Castor oil-based polyurethane acrylate and preparation method as well as application thereof

A technology based on polyurethane acrylate and castor oil, which is applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, applications, etc., can solve the problems of complex process control, high catalyst price, and harsh conditions, and achieve anti- Effect of improved hydrolysis properties, high tensile strength and elongation at break, excellent flexibility and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

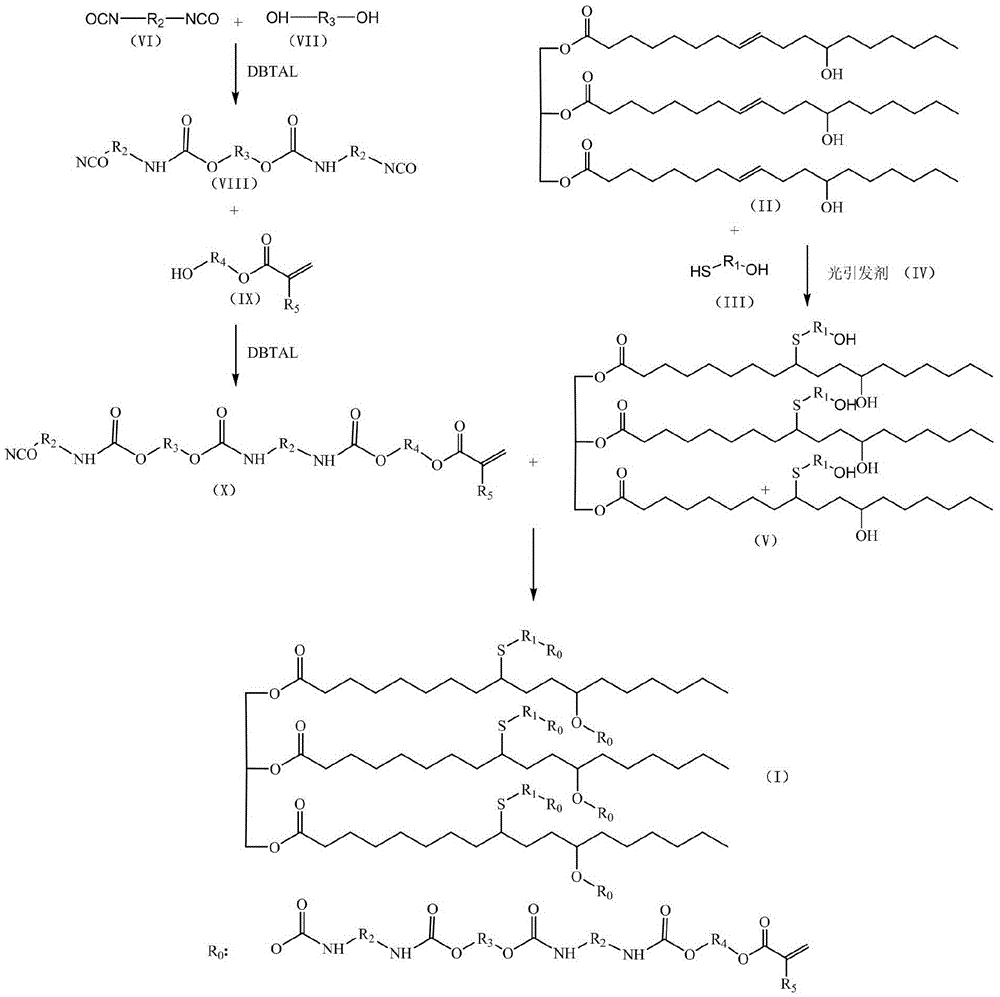

[0084] One, the synthetic steps of intermediate product (V) polyhydroxy castor oil:

[0085] Add castor oil (115g), 2-mercaptoethanol (156g) and 2-hydroxyl-2-methyl-1-phenylacetone (1173, 1.64g) into a dry single-necked bottle, stir well at room temperature, 20mW / cm 2 React under the irradiation of ultraviolet light until the infrared spectrometer can not detect the 1657cm in the system -1 The double-bond signal can also be tracked at 5.42ppm by NMR. Then add an appropriate amount of chloroform to dilute the product, wash off excess 2-mercaptoethanol and residual 1173 with distilled water and saturated NaCl solution successively, dry the organic phase with anhydrous magnesium sulfate, and rotary evaporate to obtain the intermediate product (V) polyhydroxy castor oil.

[0086] Two, the synthetic steps of target product (1) urethane modified castor oil (meth) acrylate resin:

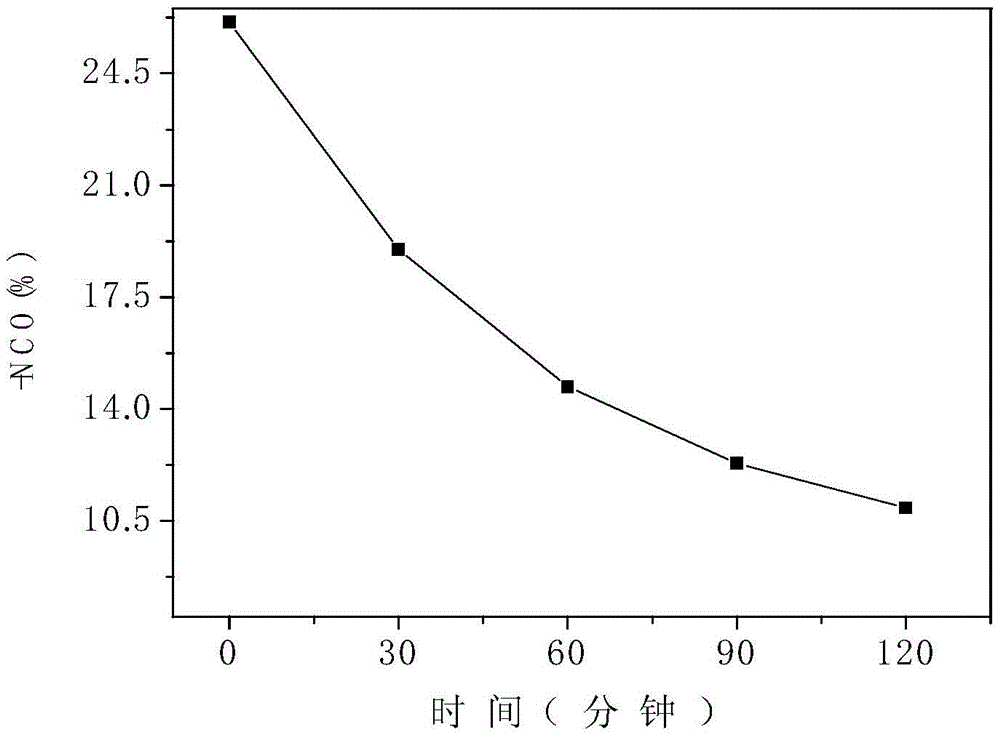

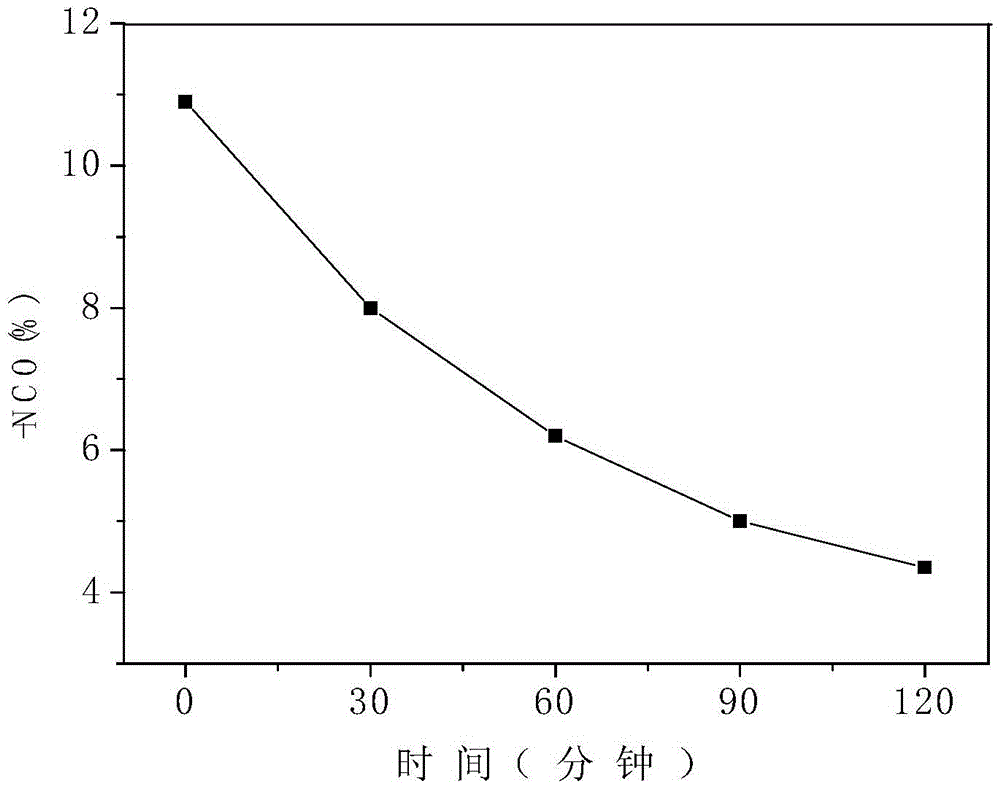

[0087] (1) Add isophorone diisocyanate (IPDI, 5.56g) and dibutyltin dilaurate (DBTDL, 0.013g) into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com