Polyethyleneimine-chitosan adsorbent one-step synthesis method

A technology of polyethylenimine and chitosan, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of small single treatment volume, high treatment cost and poor treatment effect Inadequate and other problems, to achieve the effect of stable and effective adsorption performance, simple and reliable preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

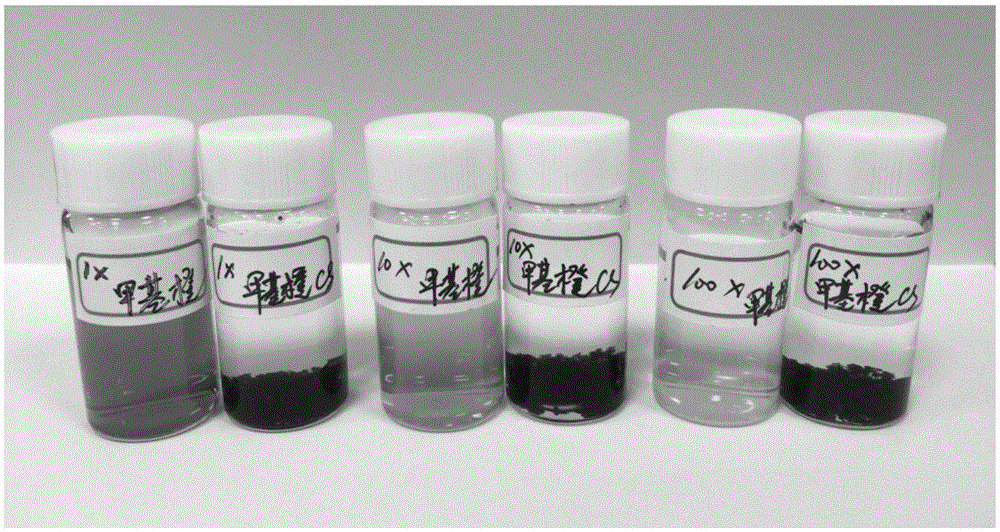

[0048] Example 1: Adsorption of different initial concentrations of methyl orange dyes using polyethyleneimine-chitosan adsorbents

[0049] Preparation of polyethyleneimine-chitosan adsorbent:

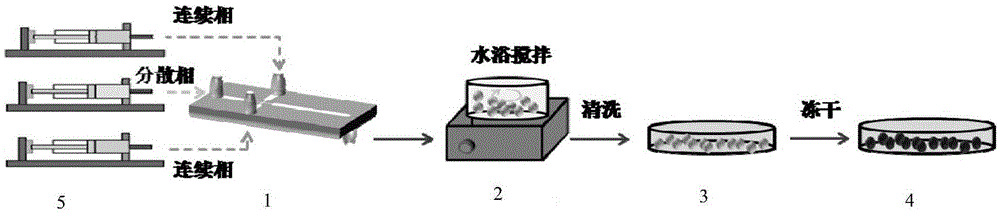

[0050] Step 1: 2 parts by weight of chitosan, 30% polyethyleneimine of 3 parts by weight and glacial acetic acid of 2 parts by weight were slowly stirred for 6 hours in a water bath at 50°C until uniformly mixed to obtain an internal phase; , mixing liquid paraffin and petroleum ether in a volume ratio of 7:5, and adding 2 parts by weight of Span 80 (purchased from Sinopharm Chemical Reagent Co., Ltd.), fully mixed to obtain the external phase;

[0051] Step 2: using the external syringe pump system to pass the internal phase and the external phase into the focused flow microfluidic chip respectively according to the flow rate ratio of 1:7, to obtain chitosan droplets;

[0052] Step 3: After the chitosan droplet that obtains in step 2 is stable, pass into the cross-linking solidific...

Embodiment 2

[0059] Embodiment 2: Utilize polyethyleneimine-chitosan adsorbent to adsorb acidic and alkaline solutions with different pH values

[0060] Preparation of polyethyleneimine-chitosan adsorbent:

[0061] The polyethyleneimine-chitosan adsorbent was prepared according to the method described in Example 1.

[0062] Adsorption of acidic and alkaline solutions with different pH values:

[0063] Dilute hydrochloric acid solutions with pH values of 3, 4, and 5 were prepared, transferred to a 30 mL straight screw-shaped glass bottle, and 0.1 mL of an acid indicator (0.1% methyl orange solution) was added thereto.

[0064] Sodium hydroxide solutions with pH values of 8, 9, and 10 were prepared, transferred to a 30 mL straight glass bottle with a screw top, and 0.1 mL of an alkaline indicator (0.5% phenolphthalein solution) was added thereto.

[0065] Weigh 0.01g of polyethylenimine-chitosan adsorbent and add it into straight glass bottles with different pH values of acidic and...

Embodiment 3

[0071] Embodiment 3: Utilize polyethyleneimine-chitosan adsorbent to adsorb copper ions in copper sulfate solution

[0072] Preparation of polyethyleneimine-chitosan adsorbent:

[0073] The polyethyleneimine-chitosan adsorbent was prepared according to the method described in Example 1.

[0074] Adsorption of copper ions in copper sulfate solution:

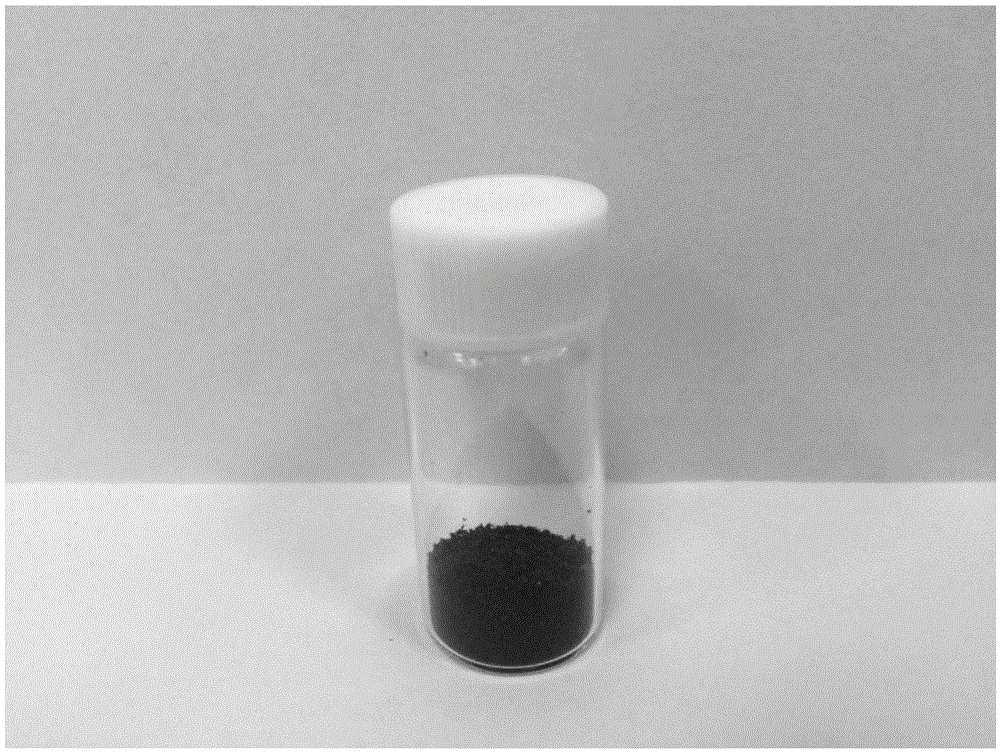

[0075] Weigh 0.1 g of polyethyleneimine-chitosan adsorbent and add it to 50 mL of copper sulfate solution with initial pH value of 5 and copper ion concentration of 100 ppm. And in a test tube mixer at a vibration frequency of 800min -1 And vibration amplitude 8mm continuous vibration. Every 10 minutes, take 2mL of copper sulfate solution, and use full-spectrum direct-reading plasma emission spectrometer to measure it. Finally, it was measured that the polyethyleneimine-chitosan adsorbent reached adsorption equilibrium after 80 minutes, the copper ion concentration at this time was 11.08ppm, and the adsorption efficiency was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com