, and low consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

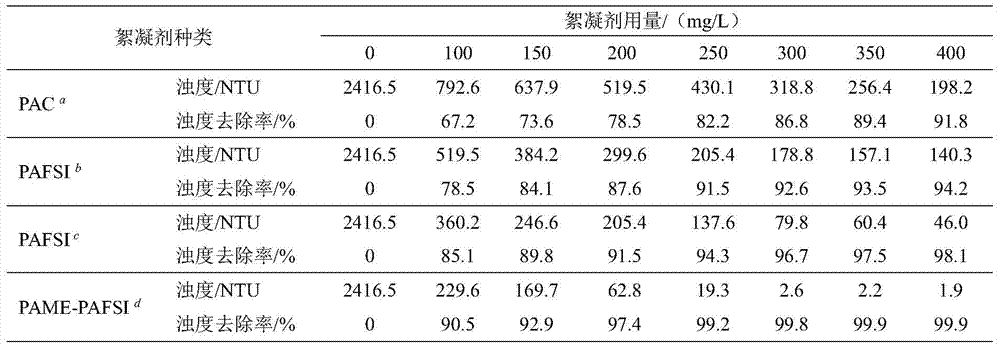

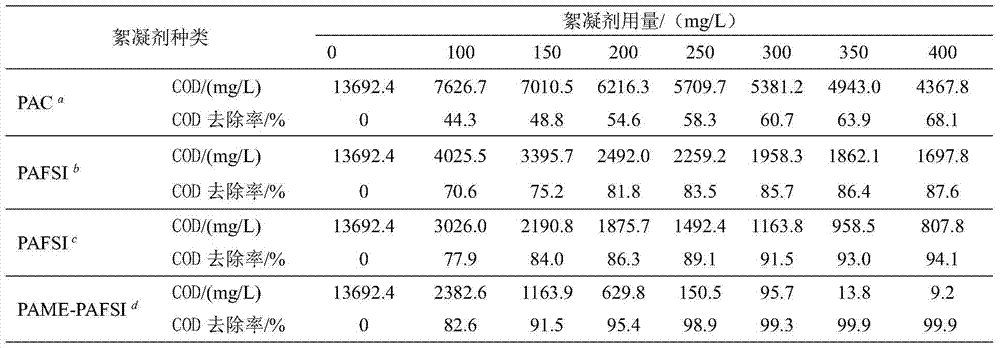

Examples

Embodiment 1

[0023] 10 g Na 2 SiO 3 Add 125 grams of deionized water into a three-necked reaction flask, stir to make a solution, adjust the pH value of the solution to 3 with hydrochloric acid, and react for 2 hours at 25°C to obtain activated silicic acid; the mass fraction of the aluminum component is weighed as 30 grams of 30% aluminum slag, join in the three-necked reaction flask, add iron component, HCl massfraction and be respectively 105 grams of iron-containing waste hydrochloric acid of 15% and 4% and HCl massfraction be 129 grams of industrial hydrochloric acid of 33%, The reaction was stirred at room temperature for 2 hours, separated by filtration, and the filtrate was concentrated to obtain AlCl 3 and FeCl 2 Mixed crystals; 2.7 g of AlCl in 25 g of activated silicic acid 3 and FeCl 2 Mix the crystals, stir the reaction at 45 °C for 2 hours, control the pH value to 2, and then add 0.25 g of KClO 3 , stirred and reacted for 1 hour, the reaction temperature was controlled a...

Embodiment 2

[0025] 10 g Na 2 SiO 3 Add 125 grams of deionized water into a three-necked reaction flask, stir to form a solution, adjust the pH value of the solution to 2.5 with hydrochloric acid, and react for 2 hours at 25°C to obtain activated silicic acid; the mass fraction of the aluminum component is weighed as 30 grams of 25% aluminum ash, join in the three-necked reaction flask, add iron component, HCl massfraction be respectively 10% and 5% iron-containing waste hydrochloric acid 90 grams and HCl massfraction be 118 grams of industrial hydrochloric acid of 33%, The reaction was stirred at room temperature for 2 hours, separated by filtration, and the filtrate was concentrated to obtain AlCl 3 and FeCl 2 Mixed crystals; 7.8 g of AlCl in 25 g of activated silicic acid 3 and FeCl 2 Mix the crystals, stir the reaction at 50 °C for 1.5 hours, control the pH value to 3, then add 0.5 g NaClO 3 , stirred and reacted for 1 hour, the reaction temperature was controlled at 50°C, and lef...

Embodiment 3

[0027] 10 g Na 2 SiO 3 Add 125 grams of deionized water into a three-necked reaction flask, stir to make a solution, adjust the pH value of the solution to 4 with hydrochloric acid, and react for 3 hours at 30°C to obtain activated silicic acid; the mass fraction of the aluminum component is weighed as 30 grams of 40% aluminum slag, join in the three-necked reaction flask, add iron component, HCl massfraction and be respectively 165 grams of iron-containing waste hydrochloric acid of 15% and 4% and HCl massfraction be 231 grams of industrial hydrochloric acid of 33%, The reaction was stirred at room temperature for 1.5 hours, separated by filtration, and the filtrate was concentrated to obtain AlCl 3 and FeCl 2 Mixed crystals; 12.0 g AlCl in 25 g activated silicic acid 3 and FeCl 2 Mix the crystals, stir and react at 50°C for 1.5 hours, control the pH value to 3.5, then add 2.6 grams of NaClO, stir and react for 1 hour, control the reaction temperature at 55°C, let stand a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com