A manufacturing method of a friction plate

A manufacturing method and friction plate technology, which are applied to friction linings, chemical instruments and methods, and other chemical processes, etc., can solve the problems of poor bonding force between metal substrates and friction materials, poor wear resistance, etc., and achieve short processing time, Low wear rate and good bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

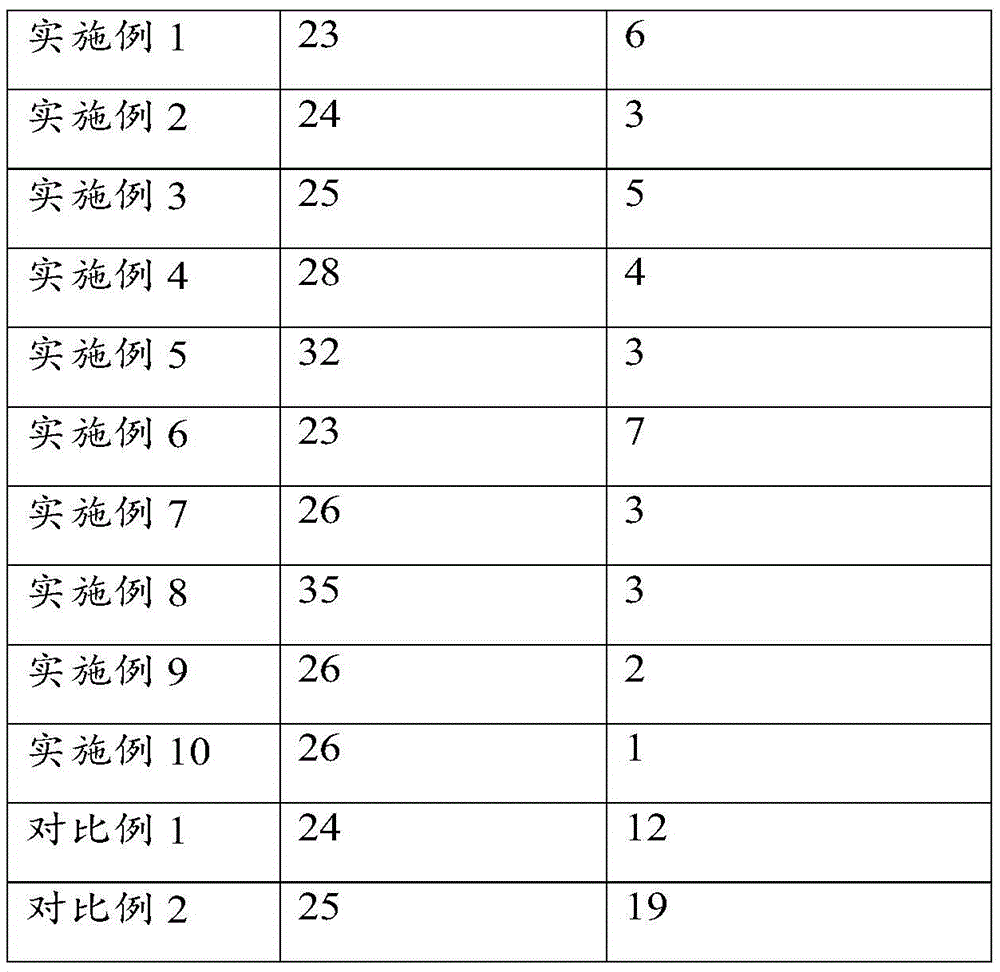

Examples

Embodiment 1

[0044] This embodiment provides a method for manufacturing a friction plate, including the following steps:

[0045] Ingredients and mixing steps: In parts by weight, weigh the following ingredients and add them to the mixer for stirring and mixing to obtain an ingredient mixture: 10 parts of cellulose fiber, 3 parts of aramid pulp, 18 parts of phenolic resin, 2 parts of zinc stearate, silicon 2 parts of zirconium acid, 2 parts of potassium feldspar powder, 6 parts of calcium carbonate, 3 parts of biotite powder, 1 part of fluorite powder, 2 parts of magnesium oxide, 2 parts of barium sulfate, 2 parts of antimony trisulfide, 6 parts of mica iron oxide, 3 parts of iron black, 8 parts of potassium hexatitanate whisker, 4 parts of copper cotton, 2 parts of friction powder, 1 part of rubber powder, 3 parts of flake graphite, 3 parts of electrolytic copper powder, and 5 parts of zinc powder;

[0046] The surface treatment step of the metal substrate: the metal substrate is first su...

Embodiment 2

[0053] This embodiment provides a method for manufacturing a friction plate, including the following steps:

[0054] Ingredients and mixing steps: in parts by weight, weigh the following ingredients and add them to the mixer for stirring and mixing to obtain an ingredient mixture: 12 parts of cellulose fiber, 4 parts of aramid pulp, 20 parts of phenolic resin, 3 parts of zinc stearate, silicon 3 parts of zirconium acid, 3 parts of potassium feldspar powder, 4 parts of calcium carbonate, 4 parts of biotite powder, 2 parts of fluorite powder, 3 parts of magnesium oxide, 3 parts of barium sulfate, 3 parts of antimony trisulfide, 4 parts of mica iron oxide, 6 parts of iron black, 8 parts of potassium hexatitanate whisker, 5 parts of copper cotton, 4 parts of friction powder, 2 parts of rubber powder, 4 parts of flake graphite, 4 parts of electrolytic copper powder, 6 parts of zinc powder;

[0055] The surface treatment step of the metal substrate: the metal substrate is first subj...

Embodiment 3

[0062] This embodiment provides a method for manufacturing a friction plate, including the following steps:

[0063] Ingredients and mixing steps: In parts by weight, weigh the following ingredients and add them to the mixer for stirring and mixing to obtain an ingredient mixture: 13 parts of cellulose fiber, 5 parts of aramid pulp, 22 parts of phenolic resin, 3 parts of zinc stearate, silicon 3 parts of zirconium acid, 4 parts of potassium feldspar powder, 5 parts of calcium carbonate, 6 parts of biotite powder, 4 parts of fluorite powder, 4 parts of magnesium oxide, 3 parts of barium sulfate, 4 parts of antimony trisulfide, 5 parts of mica iron oxide, 7 parts of iron black, 6 parts of potassium hexatitanate whisker, 5 parts of copper cotton, 4 parts of friction powder, 4 parts of rubber powder, 4 parts of flake graphite, 4 parts of electrolytic copper powder, 6 parts of zinc powder;

[0064] The surface treatment step of the metal substrate: the metal substrate is first subj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com