Coating titanium electrode for metal electrodeposition and preparation method of coating titanium electrode

A titanium electrode and coating technology, which is applied in the coating process of metal materials, electrodes, coatings, etc., can solve the problems of short service life and poor corrosion resistance, and achieve high matrix strength, extended service life, and precipitation potential low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

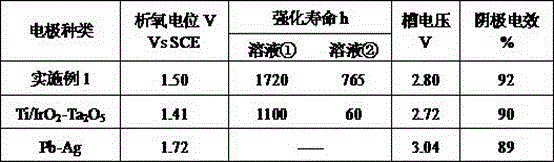

Embodiment 1

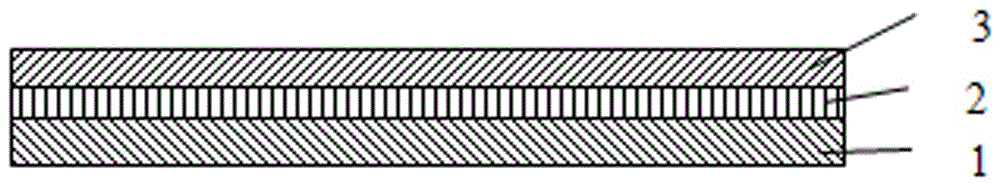

[0027] Substrate 1: Boil the pure titanium plate with 5% soda ash aqueous solution for 1 hour, wash with water, then immerse in 8% oxalic acid solution, boil for 3 hours, wash with water, rinse with deionized water, and dry at 100°C;

[0028] Intermediate layer 2: Then immerse the pure titanium plate in the electroless plating solution containing tetraacetate hexammonium platinum complex solution (5g / L as platinum) and hydrazine hydrate 5mL / L. The pH of the plating solution is 10, washed with water, rinsed with deionized water, and dried at 110°C to obtain a platinum loading of 5g / m 2 The middle layer 2;

[0029] Outer coating 3: use an outer coating liquid of 18g of chloroiridic acid, 50g of tin tetrachloride pentahydrate, 2.68g of bismuth chloride, 225mL of ethanol and 250mL of n-butanol. Use a soft brush to evenly brush the above outer layer coating solution on the middle layer 2 of the pure titanium plate, dry it at 80°C for 10 minutes, then move it into hot air at a temp...

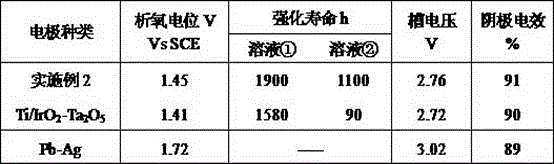

Embodiment 2

[0035] Substrate 1: Boil the pure titanium-clad aluminum layered composite board with 5% soda ash aqueous solution for 1 hour, wash with water, then immerse in 10% oxalic acid solution, boil for 2.5 hours, wash with water, rinse with deionized water, and dry at 120°C;

[0036] Intermediate layer 2: Then immerse the cleaned pure titanium-clad aluminum laminated composite plate in the platinum coating solution, take it out after dipping, and dry it at 80°C for 10 minutes, then move it into hot air at 400°C for oxidation for 10 minutes, and then immerse it after cooling Platinum coating solution, then dry, oxidize, and cool, repeat the above process 3 times, and finally heat-treat at 400°C for 0.5h. The platinum coating solution is a chloroplatinic acid n-butanol solution with a platinum concentration of 12g / L to obtain a platinum loading 4g / m 2 The middle layer 2;

[0037] Outer coating 3: use an outer coating liquid of 10 g of chloroiridic acid, 3.23 g of ruthenium trichloride...

Embodiment 3

[0042] Substrate 1: Boil the pure titanium-clad aluminum layered composite board with 5% soda ash aqueous solution for 1 hour, wash with water, then immerse in 10% oxalic acid solution, boil for 2.5 hours, wash with water, rinse with deionized water, and dry at 120°C;

[0043] Intermediate layer 2: Next, the cleaned pure titanium-clad aluminum layered composite plate is sputter-deposited for 16 minutes under the conditions of power 100W, vacuum degree 2.0MPa, and argon pressure 2Pa, to obtain a platinum loading of 8g / m 2 The middle layer 2;

[0044] Outer coating 3: use an outer coating solution of 18g of chloroiridic acid, 19.15g of tin tetrachloride, 4.32g of manganese chloride tetrahydrate, 150mL of ethanol and 290mL of n-butanol. Use a soft brush to evenly brush the above outer layer coating solution on the middle layer 2 of the composite board, dry it at 90°C for 10 minutes, then move it into hot air at a temperature of 500°C for oxidation for 15 minutes, and then brush t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com