Chitosanase mutant

A chitosanase and mutant technology, applied in the directions of glycosylase, enzyme, hydrolase, etc., can solve the problems of secondary or tertiary environmental pollution, poor thermal stability, extensive chemical processing technology, etc. Application Prospect, High Catalytic Efficiency, Excellent Thermal Stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

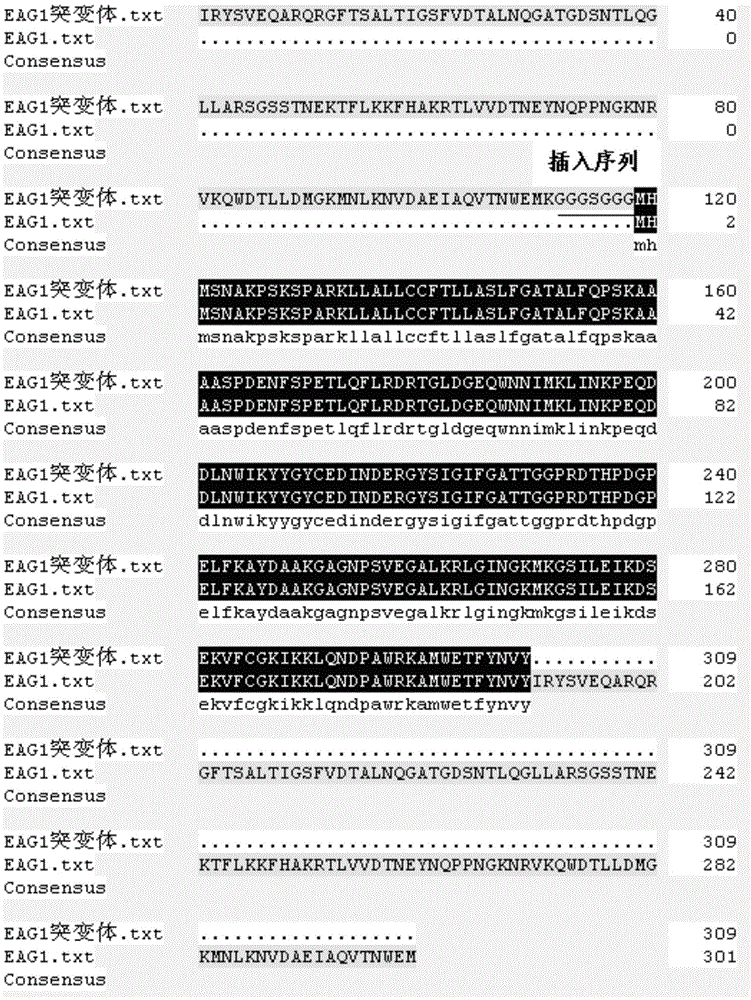

[0016] Embodiment 1: the acquisition of chitosanase EAG1 mutant gene

[0017] To mutate chitosanase EAG1 (GenBank accession number AB008788), the specific steps are as follows:

[0018] ① Artificially synthesize a nucleic acid fragment encoding 7 amino acids and rich in glycine:

[0019] 5′-ggaggaggatccggaggagga-3′; the amino acid encoded by this fragment is -GGGSGGG-

[0020] ②The above sequence was introduced into the EAG1 gene by PCR amplification; the forward primer was

[0021] 5'-ggaggaggatccggaggaggaatgcatatgtccaatgcgaaaccat-3' (the part in italics is an artificially inserted fragment), the reverse primer is 5'-cttcatttcccagttcgtgacttgag-3', and the template is EAG1 gene.

[0022] The amplified EAG1 gene containing the insert was ligated with T4 DNA ligase at 16°C for 12 hours. The reaction system is as follows:

[0023]

[0024] ③ The above-mentioned EAG1 mutant gene connected to form a circle is subjected to enzyme cutting to open the circle. The enzyme used i...

Embodiment 2

[0032] Expression and protein purification of embodiment 2 chitosanase EAG1 mutant gene

[0033] The chitosanase EAG1 mutant gene obtained in Example 1 was connected to the expression vector pIC9K and transferred into Pichia pastoris GS115 by electroporation. Electric shock conditions for electroporation conversion: voltage: 1500V; resistance: 400Ω; capacitance: 25μF; pulse time: 10mS; 1-2 electric shocks.

[0034] Insert the transformant containing the mutated gene into BMGY liquid medium, culture at 250-300rpm, OD600 to 12-16 at 28°C; centrifuge at 3000rpm for 5 minutes, discard the supernatant, collect the cells and transfer to 20mL BMMH liquid medium 20mL BMMY needs to be configured in a 100mL shake flask to ensure a certain amount of ventilation, and continue to culture at 28°C; add 100% methanol to the medium every 24 hours to a final concentration of 0.5%. After culturing for 96 hours, the fermentation supernatant was centrifuged, concentrated with a 10KDa ultrafiltrat...

Embodiment 3

[0035] Embodiment 3: the enzymatic property of chitosanase EAG1 mutant

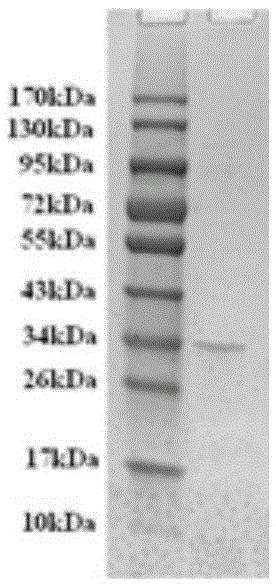

[0036] ①Molecular weight of chitosanase EAG1 mutant

[0037] The purified EAG1 mutant samples were subjected to discontinuous sodium dodecyl sulfate-polyacrylamide (SDS-PAGE) gel electrophoresis, and the results were as follows: figure 2 shown. It is detected as an electrophoresis band by denaturing polyacrylamide gel electrophoresis, and compared with the standard protein SDS-PAGE electrophoresis pattern of known molecular weight, the molecular weight of the EAG1 mutant is about 34,000 Daltons (34kDa), and the enzyme is a monomeric protein .

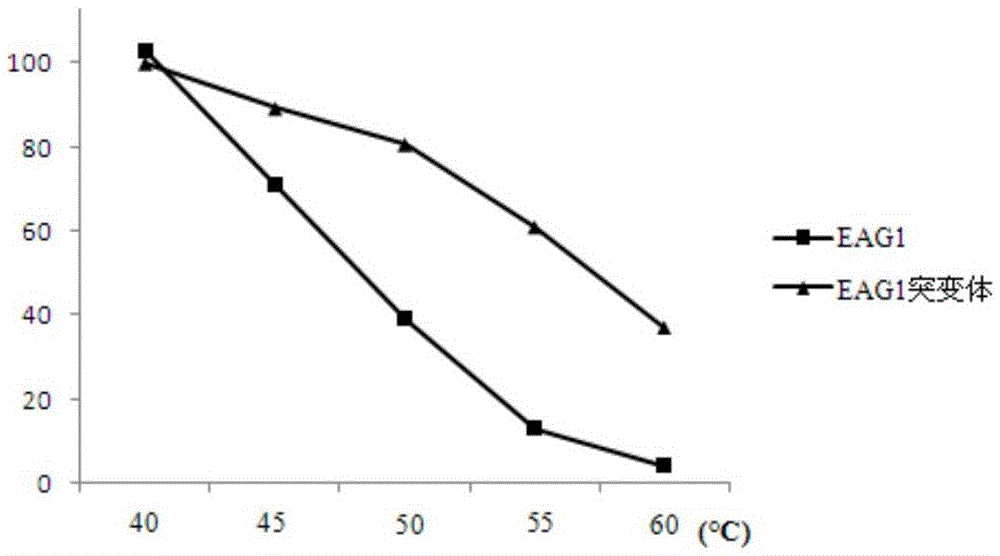

[0038] ② Thermal stability and half-life at 50°C of purified EAG1 mutants

[0039] The purified EAG1 mutants were incubated at 40-60°C for 30 minutes, then transferred to ice for 5 minutes, and the remaining chitosanase activity was measured at 37°C. The results are shown in image 3 . The thermostability of the EAG1 mutant was significantly improved compared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com